Medical-grade PP Toughening and anti-reflection master batch

A toughening and masterbatch technology, which is applied in the field of medical polymer materials, can solve the problems of material yellowing, low temperature conditions are not representative enough, and are not easy to disperse, so as to achieve low processing temperature, avoid multiple high temperature processing, and reduce yellowing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

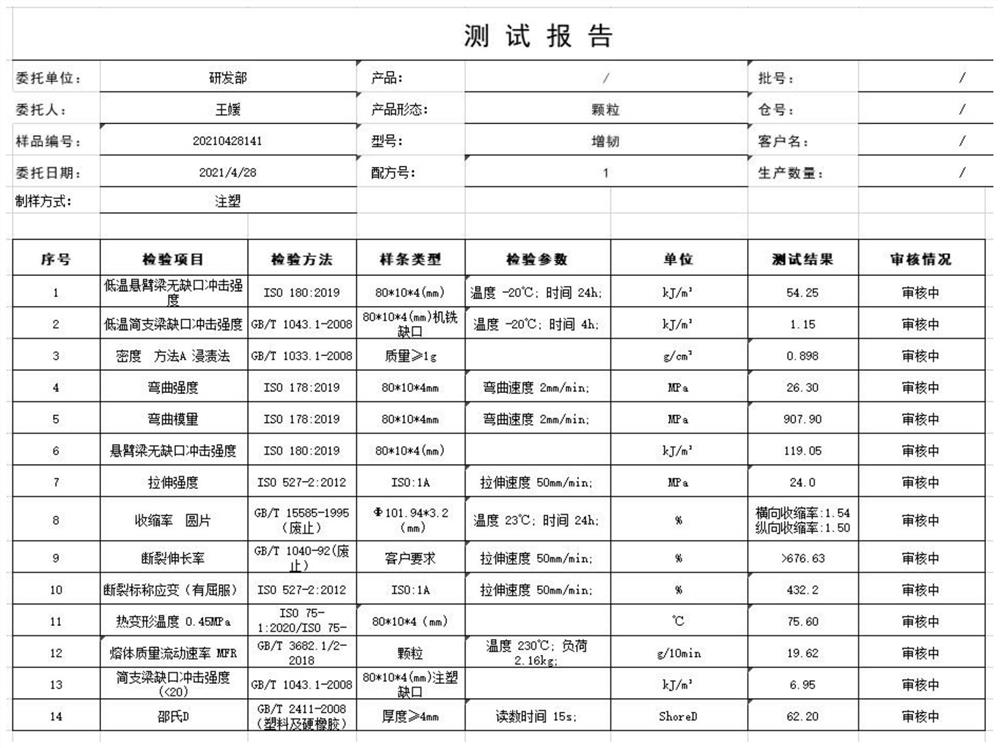

Examples

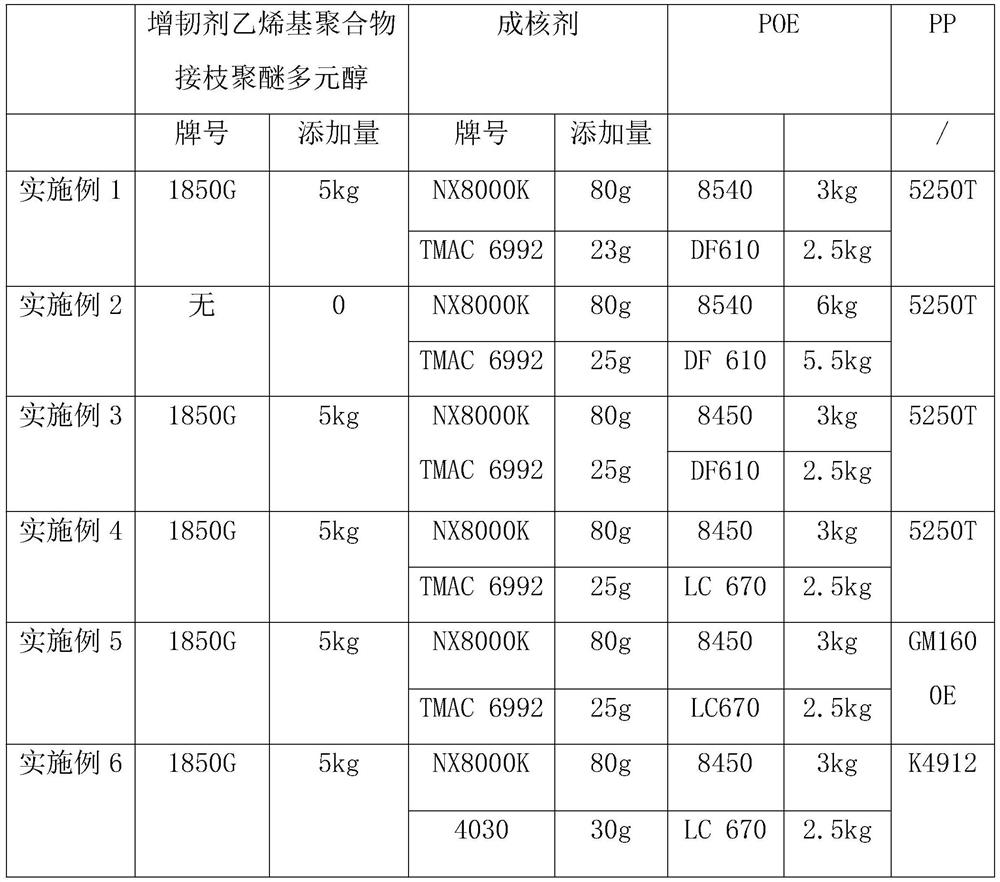

Embodiment 1

[0034] Step 1: Weigh toughening agent vinyl polymer grafted polyether polyol 1850G 5kg, POE 8540 3kg, POEDF610 2.5kg, nucleating agent NX8000K 80g, nucleating agent TMAC 6992 23g, lubricant oleic acid amide 100g, Oxygen agent 1076 120g. Put all the above in a high-speed mixer and mix for 10 minutes, and release it after the time is up.

