Patents

Literature

73 results about "Computed radiography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

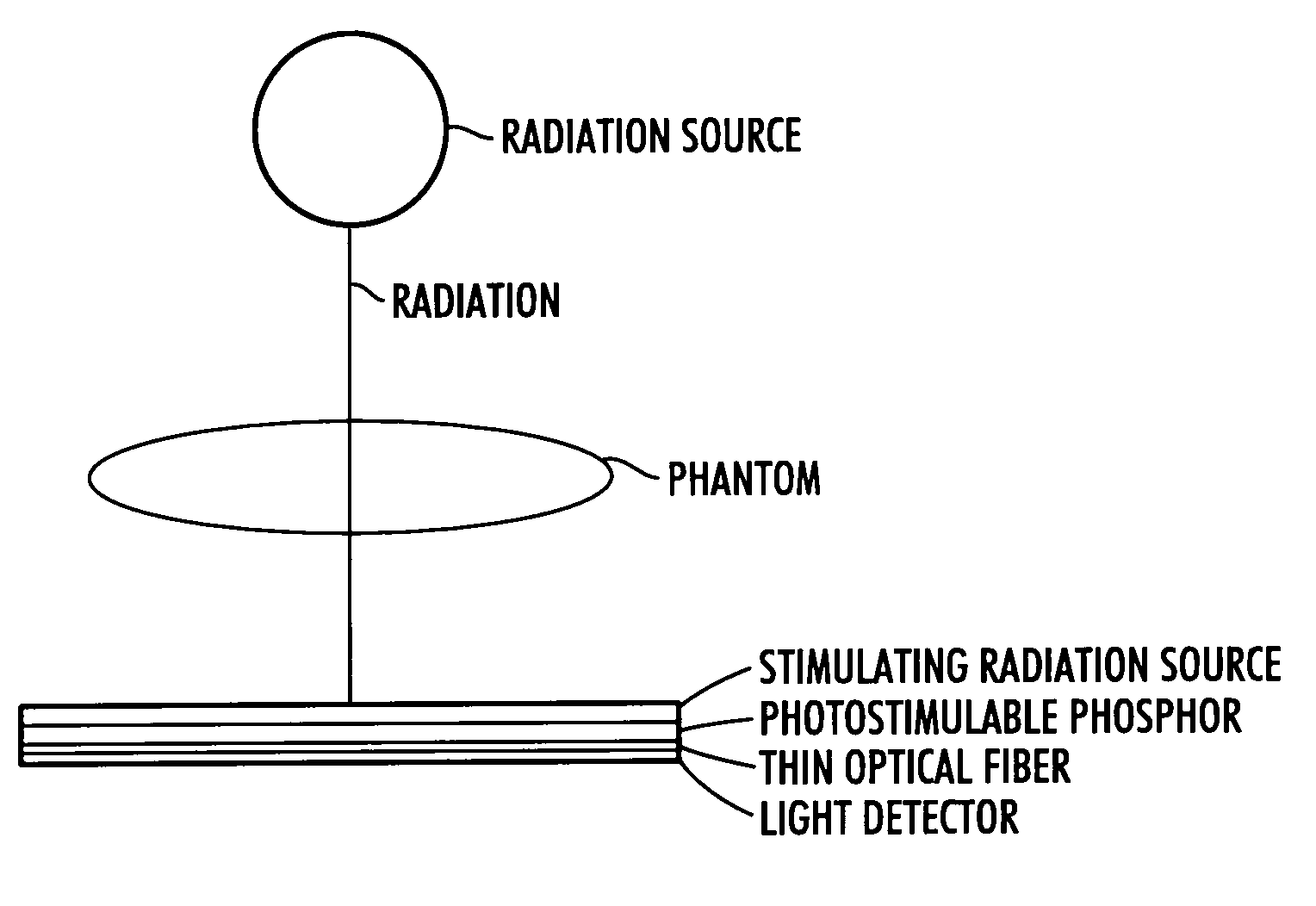

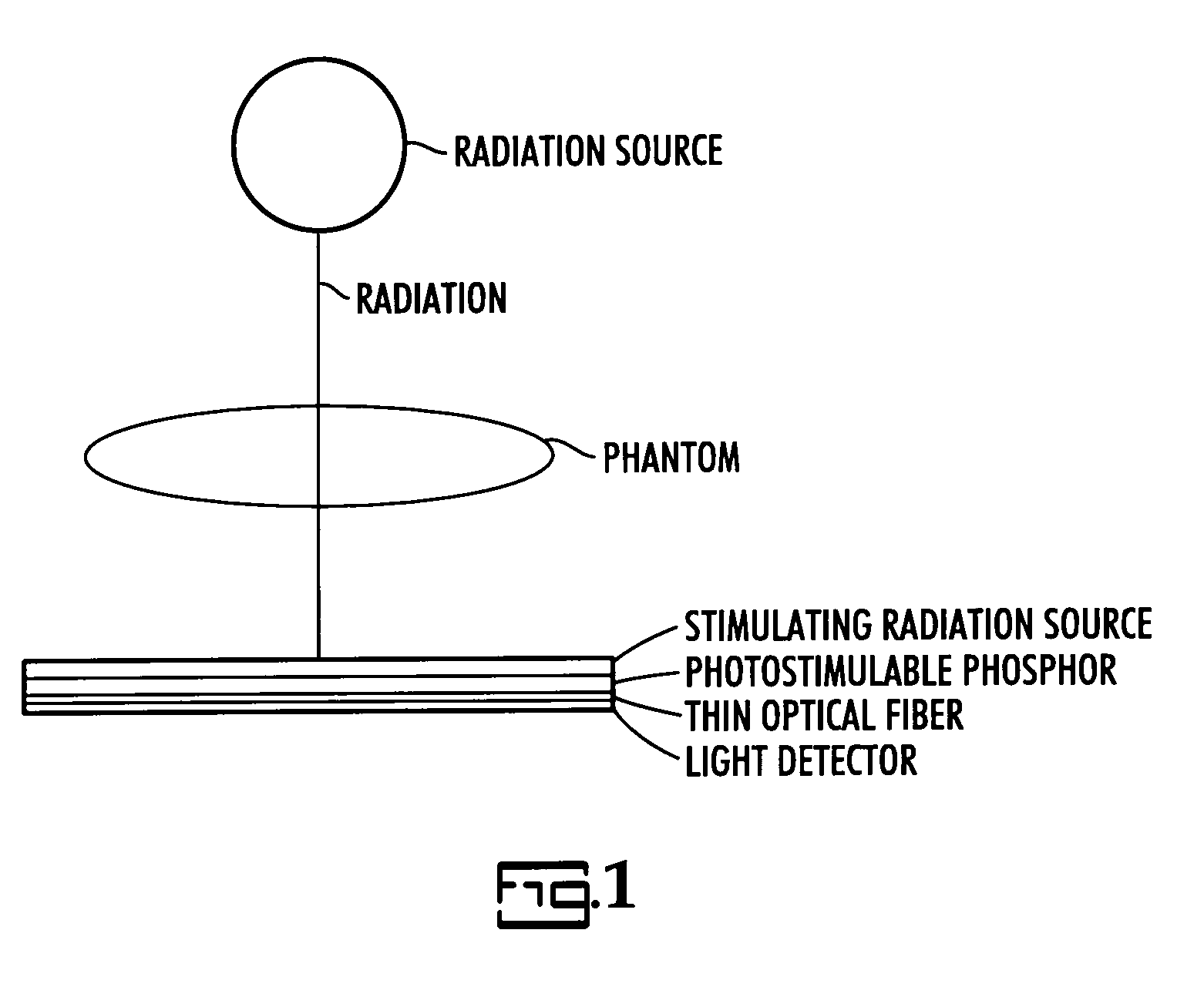

Computed radiography uses very similar equipment to conventional radiography except that in place of a film to create the image, an imaging plate made of photostimulable phosphor is used. The imaging plate is housed in a special cassette and placed under the body part or object to be examined and the x-ray exposure is made. Hence, instead of taking an exposed film into a darkroom for developing in chemical tanks or an automatic film processor, the imaging plate is run through a special laser scanner, or CR reader, that reads and digitizes the image. The digital image can then be viewed and enhanced using software that has functions very similar to other conventional digital image-processing software, such as contrast, brightness, filtration and zoom.

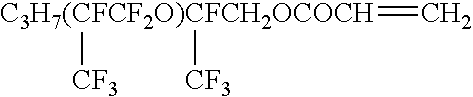

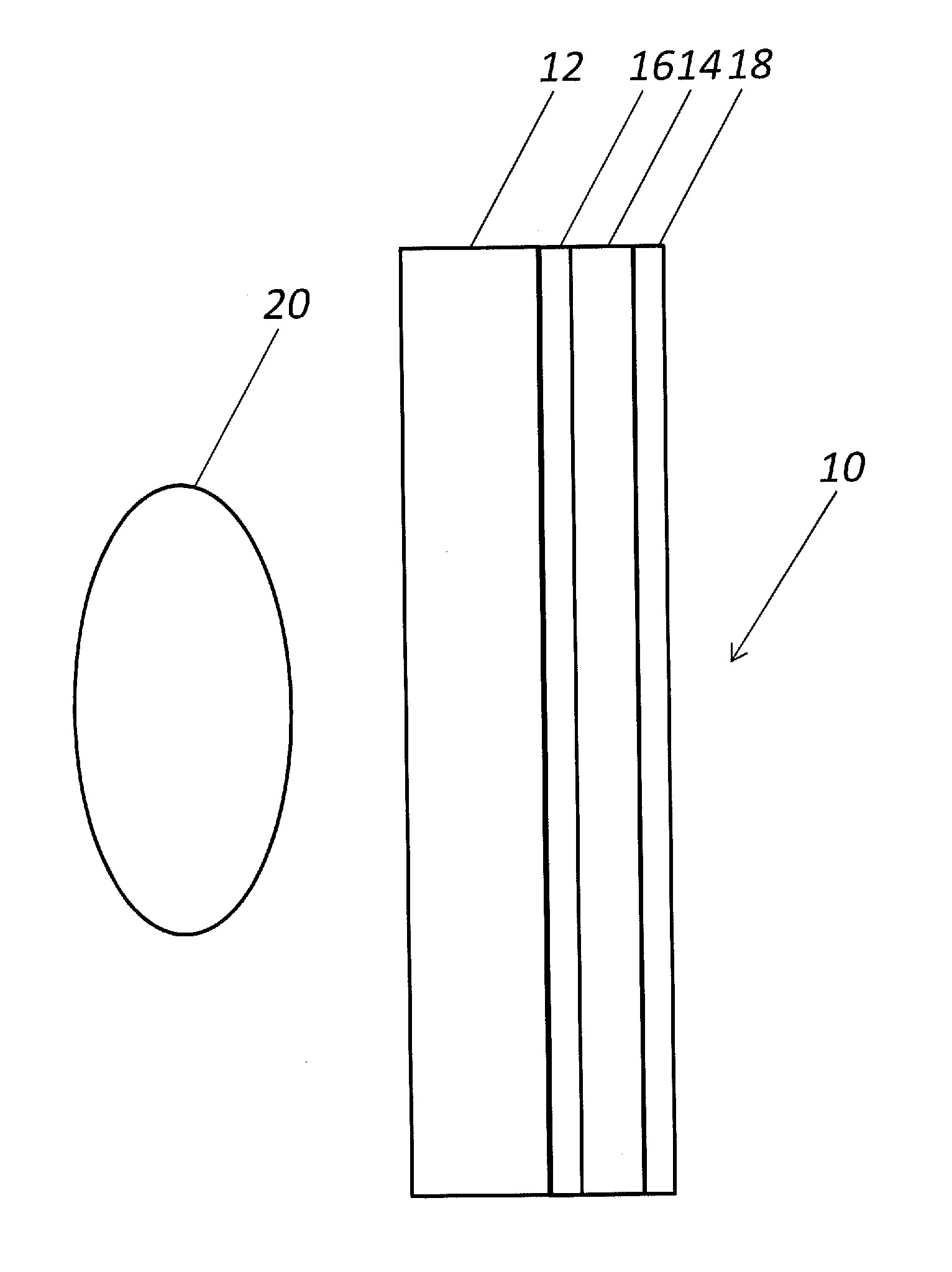

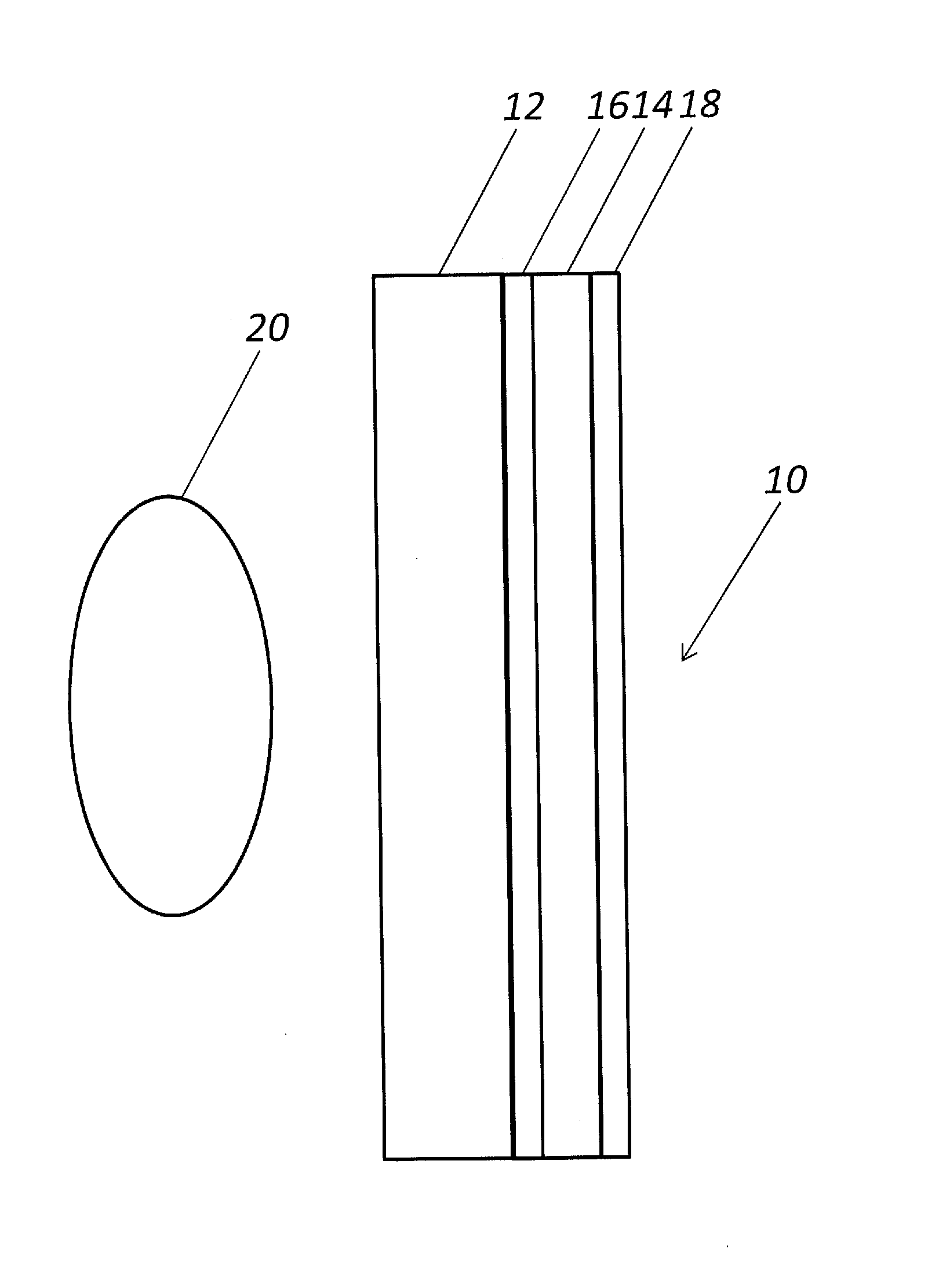

Manufacturing method of phosphor or scintillator sheets and panels suitable for use in a scanning apparatus

InactiveUS20040219289A1Easy to implementInhibition formationX-ray/infra-red processesVacuum evaporation coatingImaging qualityGas phase

In a method for coating a phosphor or a scintillator layer onto a flexible substrate, within a sealed zone maintained under vacuum conditions, by the step of vapor deposition, said phosphor or scintillator layer is, continuously or discontinuously, deposited onto said substrate, and said substrate is deformed at least before, during or after said step of vapor deposition, in order to provide the manufacturer, by a process of exceptionnally high yield, with large deposited phosphor or a scintillator sheets having constant speed and image quality properties, further offering availablity of all formats as desired for screens, plates or panels ready-for-use in a scanning apparatus in computed radiography, screen / film radiography and direct radiography.

