High-thermal-conductivity flexible heat pipe of graphene-coated carbon nanotube aerogel and preparation method of high-thermal-conductivity flexible heat pipe

A technology of graphene coating and carbon nanotubes, which is applied in the direction of airgel preparation, chemical instruments and methods, electrical components, etc., can solve the problems of weather resistance and low thermal conductivity, and achieve high-efficiency heat dissipation, strong capillary force, effective Good for heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

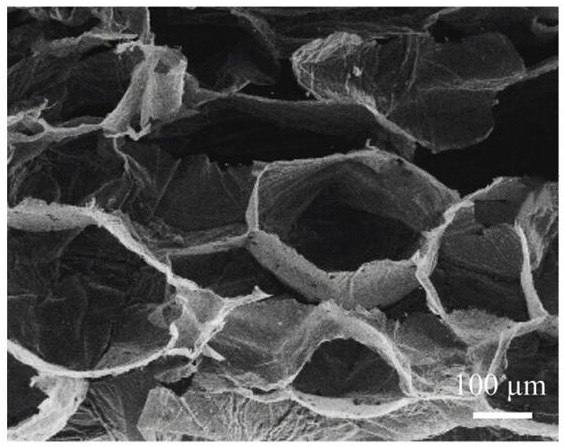

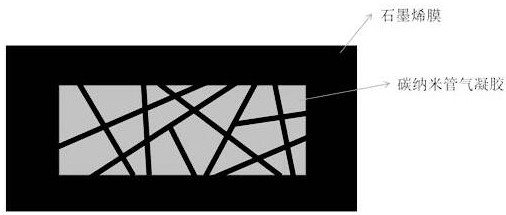

[0032] A new type of graphene-coated carbon nanotube airgel flexible heat pipe with high thermal conductivity. First, prepare carbon nanotube airgel with regular microporous channels as a liquid-absorbing core, and then wrap graphene film on carbon nanotubes The airgel liquid-absorbing core, finally injects the ethanol solution into the carbon nanotube-graphene flexible heat pipe, and vacuumizes and seals it, which specifically includes the following steps:

[0033] The first step is to prepare carbon nanotube airgel with regular microporous channels as a liquid-absorbing core:

[0034] By adding H 2 SO 4 and H 2 o 2 The solutions were mixed at a volume ratio of 3:1 to prepare H 2 SO 4 / H 2 o 2 mixture. Soak the CNT film in the solution for 1 hour;

[0035] Wash the airgel several times in deionized water until the pH value reaches 7, and then dry it in an oven at 100°C for 12 hours;

[0036] Hydrophilic treatment on the surface of carbon nanotube aerogel: place the ...

example 2

[0040] A new type of graphene-coated carbon nanotube airgel flexible heat pipe with high thermal conductivity. First, prepare carbon nanotube airgel with regular microporous channels as a liquid-absorbing core, and then wrap graphene film on carbon nanotubes The airgel liquid-absorbing core, finally injects the ethanol solution into the carbon nanotube-graphene flexible heat pipe, and vacuumizes and seals it, which specifically includes the following steps:

[0041] The first step is to prepare carbon nanotube airgel with regular microporous channels:

[0042] By adding H 2 SO 4 and H 2 o 2 The solutions were mixed at a volume ratio of 4:1 to prepare H 2 SO 4 / H 2 o 2 mixture. Soak the CNT film in the solution for 2 hours;

[0043] Wash the airgel several times in deionized water until the pH value reaches 7, and then dry it in an oven at 100°C for 12 hours;

[0044]Hydrophilic treatment on the surface of carbon nanotube aerogel: place the foamed carbon nanotube aero...

example 3

[0048] A new type of graphene-coated carbon nanotube airgel flexible heat pipe with high thermal conductivity. First, prepare carbon nanotube airgel with regular microporous channels as a liquid-absorbing core, and then wrap graphene film on carbon nanotubes The airgel liquid-absorbing core, finally injects the ethanol solution into the carbon nanotube-graphene flexible heat pipe, and vacuumizes and seals it, which specifically includes the following steps:

[0049] The first step is to prepare carbon nanotube airgel with regular microporous channels as a liquid-absorbing core: by adding H 2 SO 4 and H 2 o 2 The solutions were mixed at a volume ratio of 5:1 to prepare H 2 SO 4 / H 2 o 2 mixture. Soak the CNT film in the solution for 3 hours;

[0050] Wash the airgel several times in deionized water until the pH value reaches 7, and then dry it in an oven at 100°C for 12 hours;

[0051] Hydrophilic treatment on the surface of carbon nanotube aerogel: place the foamed ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com