Preparation method of polyethylene reinforced modified plastic particles

A technology for plastic granules and polyethylene waste, which is applied in the field of preparation of polyethylene reinforced modified plastic granules, can solve the problems of easy fire and flammability of polyethylene plastics, and achieves reduction of processing steps, weight reduction, and good flame retardancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

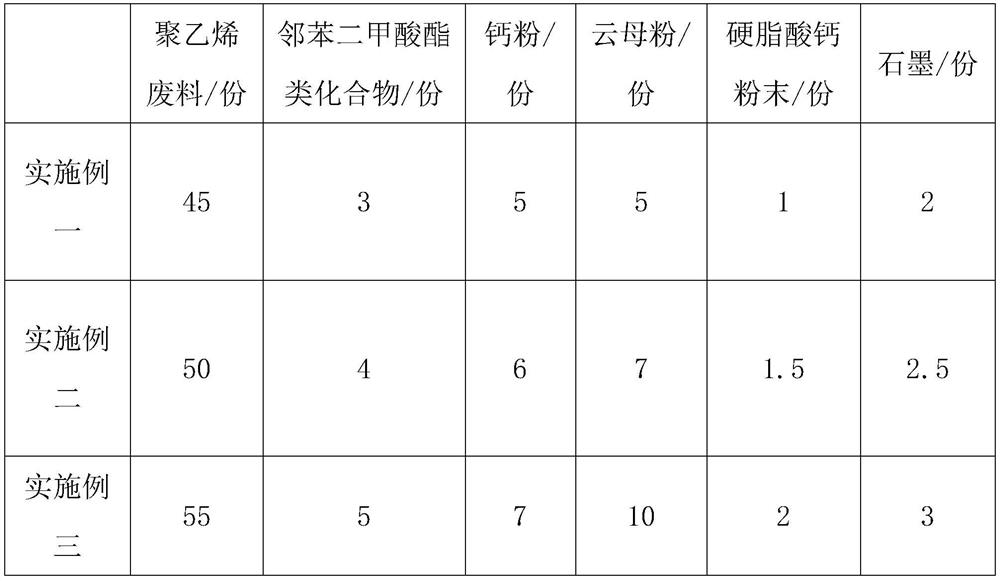

[0027] A method for preparing polyethylene reinforced modified plastic particles, comprising the following raw materials in parts by weight: 45 parts of polyethylene waste, 3 parts of phthalate compounds, 5 parts of calcium powder, 5 parts of mica powder, and calcium stearate powder 1 part, graphite 2 parts;

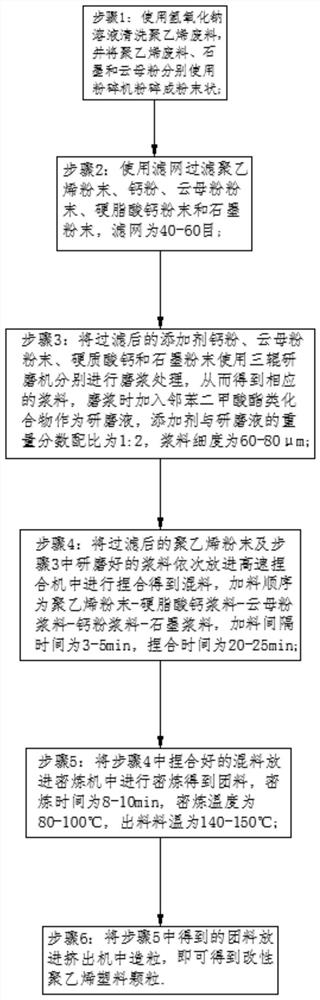

[0028] Such as figure 1 Shown, the concrete steps of this preparation method are as follows:

[0029] Step 1: Clean the polyethylene waste with sodium hydroxide solution, and crush the polyethylene waste, graphite and mica powder into powders using a pulverizer;

[0030] Step 2: Use a filter screen to filter polyethylene powder, calcium powder, mica powder, calcium stearate powder and graphite powder, and the filter screen is 40 mesh;

[0031] Step 3: Refining the filtered additive calcium powder, mica powder, calcium hardate and graphite powder using a three-roll mill to obtain the corresponding slurry, adding phthalates during refining The compound is used as a grin...

Embodiment 2

[0037] A method for preparing polyethylene reinforced modified plastic particles, comprising the following raw materials in parts by weight: 50 parts of polyethylene waste, 4 parts of phthalate compounds, 6 parts of calcium powder, 7 parts of mica powder, and calcium stearate powder 1.5 parts, graphite 2.5 parts;

[0038] Such as figure 1 Shown, the concrete steps of this preparation method are as follows:

[0039] Step 1: Clean the polyethylene waste with sodium hydroxide solution, and crush the polyethylene waste, graphite and mica powder into powders using a pulverizer;

[0040] Step 2: Use a filter screen to filter polyethylene powder, calcium powder, mica powder, calcium stearate powder and graphite powder, and the filter screen is 50 mesh;

[0041] Step 3: Refining the filtered additive calcium powder, mica powder, calcium hardate and graphite powder using a three-roll mill to obtain the corresponding slurry, adding phthalates during refining The compound is used as a...

Embodiment 3

[0047] A method for preparing polyethylene reinforced modified plastic particles, comprising the following raw materials in parts by weight: 55 parts of polyethylene waste, 5 parts of phthalate compounds, 7 parts of calcium powder, 10 parts of mica powder, and calcium stearate powder 2 parts, 3 parts of graphite;

[0048] Such as figure 1 Shown, the concrete steps of this preparation method are as follows:

[0049] Step 1: Clean the polyethylene waste with sodium hydroxide solution, and crush the polyethylene waste, graphite and mica powder into powders using a pulverizer;

[0050] Step 2: Use a filter screen to filter polyethylene powder, calcium powder, mica powder, calcium stearate powder and graphite powder, and the filter screen is 60 mesh;

[0051] Step 3: Refining the filtered additive calcium powder, mica powder, calcium hardate and graphite powder using a three-roll mill to obtain the corresponding slurry, adding phthalates during refining The compound is used as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com