Mirror inlaid from front side

A mirror and mirror body technology, applied in the field of mirrors, can solve the problems of unfavorable use, affecting the imaging field of view, and the edge of the mirror will be blocked, so as to achieve high utilization rate, wide field of view, and improve the effect of collection and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

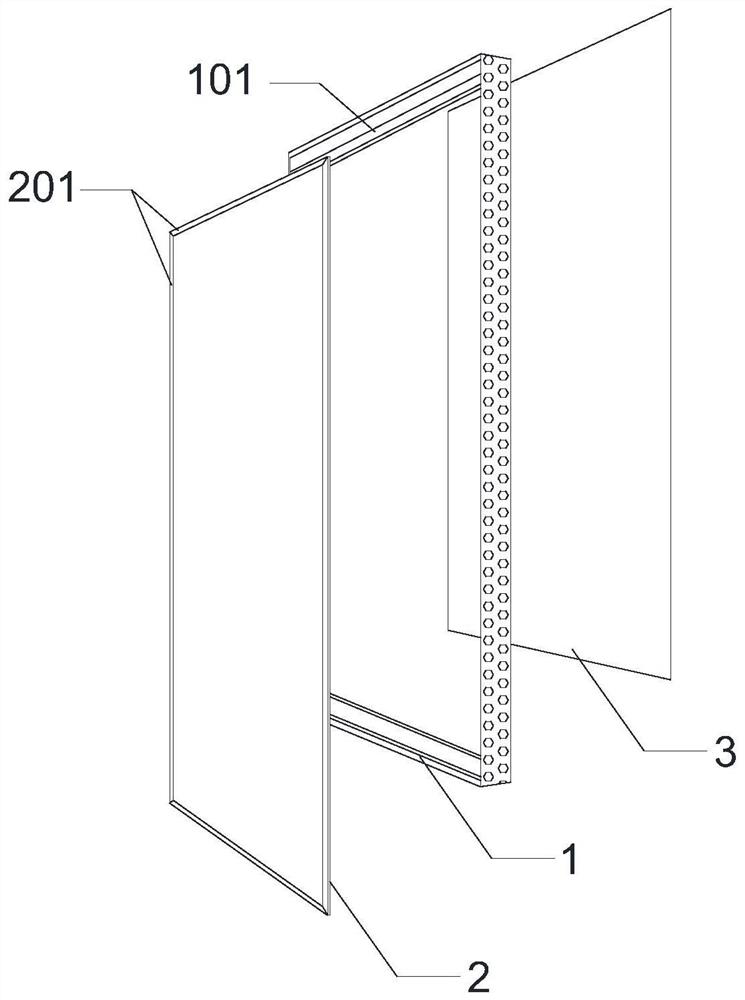

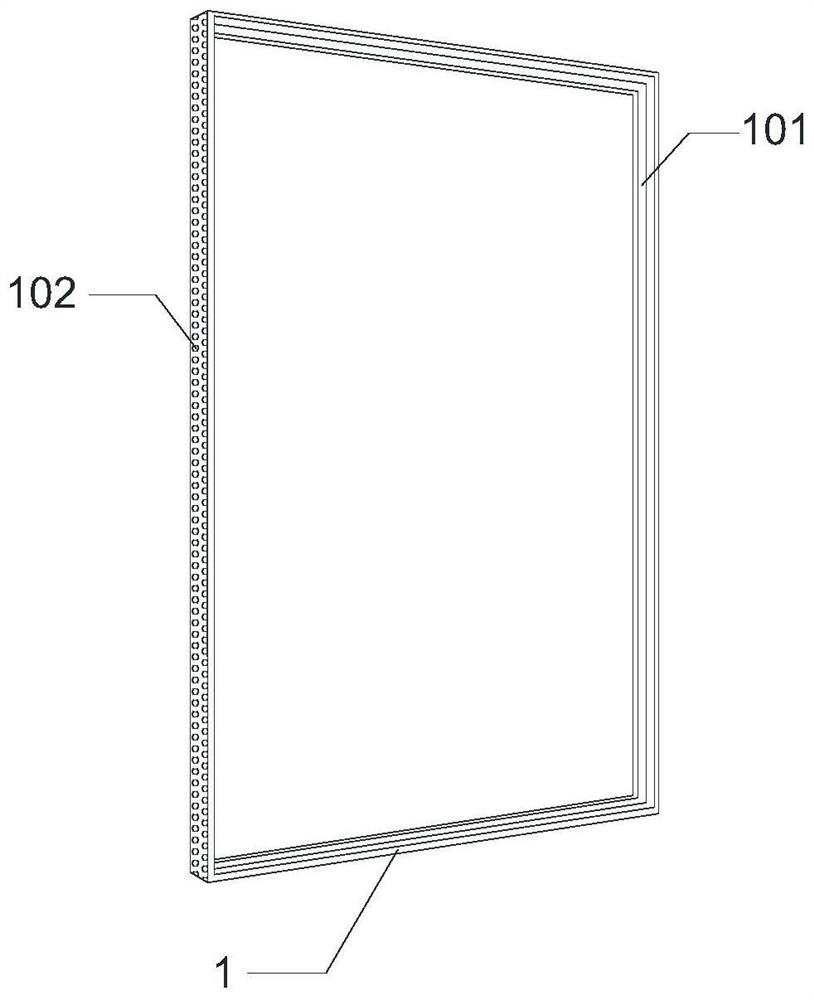

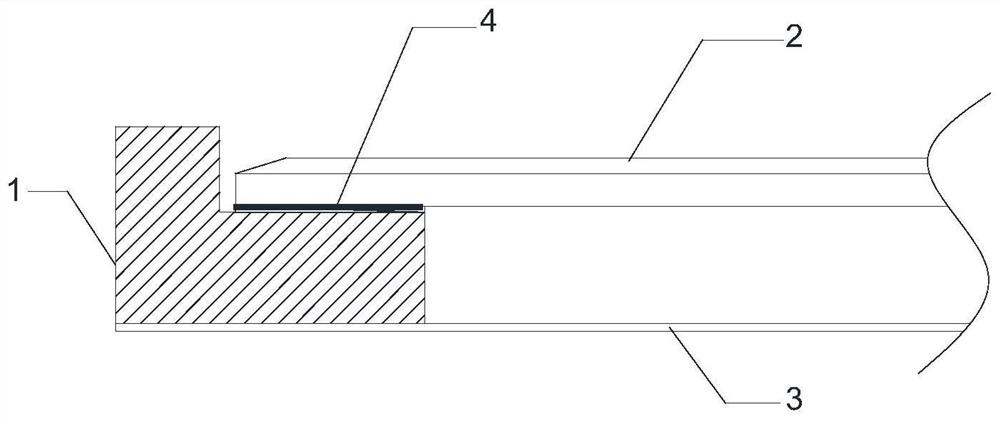

[0034] like Figures 1 to 3 As shown in , a mirror inlaid from the front includes a rectangular frame 1 and a mirror body 2 . The front of the frame is provided with a groove 101, the depth of the groove of the frame is 1.2cm, the back of the frame is provided with a protective film 3 for sealing the back of the frame, the protective film is made of kraft paper, and the sides of the kraft paper are bonded to the back of the frame; The texture 102, the anti-skid texture is in the shape of evenly distributed pits. The mirror body is embedded in the groove of the frame from the front, the back of the mirror body and the frame are bonded by adhesive 4, the edge of the mirror body is ground into a bevel 201, the periphery of the mirror body is polished, and the mirror body is made of commercially available 0.7cm thick Aluminum mirror.

[0035]Among them, the adhesive is a two-component epoxy resin adhesive, including the A component and the B component with a mass ratio of 2.5:1;...

Embodiment 2

[0042] The mirror structure and installation method in Example 2 are the same as in Example 1; the two-component epoxy resin adhesive used includes A component and B component in a mass ratio of 2:1; in parts by weight, A component The raw materials include: 90 parts epoxy resin E51, 3 parts diluent 1,4-butanediol diglycidyl ether; B component raw materials include: 80 parts phytic acid and POSS modified amine curing agent, 3 parts two Methylimidazole, 8 parts toluene.

