Joint cutting protection device for road and bridge construction

A technology for bridge construction and protective devices, which is applied in the directions of roads, bridges, roads, etc., can solve the problems of generating high temperature, unable to cut the cooling effect of the cutter head, etc., to achieve good cooling and dust removal, easy stability and movement, and increased water spray Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

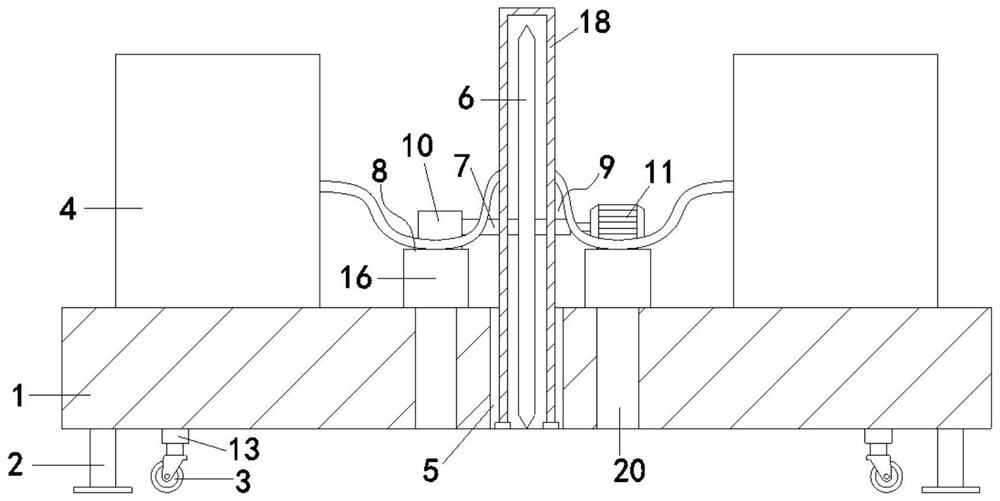

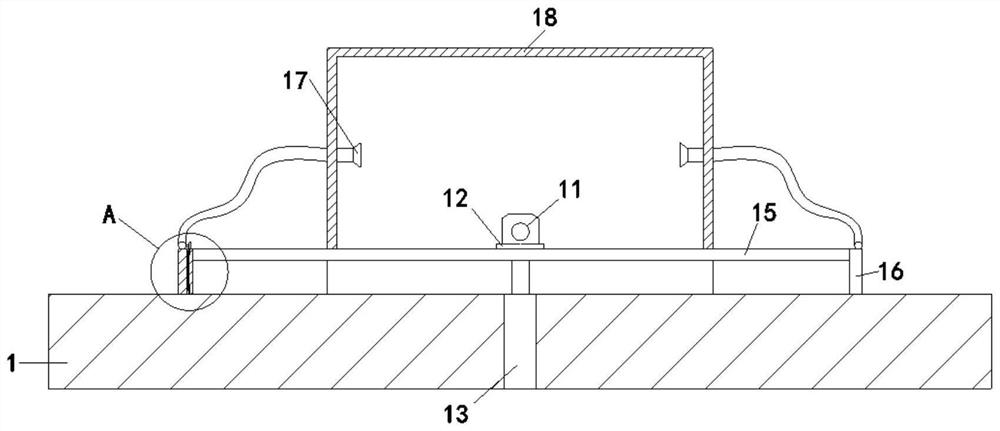

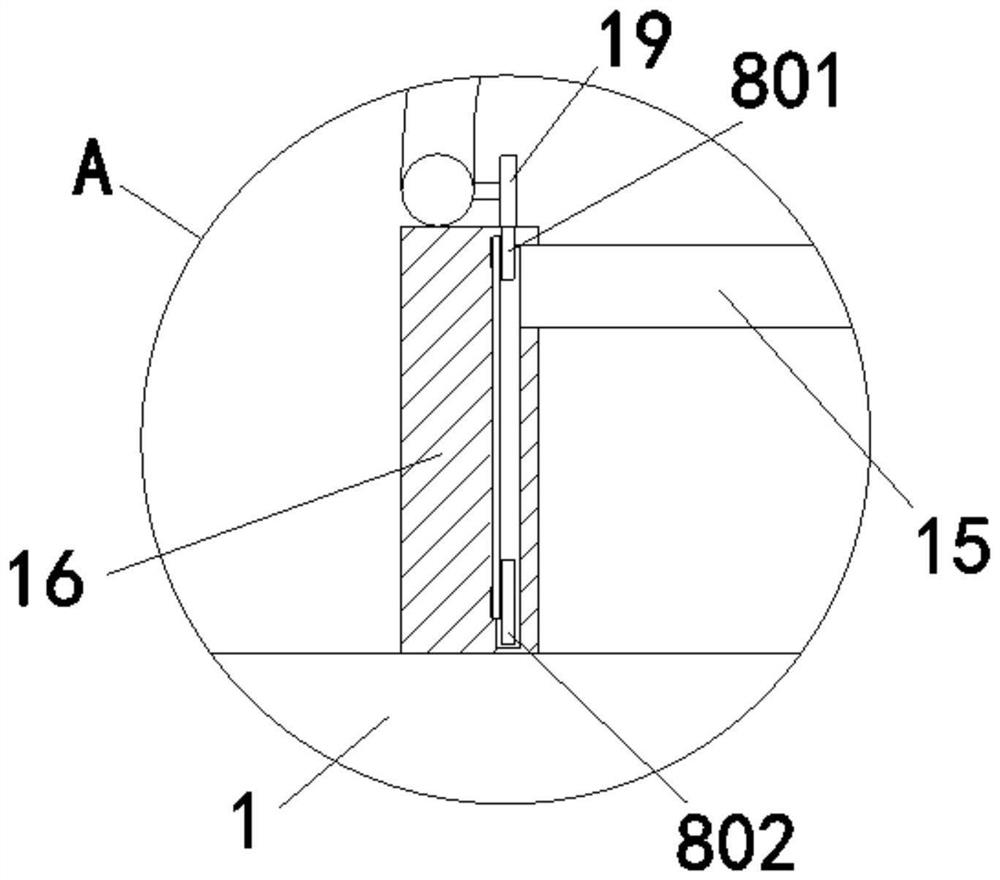

[0032] see Figure 1-6 , the present invention provides a technical solution: a kerf protection device for road and bridge construction, comprising a mobile platform 1, the four corners of the top of the mobile platform 1 are provided with supporting legs 2, and the inner side of the supporting legs 2 is provided with universal wheels 3. A first electric push rod 13 is connected to the top of the wheel 3, and the first electric push rod 13 is fixedly connected to the bottom of the mobile platform 1. A water tank 4 is provided on both sides of the top of the mobile platform 1, and a booster pump is arranged in the water tank 4. Can provide pressure for the nozzle 17, which belongs to the prior art and will not be described in detail. The middle of the mobile platform 1 is longitudinally provided with a through groove 5, and a cutting knife 6 is arranged in the through groove 5. The center of the cutting knife 6 is fixed with a rotating shaft 7, and the rotating shaft 7 The righ...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, the difference is that the bottom of the moving block 10 and the motor 11 is provided with an electric slider 12, and the tops of the first slide 14 and the second slide 15 are longitudinally provided with electric slide rails. The slide block 12 is slidingly connected with the electric slide rail, and the electric slide block 12 and the electric slide rail belong to the prior art, and the sliding of the electric slide block 12 can make the cutting knife 6 move back and forth, so as to facilitate linear cutting on the ground.

[0041] The bottom of lifting protective shell 18 is provided with small-sized mobile roller, and when cutting knife 6 moves back and forth and carries out longitudinal cutting, lifting protective shell 18 can move forward and backward stably thereupon, keeps good protective effect.

[0042] The bottom of the support leg 2 is provided with a fixed piece, which increases the contact area between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com