[0035]Step 2: Put the mixed material in a twin-screw extruder for melt blending and extrusion, the first zone is 60°C, the second zone is 160°C, the third zone is 160°C, the fourth zone is 165°C, the fifth zone is 170°C, and the sixth zone is 170°C ℃, 180℃ in the seventh zone, 180℃ in the eighth zone, 180℃ in the ninth zone, 180℃ in the tenth zone, 180℃ in the eleventh zone, and 160℃ in the machine head. The speed of the host machine is 350r / min, the speed of feeding is 25r / min, and the pelletizing is water-cooled.

[0036] Step 3: Mix the prepared toughening and antireflection masterbatch with PP 5250T at a ratio of 1:10 for testing.

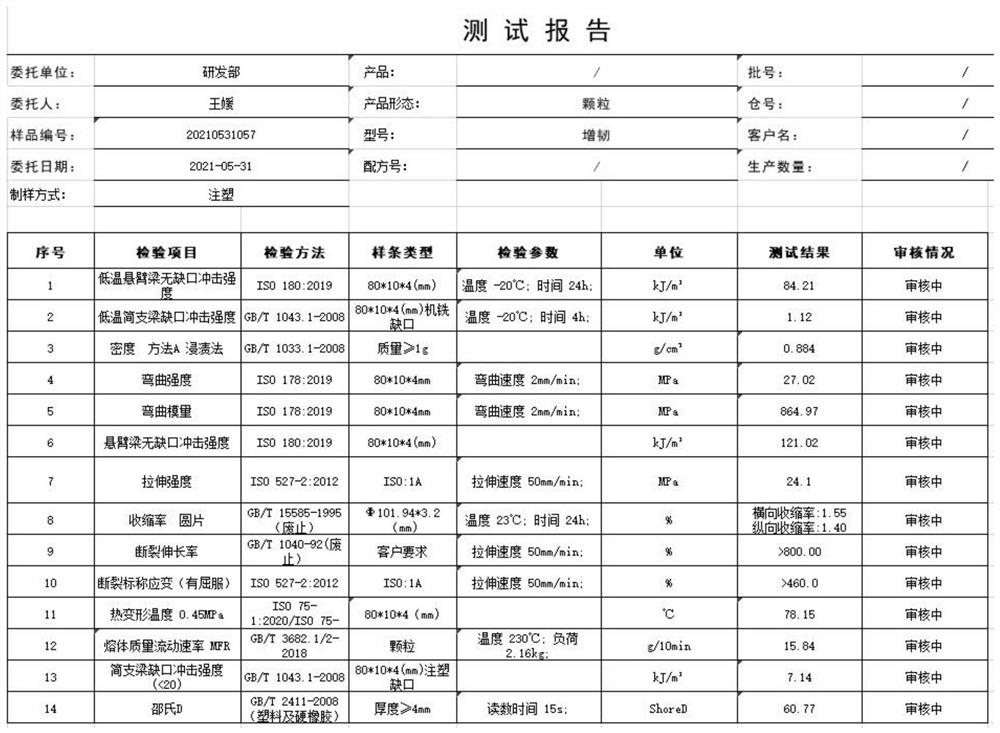

Embodiment 2

[0038] Step 1: Weigh POE 8540 6kg, POE DF610 5.5kg, nucleating agent NX8000K 80g, nucleating agent TMAC6992 25g, lubricant oleamide 150g, antioxidant 1076 100g. Put all the above in a high-speed mixer and mix for 10 minutes, and release it after the time is up.

[0039] Step 2: Place the mixed material in a twin-screw extruder for melt blending and extrusion, the first zone is 60°C, the second zone is 160°C, the third zone is 160°C, the fourth zone is 165°C, the fifth zone is 170°C, and the sixth zone is 170°C ℃, 180℃ in the seventh zone, 180℃ in the eighth zone, 180℃ in the ninth zone, 180℃ in the tenth zone, 180℃ in the eleventh zone, and 160℃ in the machine head. The speed of the main machine is 350r / min, the speed of feeding is 25r / min, and the pelletizing is water-cooled.

[0040] Step 3: Mix the prepared toughening and antireflection masterbatch with PP 5250T at a ratio of 1:10 for testing.

Embodiment 3

[0042] Step 1: Weigh toughening agent vinyl polymer graft polyether polyol 1850G 5kg, POE 8540 3kg, POEDF610 2.5kg, nucleating agent NX8000K 80g, TMAC 6992 25g, lubricant erucamide 150g, antioxidant 1076100g . Put all the above in a high-speed mixer and mix for 10 minutes, and release it after the time is up.

[0043] Step 2: Put the mixed material in a twin-screw extruder for melt blending and extrusion, the first zone is 60°C, the second zone is 160°C, the third zone is 160°C, the fourth zone is 165°C, the fifth zone is 170°C, and the sixth zone is 170°C ℃, 180℃ in the seventh zone, 180℃ in the eighth zone, 180℃ in the ninth zone, 180℃ in the tenth zone, 180℃ in the eleventh zone, and 160℃ in the machine head. The speed of the host machine is 350r / min, the speed of feeding is 25r / min, and the pelletizing is water-cooled.

[0044] Step 3: Mix the prepared toughening and antireflection masterbatch with PP 5250T at a ratio of 1:10 for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com