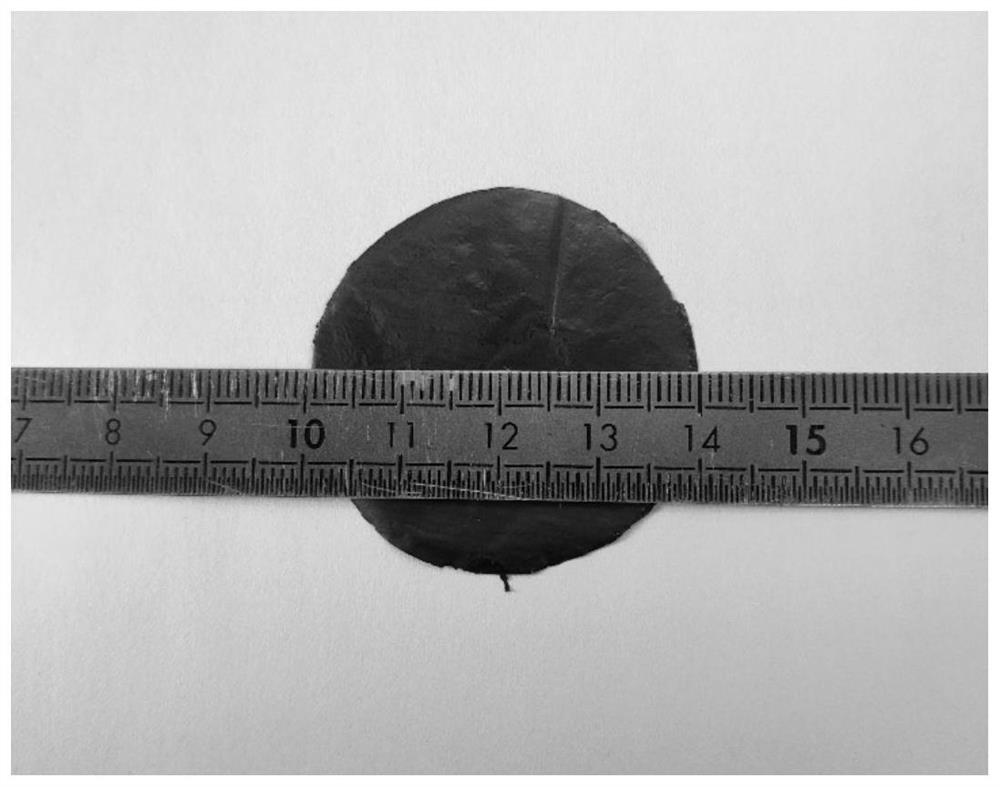

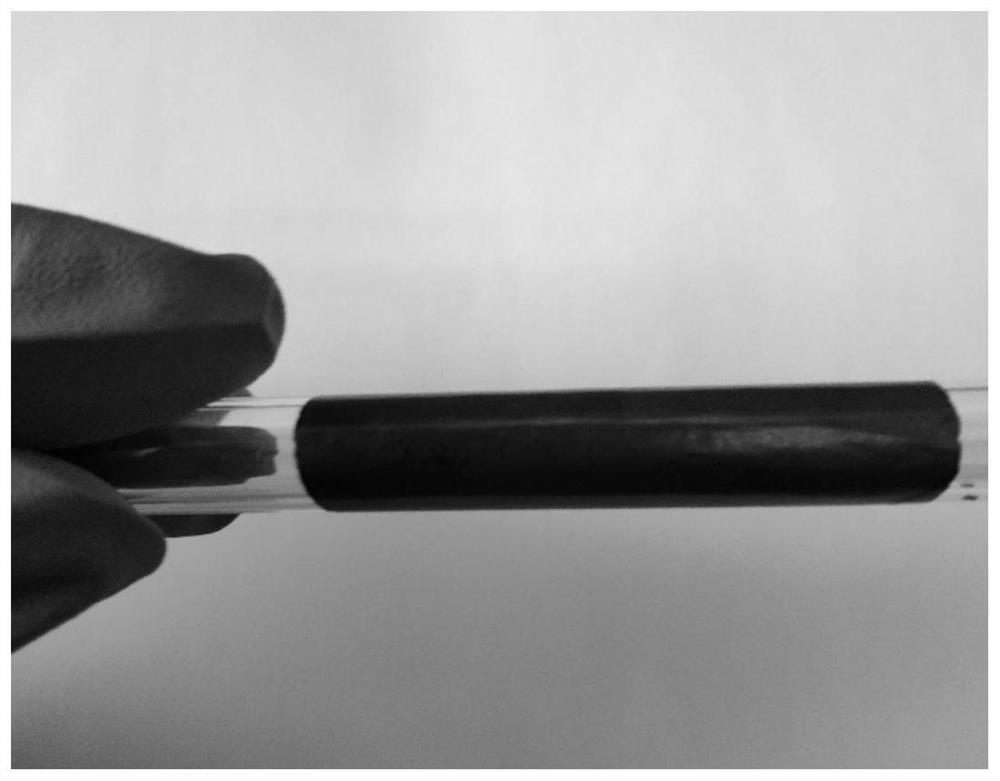

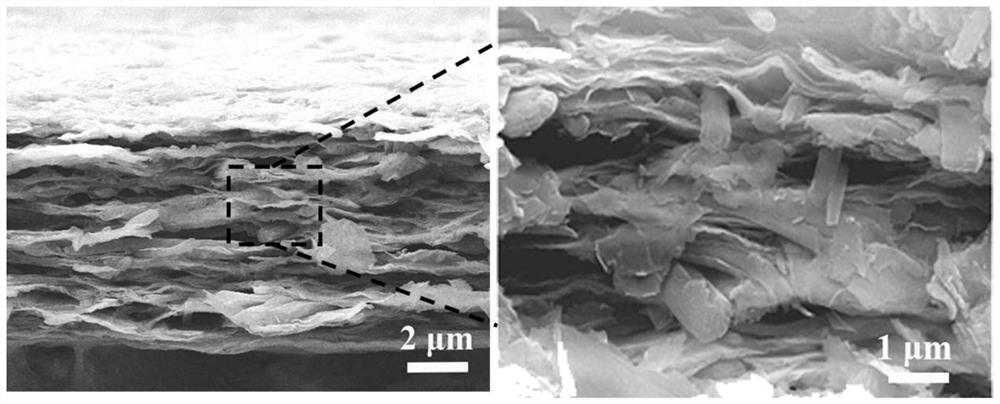

Preparation method and application of high-density HATN@MXene flexible self-supporting film electrode

A self-supporting film and film electrode technology, applied in electrode manufacturing, active material electrodes, hybrid capacitor electrodes, etc., to achieve the effects of high tap density, good flexibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention is a method for preparing a high-density HATN@MXene flexible self-supporting thin film electrode, which specifically includes the following steps:

[0031] Step 1: Preparation of nanorod-shaped HATN: HATN is obtained by dehydration condensation. Take 0.6g of hexaketonecyclohexane, and dissolve it in 50ml of acetic acid under uniform stirring; then add 0.75g of o-phenylenediamine to it, and heat the resulting solution under reflux at 120°C for 10h; after the reaction is completed, put The suspension was vacuum-filtered and washed several times with hot acetic acid, acetone, methanol, ethanol and water respectively; finally, vacuum-dried at 50°C to obtain HATN powder.

[0032] Step 2: Preparation of MXene nanosheet dispersion: slowly dissolve 1.8g of lithium fluoride in 25ml of hydrochloric acid with a concentration of 9M, stir for 10 minutes, and slowly add 2g of Ti 3 AlC 2 , stirred at 35°C for 20 hours to obtain a fully reacted mixed solution; then wash...

Embodiment 2

[0037] The preparation method of the present invention comprises the steps:

[0038] Step 1: Preparation of nanorod-shaped HATN: HATN is obtained by dehydration condensation. Take 0.6g of hexaketonecyclohexane, and dissolve it in 50ml of acetic acid under uniform stirring; then add 0.75g of o-phenylenediamine to it, and heat the resulting solution under reflux at 120°C for 10h; after the reaction is completed, put The suspension was vacuum-filtered and washed several times with hot acetic acid, acetone, methanol, ethanol and water respectively; finally, vacuum-dried at 50°C to obtain HATN powder.

[0039] Step 2: Preparation of MXene nanosheet dispersion: slowly dissolve 1.8g of lithium fluoride in 25ml of hydrochloric acid with a concentration of 9M, stir for 10 minutes, and slowly add 2g of Ti 3 AlC 2 , stirred at 35°C for 20 hours to obtain a fully reacted mixed solution; then washed and centrifuged with deionized water at a speed of 3600 rpm, centrifuged for 7 minutes ea...

Embodiment 3

[0042] The preparation method of the present invention comprises the steps:

[0043] Step 1: Preparation of nanorod-shaped HATN: HATN is obtained by dehydration condensation. Take 0.6g of hexaketonecyclohexane, and dissolve it in 50ml of acetic acid under uniform stirring; then add 0.75g of o-phenylenediamine to it, and heat the resulting solution under reflux at 120°C for 10h; after the reaction is completed, put The suspension was vacuum-filtered and washed several times with hot acetic acid, acetone, methanol, ethanol and water respectively; finally, vacuum-dried at 50°C to obtain HATN powder.

[0044] Step 2: Preparation of MXene nanosheet dispersion: slowly dissolve 1.8g of lithium fluoride in 25ml of hydrochloric acid with a concentration of 9M, stir for 10 minutes, and slowly add 2g of Ti 3 AlC 2 , stirred at 35°C for 20 hours to obtain a fully reacted mixed solution; then washed and centrifuged with deionized water at a speed of 3600 rpm, centrifuged for 7 minutes ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com