Owner:AGFA NV

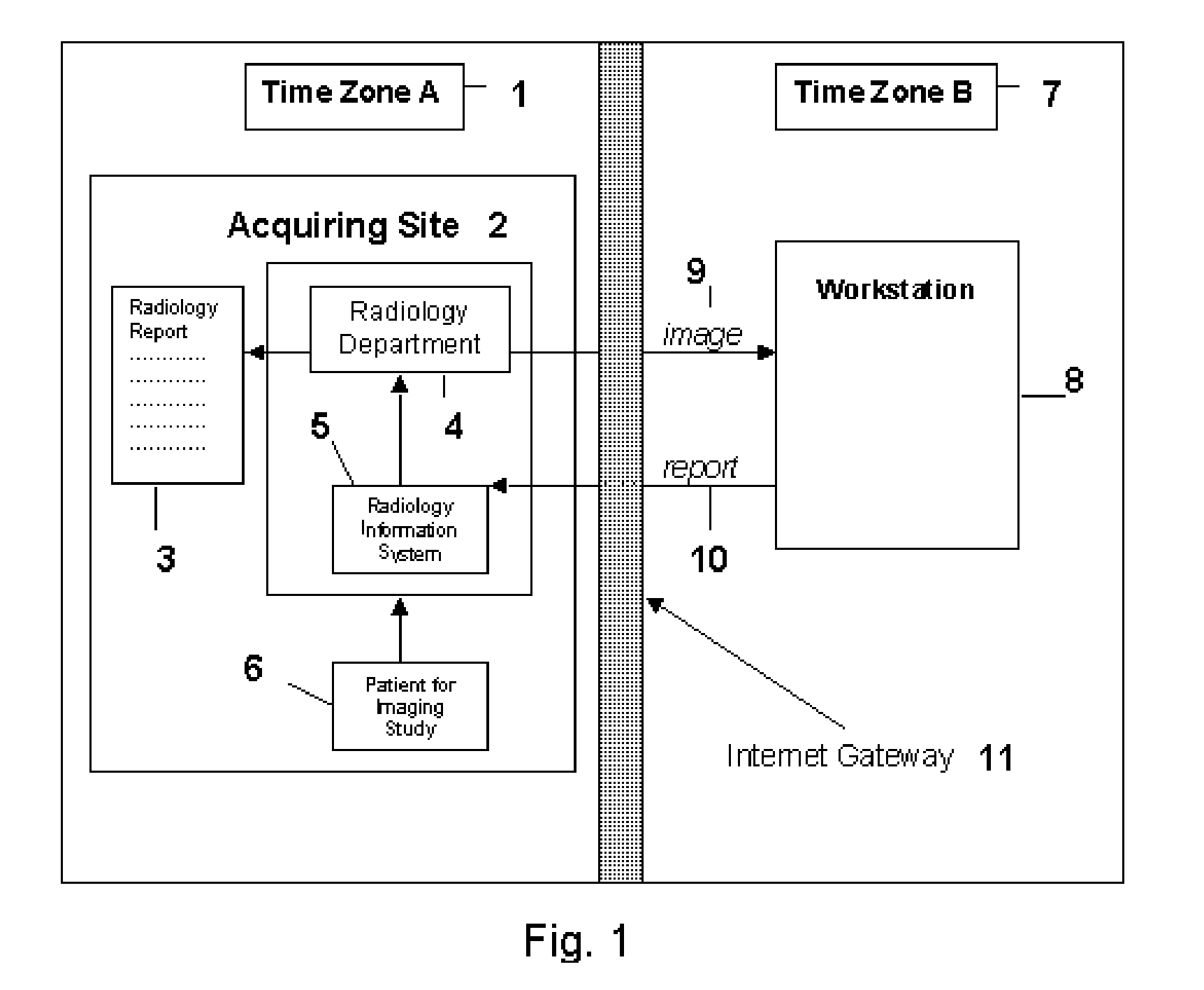

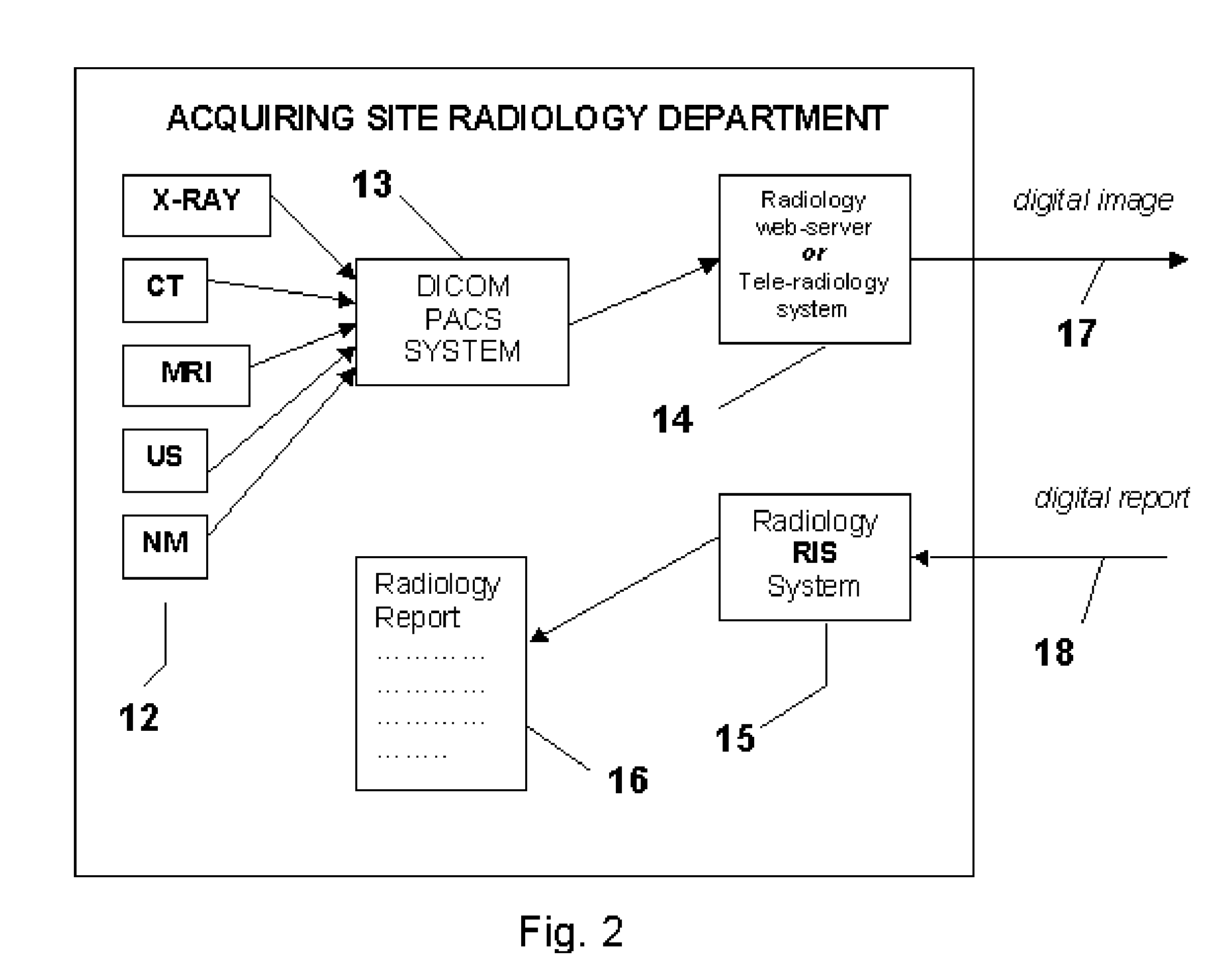

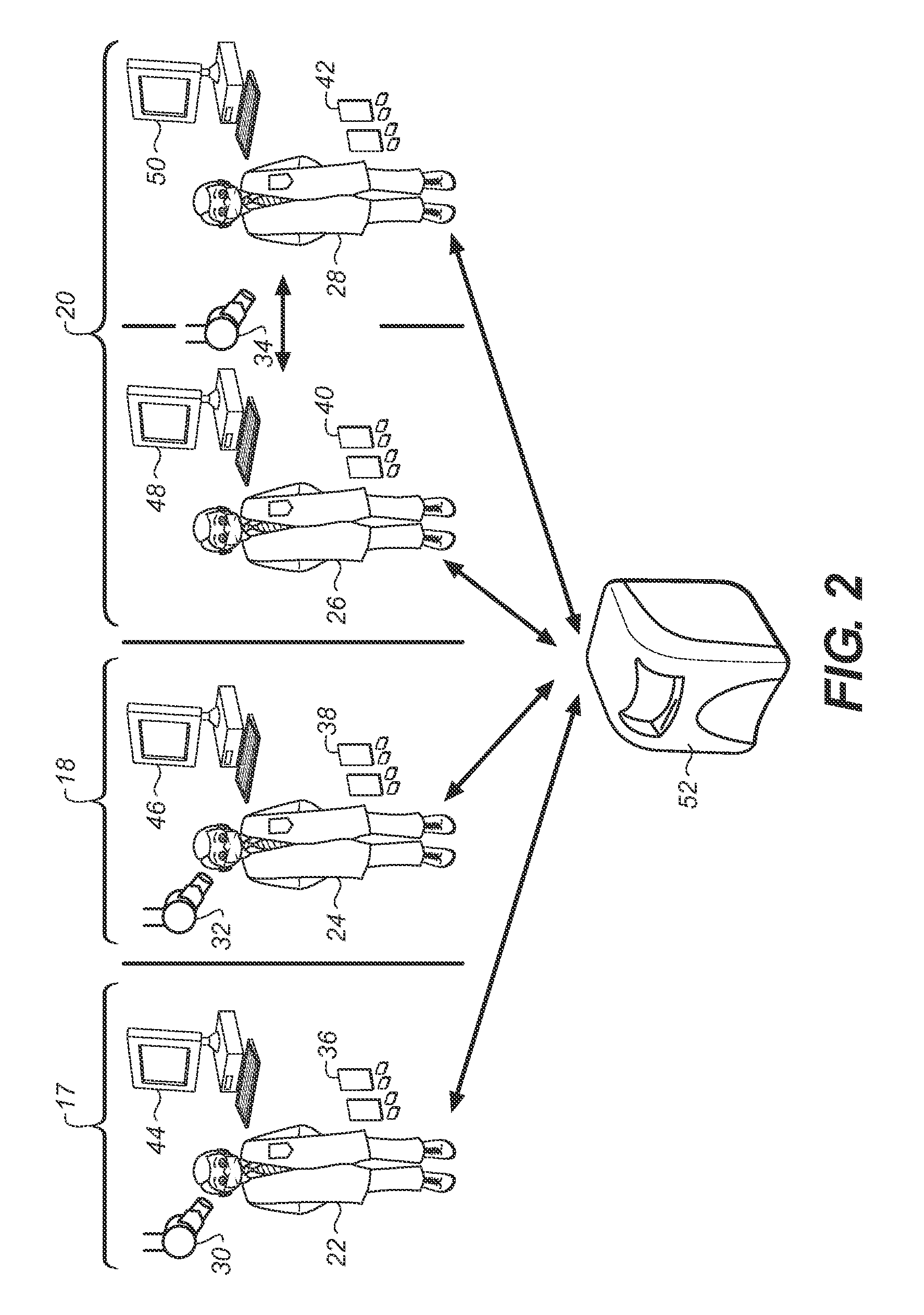

Apparatus and method for radiological image interpretation using different time zones

InactiveUS20050002483A1High level of performanceImprove performanceRadiation diagnosis data transmissionMaterial analysis using wave/particle radiationSonificationImaging interpretation

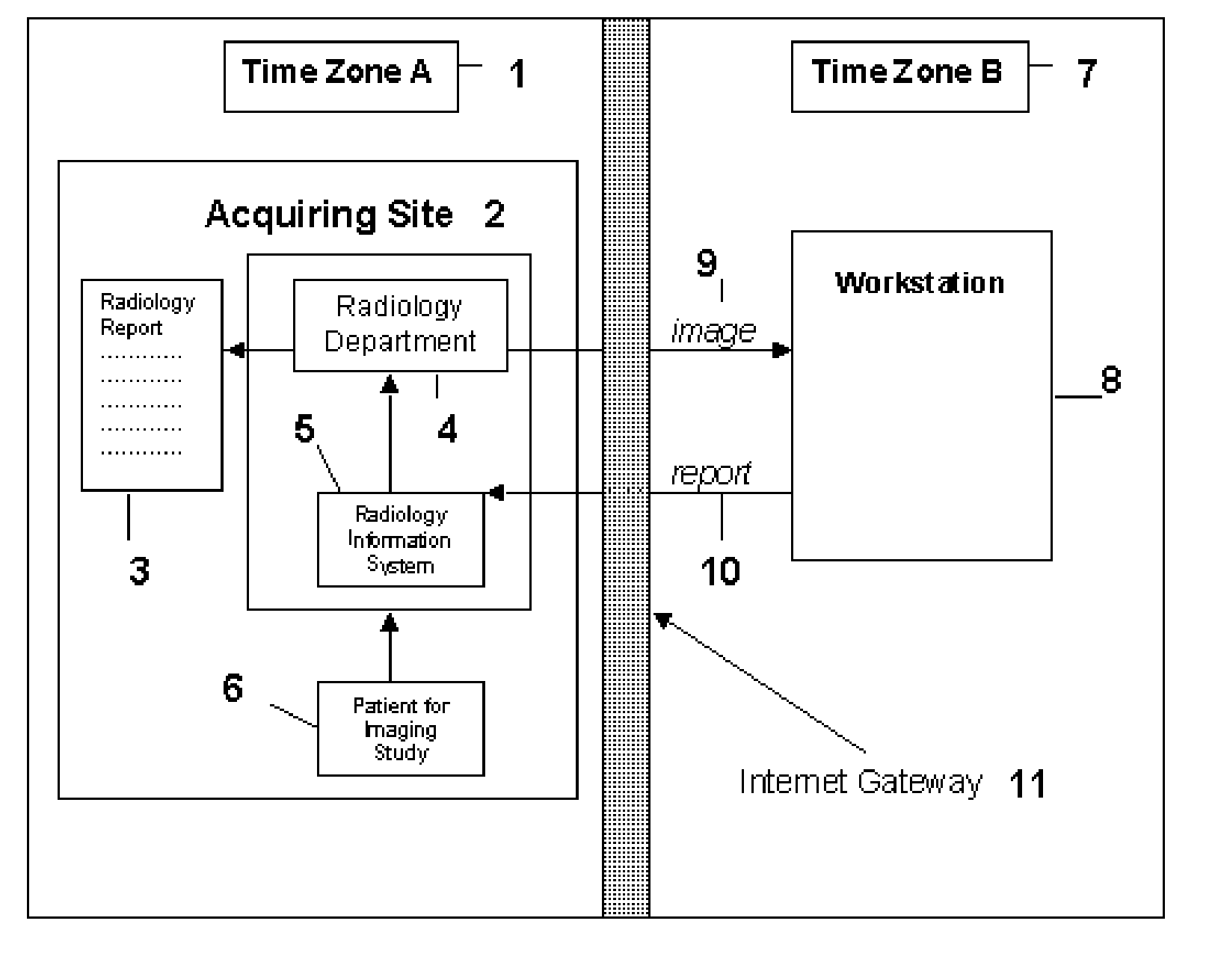

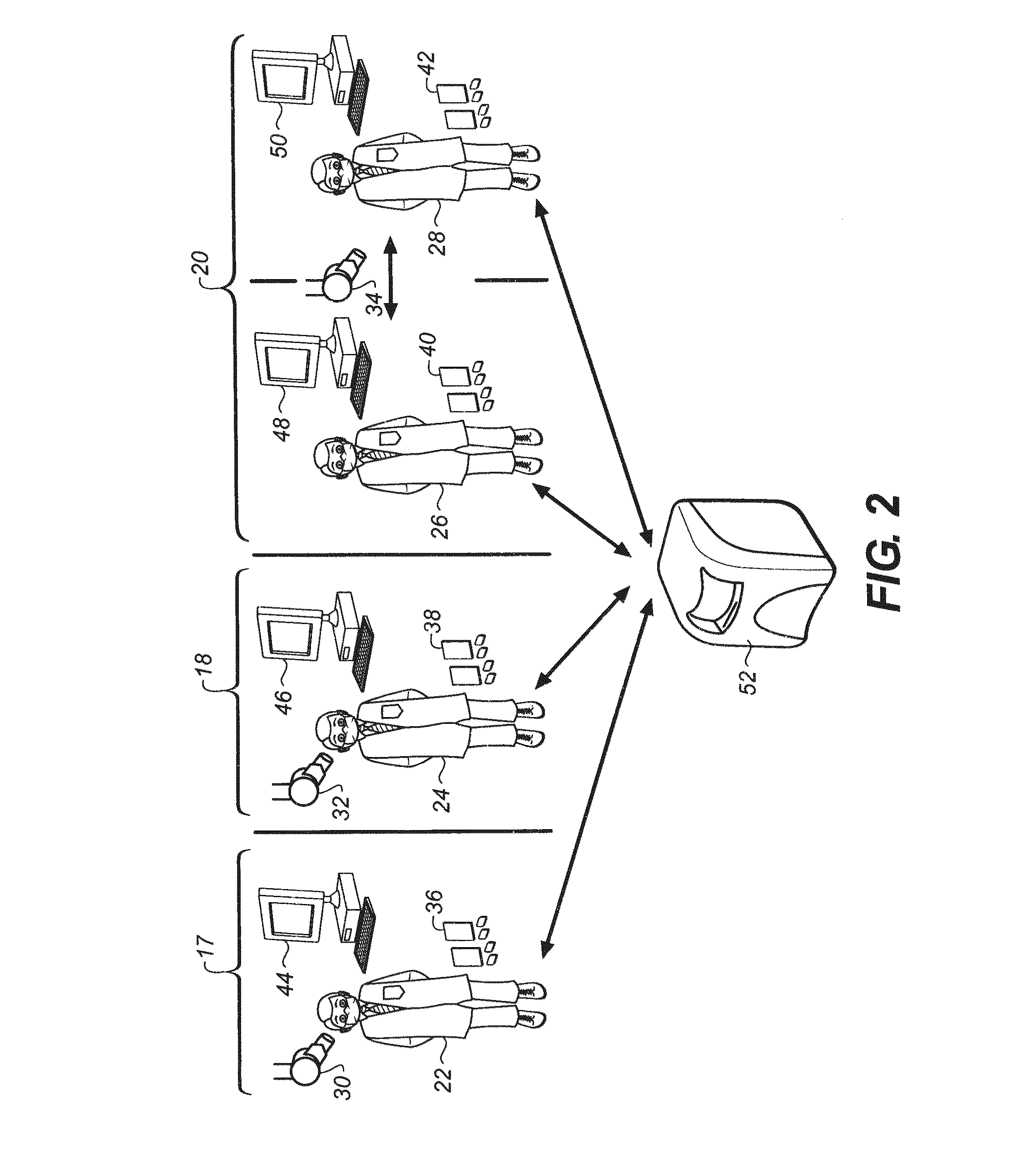

A method and apparatus for high quality, timely medical interpretations of radiological images acquired in one time zone and interpreted and a different time zone. The use of a different time zone allows images acquired at night to be interpreted during regular working daylight hours. The images can include images created by conventional x-ray technology, computed radiography, magnetic resonance imaging (MRI), computed tomography (CT), ultrasound imaging, and nuclear medicine equipment. The invention includes the transmission of these images, the interpretation of these images, and the transmission of the interpretations back to the originating facility. The interpretation is performed on high-resolution workstations and the written report is created either by voice recognition software or dictation and typed transcription.

Owner:WILCOX JOHN RICHARDSON JR

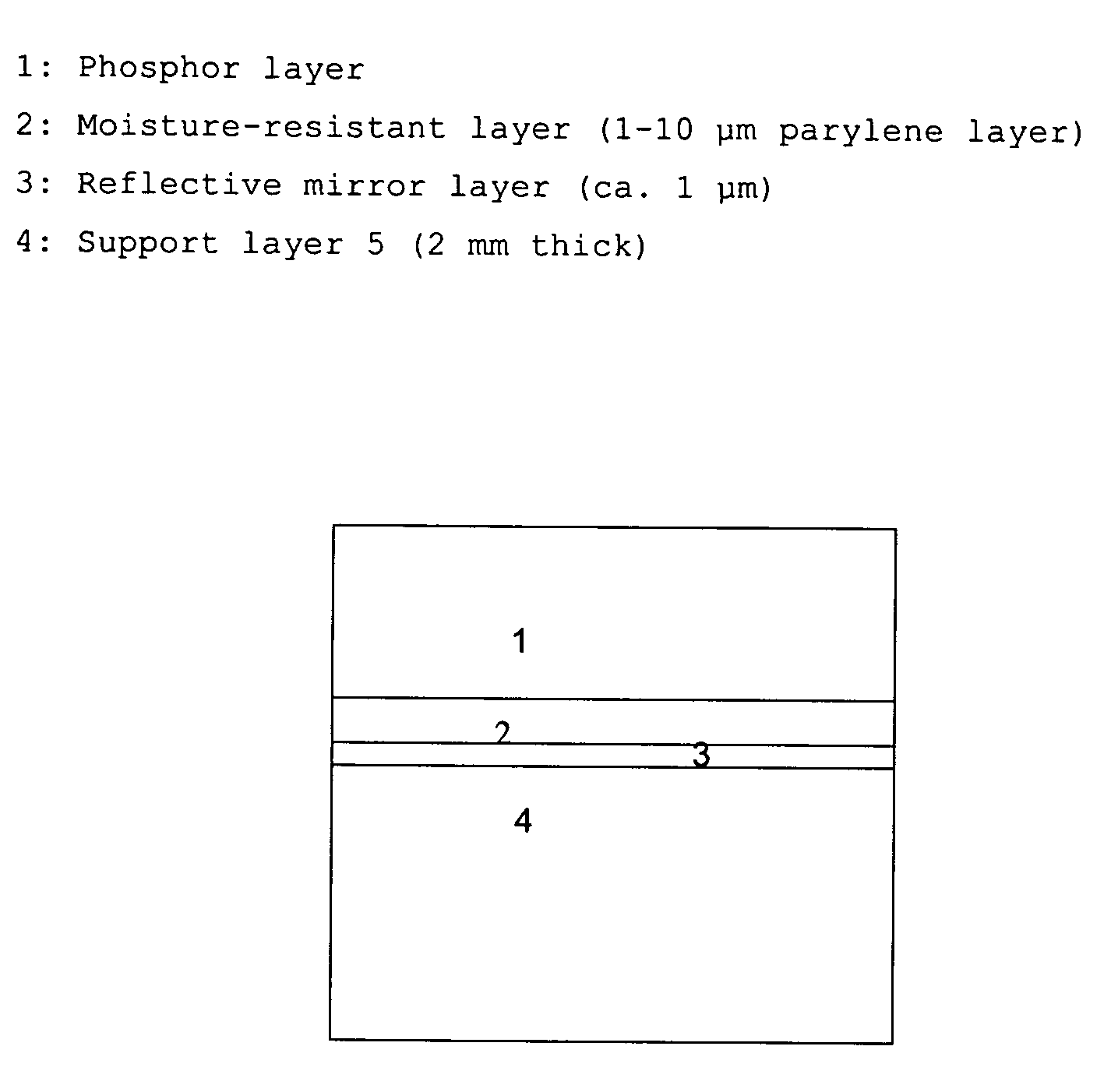

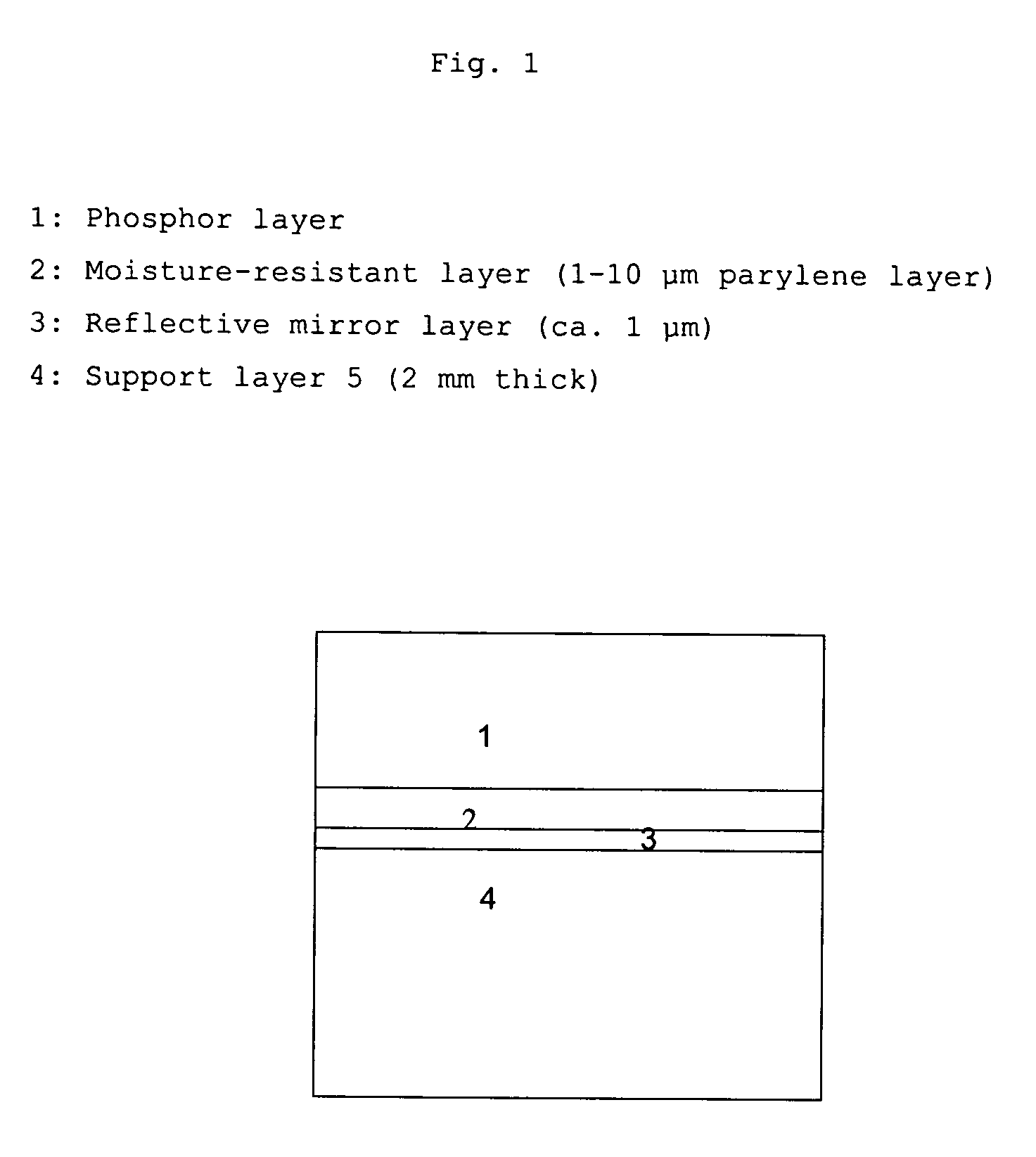

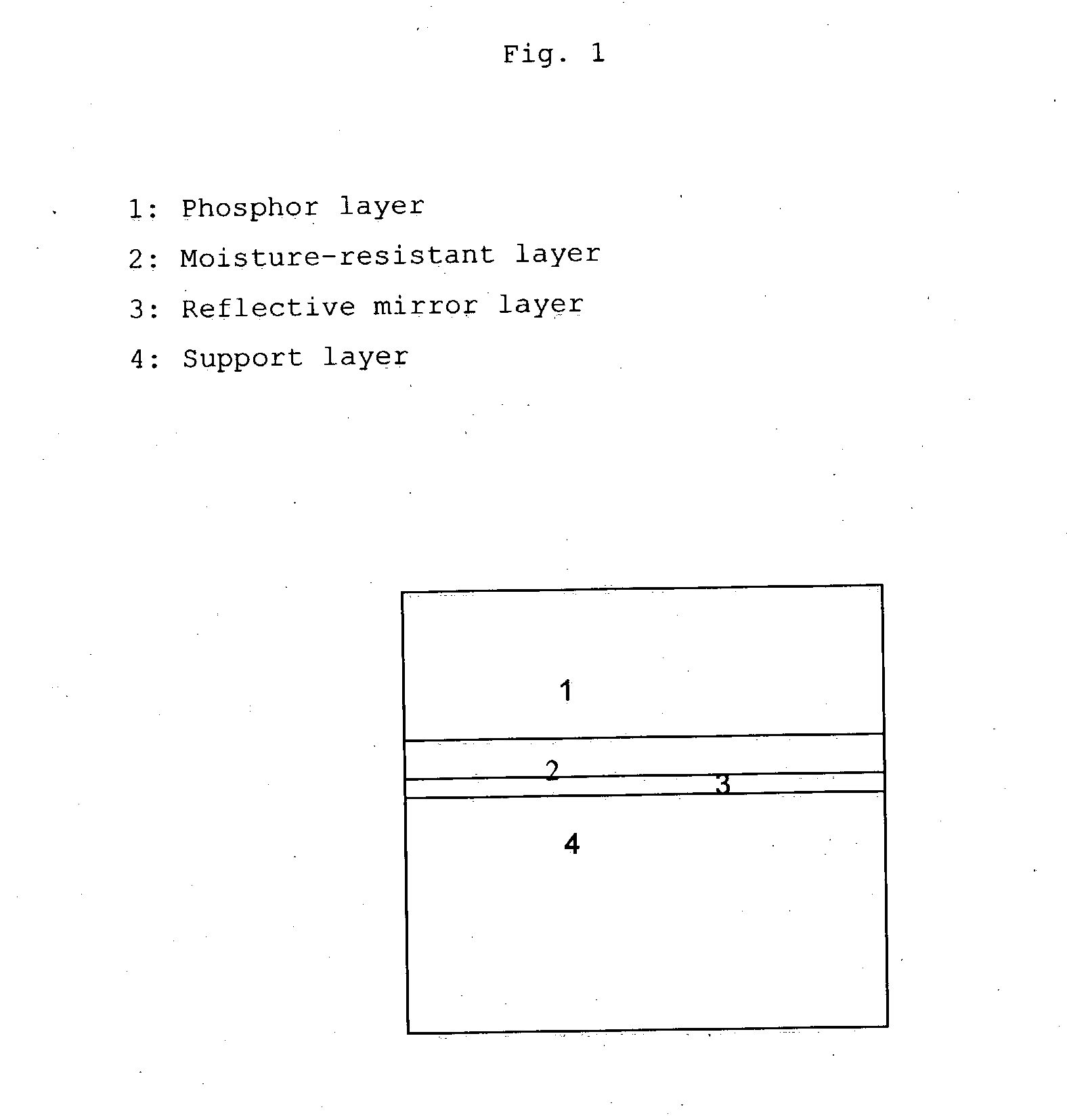

Binderless storage phosphor screen

InactiveUS20040051438A1Create efficientlyEfficient detectionX-ray/infra-red processesCathode ray tubes/electron beam tubesSurface roughnessComputer science