[0043] The preparation method of phytic acid and POSS modified amine curing agent comprises the following steps:

[0044] (1) An aqueous solution of 3-glycidyloxypropyltrimethoxysilane and 5wt% tetramethylammonium hydroxide was added to isopropanol, 3-glycidyloxypropyltrimethoxysilane, tetramethylhydrogen The ratio of the aqueous solution of ammonium oxide and the amount of isopropanol added was 90g:45g:400mL; after stirring for 5 hours, the isopropanol was distilled off under reduced pressure, then toluene w...

Embodiment 3

[0048] The mirror structure and installation method in Example 3 are the same as in Example 1; the two-component epoxy resin adhesive used includes A component and B component in a mass ratio of 3:1; in parts by weight, A component The raw materials include: 100 parts epoxy resin E51, 5 parts diluent 1,4-butanediol diglycidyl ether; the raw materials of component B include: 90 parts phytic acid and POSS modified amine curing agent, 5 parts two Methylimidazole, 10 parts toluene.

[0049] The preparation method of phytic acid and POSS modified amine curing agent comprises the following steps:

[0050] (1) An aqueous solution of 3-glycidyloxypropyltrimethoxysilane and 8wt% tetramethylammonium hydroxide was added to isopropanol, 3-glycidyloxypropyltrimethoxysilane, tetramethylhydrogen The ratio of the aqueous solution of ammonium oxide and the addition of isopropanol is 100g:35g:500mL; after stirring the reaction for 6h, the isopropanol is distilled off under reduced pressure, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com