A kind of flexible anti-cracking covering anti-seepage material with steel slag as main material and construction technology

A technology of anti-seepage material and construction technology, which is applied in the field of flexible anti-cracking covering anti-seepage material and construction technology with steel slag as the main material, which can solve the problems of deterioration of anti-seepage performance and easy cracking of the anti-seepage material of the covering layer, and achieve improvement Effects of compactness, drastic decrease in solution performance, and reduction in concentration of metal cations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation and construction process using the above-mentioned anti-seepage and anti-cracking material includes the following steps:

[0046] (1) The natural steel slag is washed with water and then air-dried, and then sieved according to the four particle size ranges of 0.5-1mm, 0.25-0.5mm, 0.1-0.25mm and 0.075-0.1mm, and the steel slag 1 is configured with reference to the preferred gradation: The mass between 0.5-1mm accounts for 40%, the mass between 0.25-0.5mm accounts for 30%, the particle size between 0.1-0.25mm accounts for 20%, and the particle size between 0.075-0.1mm 10%), and stir well. Then according to the demand, calculate and weigh the required total amount of steel slag (accounting for 94.7% of the total mass) according to the compaction degree of 85%.

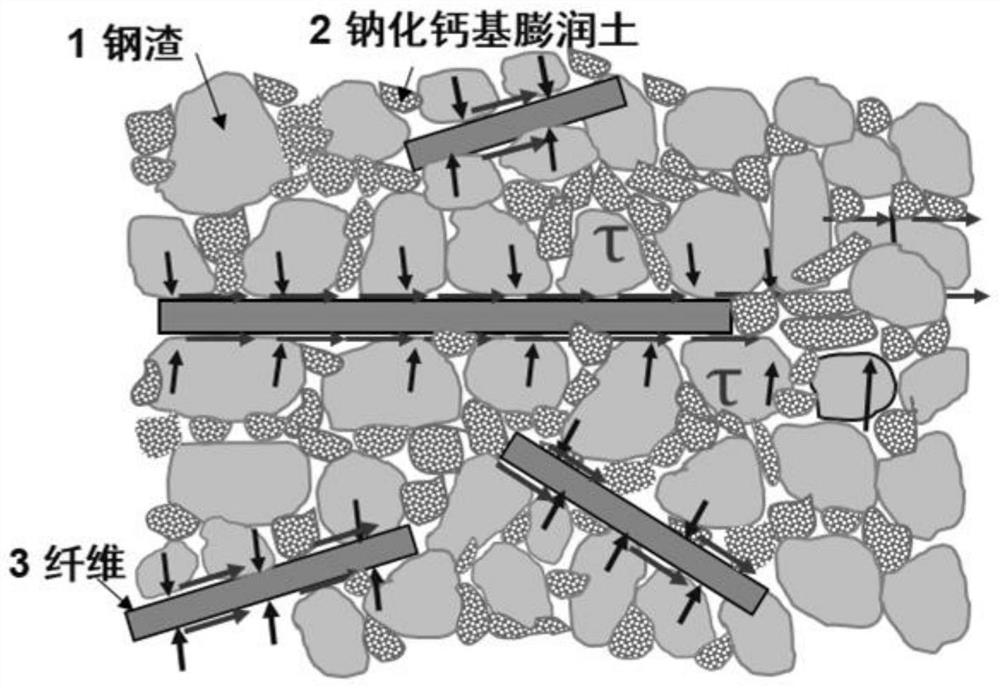

[0047] (2) Calculate and weigh the required dry sodium calcium bentonite 2 total amount (accounting for 5% of the total mass) according to the degree of compaction of 85%, evenly add it to the stee...

Embodiment 2

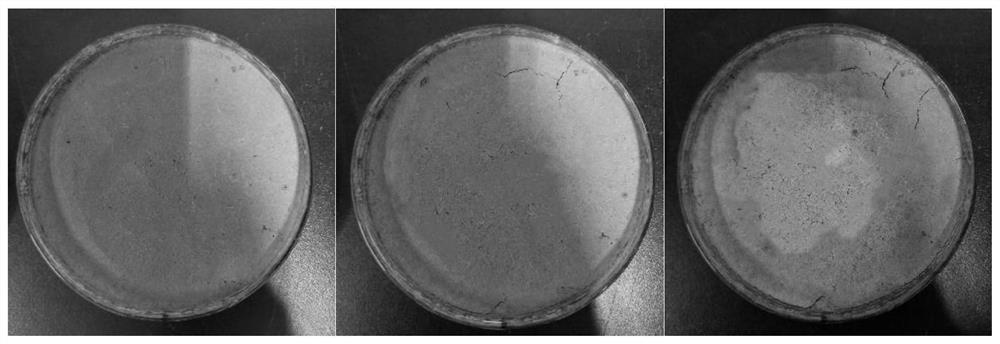

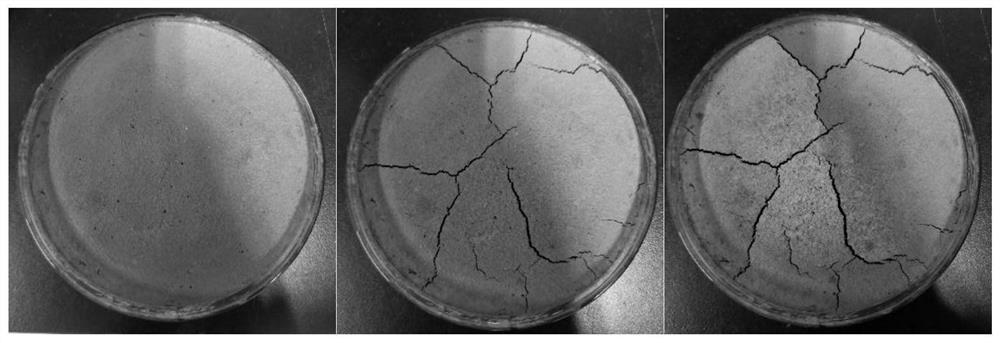

[0055] The anti-seepage material of Example 2 is slightly different from Example 1, the difference is that according to the mass ratio of steel slag, sodium calcium bentonite and fiber, specifically steel slag 92.1%, sodium calcium bentonite 7.5%, polypropylene Fiber 0.4%. In order to verify its anti-seepage performance and anti-cracking performance, the flexible wall penetration test and three dry-wet cycle tests were carried out respectively. The penetration test results are shown in Example No. 2 in Table 1, which satisfies the "Technical Specification for Domestic Waste Landfill Treatment". (GB 50869-2013) requirements for the permeability coefficient of anti-seepage materials, and there are no obvious cracks after three dry-wetting cycles.

example 3

[0057] Example 3 The anti-seepage material is slightly different from Example 1, the difference is that according to the mass ratio of steel slag, sodium calcium bentonite and fiber, specifically steel slag 89.5%, sodium calcium bentonite 10%, polypropylene fiber 0.5%. In order to verify its anti-seepage performance and anti-cracking performance, the flexible wall penetration test and 5 dry-wet cycle tests were carried out respectively. The penetration test results are shown in Example No. 3 in Table 1, and the permeability coefficient of the anti-seepage material is not greater than 10. -7 cm / s requirements, and no obvious cracks after drying and wetting cycles.

[0058] Table 1 Examples of anti-seepage and anti-cracking effects

[0059]

[0060]It can be seen from the above table that the permeability coefficients of the flexible anti-cracking and covering anti-seepage materials with steel slag as the main material obtained in Examples 1-3 all meet the requirements of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| swell index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com