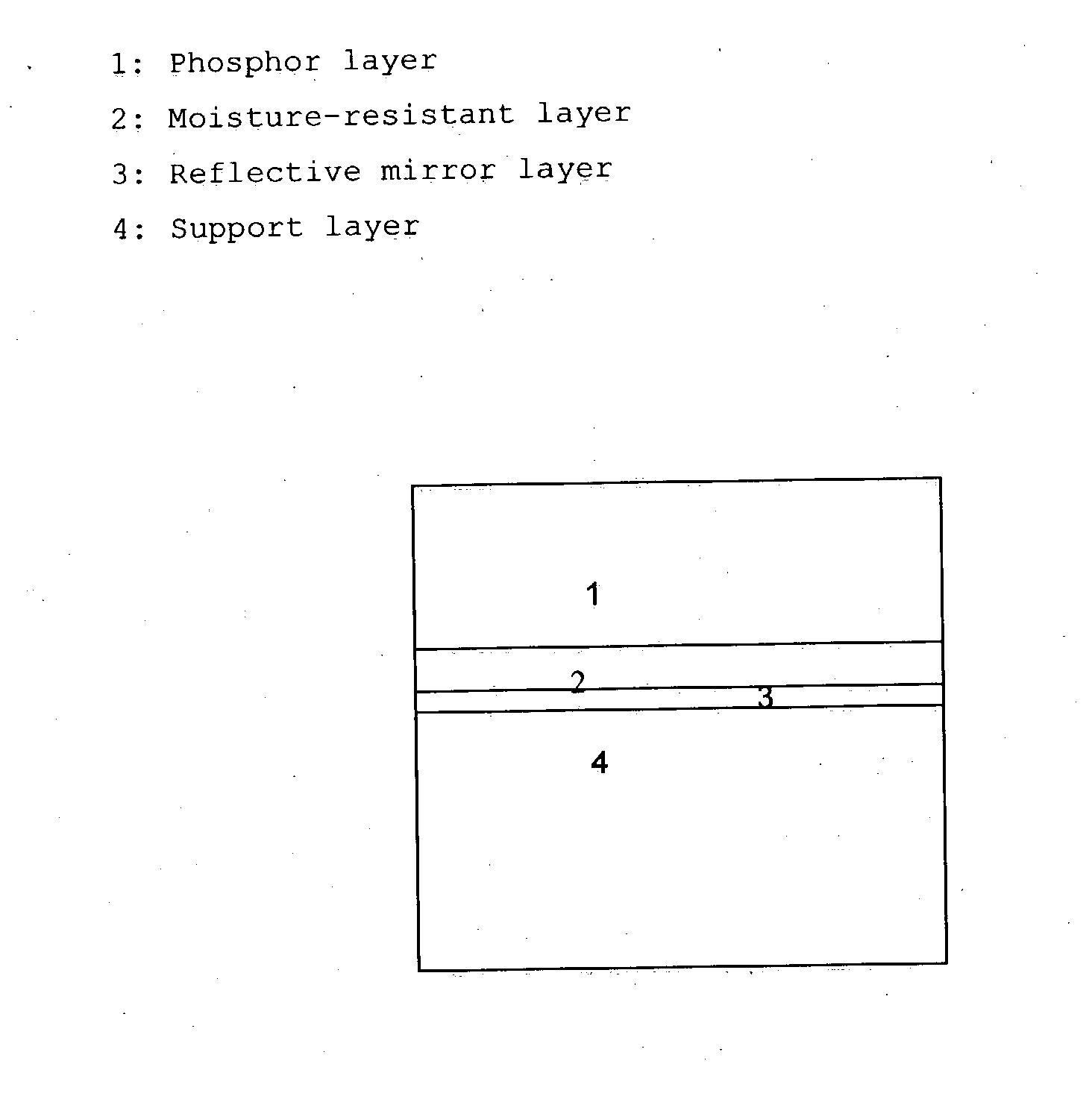

An image storage screen or panel, suitable for use in applications related with computed radiography, has been disclosed, wherein said screen or panel comprises a binderless needle-shaped stimulable (storage) phosphor and a substrate, characterized in that said substrate has a surface roughness of less than 2 mum and a reflectivity of more than 80%.

Owner:HAMAMATSU PHOTONICS KK +1

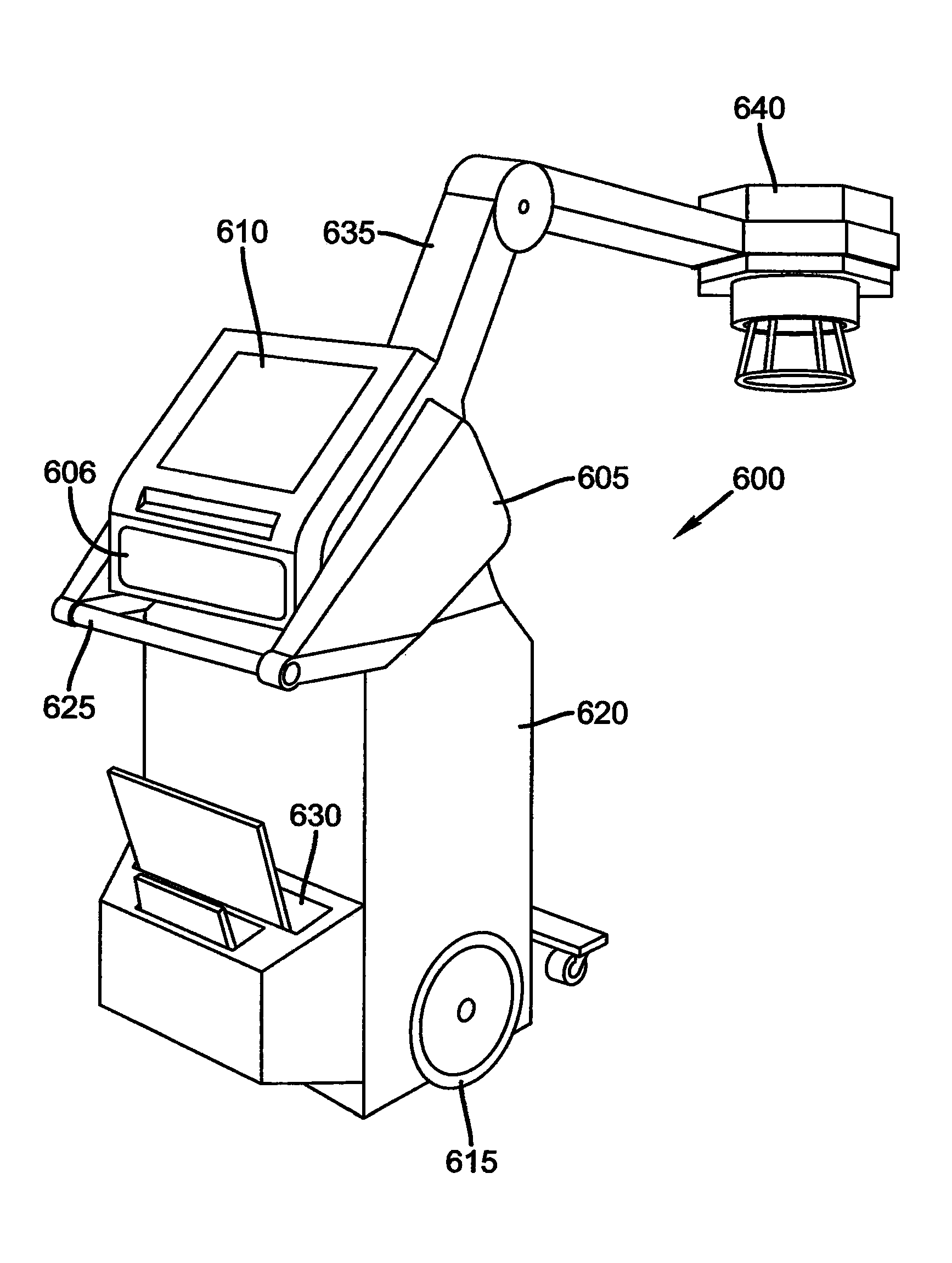

Mobile computed radiography and digital radiography

Owner:CARESTREAM HEALTH INC

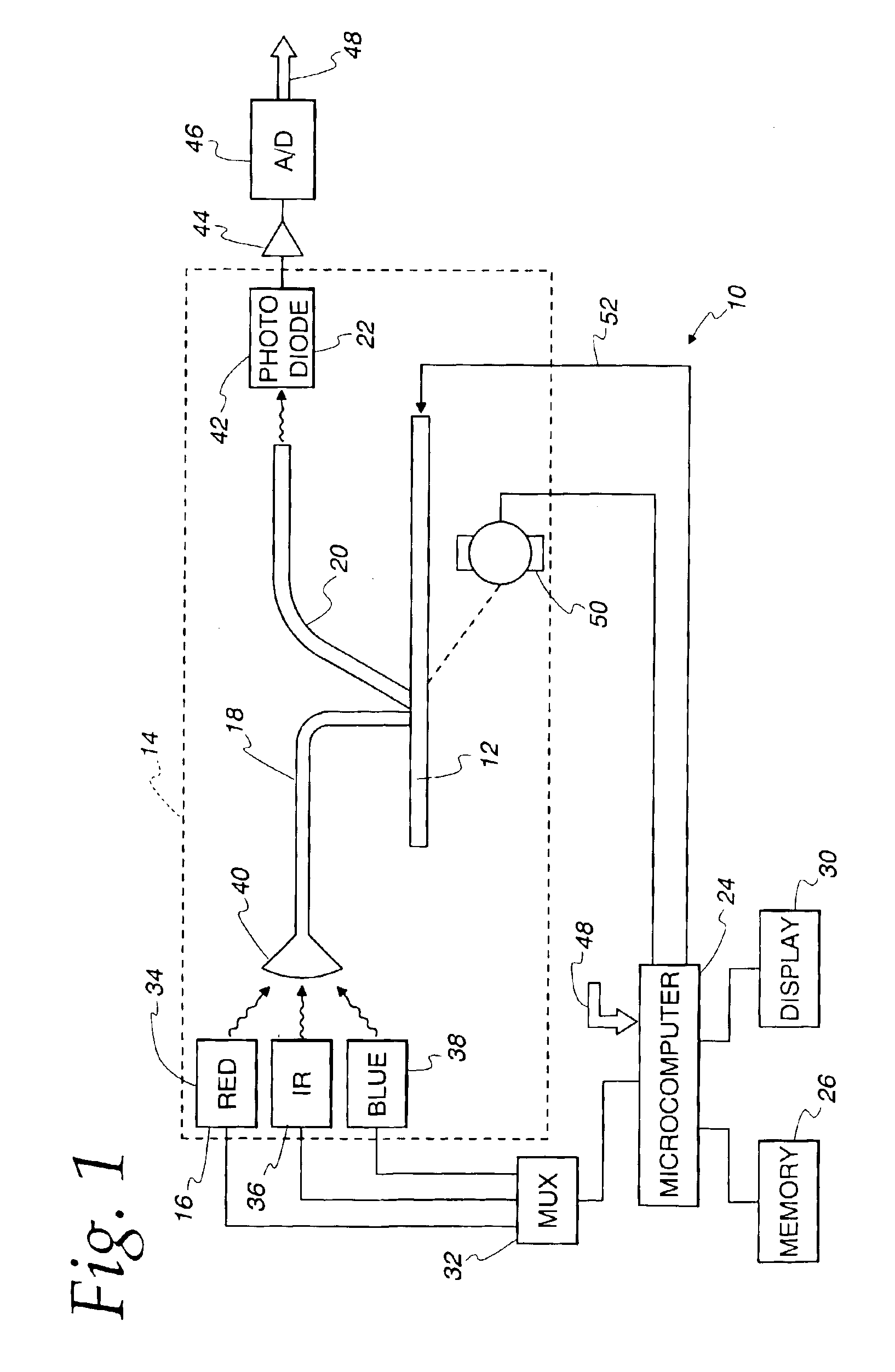

Computed radiography system for mammography

InactiveUS20090078874A1Maximize x-ray absorptionIncrease plate thicknessMaterial analysis by optical meansPatient positioning for diagnosticsLight reflexProximate

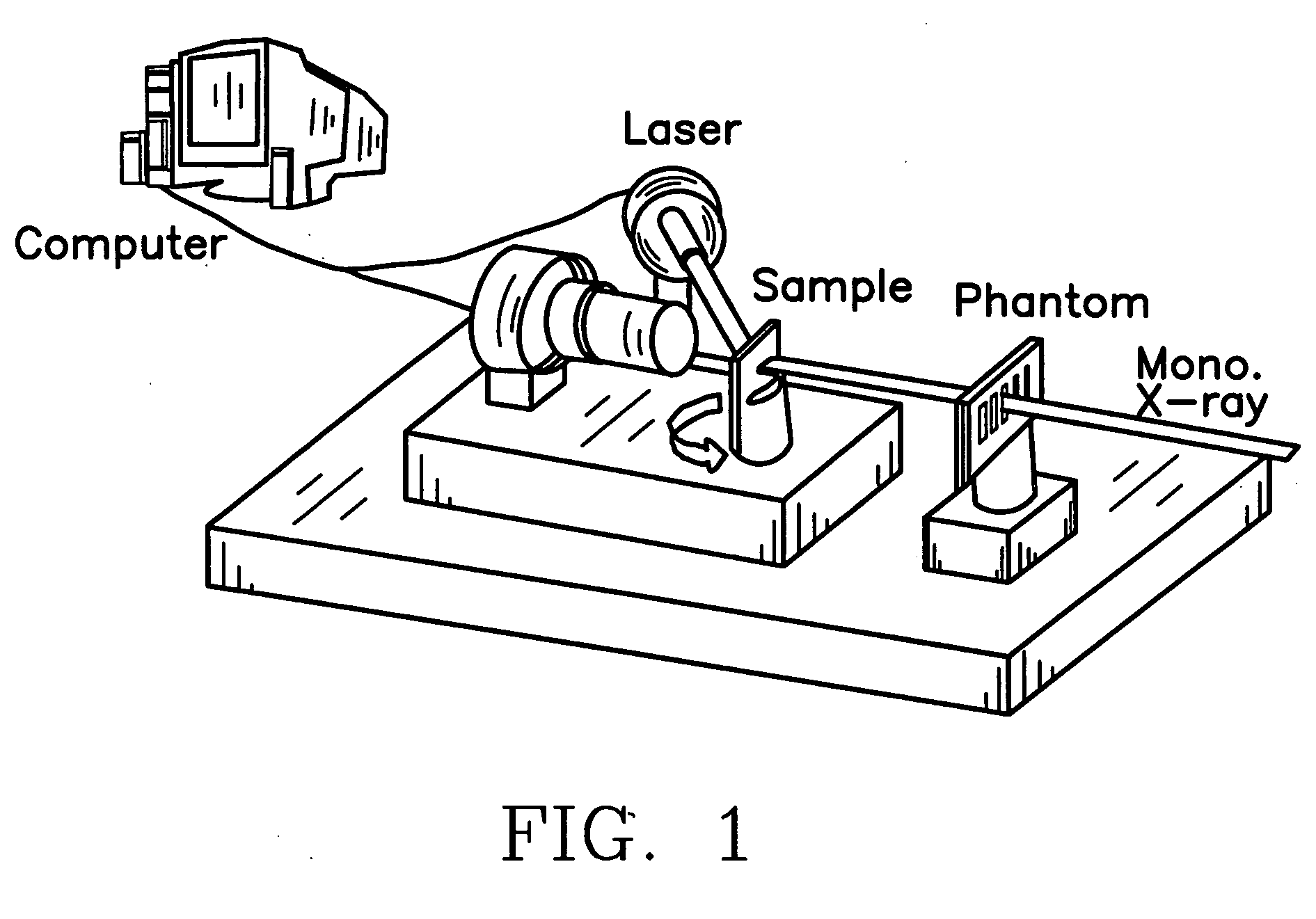

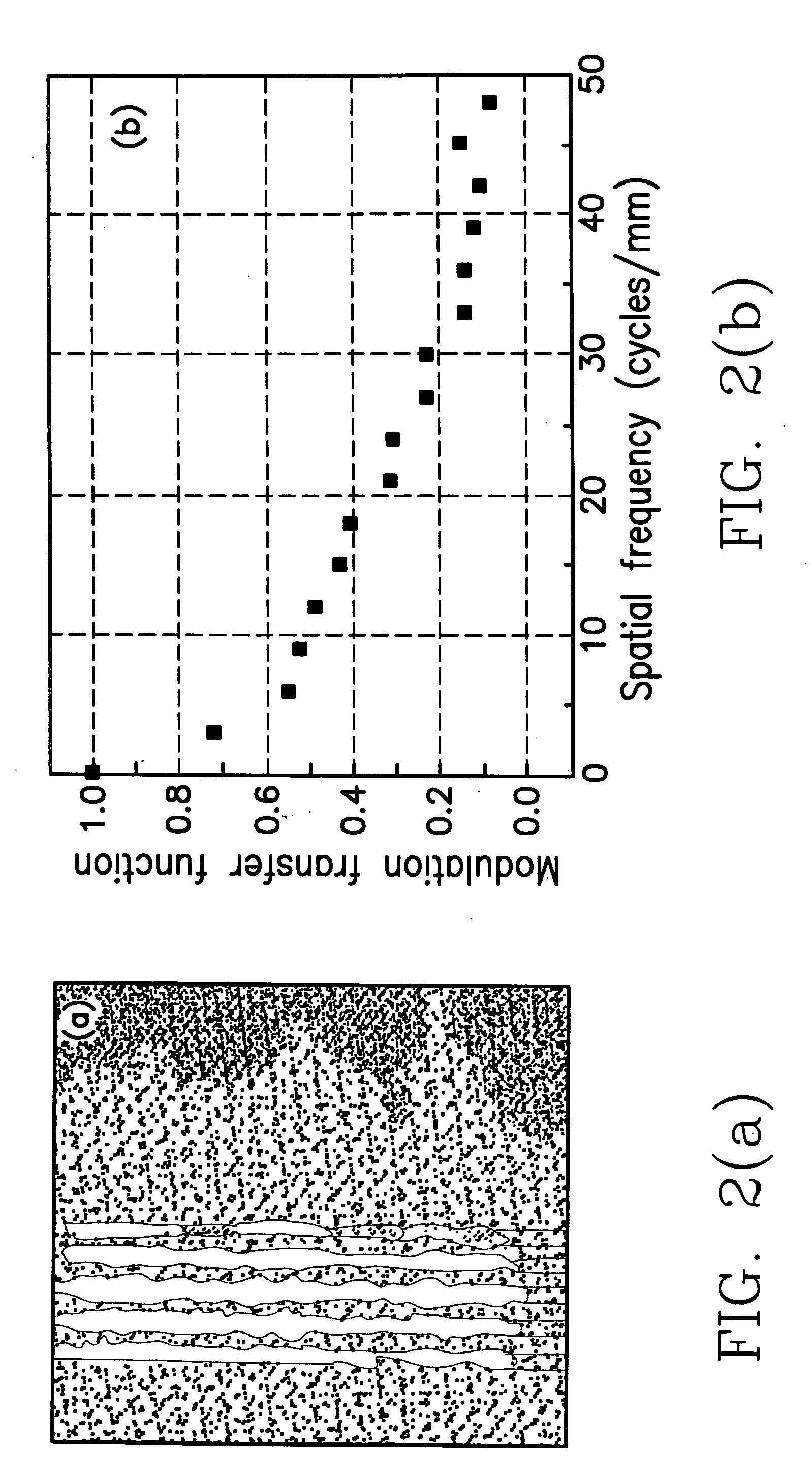

A computed radiography system including a stimulating light source such as a laser, a photostimulable glass imaging plate (PGIP) substantially transparent to the stimulating light positioned such that the stimulating light impinges the PGIP perpendicularly thereto producing photostimulated luminescence light (PLL), a light collector having a light reflecting inner surface proximate the PGIP for collecting PLL emitted from the PGIP and having a hole or slot therein for admitting stimulating light into the light collector and onto the PGIP. An optical filter in communication with the light collector for blocking stimulating light waves and passing PLL therethrough. A light detector receives PLL from the optical filter and the light collector, mechanism providing relative movement between the PGIP and the stimulating light source, and mechanism including an analog to digital converter for converting the collected and detected PLL to a diagnostic readout. The system is particularly useful in mammography.

