PA6 resin continuous polymerization process

A polymerization process and resin technology, which is applied in the continuous polymerization process of PA6 resin, can solve problems such as the inability to meet the requirements of spinning grade volatile matter, and achieve the effects of reducing investment and equipment depreciation costs, simple process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) First, mix caprolactam, water, triphenyl phosphite and benzoic acid in a mass ratio of 5:1:1.5:1.0 in a preparation kettle at 60°C, after heating and stirring for 30min, to obtain an auxiliary solution, and into the storage tank, heated to 90 ℃ insulation;

[0045] (2) Mix caprolactam at a mass flow rate of 20kg / min and the auxiliary agent solution obtained in step (1) at a mass flow rate of 1.7kg / min and preheat it to 140°C, then pump it into the top of the polymerization tube, at 240-250°C (polymerization tube). The upper, middle, and lower temperatures were 240°C, 245°C, and 250°C, respectively) and 0.2MPa, and the catalytic ring-opening polymerization was carried out for 6 hours to obtain a PA6 melt (relative intrinsic viscosity was 1.8, and the content of caprolactam monomer was 9.6%). ;

[0046] (3) Pump the PA6 melt obtained in step (2) from the bottom of the polymerization tube into the top of the vertical film devolatilizer at a flow rate of 1300kg / h (the ...

Embodiment 2~5

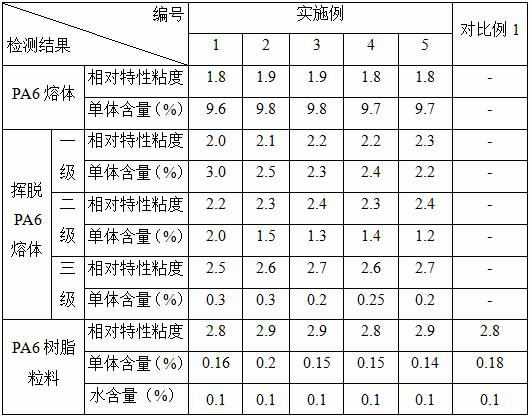

[0050] Table 1 shows the difference technical parameters between Examples 2 to 5 and Example 1. The same as in Example 1.

[0051] Table 1 Technical parameter table of Examples 1 to 5

[0052]

[0053]Note: The ratio of additive components in step (1) in the table refers to the mass ratio of caprolactam, water, catalyst and molecular weight regulator; The temperature of the temperature zone at the beginning is: 260°C, 260°C, 260°C, 270°C, 270°C; in the steps (5) of Examples 4-5 in the table, the temperatures of the temperature zone of the twin-screw extruder starting from the machine head are in order For: 270°C, 270°C, 270°C, 270°C, 280°C, 280°C, 280°C, 290°C, 290°C, 290°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com