Basalt fiber composite material drainage ditch mounting process

A basalt fiber and composite material technology, applied in water supply devices, waterway systems, sewer systems, etc., can solve problems such as hidden dangers of construction safety, heavy prefabricated parts, and personnel crushing injuries, etc., to reduce construction costs and installation processes. Lightweight, overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

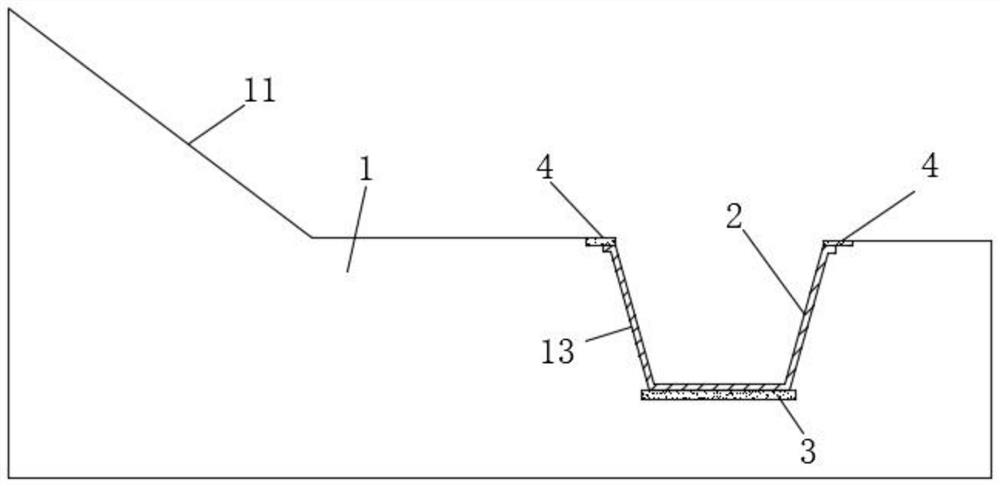

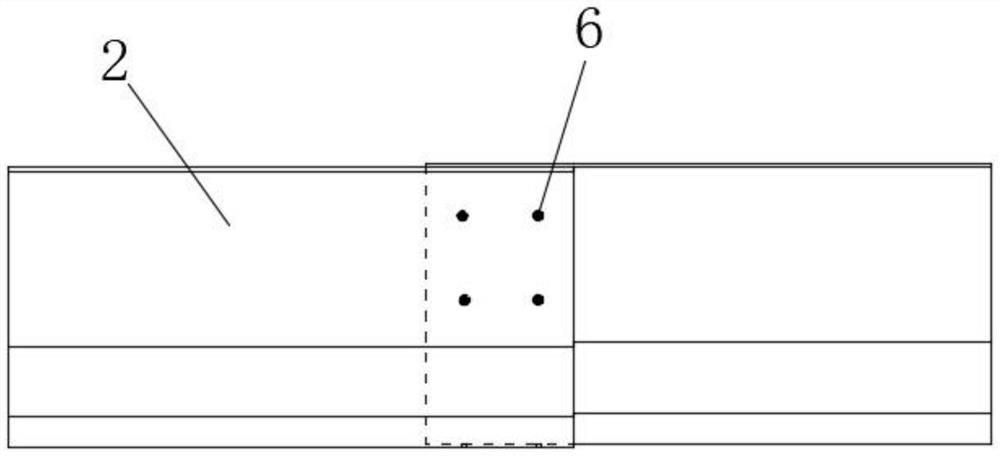

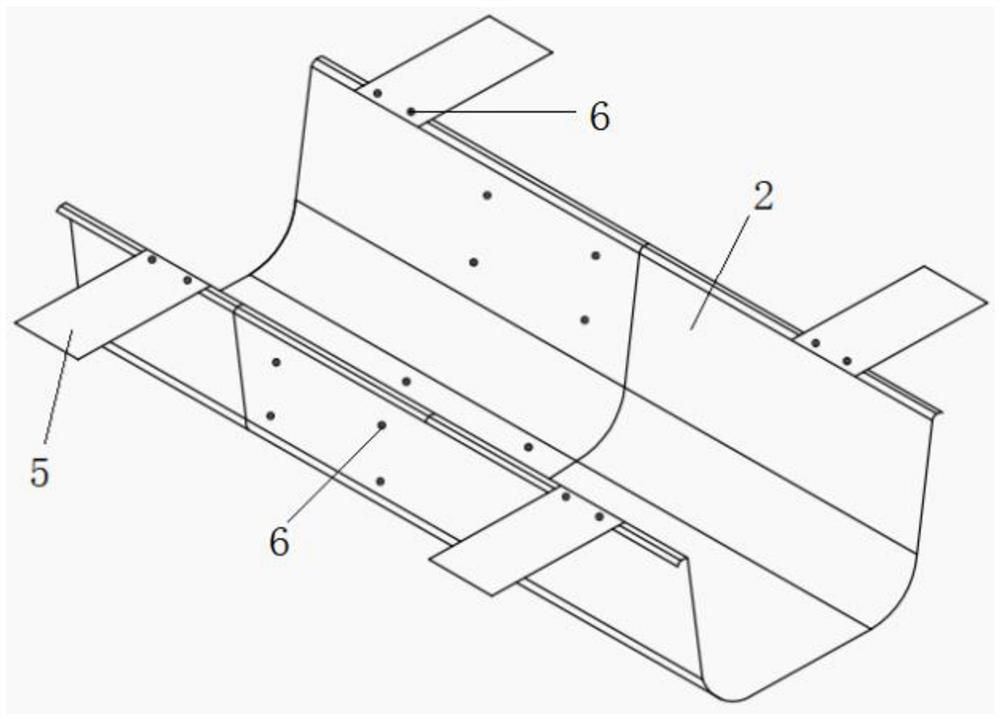

[0037] Please combine Figure 1 to Figure 3 , the basalt fiber composite drainage ditch installation process, including the following steps:

[0038] S1: According to the drawing design requirements, select a multi-section drainage ditch 2 made of basalt fiber composite material and compatible with the foundation groove 13. The top of the drainage ditch 2 is open and has an inverted trapezoidal cross-section.

[0039] The basalt fiber composite material in this embodiment is a continuous fiber drawn from natural basalt. Basalt continuous fiber not only has high strength, but also has various excellent properties such as electrical insulation, corrosion resistance, and high temperature resistance. In addition, the production process of basalt fiber determines that less waste is produced, less environmental pollution, and the product can be directly degraded in the environment after being discarded without any harm, so it is a veritable green and environmentally friendly mater...

Embodiment 2

[0061] The difference between the present embodiment 2 and the embodiment 1 is that in step S5, when it is necessary to install the drainage ditch 2 in the base groove 13 when the inclination and slope length of the embankment side slope 11 of the slope body 1 are large, it is manually lowered Every section of the drainage ditch 2 is placed in the foundation groove 13 in the same way. Use two long wooden squares on the foundation groove 13 as the temporary placement platform for the drainage ditch 2, and place two steel pipes on the embankment slope 11 and the slope protection road for the drainage ditch 2 to slide, and then the workers bind the long wooden squares on the drainage ditch 2 Rope, so that drainage ditch 2 slides and enters in the base groove 13 after passing through two long log sides.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com