Owner:UCHICAGO ARGONNE LLC

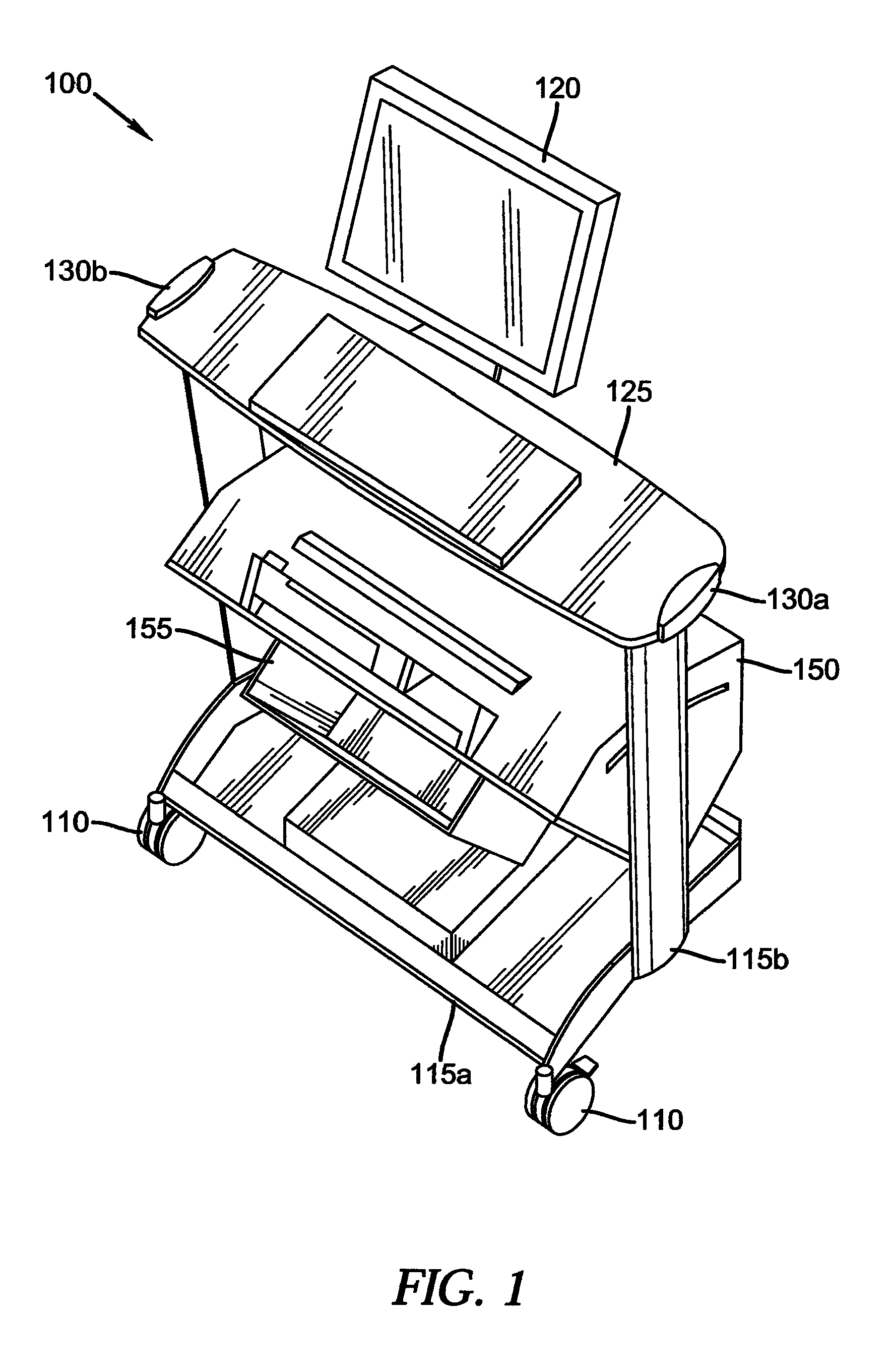

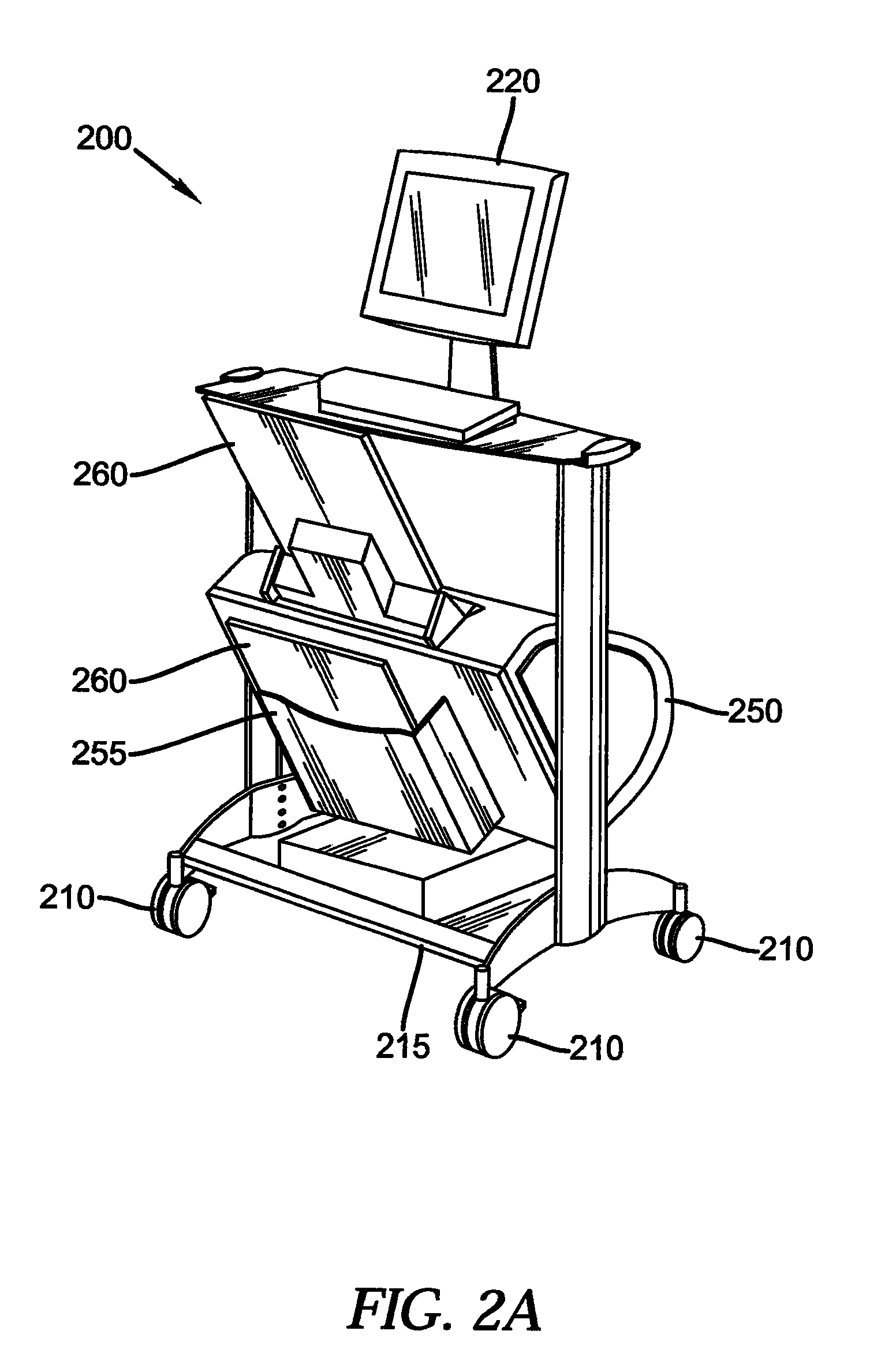

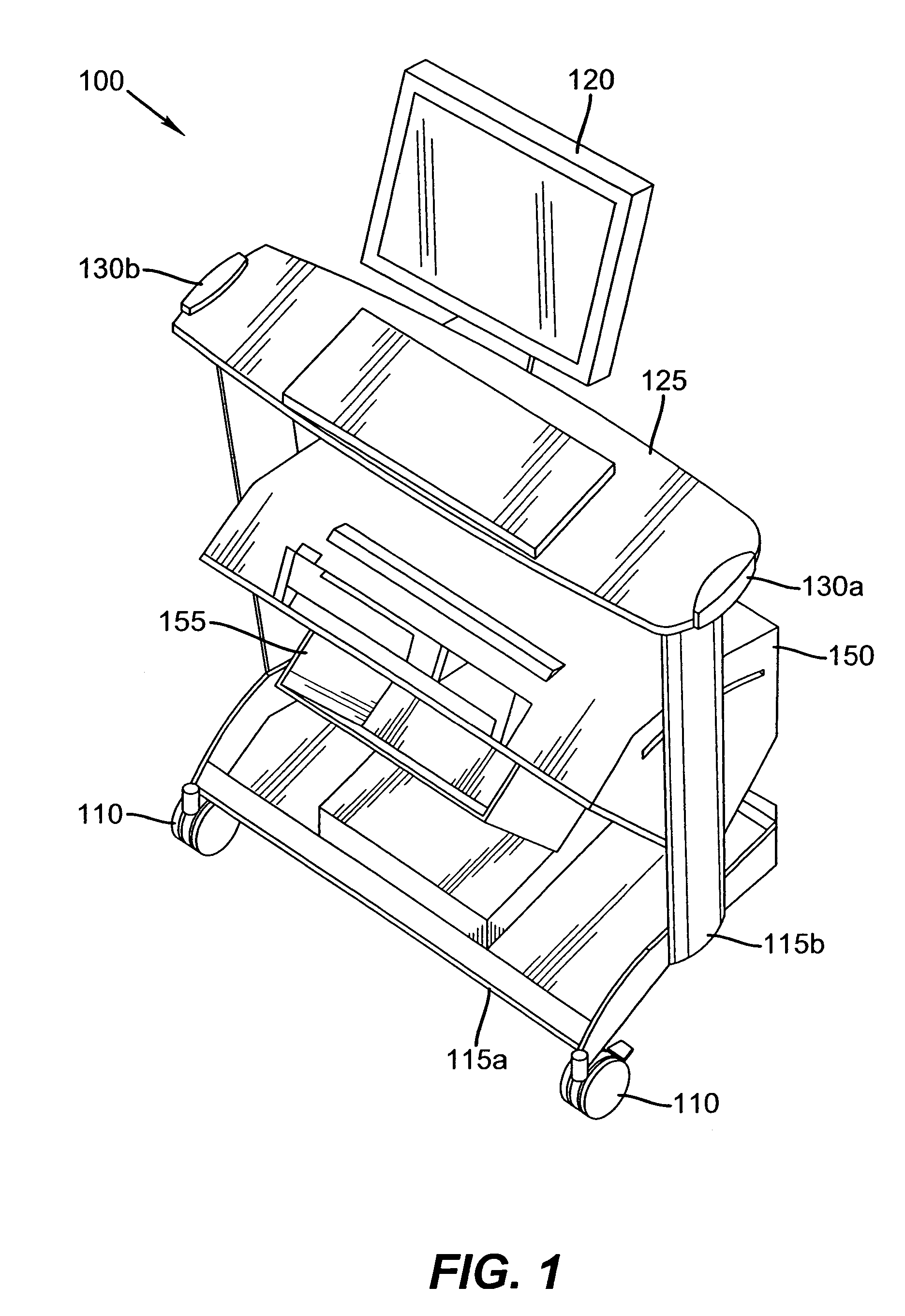

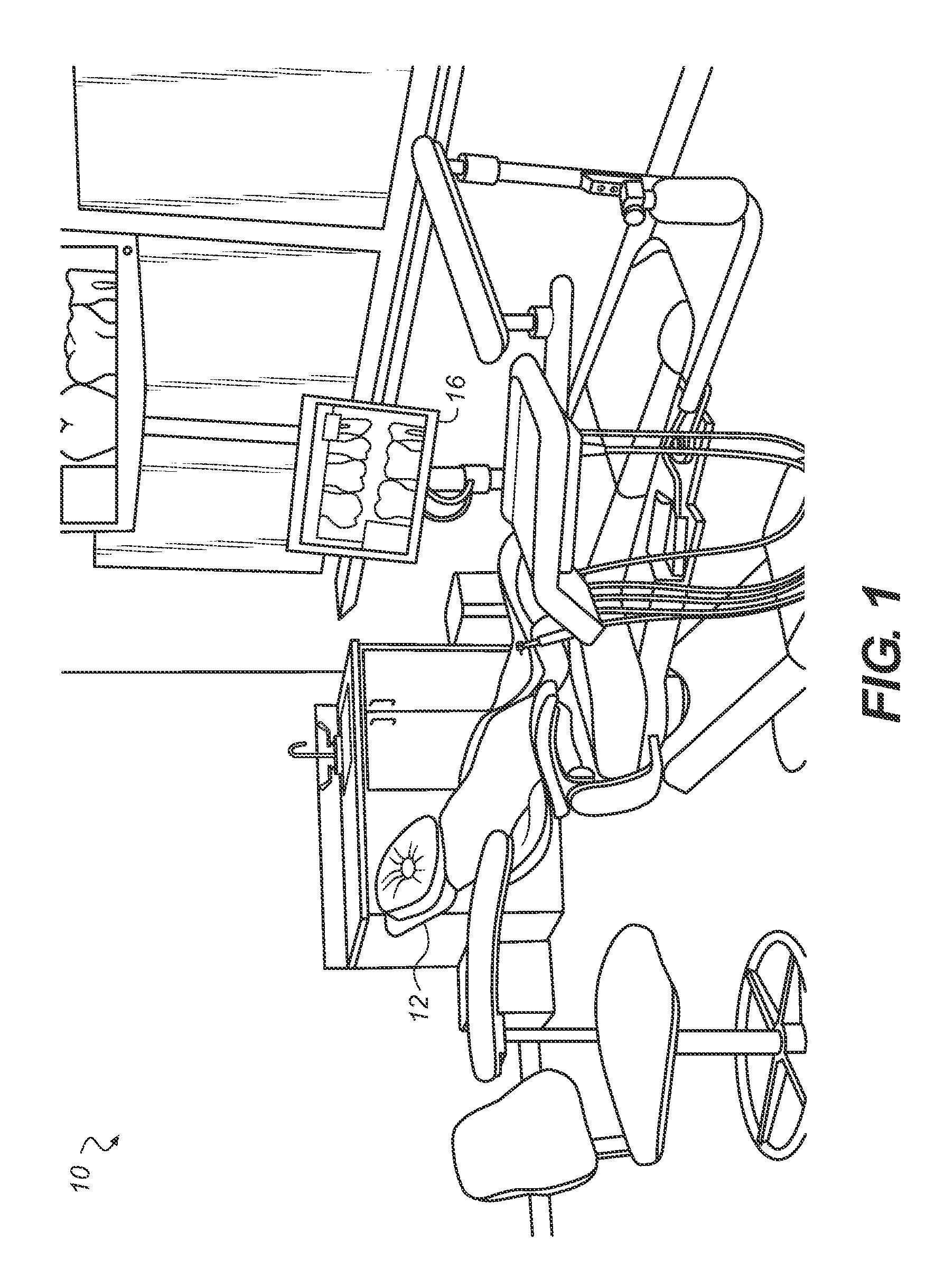

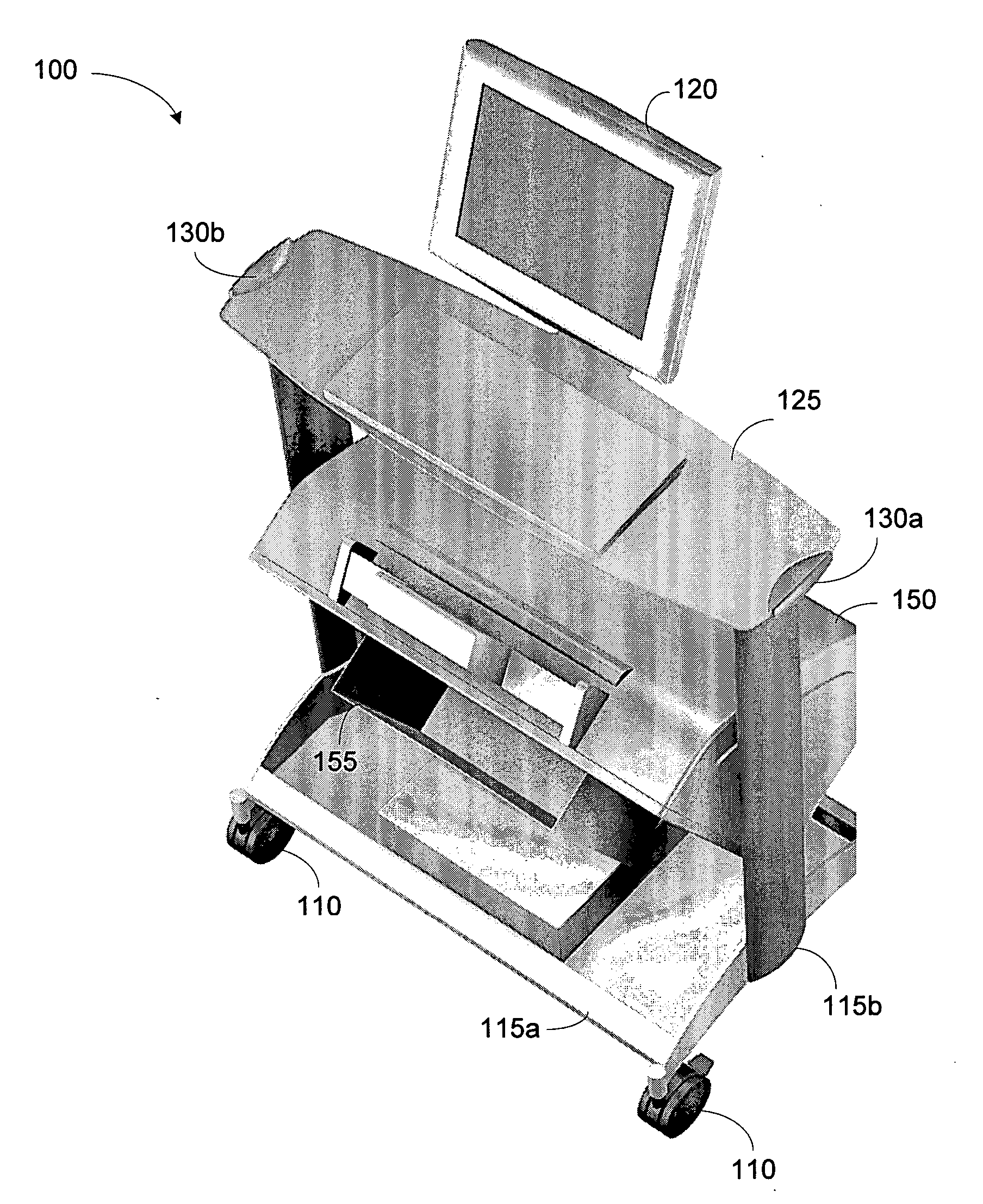

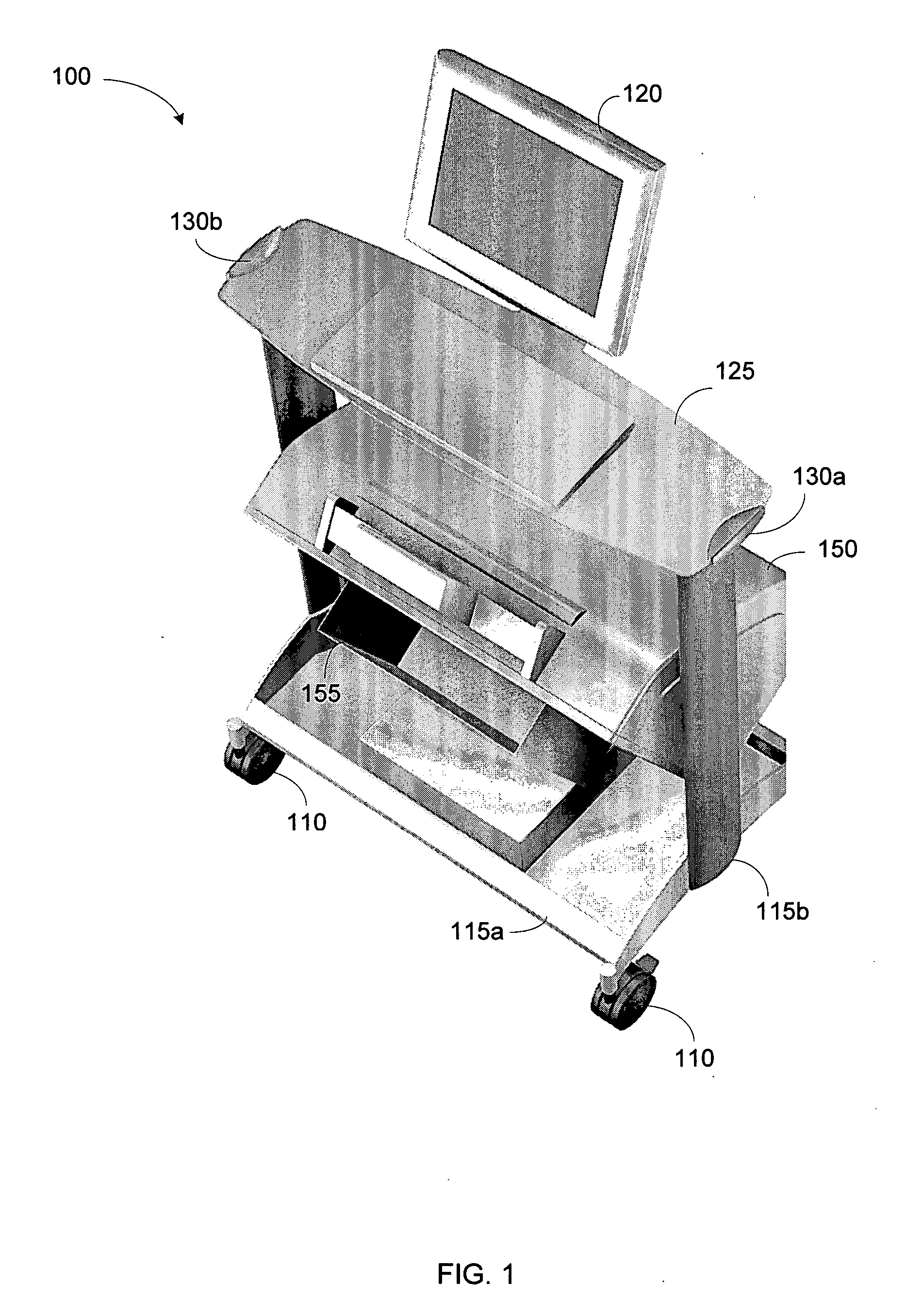

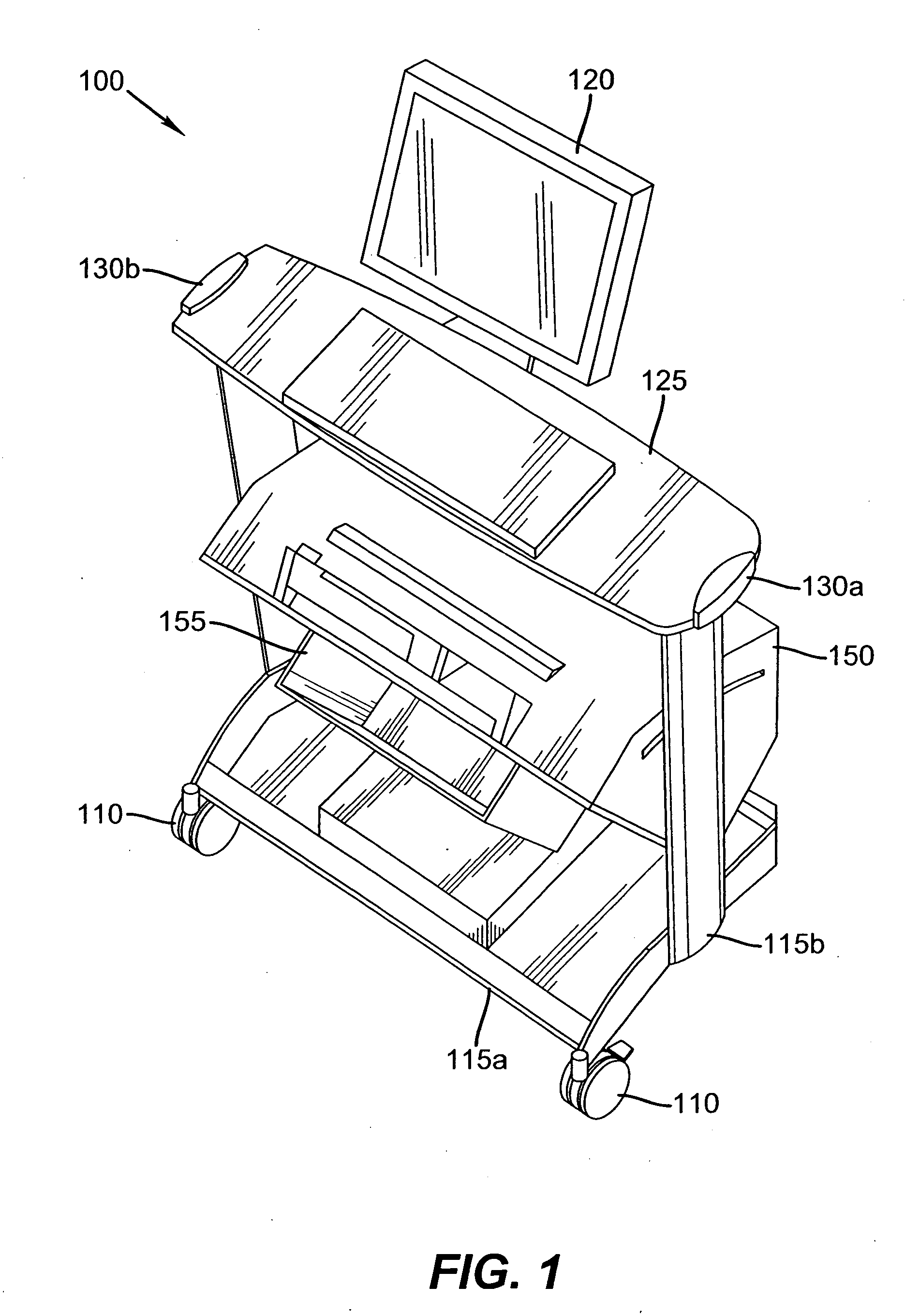

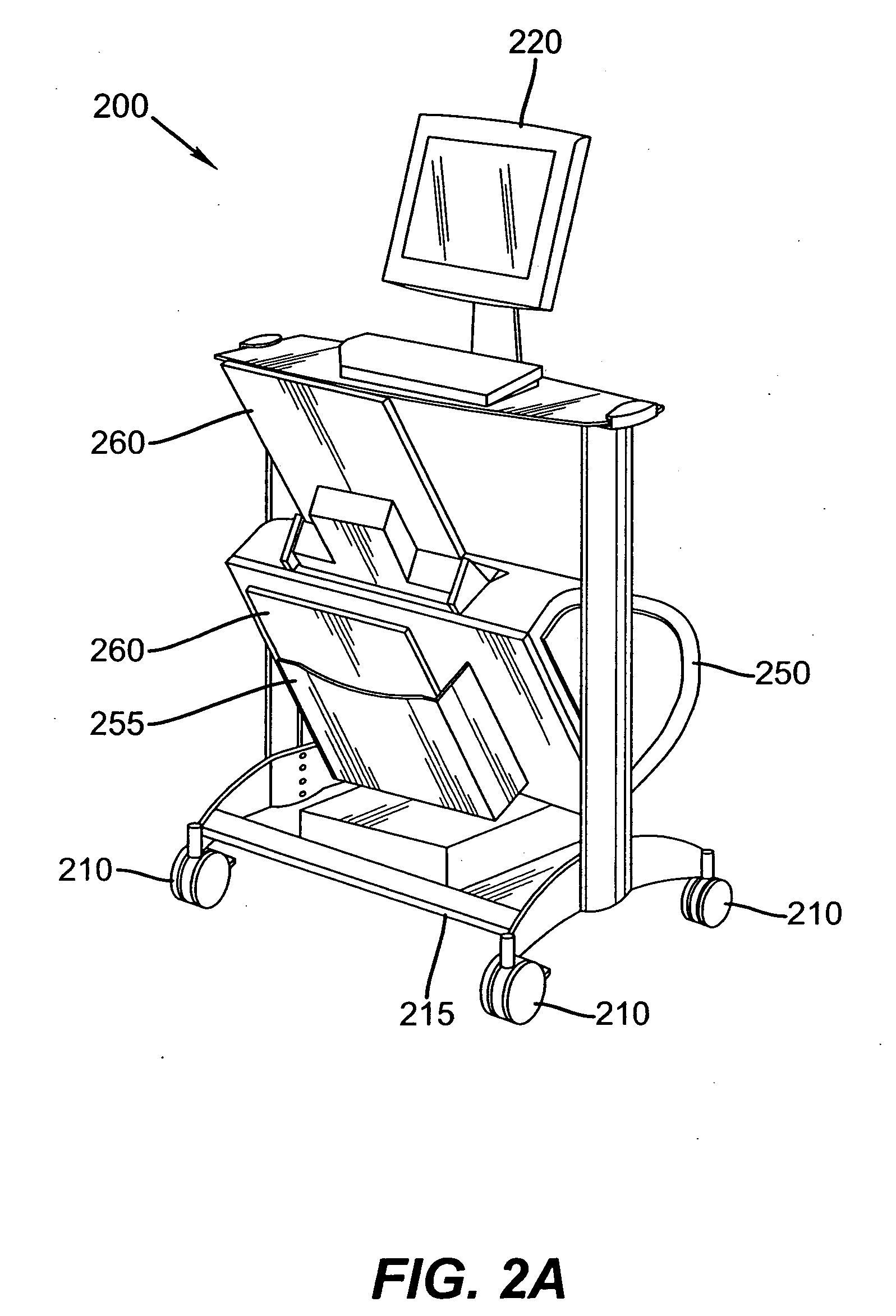

Mobile computed radiography

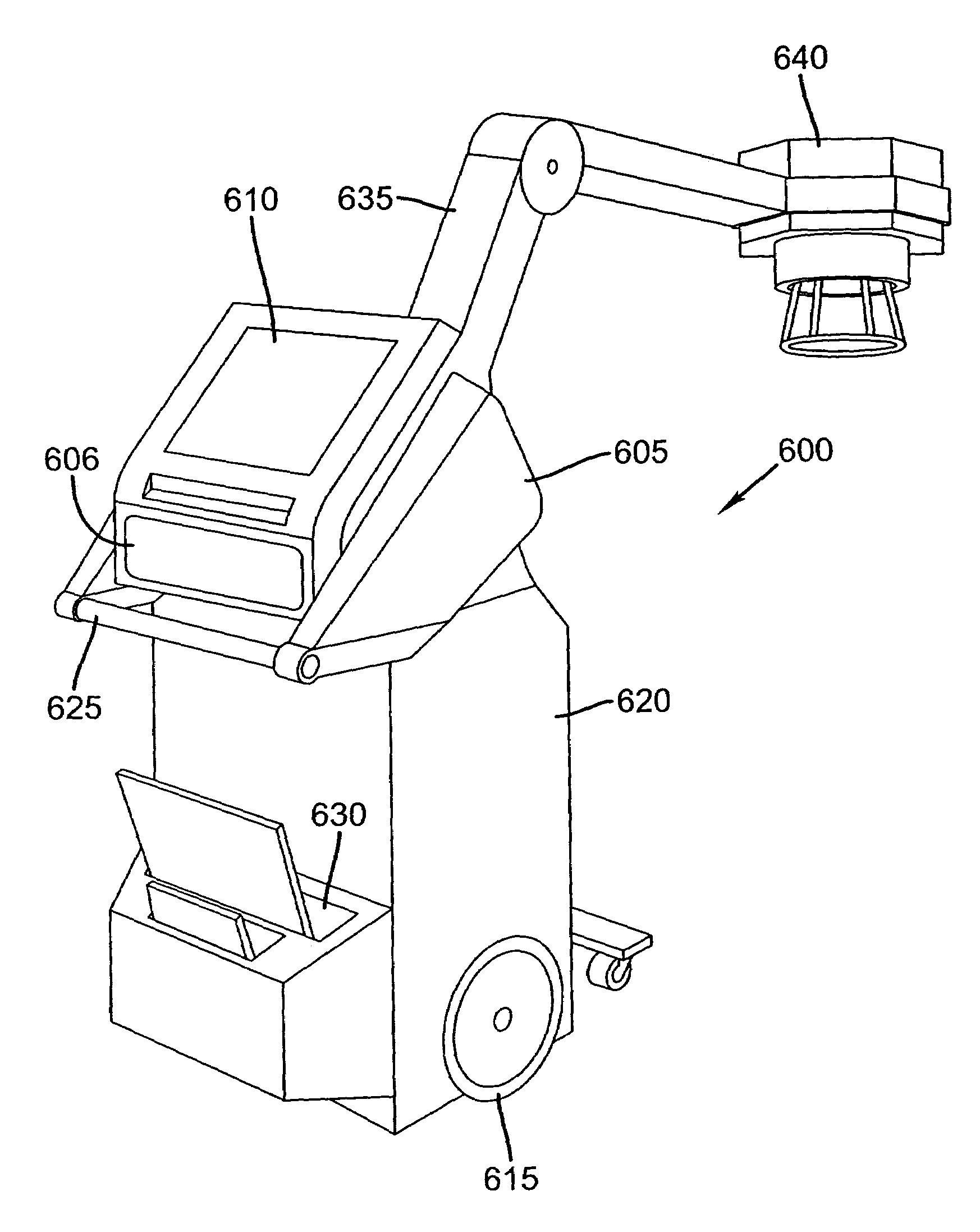

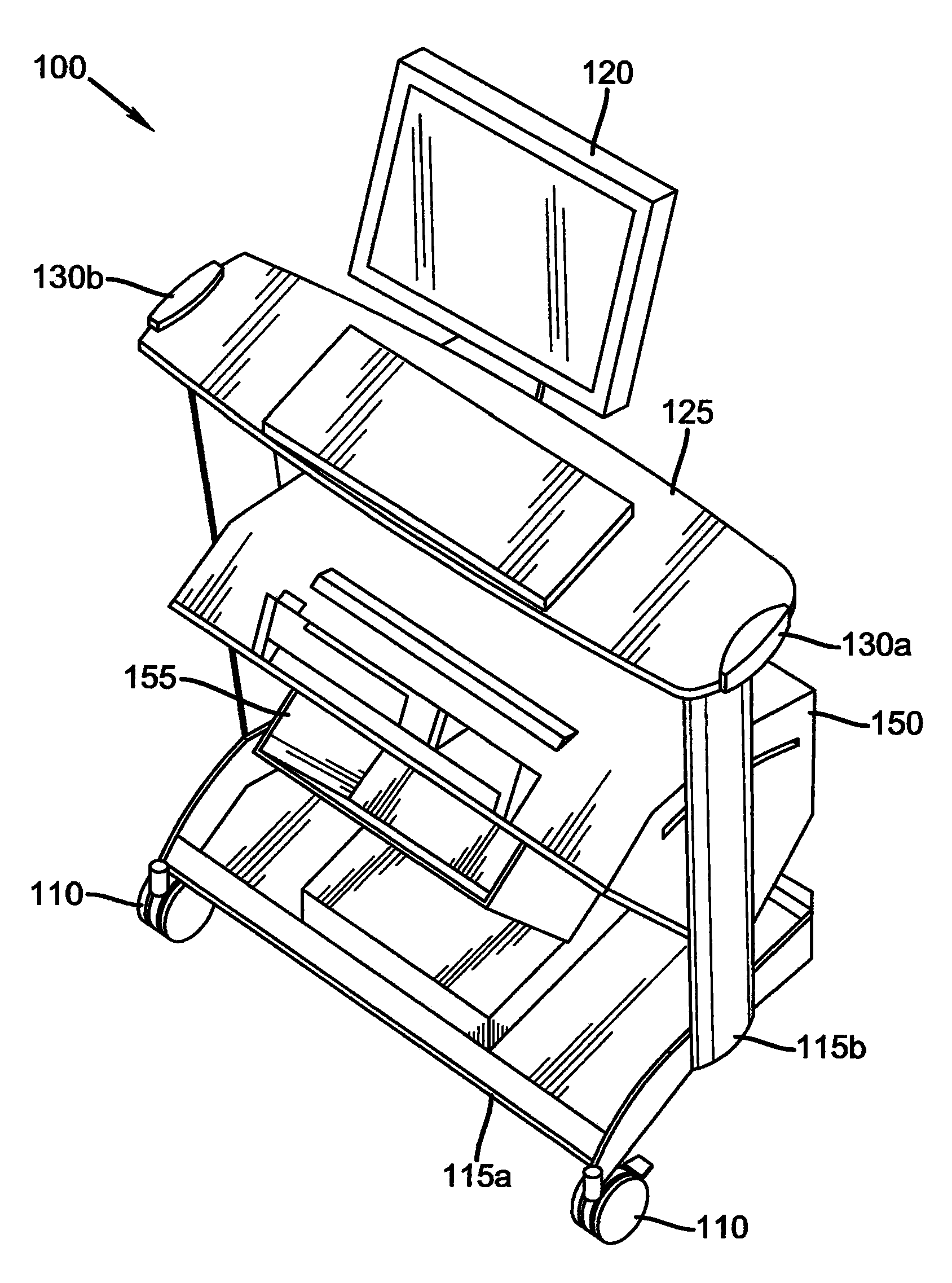

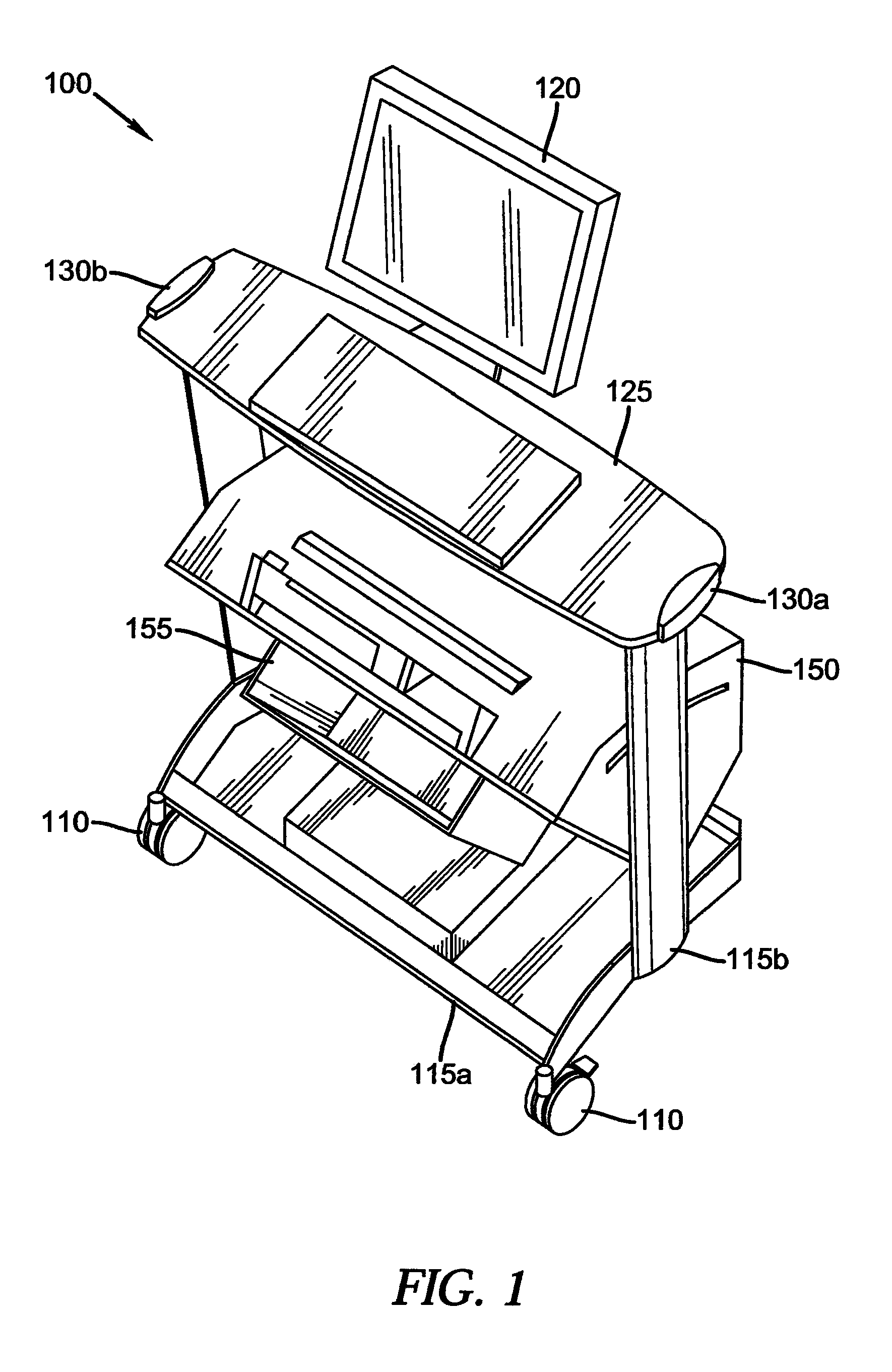

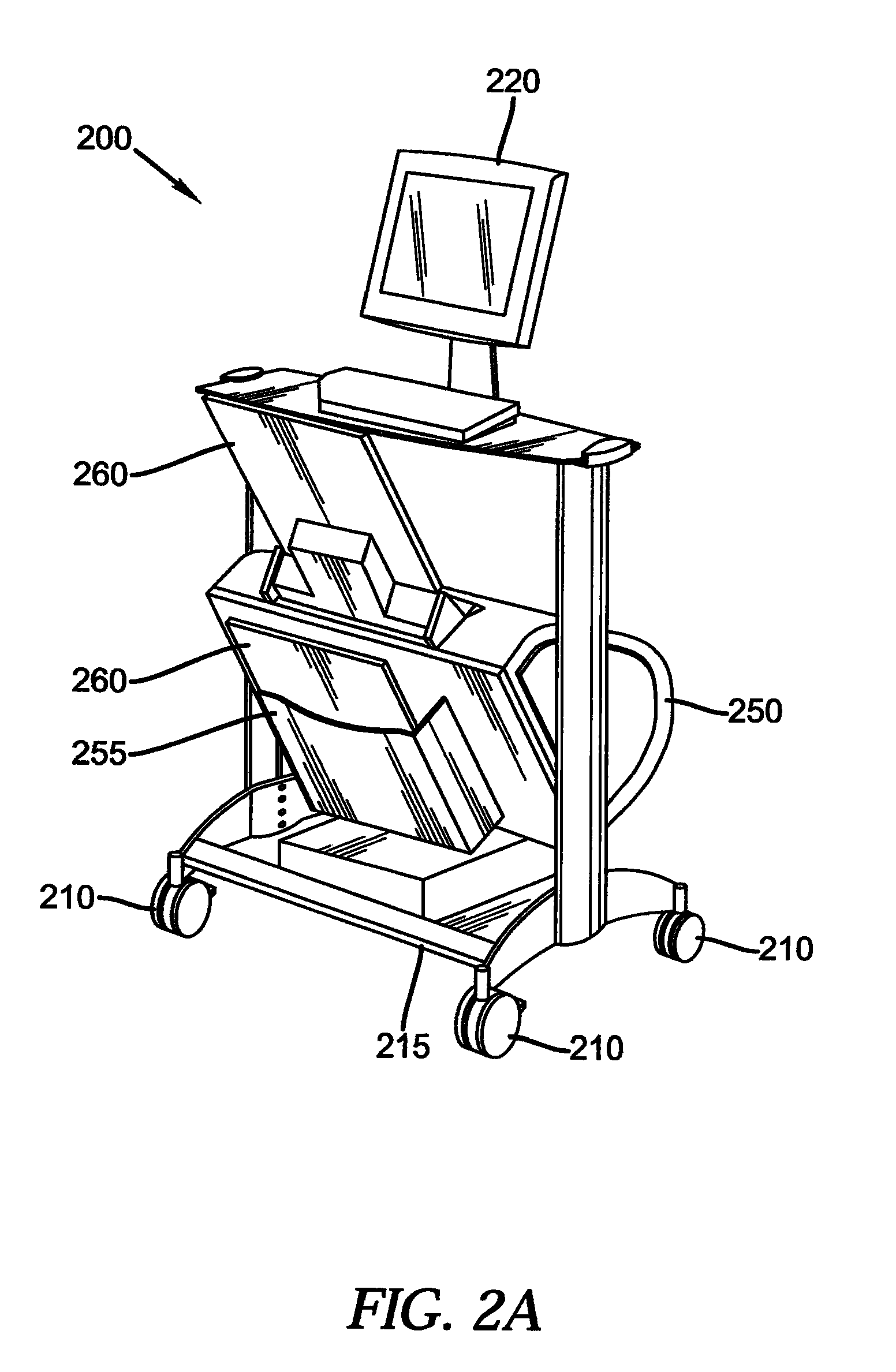

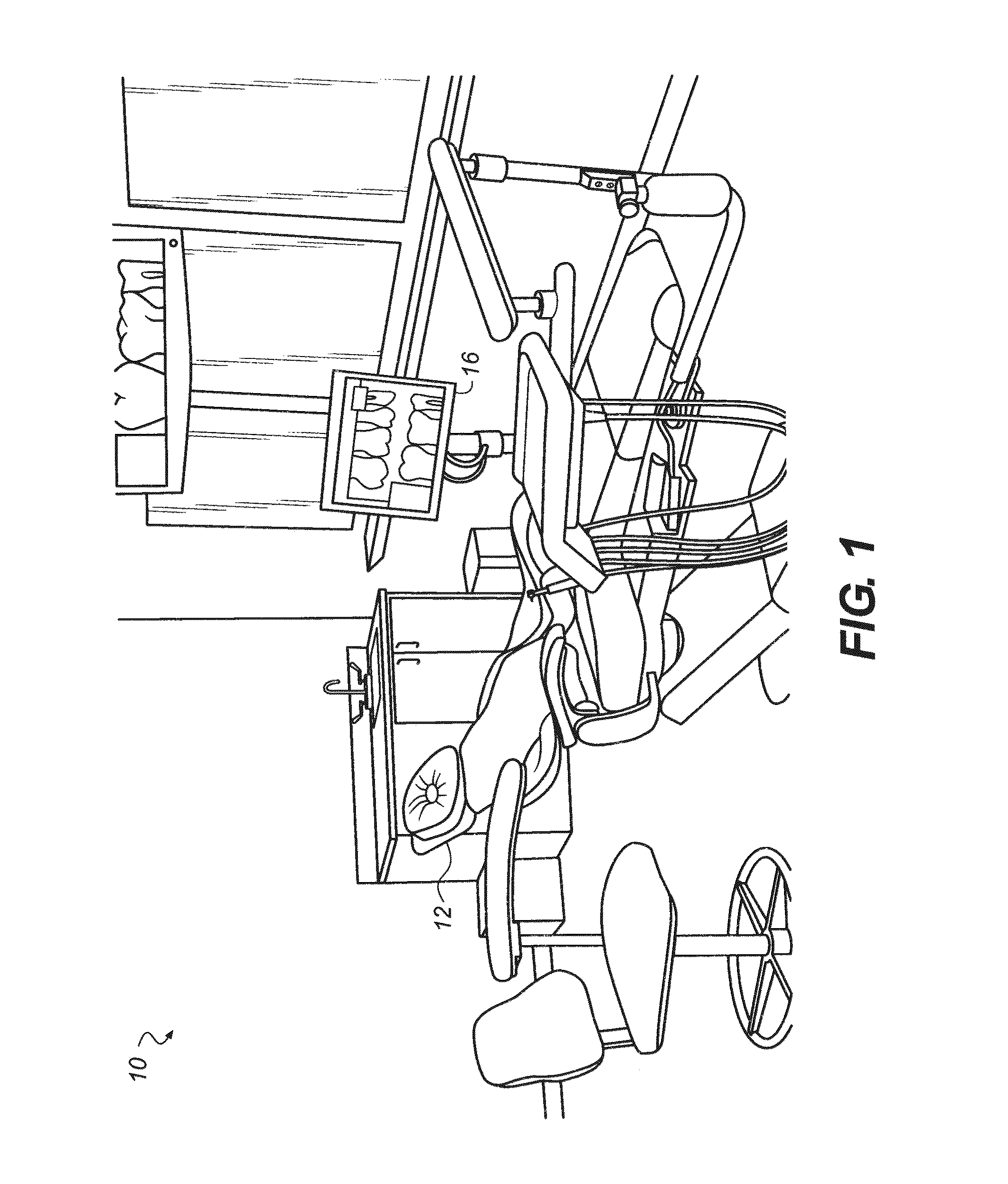

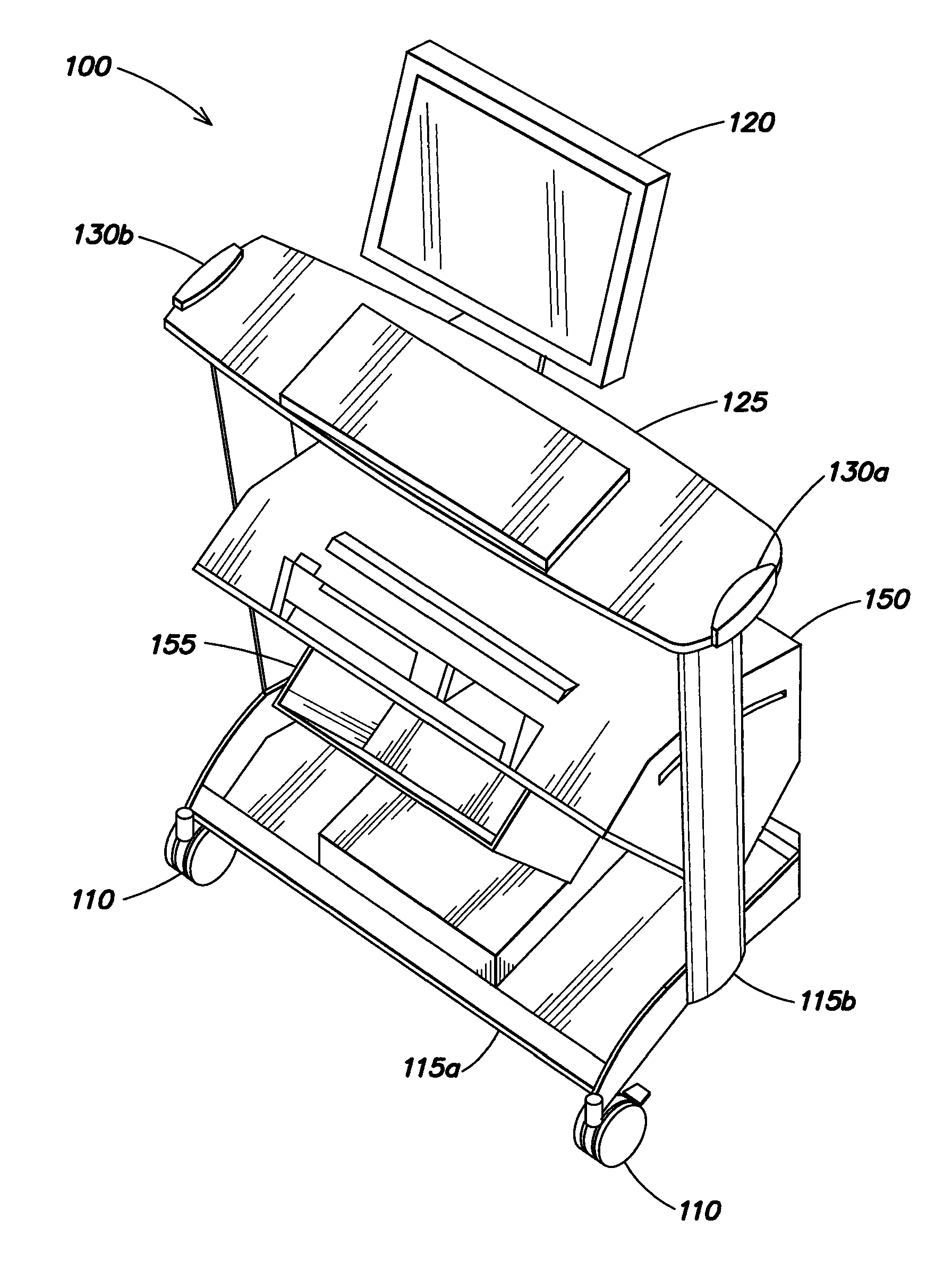

