Anthracene crystal and preparation method and application thereof

A technology of crystal and furnace body, applied in the field of anthracene crystal and its preparation, can solve problems such as unreported problems in the field of X-ray imaging, and achieve the effects of good environmental stability, fast response speed and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

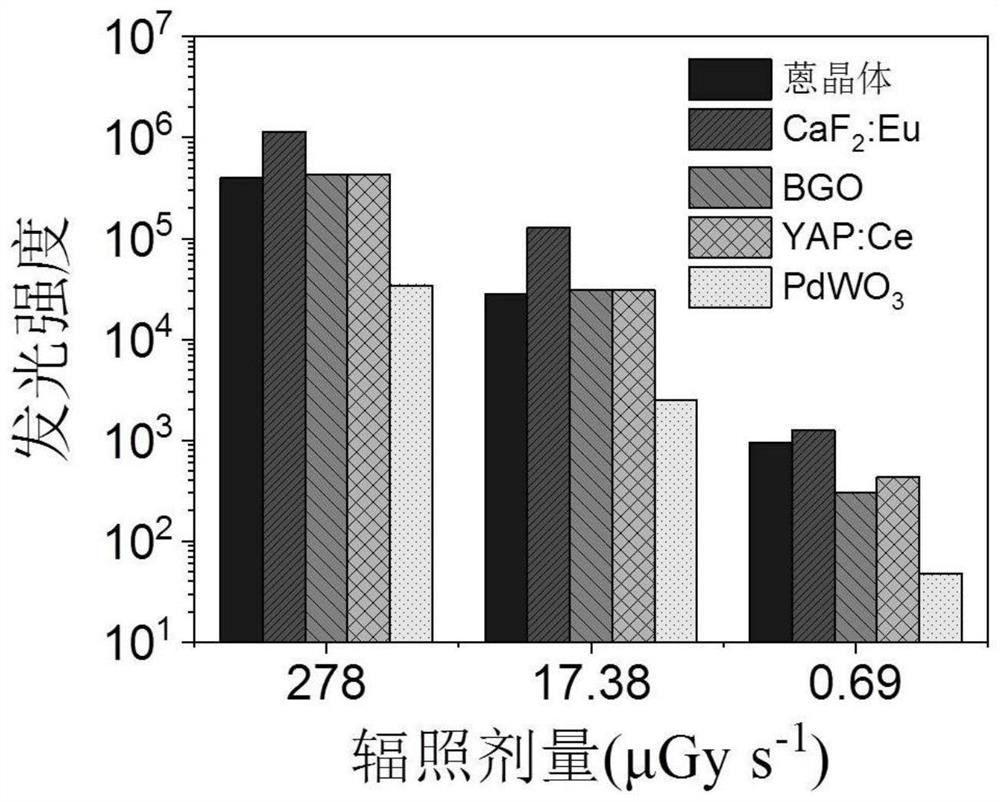

Problems solved by technology

Method used

Image

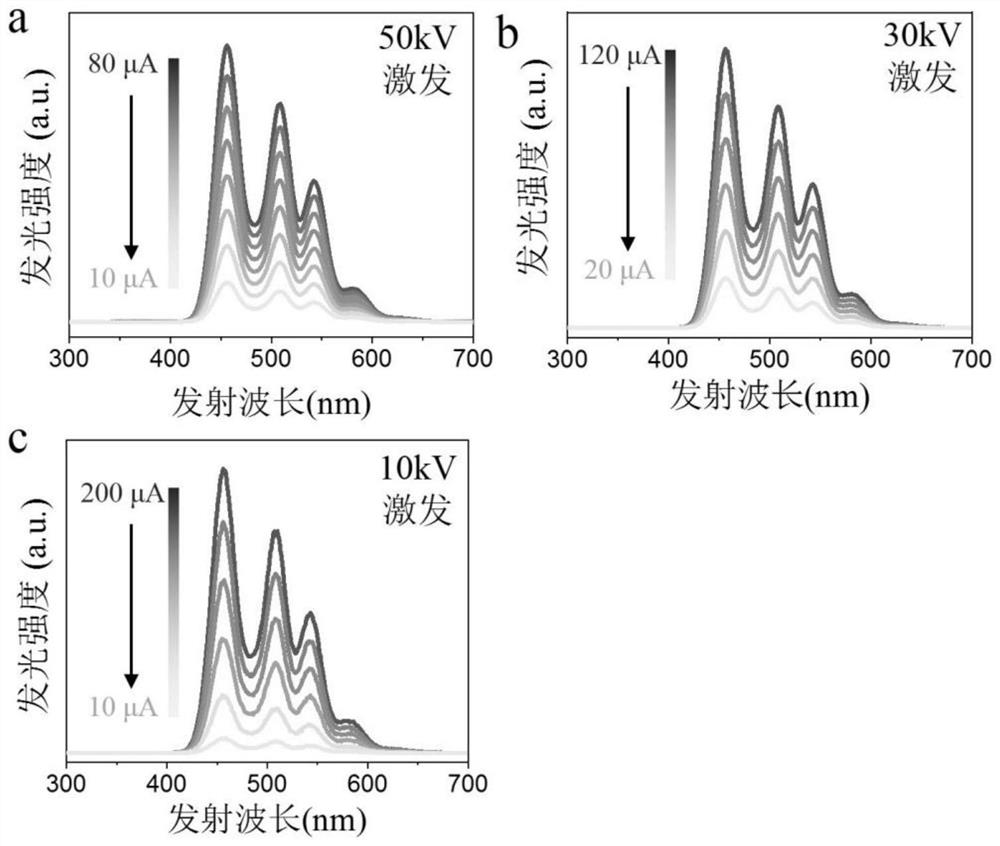

Examples

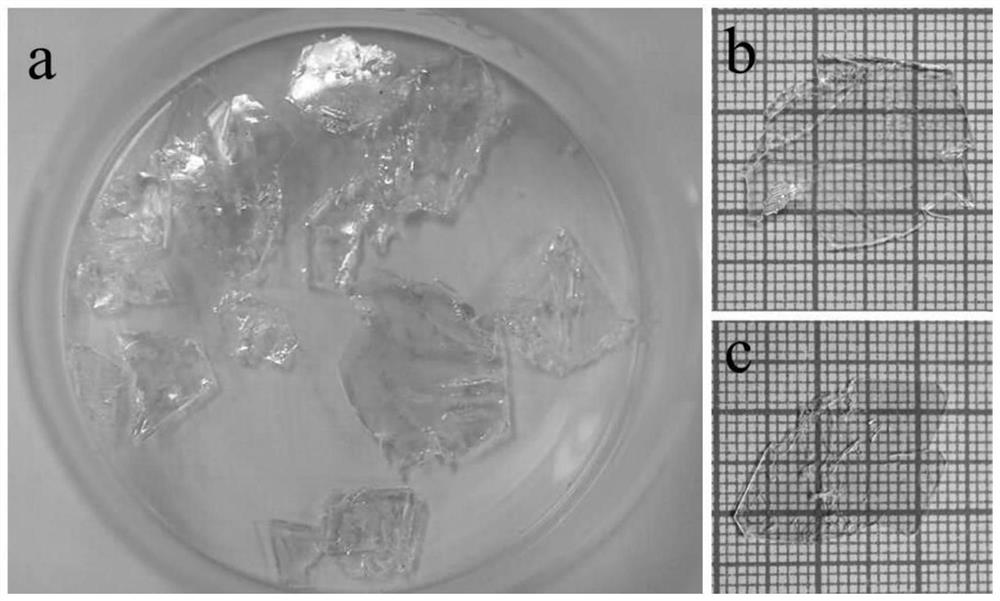

Embodiment 1

[0062] A method for preparing anthracene crystals. The white purified anthracene powder is deposited by a vapor phase deposition method to obtain anthracene crystals. The vapor phase deposition method is as follows: prepare a tube furnace as a furnace body, and set one end of the furnace body as a second In the second high temperature zone, the other end of the furnace body is set as the second room temperature zone, and the temperature of the second room temperature zone is room temperature 20-25°C. Prepare a 2cm x 2cm x 0.5cm quartz sheet as the substrate, place the substrate in the second room temperature zone, and place the purified anthracene powder in the second high temperature zone of the furnace under a protective atmosphere and a vacuum of 30 Pa. In the second high temperature zone, the gradient heating method is used for heating. After the heating is completed, it is naturally lowered to room temperature, and anthracene crystals are obtained on the substrate. 150°C,...

Embodiment 2

