Preparation method of early-strength quick-hardening cement mortar

A rapid-hardening cement and mortar technology, applied in the field of concrete, can solve the problems of easy corrosion of stressed steel bars, slow hydration reaction, low mold release strength, etc., achieve good impermeability and freeze-thaw resistance, and no loss of strength in the later stage , surface compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

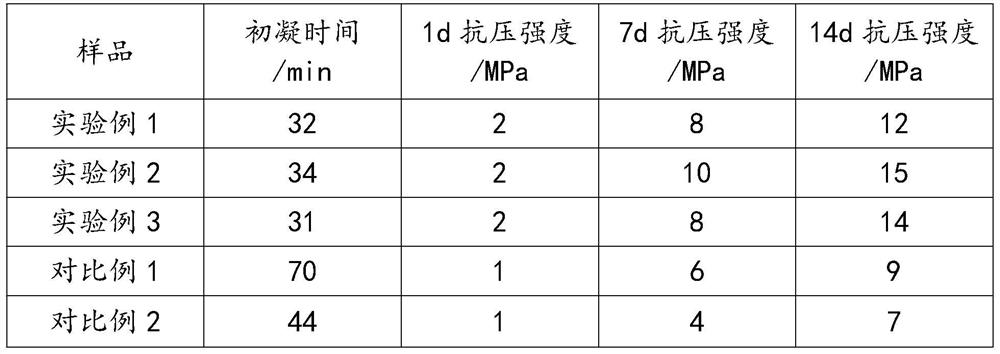

Examples

Embodiment 1

[0030] This embodiment is a preparation method of early-strength rapid-hardening cement mortar, comprising the following components in parts by weight:

[0031] 1 part of ordinary cement, 0.05 part of sulfoaluminate cement, 1.5 part of yellow sand, 0.003 part of admixture, 0.4 part of water, 0.001 part of rust inhibitor;

[0032] The preparation method of this early-strength quick-hardening cement mortar comprises the following steps:

[0033] S1: Pour the weighed tap water and admixture into the mixing bucket for simple stirring;

[0034] S2: Add ordinary cement, sulphoaluminate cement and yellow sand while stirring, control the adding time within 1 minute, continue stirring for 2 minutes after adding, and constantly change the stirring position during the stirring process to prevent the raw materials from sinking to the bottom;

[0035] S3: Add the rust inhibitor while stirring, control the stirring teeth to stay in the slurry all the time during the stirring process, and s...

Embodiment 2

[0043] This embodiment is a preparation method of early-strength rapid-hardening cement mortar, comprising the following components in parts by weight:

[0044] 1 part of ordinary cement, 0.05 part of sulfoaluminate cement, 2 parts of yellow sand, 0.005 part of admixture, 0.4 part of water, 0.002 part of rust inhibitor;

[0045] The preparation method of this early-strength quick-hardening cement mortar comprises the following steps:

[0046] S1: Pour the weighed tap water and admixture into the mixing bucket for simple stirring;

[0047] S2: Add ordinary cement, sulphoaluminate cement and yellow sand while stirring, control the adding time within 1 minute, continue stirring for 2 minutes after adding, and constantly change the stirring position during the stirring process to prevent the raw materials from sinking to the bottom;

[0048] S3: Add the rust inhibitor while stirring, control the stirring teeth to stay in the slurry all the time during the stirring process, and st...

Embodiment 3

[0056] This embodiment is a preparation method of early-strength rapid-hardening cement mortar, comprising the following components in parts by weight:

[0057] 1 part of ordinary cement, 0.1 part of sulfoaluminate cement, 2 parts of yellow sand, 0.005 part of admixture, 0.5 part of water, 0.002 part of rust inhibitor;

[0058] The preparation method of this early-strength quick-hardening cement mortar comprises the following steps:

[0059] S1: Pour the weighed tap water and admixture into the mixing bucket for simple stirring;

[0060] S2: Add ordinary cement, sulphoaluminate cement and yellow sand while stirring. The time for adding the materials is controlled within 2 minutes. After the addition, continue to stir for 3 minutes. During the stirring process, the stirring position should be constantly changed to prevent the raw materials from sinking to the bottom;

[0061] S3: Add the rust inhibitor while stirring, control the stirring teeth to always be in the slurry durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com