Hybrid power assisting system of lifting window

A power-assisted system and a technology of a power-assisted mechanism, which is applied in door/window accessories, power control mechanisms, buildings, etc., can solve the problems of increased window frame thickness, uneven force of movement distance, and affecting the appearance of window sash, so as to facilitate installation and maintenance , reduce the error of counterweight, and ensure the effect of counterweight efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

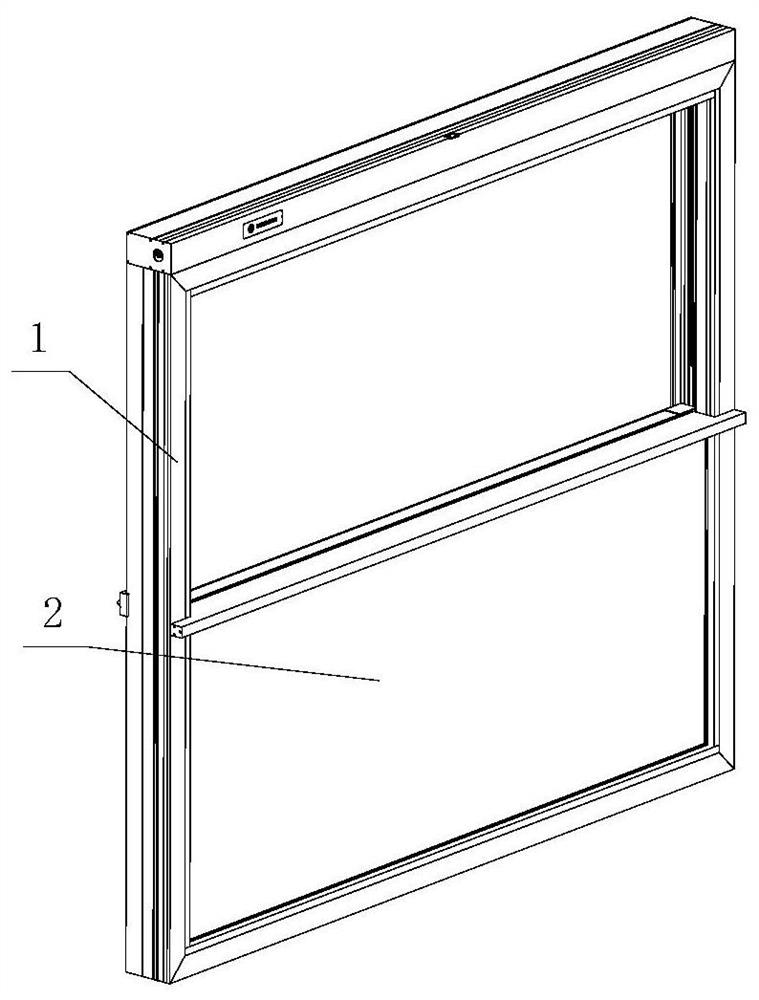

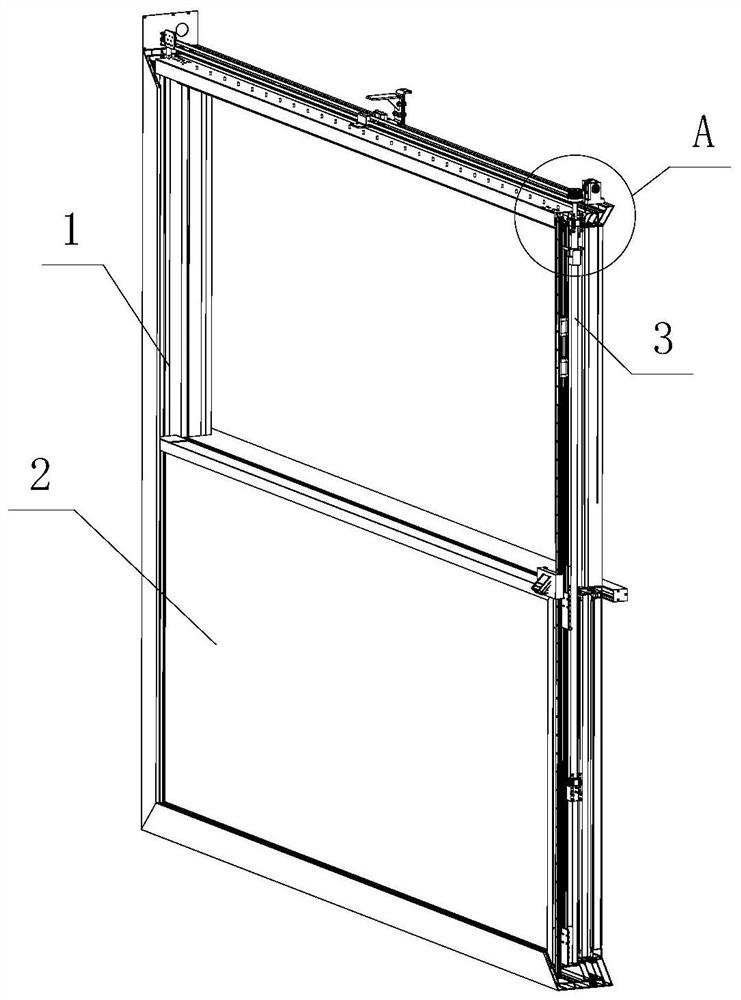

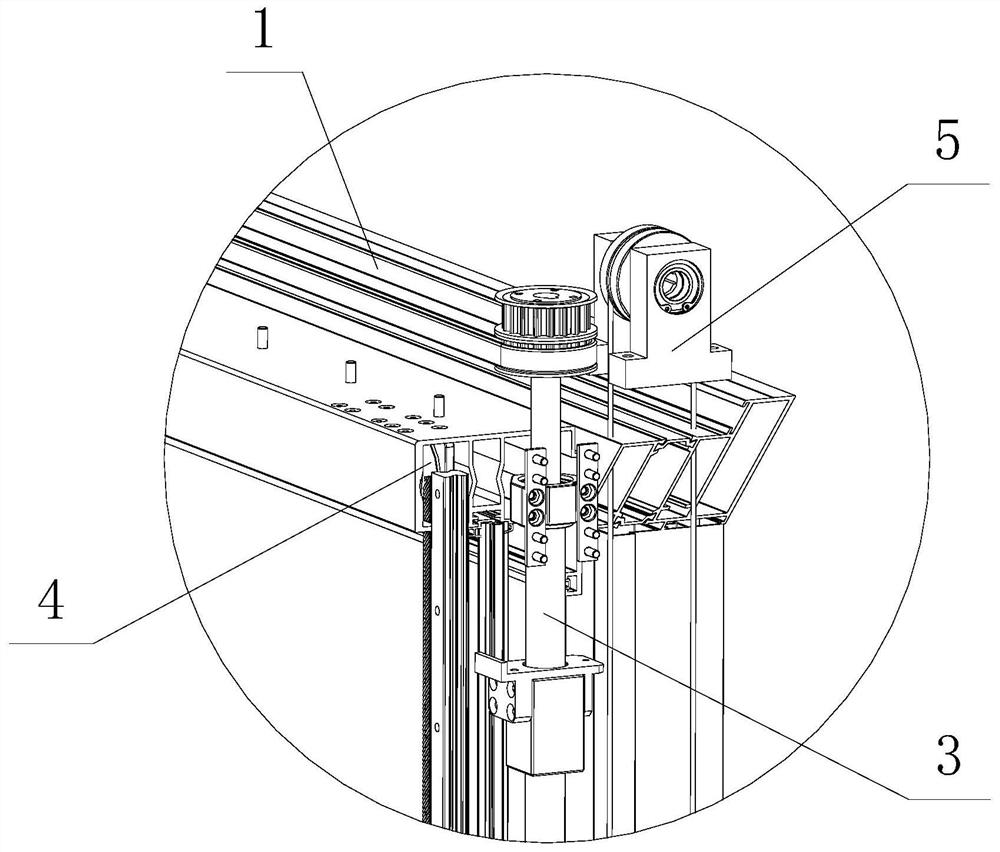

[0031] like Figure 1 to Figure 9As shown, the lift window hybrid booster system provided in this embodiment includes a window frame 1, a window sash 2, a drive mechanism 3, a gas spring booster mechanism 4 and a counterweight booster mechanism 5, and the window frame 1 is provided with an openable sash 2. The window frame 1 on both sides of the window sash 2 is provided with a drive mechanism 3 that drives the opening and closing of the window sash 2. The drive mechanism 3 includes a screw rod 31, a nut seat 32, a synchronous wheel 33 and a timing belt 34. The screw rod 31 There are two, two screw rods 31 are respectively vertically and rotatably installed in the window frame 1 on both sides of the sash 2, each screw rod 31 is threadedly connected with a liftable nut seat 32, and the nut seat 32 It is fixedly connected with the window sash 2, the nut seats 32 on the two screw rods 31 are of the same height, the upper parts of the two screw rods 31 are equipped with synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com