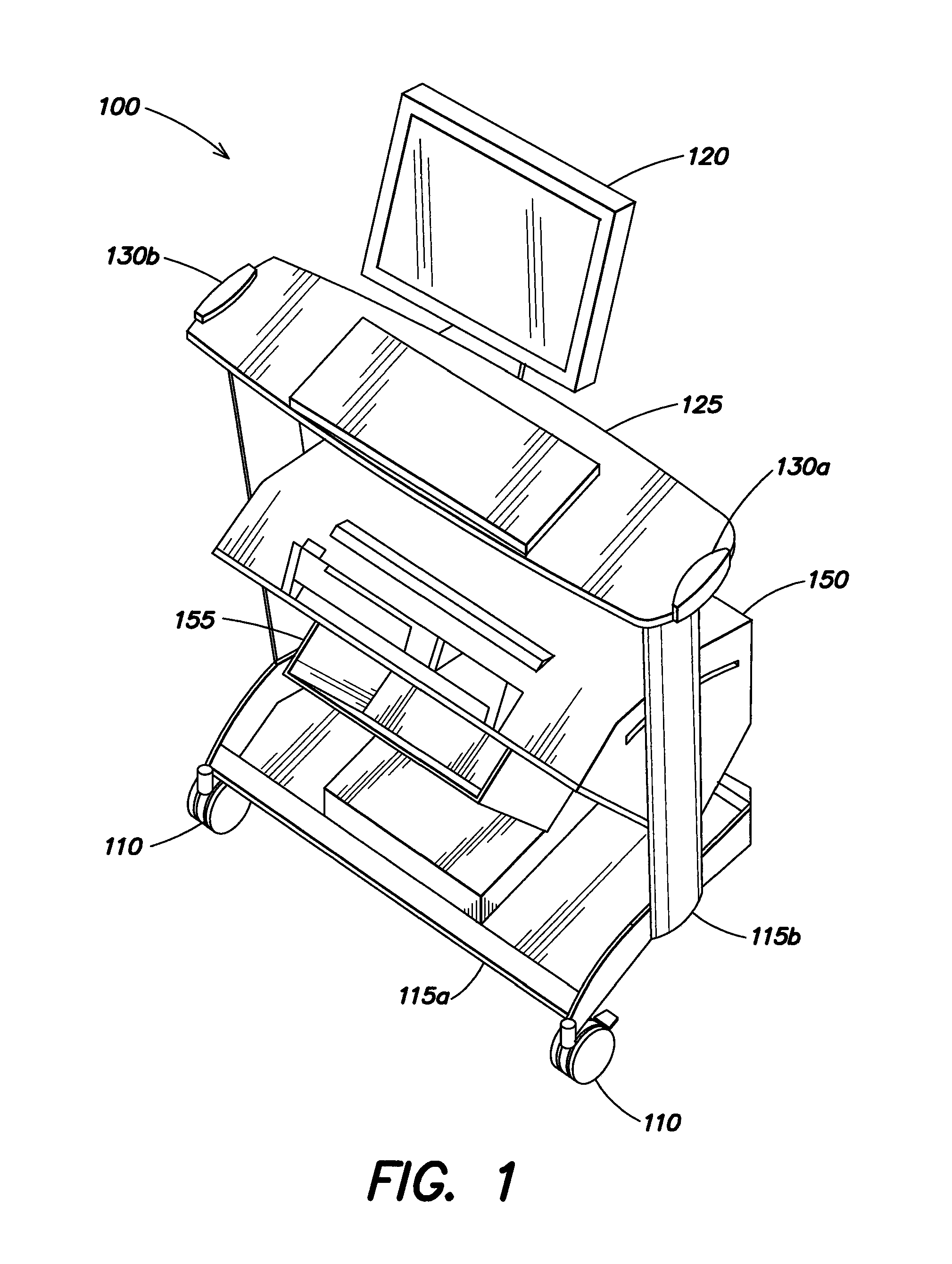

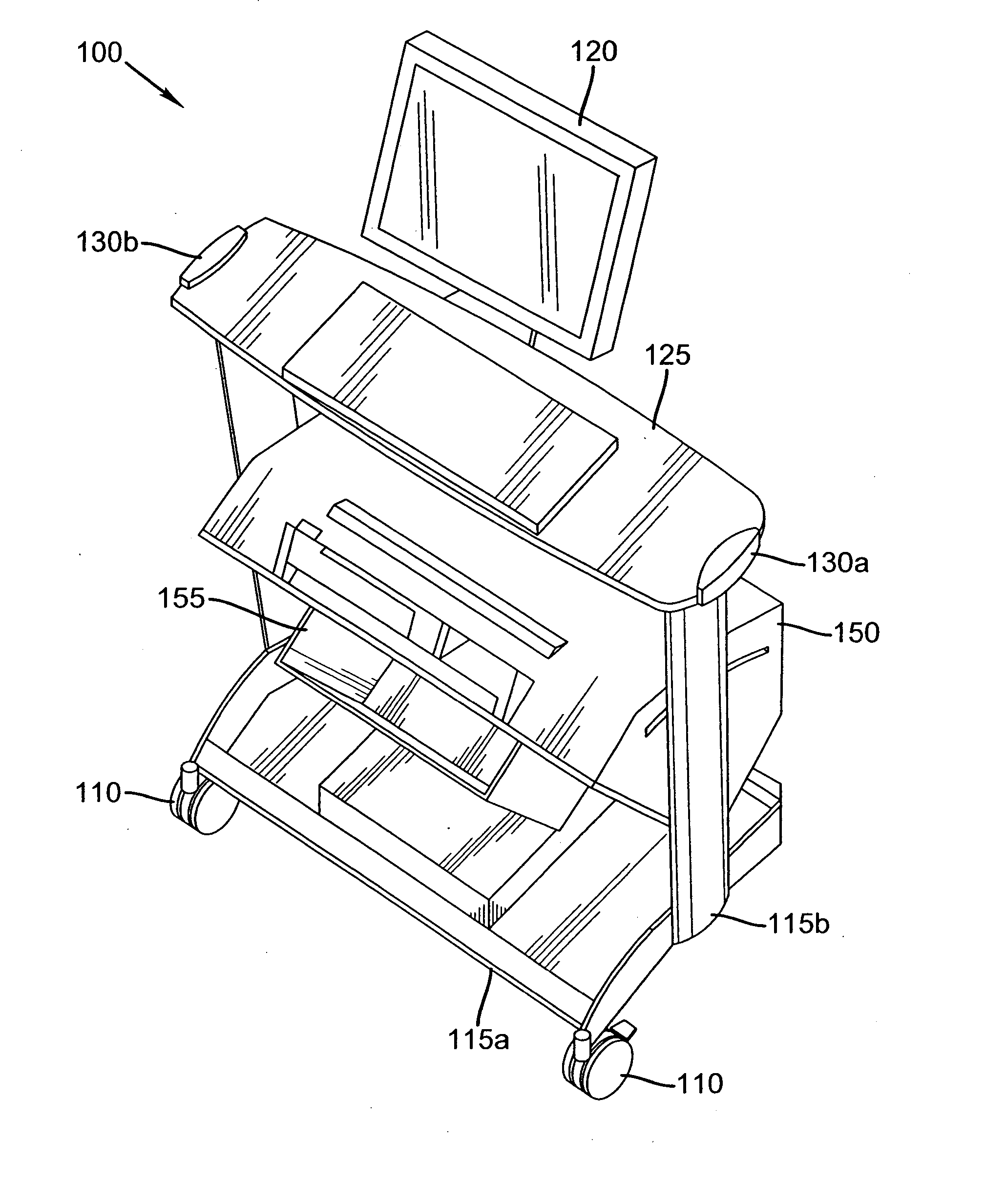

A mobile computed radiography (CR) unit. The mobile CR unit includes a CR scanner adapted to acquire one or more images from an image recording medium, a frame that supports the CR scanner, an x-ray source mounted to the frame, a transport mechanism coupled to the frame and adapted to facilitate transport of the mobile CR apparatus between locations, and a display coupled to the frame and connected to the CR scanner to display the one or more images acquired by the CR scanner. The mobile CR unit in constructed as a single free-standing integrated device which provides for the exposure of a storage phosphor media, the scanning of the exposed media to generate a digital medical image, and the display of the generated digital medical image.

Owner:CARESTREAM HEALTH INC

Binderless storage phosphor screen

InactiveUS20040262537A1Create efficientlyEfficient detectionX-ray/infra-red processesElectrical apparatusSurface roughnessImage storage

An image storage screen or panel, suitable for use in applications related with computed radiography comprises a binderless needle-shaped stimulable (storage) CsBr:Eu phosphor and a substrate, wherein said substrate has a surface roughness of less than 2 mum and a reflectivity of more than 80%.

