Aluminum-rich series zinc-based plating layer material capable of reducing brittleness caused by liquid metal in hot forming process and preparation method thereof

A liquid metal, hot forming technology, applied in the direction of metal material coating process, hot dip plating process, coating, etc., can solve the problems of brittle fracture of steel plate matrix, affect the quality of steel forming, and cannot be effectively overcome, and improve fluidity. , The effect of improving surface quality and reducing the viscosity of plating solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

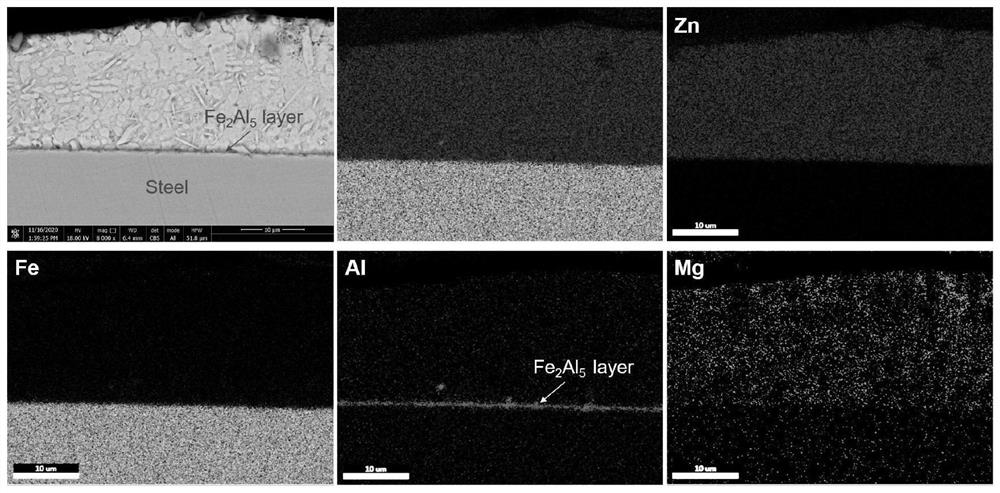

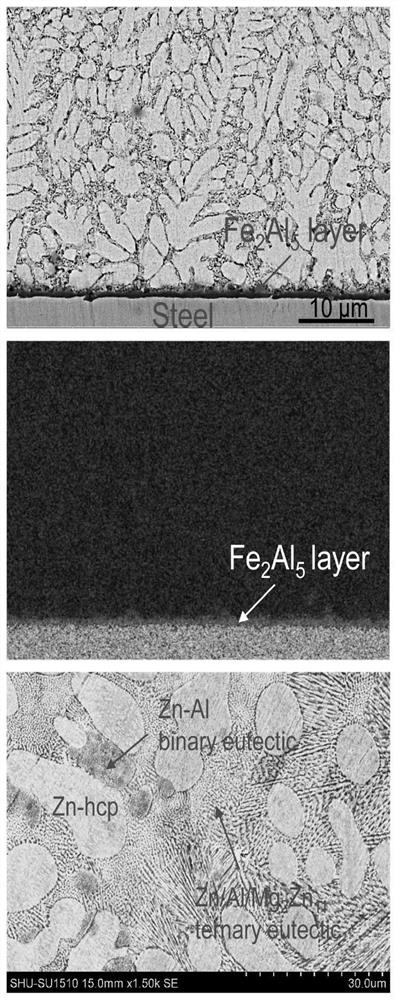

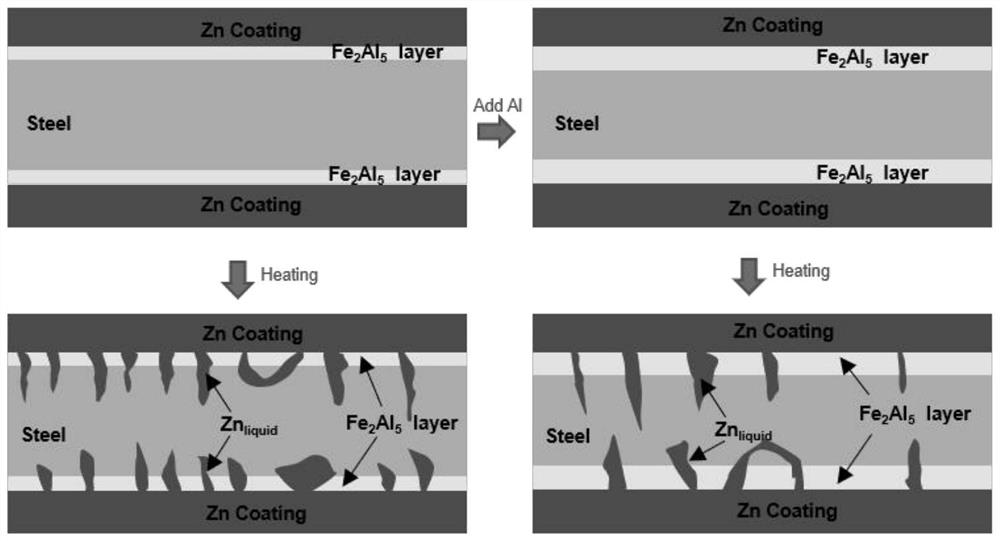

[0062] In this embodiment, an aluminum-rich zinc-based coating material that reduces embrittlement of liquid metal during hot forming is a Zn-Al-Mg alloy with the following composition and weight percentage: Al: 0.2%; Mg: 1.0%; Zn: 98.8wt.%, and the balance is unavoidable impurities.

[0063] A method for preparing an aluminum-rich zinc-based coating material that reduces the embrittlement of liquid metal during hot forming in this embodiment includes the following steps:

[0064] a. Preparation process of hot-plating solution:

[0065] According to the following elemental compositions and weight percentages required for the preparation of aluminum-rich zinc-based coating materials, the prepared raw materials are weighed: the content of Al is 0.2wt.%, the content of Mg is 1.0wt.%, and the balance is Zn and unavoidable Impurities include Zn blocks, Al blocks and Mg blocks, and then the following preparation process steps are used to prepare aluminum-rich zinc-based coating mat...

Embodiment 2

[0111] This embodiment is basically the same as Embodiment 1, especially in that:

[0112] In this embodiment, an aluminum-rich zinc-based coating material that reduces embrittlement of liquid metal during hot forming is a Zn-Al-Mg alloy with the following composition and weight percentage: Al: 3.5%; Mg: 1.8%; the balance is Zn and unavoidable impurities.

[0113] A method for preparing an aluminum-rich zinc-based coating material that reduces the embrittlement of liquid metal during hot forming in this embodiment includes the following steps:

[0114] a. Preparation process of hot-plating solution:

[0115] According to the following elemental compositions and weight percentages required for the preparation of aluminum-rich zinc-based coating materials, the prepared raw materials are weighed: the content of Al is 3.5wt.%, the content of Mg is 1.8wt.%, and the balance is Zn and unavoidable Impurities include Zn blocks, Al blocks and Mg blocks, and then the following preparat...

Embodiment 3

[0161] This embodiment is basically the same as the previous embodiment, and the special features are:

[0162] In this embodiment, an aluminum-rich zinc-based coating material that reduces embrittlement of liquid metal during hot forming is a Zn-Al-Mg alloy with the following composition and weight percentage: Al: 0.2%; Mg: 1.0%; Zn: 98.8wt.%, the balance is unavoidable impurities.

[0163] A method for preparing an aluminum-rich zinc-based coating material that reduces the embrittlement of liquid metal during hot forming in this embodiment includes the following steps:

[0164] a. Preparation process of hot-plating solution:

[0165] According to the following elemental compositions and weight percentages required for the preparation of aluminum-rich zinc-based coating materials, the prepared raw materials are weighed: the content of Al is 0.2wt.%, the content of Mg is 1.0wt.%, and the balance is Zn and unavoidable Impurities include Zn blocks, Al blocks and Mg blocks, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com