[0066] A method for preparing anthracene crystals. The white purified anthracene powder is deposited by a vapor phase deposition method to obtain anthracene crystals. The vapor phase deposition method is as follows: prepare a tube furnace as a furnace body, and set one end of the furnace body as a second In the second high temperature zone, the other end of the furnace body is set as the second room temperature zone, and the temperature of the second room temperature zone is room temperature 20-25°C. Prepare a 2cm × 2cm × 0.5cm quartz plate as the substrate, place the substrate in the second room temperature zone, and place the purified anthracene powder in the second high temperature zone of the furnace under a protective atmosphere and a vacuum of 25 Pa. In the second high-temperature zone, a gradient heating method is used for heating. After the heating is completed, it is naturally lowered to room temperature, and anthracene crystals are obtained on the substrate. 135°C, t...

Embodiment 3

[0070] A method for preparing anthracene crystals. The white purified anthracene powder is deposited by a vapor phase deposition method to obtain anthracene crystals. The vapor phase deposition method is as follows: prepare a tube furnace as a furnace body, and set one end of the furnace body as a second In the second high temperature zone, the other end of the furnace body is set as the second room temperature zone, and the temperature of the second room temperature zone is room temperature 20-25°C. Prepare a 2cm x 2cm x 0.5cm quartz sheet as the substrate, place the substrate in the second room temperature zone, and place the purified anthracene powder in the second high temperature zone of the furnace under a protective atmosphere and a vacuum of 30 Pa. In the second high-temperature zone, the gradient heating method is used for heating. After the heating is completed, the temperature is naturally lowered to room temperature, and anthracene crystals are obtained on the subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com