Owner:T2PHARMA GMBH

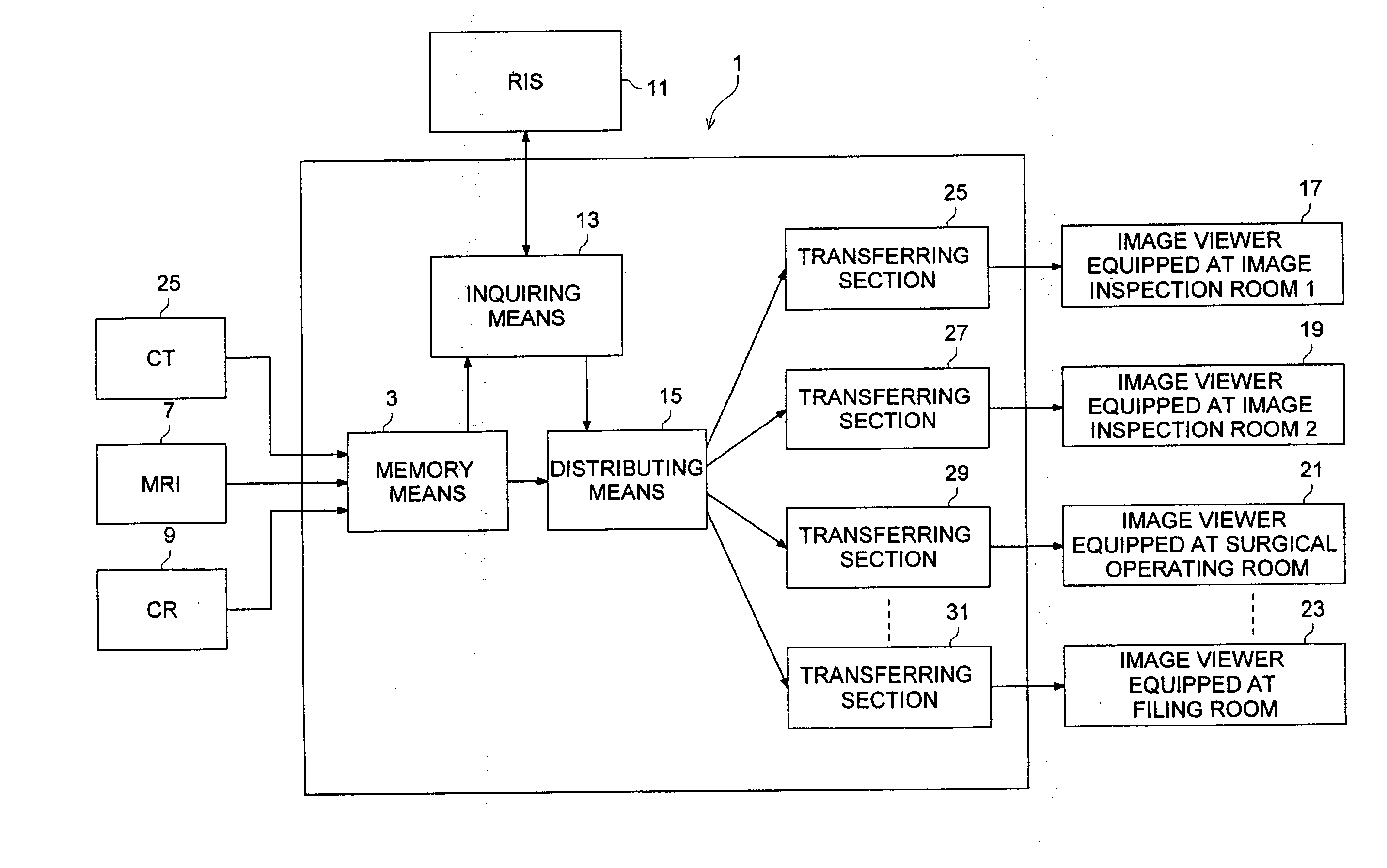

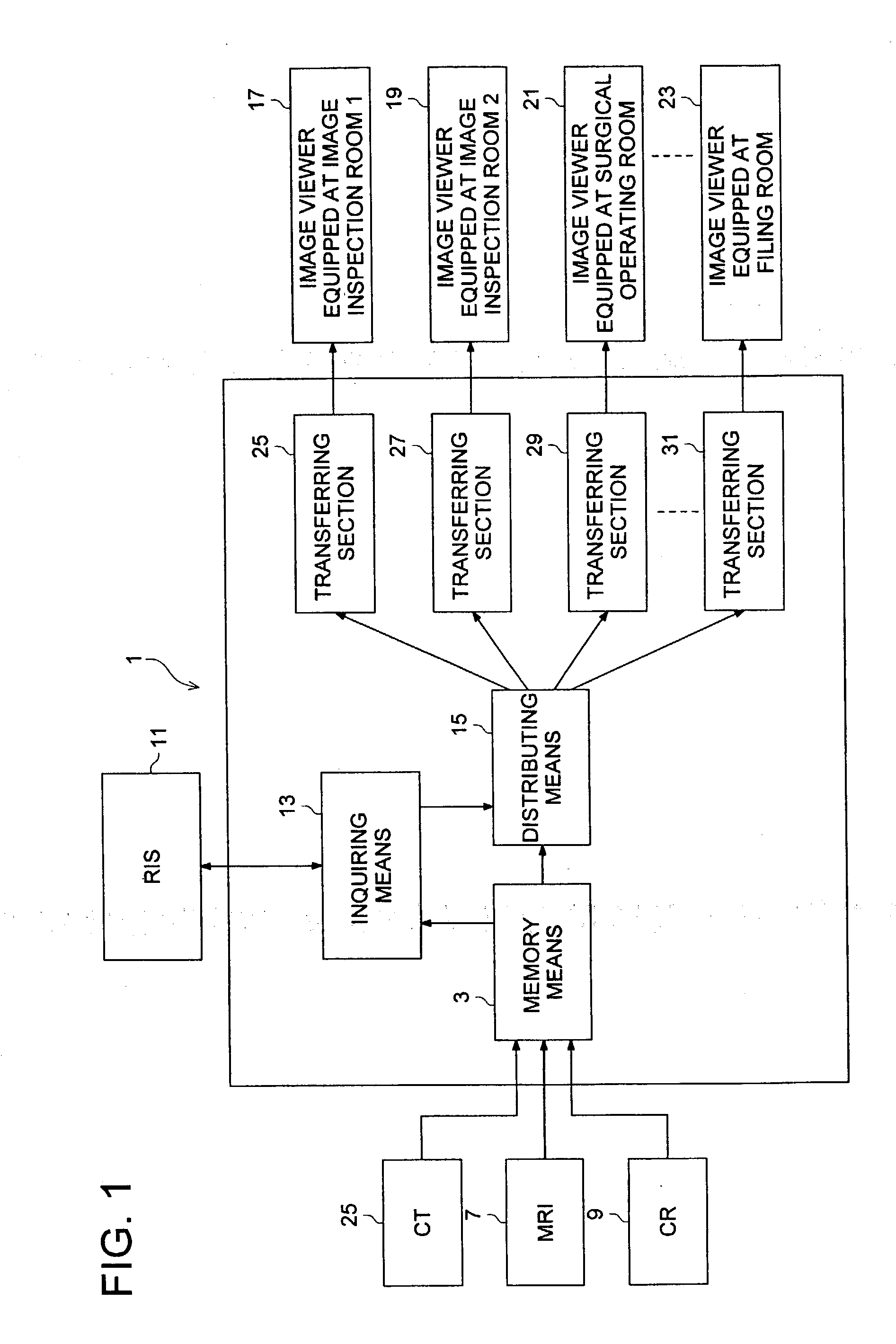

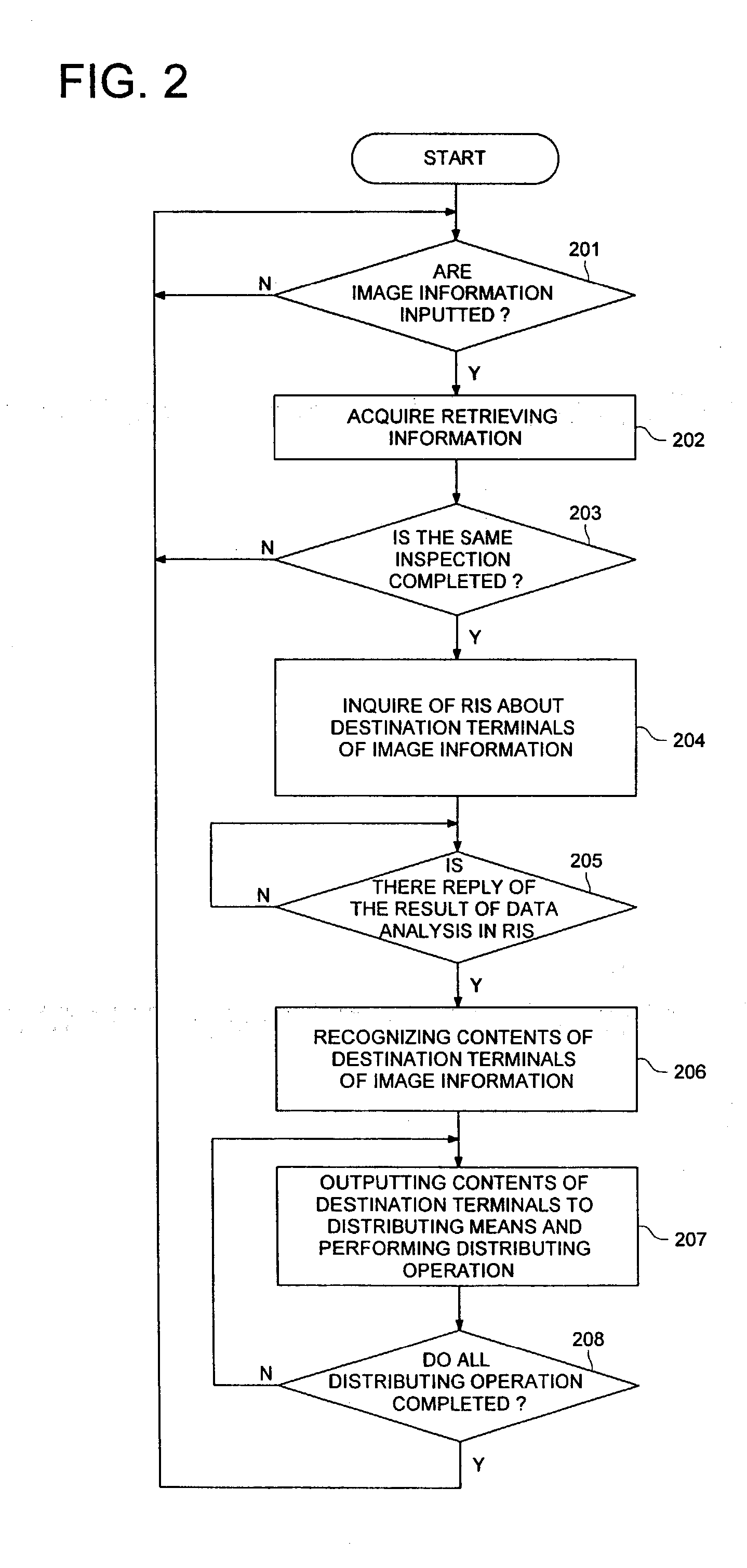

Image delivery apparatus

InactiveUS20030156765A1Data processing applicationsMaterial analysis using wave/particle radiationImage InspectionResonance

The present invention provides an image distributing apparatus, which makes it possible to automatically and appropriately classify destination terminals, to which the image information sets are distributed, without requiring the hospital to prepare extra personnel for this operation, and as a result, to improve the efficiency of the operation. The image distributing apparatus is provided with: a memory means for storing the image information, formed by image-forming apparatus, etc., such as a Computer Tomographic Scanner, a Magnetic Resonance image-forming apparatus and an X-ray image-forming apparatus (including Computed Radiography), and to which the retrieving information are added; an inquiring means for inquiring of an information managing server of a hospital information system about destination terminals of the image information based on the retrieving information; and a distributing means for distributing the image information to an image viewer equipped in a medical room, an image viewer equipped in an image inspection room, an image viewers equipped in a filing room, etc., each serving as a destination terminal inquired by the inquiring means.

Owner:KONICA CORP

Method and apparatus for managing imaging system workflow

InactiveUS20050156125A1Improved workflow configurationMaterial analysis by optical meansStereoscopic photographyWorkstationX ray image

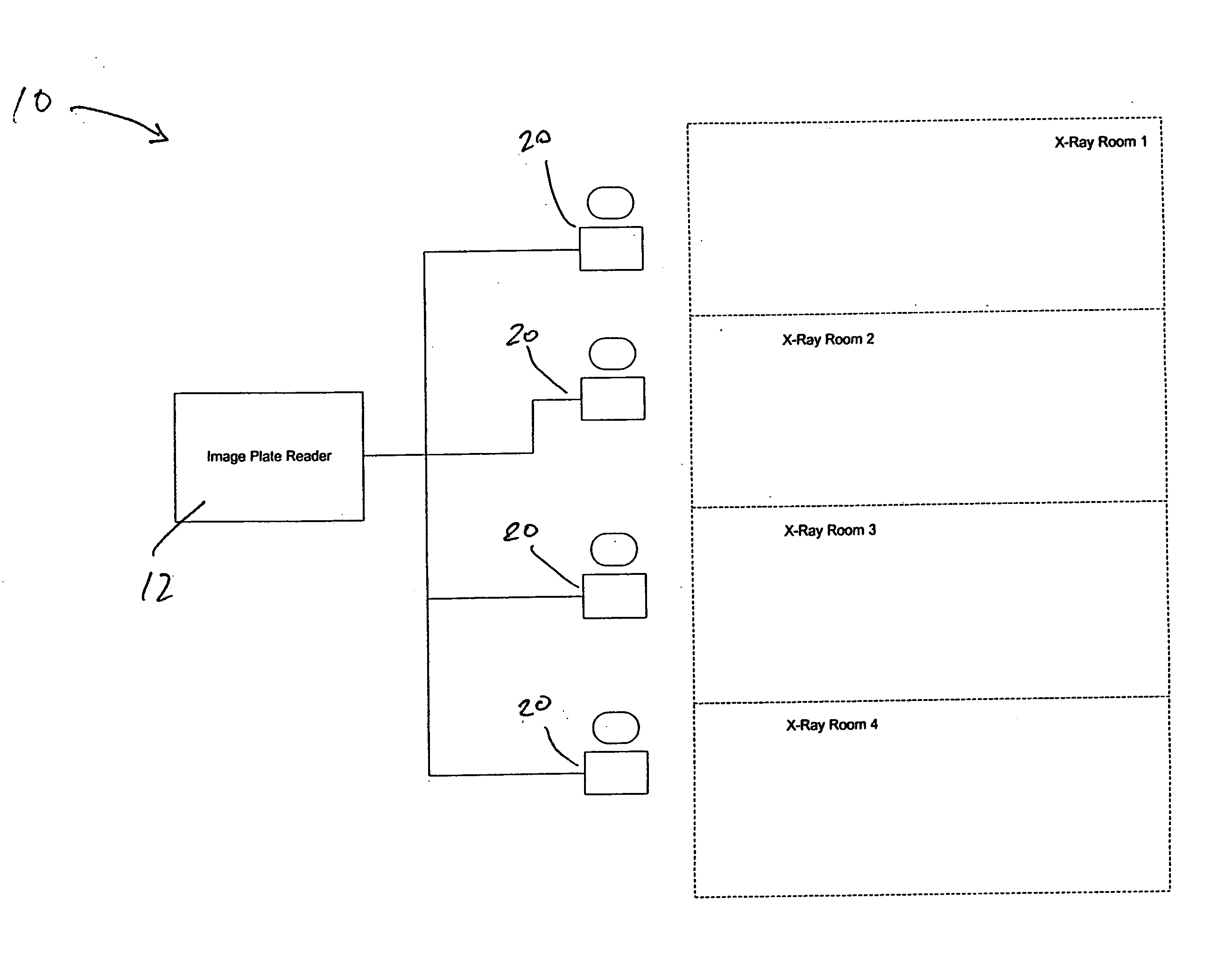

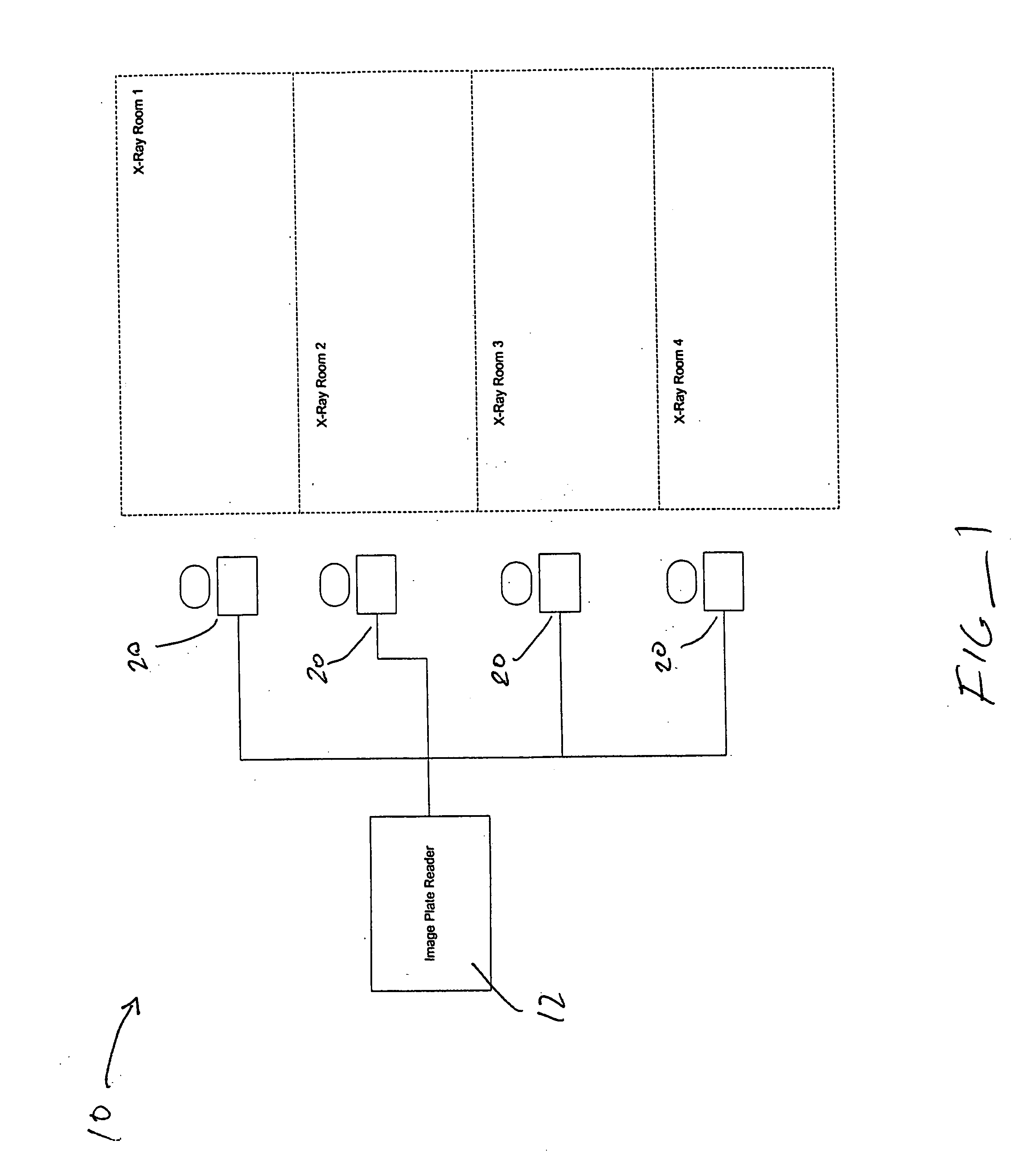

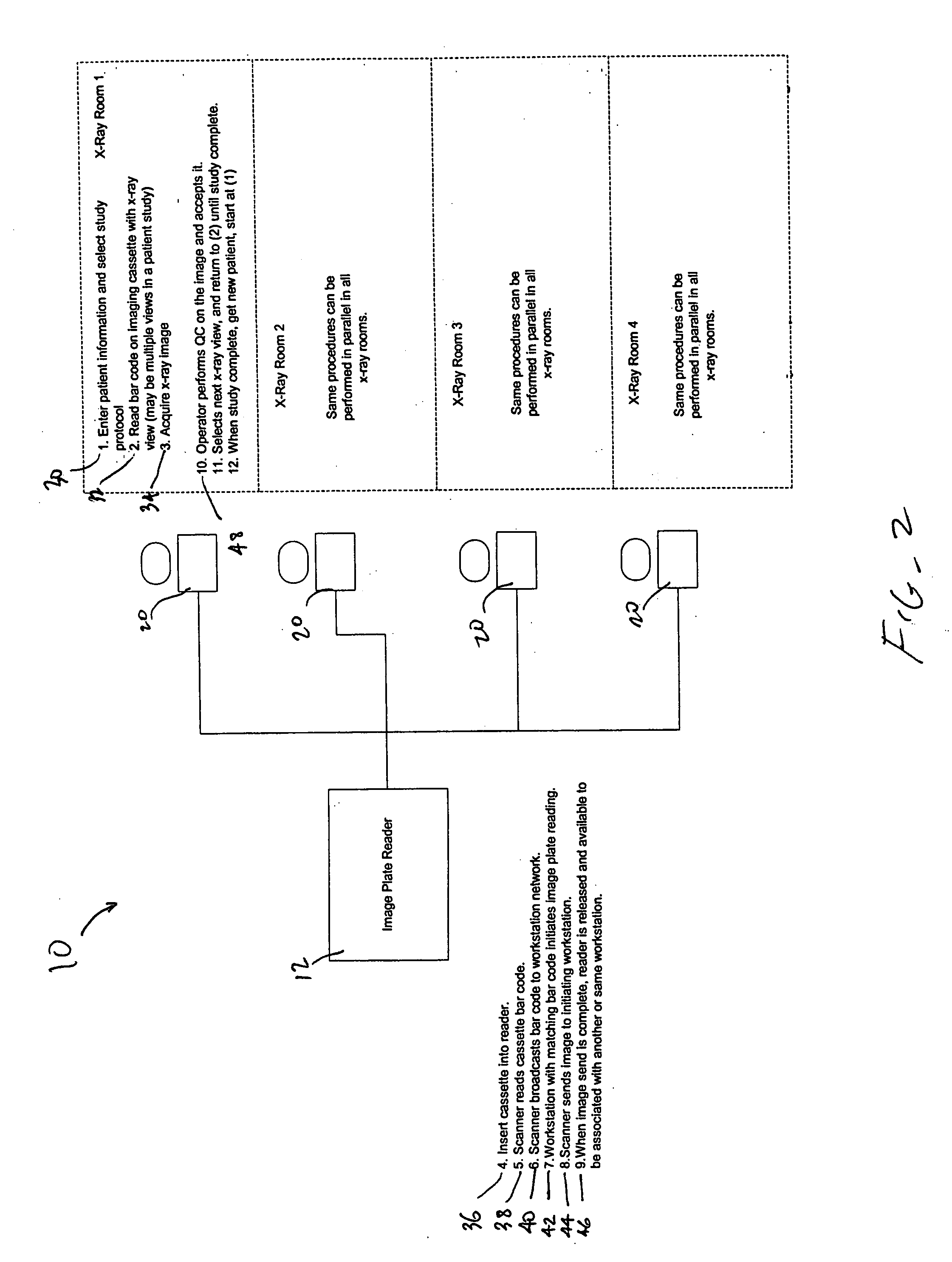

A method and system is provided for improving and organizing workflow of a computed radiography system comprising of one or more storage phosphor readers, and multiple workstations which control and receive image data from the readers. In one embodiment, the method comprises temporarily associating an imaging cassette, containing a storage phosphor imaging plate, with a specific workstation. The imaging cassette is transported to the reader and inserted into the reader. The image plate reader is temporarily associated with the specific workstation. This temporary association allows the workstation to control the reader; and allow for sending of an X-ray image data from the reader only to the specific workstation. In other embodiments, this workflow may be adapted for use with networks having a plurality of image plate readers and a plurality of workstations.

