Visual purification equipment for industrial wastewater treatment

A technology for industrial wastewater and purification equipment, which is applied in processing wastewater treatment, water/sewage treatment equipment, multi-stage water treatment, etc. The effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] as attached figure 1 to attach Figure 6 Shown:

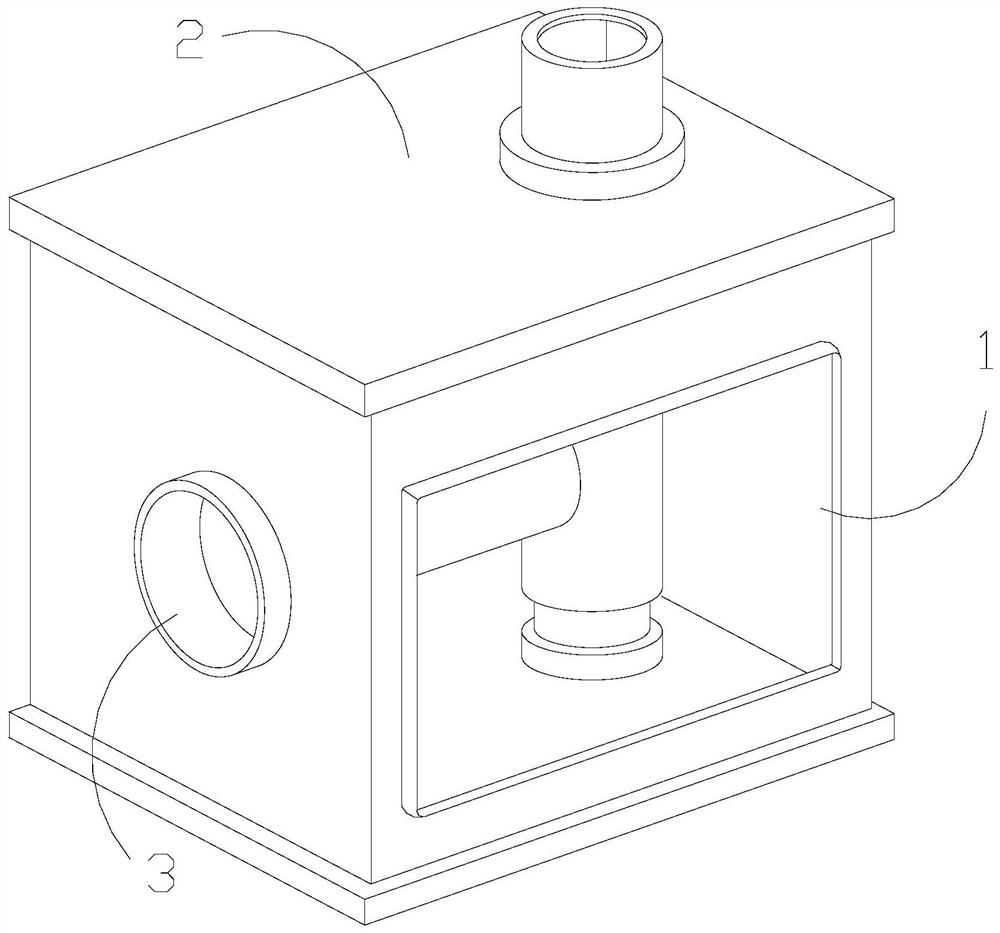

[0032] The present invention provides a kind of visible purification equipment for industrial wastewater treatment, its structure is provided with a visible window 1, a purification box 2, and a water outlet 3, and the visible window 1 and the purification box 2 are integrated structures and are located at the front end position, the water outlet 3 is provided through one side of the purification box 2 .

