Plate blank cooling and pressing method for improving quality of casting blank

A casting billet and slab technology, applied in the field of continuous casting, can solve the problems of low efficiency, poor segregation problem, low deformation rate, etc. , the effect of reducing the occurrence of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

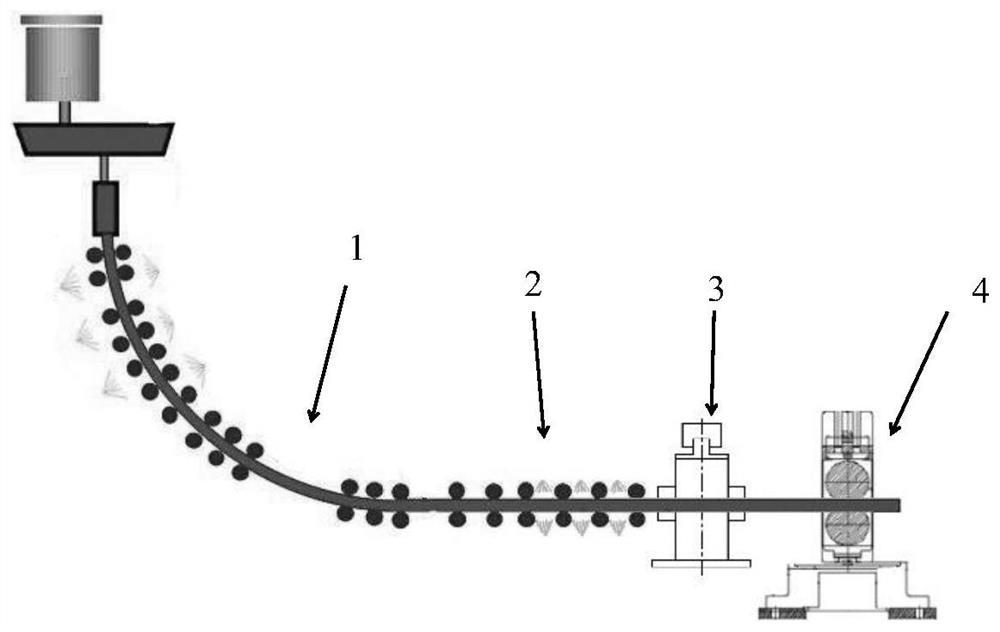

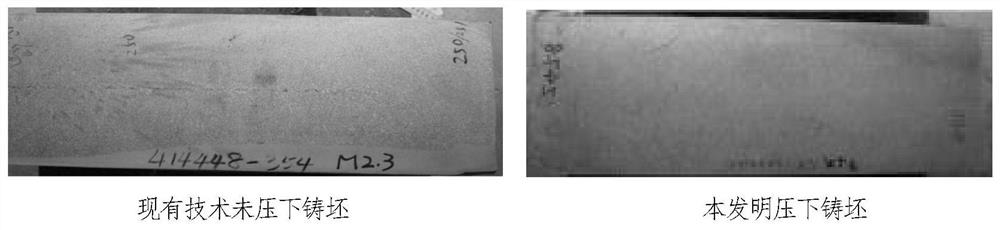

[0030] Taking low-carbon alloy pipeline steel as an example, the billet forms a two-phase region after the straightening point, that is, the horizontal section of the billet is the solidification region of the two-phase region of the billet, and the surface temperature of the billet 1 is 900°C. In this area the slab solidifies completely and loose defects form at the ends. Spray and cool the surface of the slab in the horizontal section of the casting machine 2, and quickly reduce the temperature of the slab to 600°C. 600°C, heat the corners of the slab by induction heating 3 after it exits the casting machine, increase the temperature of the corners of the slab to be equal to or higher than the temperature of the wide surface, and then use the pressing device 4 to press the slab 1 by 20mm Under normal circumstances, due to the large temperature difference between the inside and outside of the slab and the high internal temperature, the deformation is easily transmitted to the...

Embodiment 2

[0033] Taking the peritectic alloy steel ship plate steel as an example, the same cast slab 1 forms a two-phase region in the horizontal section and is completely solidified. Since the peritectic alloy steel is a crack-sensitive steel, the surface of the cast slab is generally cooled 2 to maintain its surface temperature. At this time, the temperature of the corner is about 700°C, the corner is heated 3 by induction, raised to 900°C, and then pressed 4 by 20mm to improve the internal quality. This example also gets figure 2 technical effect.

[0034] The electromagnetic induction heating device at the corner of the slab is installed at the exit of the casting machine. The electromagnetic induction heating device at the corner of the slab adopts a C-shaped frame, and the C-shaped frame is fixed on a trolley. The trolley can move laterally and is suitable for slabs of different widths. . The pressing device is installed at the rear of the corner heating device; the pressing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com