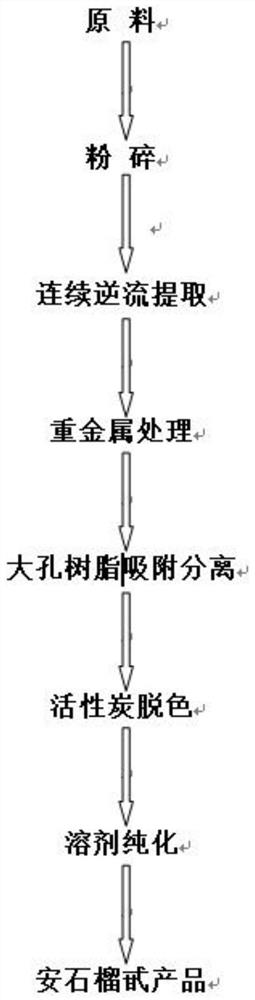

Pomegranate peel extracting solution heavy metal treatment and punicalagin purification method

A pomegranate peel extract, a technology for pomegranate peel extract, applied in chemical instruments and methods, organic chemistry, esterification saccharide and other directions, can solve the problems of strict control of heating temperature, uneven raw material layers, difficult screening, etc., and achieves remarkable results. Economic benefits, poor solvent concentration, and small solvent times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

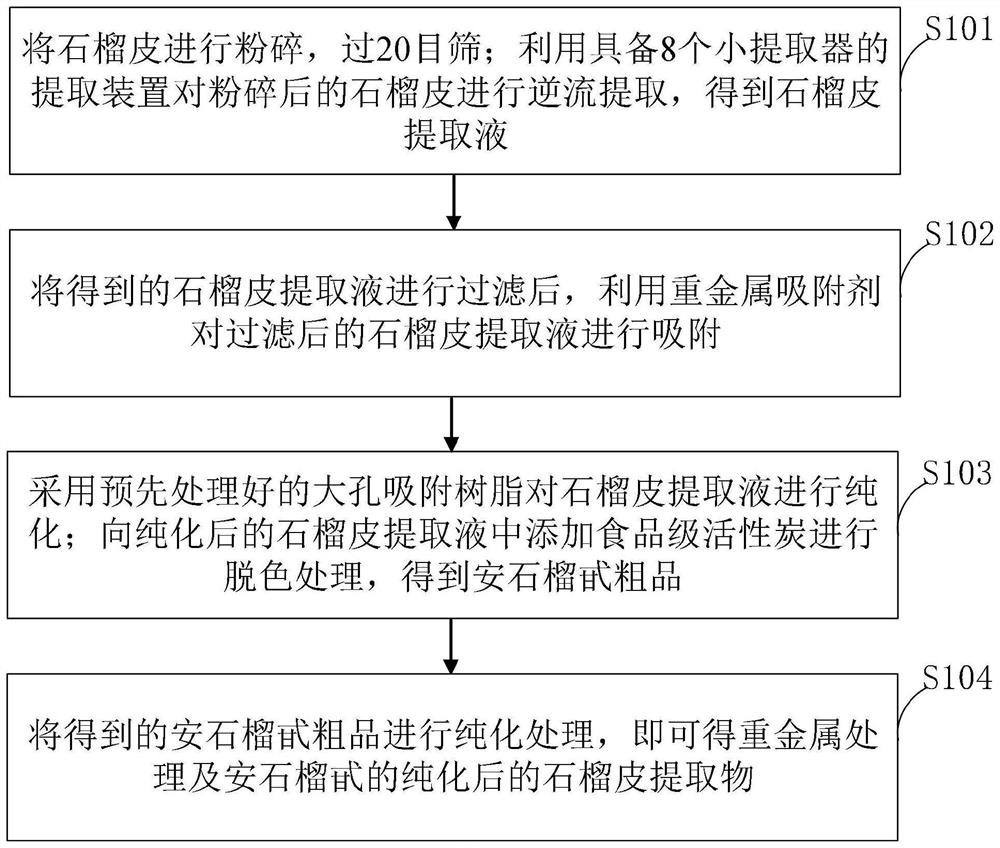

[0070] The heavy metal treatment of pomegranate peel extract and the purification method of punicalagin provided in the embodiment of the present invention specifically include the following steps:

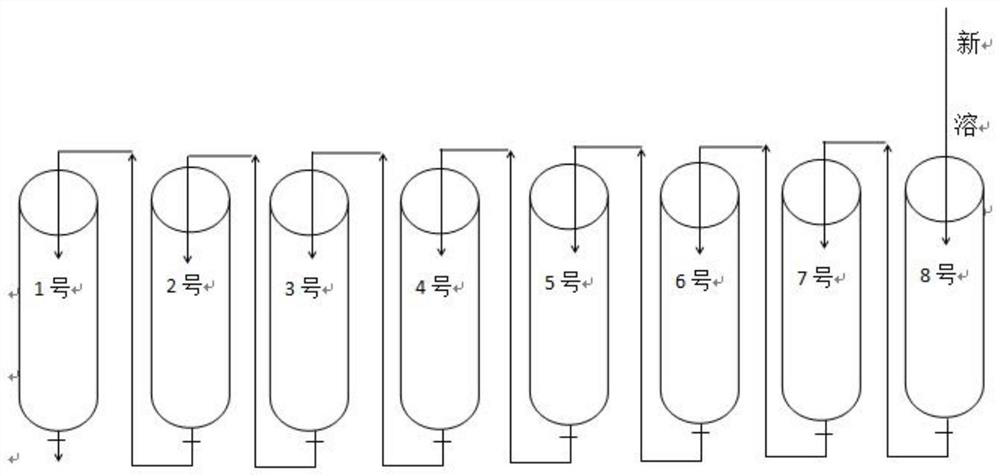

[0071] (1) The pomegranate peel raw material is crushed through a 20-mesh sieve, and each extractor is fed with 100g. Purified water is added from the eighth extractor. The temperature of the purified water is 75°C. The first purification The amount of water used is 500ml (5BV), and it takes 1-1.5h to percolate, and the percolated extract extracts the raw materials of the seventh extractor, and percolates the sixth, five, four, three, two and one extractors in sequence The raw material, that is, the solvent obtained by each extractor percolates the raw material of the next extractor, and the eighth extractor always adds new solvent, which is equivalent to unloading after a single extractor uses 40BV of extraction solvent, and uses the solvent as raw material 5 Doubling the amount,...

Embodiment 2

[0077] The heavy metal treatment of pomegranate peel extract and the purification method of punicalagin provided in the embodiment of the present invention specifically include the following steps:

[0078](1) The pomegranate peel raw material is crushed through a 20-mesh sieve, and each extractor feeds 80g, and the purified water is added from the eighth extractor, the temperature of the purified water is 75°C, and the first purification The water consumption is 480ml (6BV), and it takes 1-1.5h to percolate, and the percolated extract extracts the raw materials of the seventh extractor, and percolates the sixth, five, four, three, two and one extractors in sequence The raw material, that is, the solvent obtained by each extractor percolates the raw material of the next extractor, and the eighth extractor always adds new solvent, which is equivalent to unloading after a single extractor uses 48BV of extraction solvent, and uses the solvent as raw material 5 Doubling the amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com