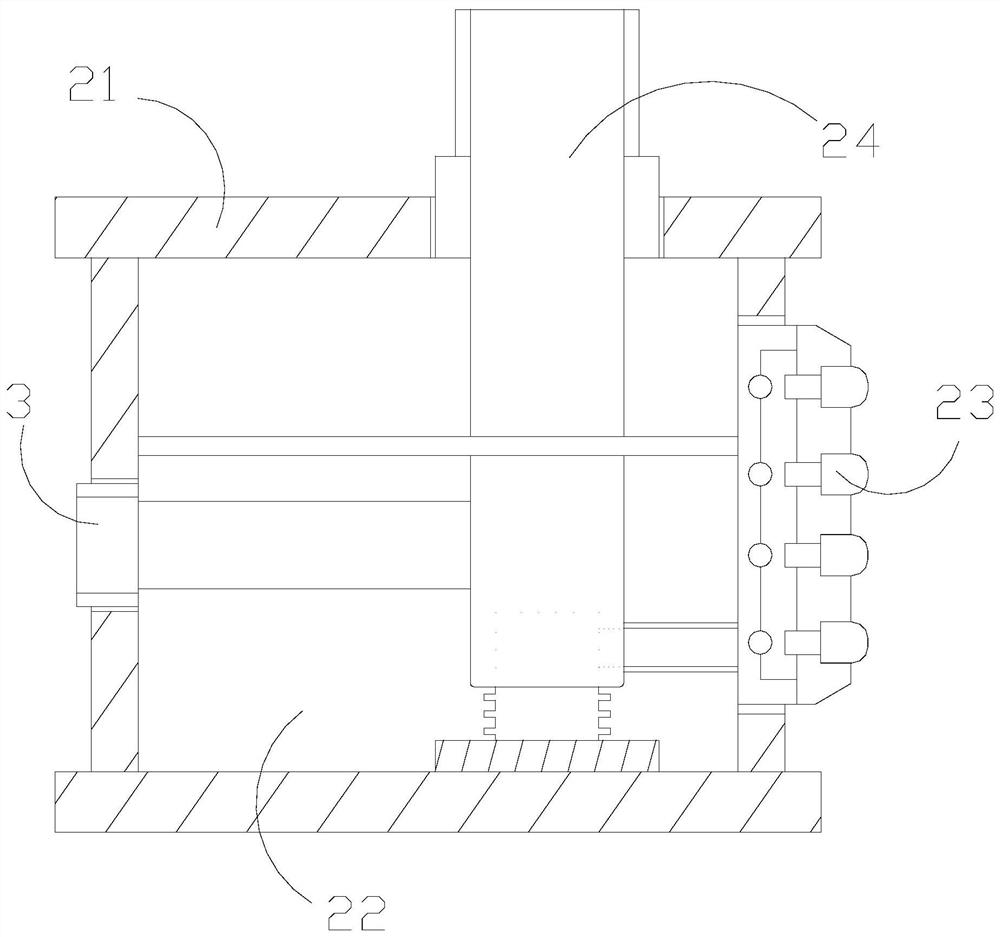

[0033] The clean box 2 is provided with a frame 21, a clean room 22, a control panel 23, and a clean device 24. The clean room 22 is located inside the frame 21, and the control panel 23 is fixedly mounted on one side of the outer periphery of the frame 21. The purification device 24 is embedded in the purification chamber 22 , and the purification device 24 cooperates with the control panel 23 .

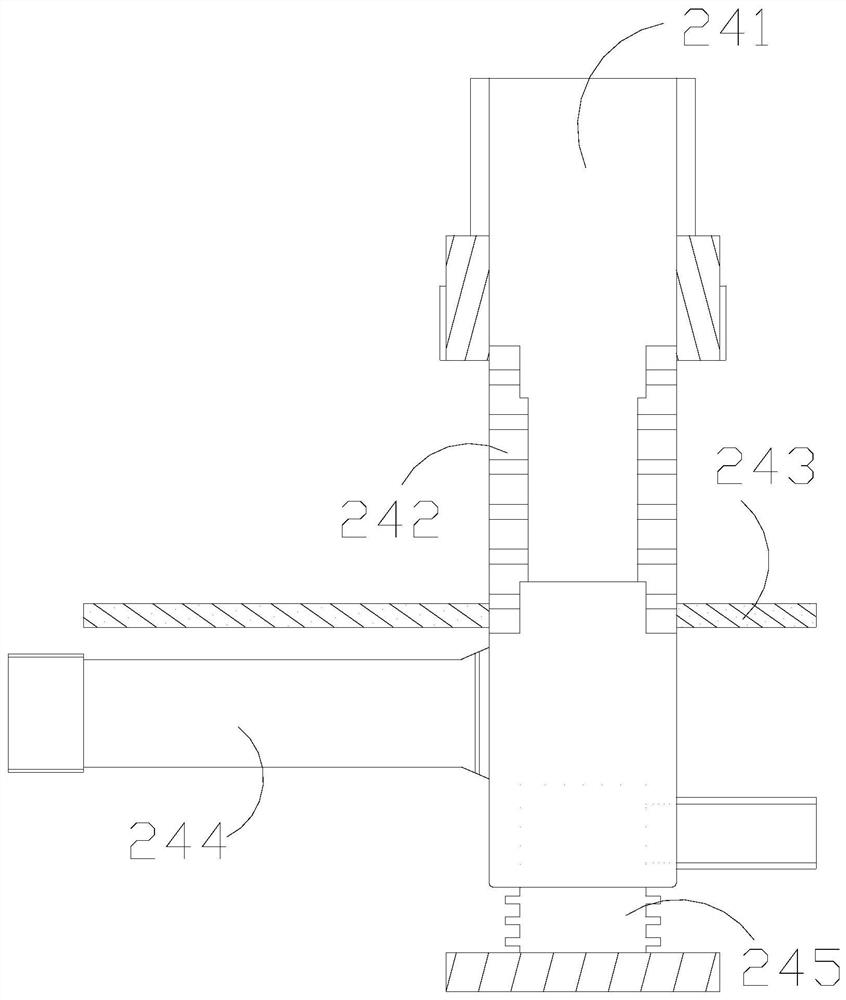

[0034] Wherein, the purification device 24 is provided with a water-carrying chamber 241, a side discharge port 242, a ...

Embodiment 2

[0040] as attached Figure 7 to attach Figure 9 Shown:

[0041] Wherein, the folding plate device a33 is provided with an inner plate cavity w1 and an outer plate body w2, the inner plate cavity w1 and the outer plate body w2 are integrated structures and located inside them, the inner plate cavity w1 is in a hollow state, The outer plate body w2 is folded, which drives the inner plate cavity w1 to move accordingly, and the force of the inner plate cavity w1 is reversed to assist the outer plate body w2 to produce a trembling movement.

[0042] Wherein, the inner panel cavity w1 is provided with a fixing plate w11, a bumping block w12, and a spring w13, the spring w13 is connected between the bumping blocks w12, and the fixing plate w11 is embedded in the middle end of the inner panel cavity w1, so The spring w13 is hingedly connected with the fixed plate w11. The bumping block w12 and the spring w13 form a group for cooperating activities. There are three groups, and they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com