Owner:ALARA INC

Computed radiography systems and methods of use

ActiveUS7244955B2X-ray/infra-red processesMaterial analysis by optical meansStimulated emissionComputed radiography

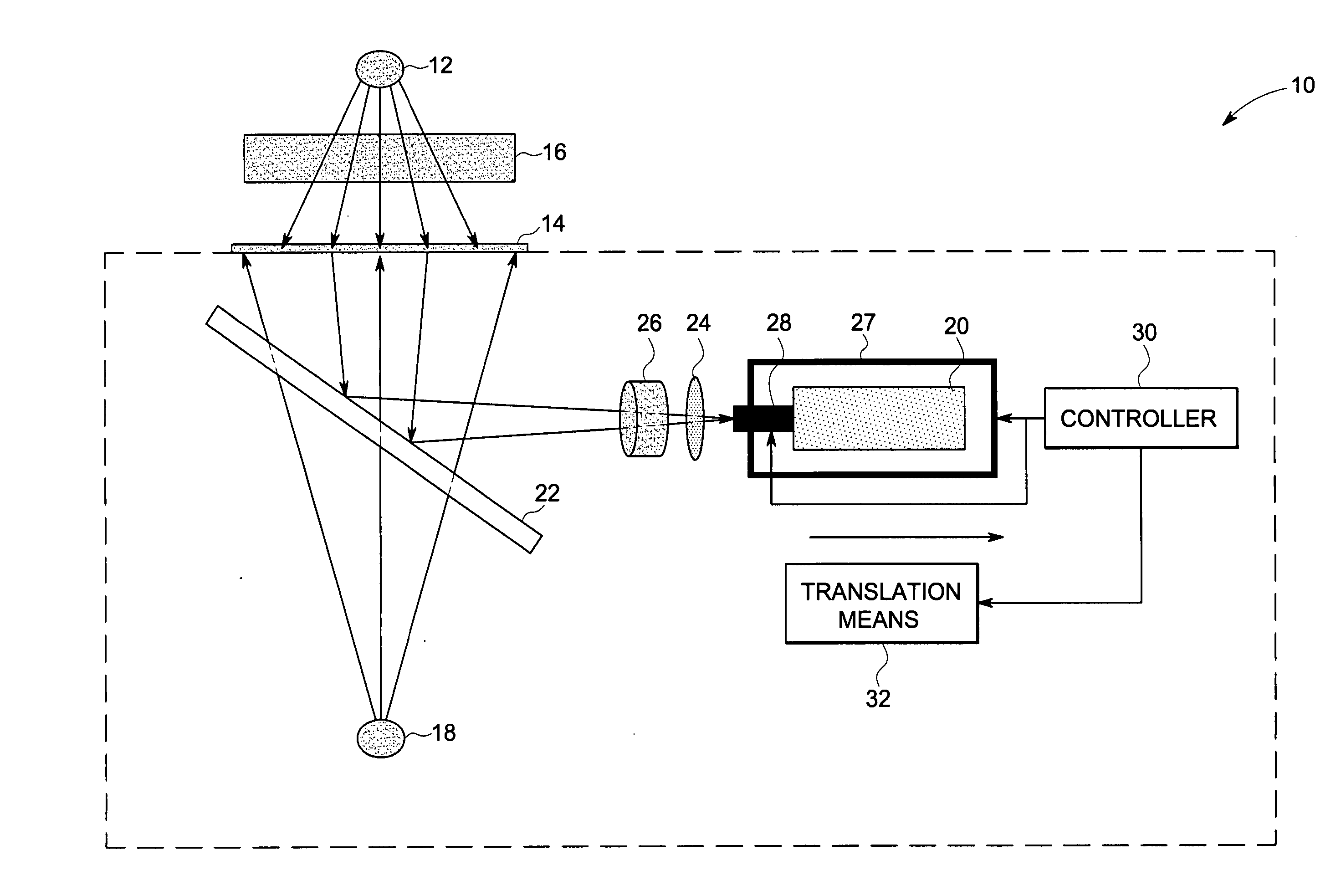

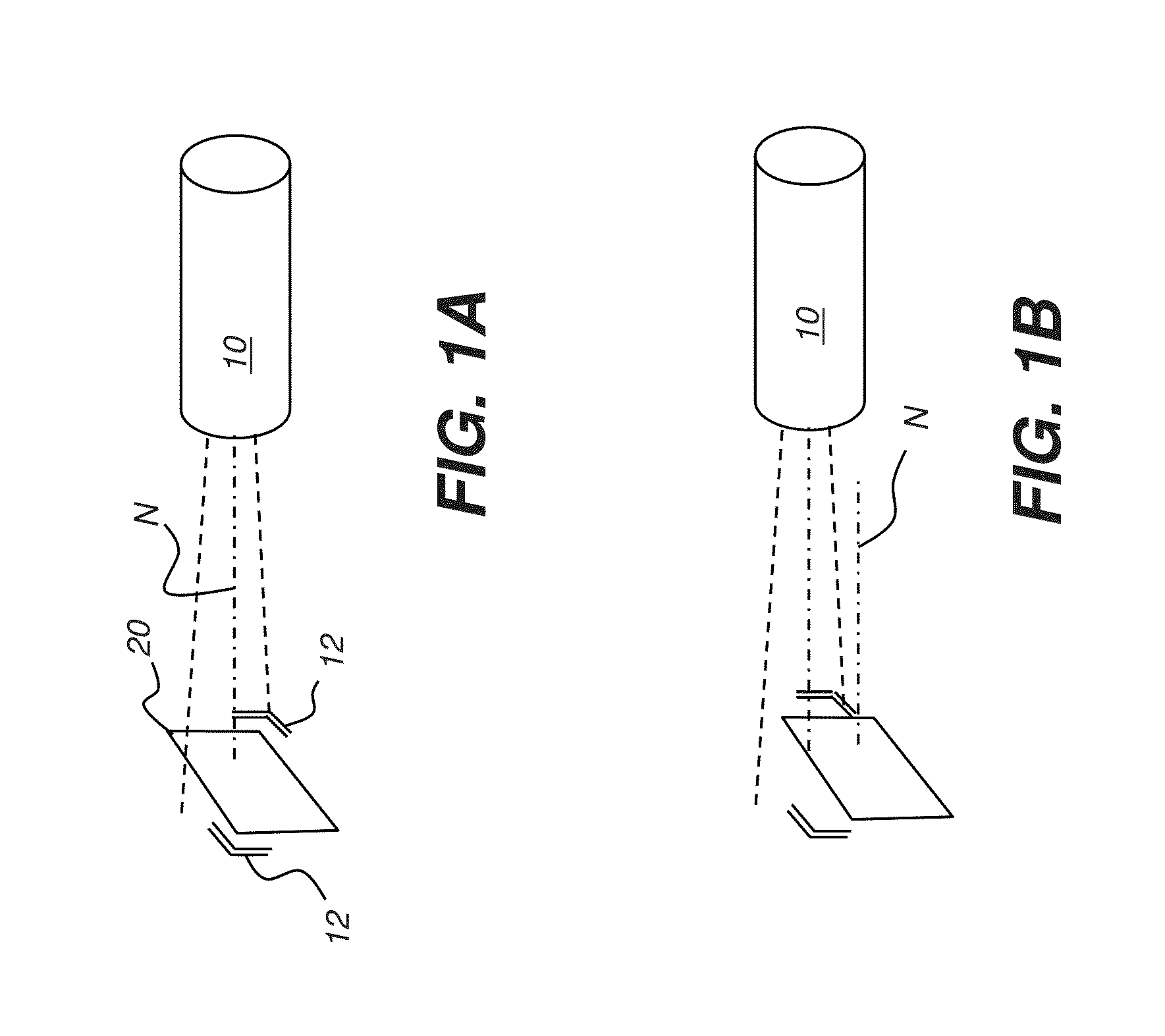

A computed radiography (CR) system for imaging an object is provided. The system includes a radiation source, a storage phosphor screen, an illumination source and a two dimensional imager. The radiation source is configured to irradiate the storage phosphor screen, and the storage phosphor screen is configured to store the radiation energy. The illumination source is configured to illuminate at least a sub-area of the storage phosphor screen to stimulate emission of photons from the storage phosphor screen. The two dimensional (2D) imager is configured to capture a two dimensional image from the storage phosphor screen using the stimulated emission photons. A method of reading a storage phosphor screen is also provided. The method includes illuminating at least a sub-area of the storage phosphor screen using an illumination source to stimulate emission of photons from the storage phosphor screen. The method further includes capturing at least one 2D image using a 2D imager, from at least a sub-array of the storage phosphor screen using the stimulated photons.

Owner:BAKER HUGHES INC

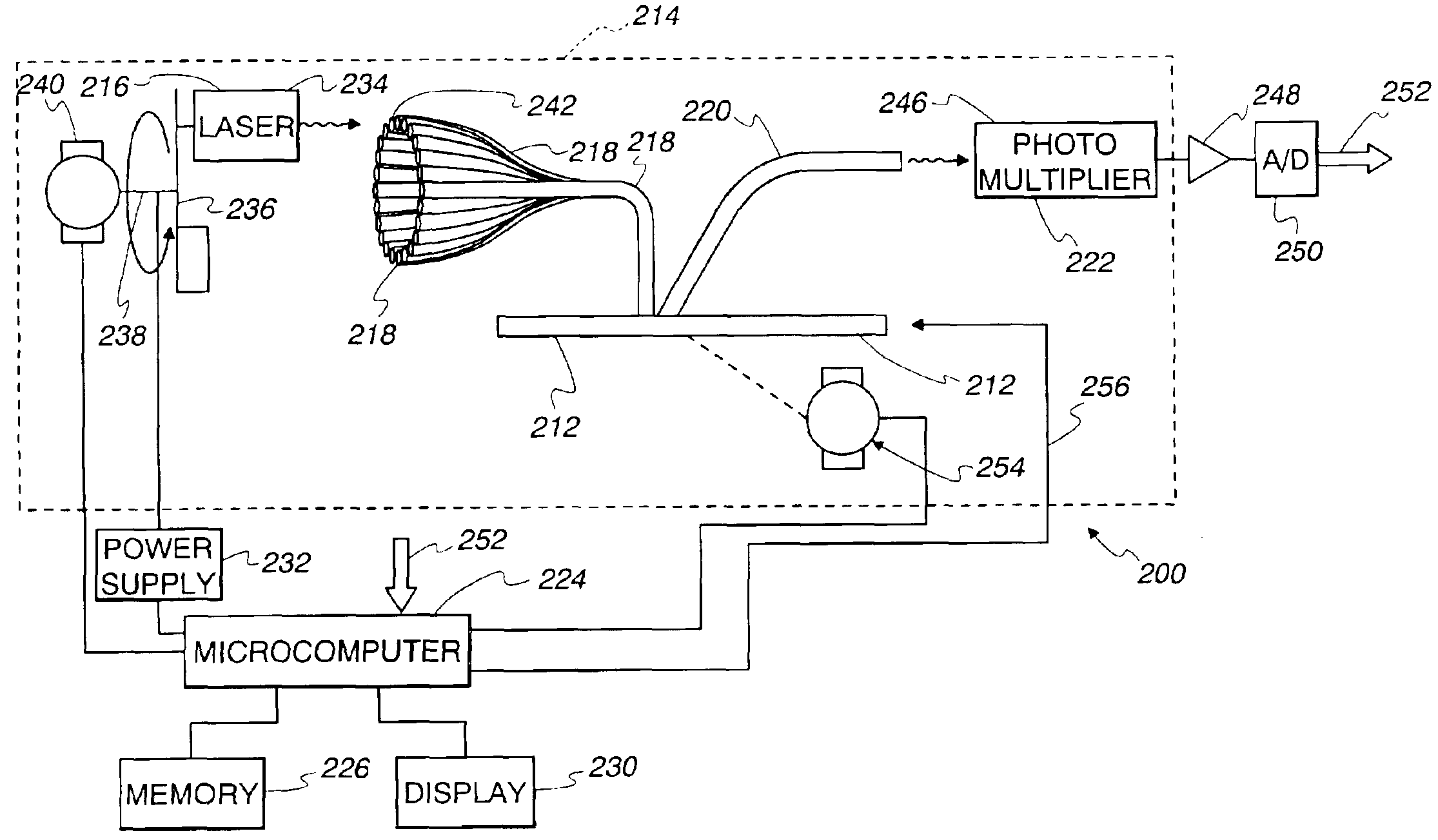

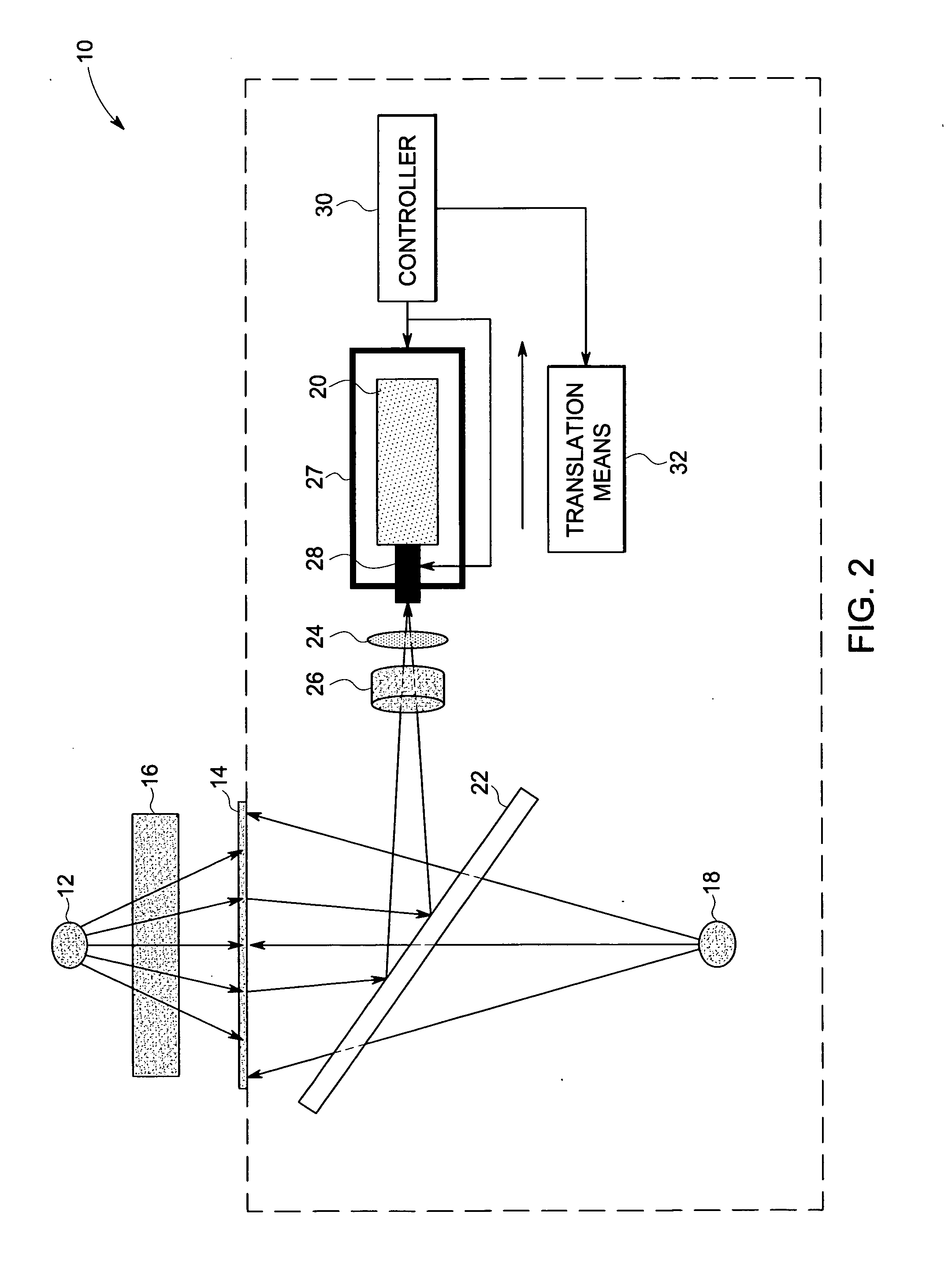

Method and apparatus for radiographic imaging

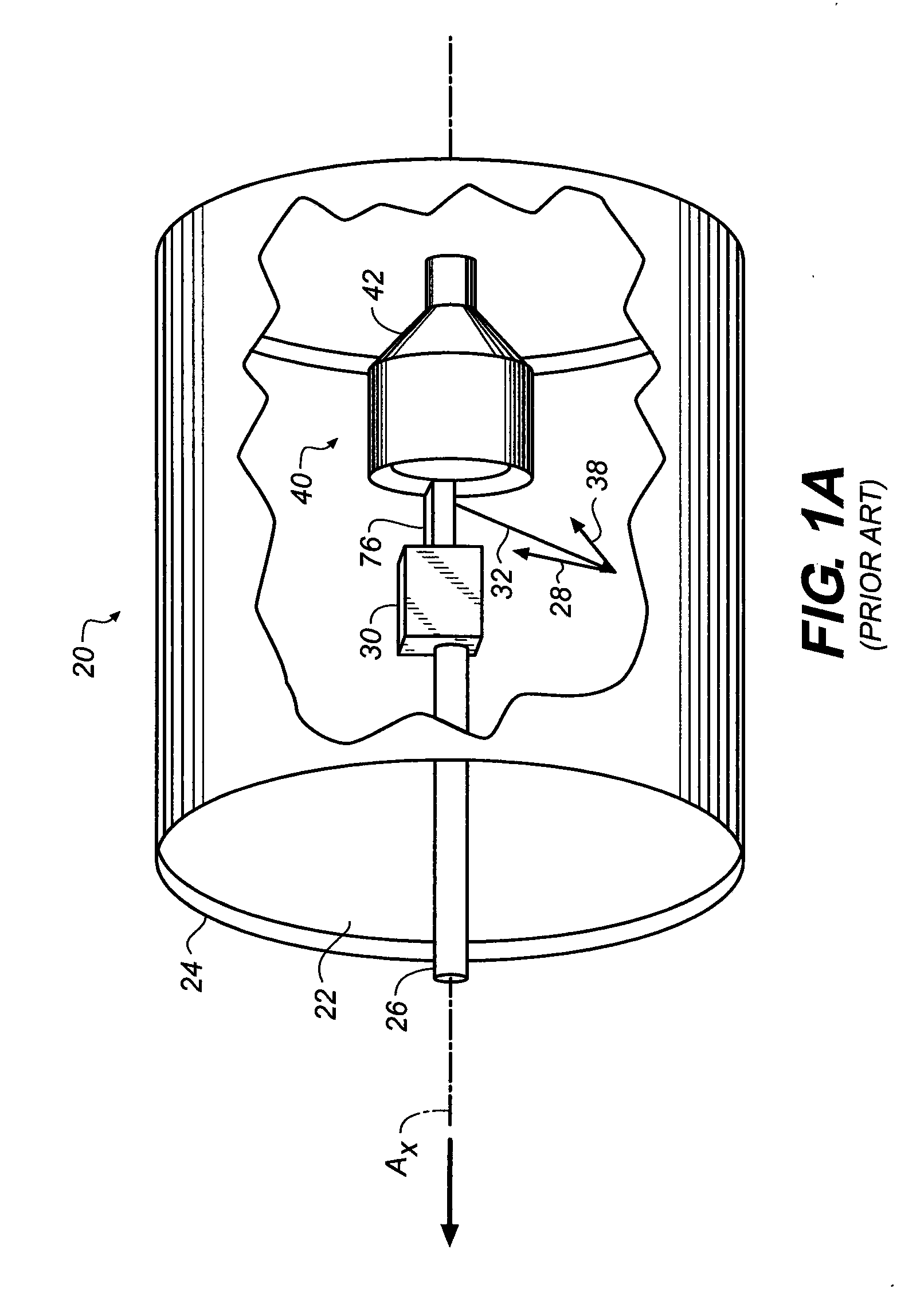

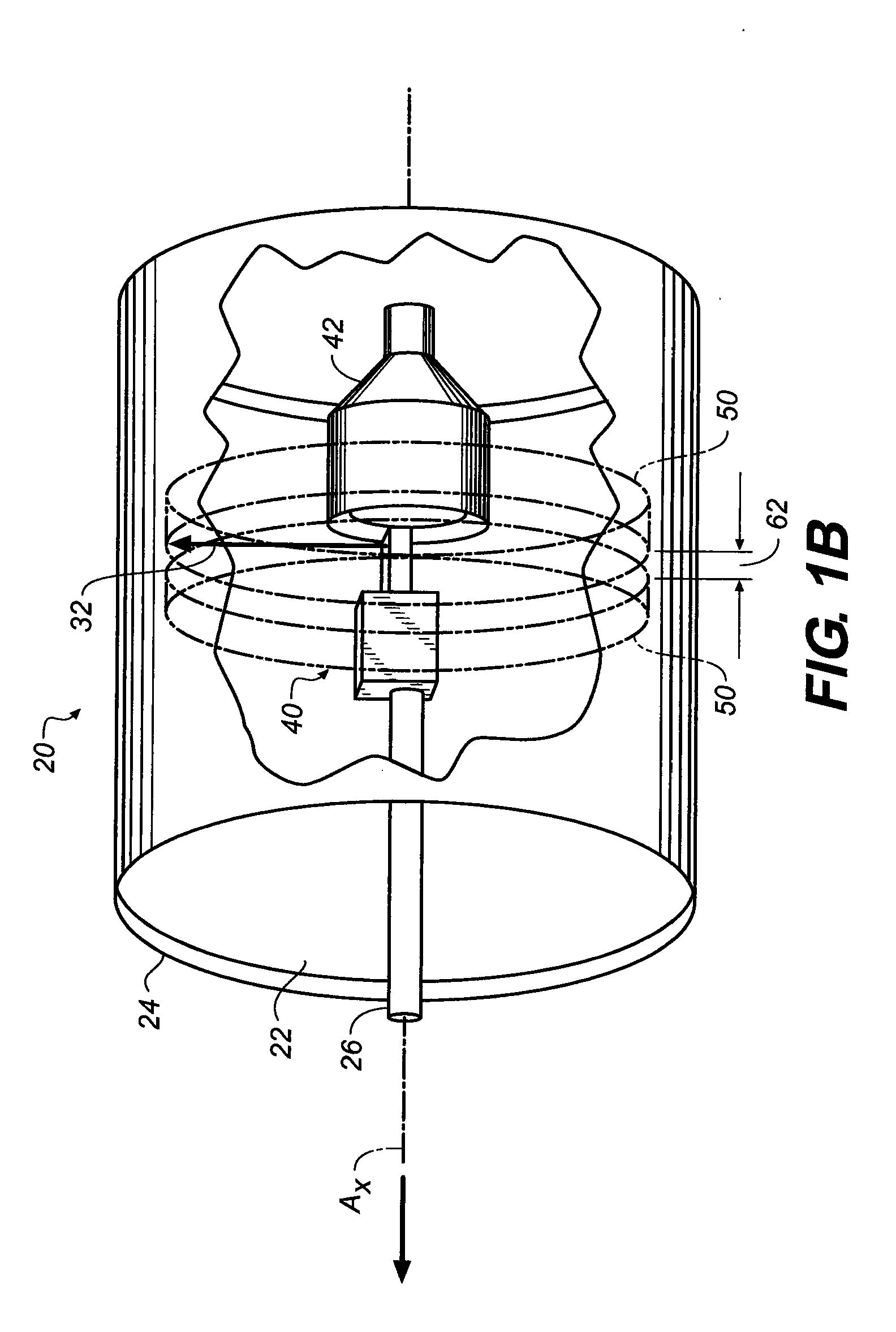

InactiveUS6894303B2Reduce sensitivityEliminate other problemPhotometryMaterial analysis by optical meansFiberRotational axis

An apparatus and method for computed radiography includes a rotating laser as a pumping source for delivering light, without the use of a rotating mirror, successively to ends of each of a plurality of optical fibers arranged in an arc. Opposite ends of the optical fibers are arranged in a linear array to a previously-exposed computed radiography plate having a latent X-ray image formed thereon. The plate is moved with respect to the fibers. Light emitted from the radiographic medium due to excitation by the pumping light travels through a light guide to an optical receiver where an image signal responsive to the light intensity of the emitted light is generated. The image signal is sent to a processor to generate an image representative of the latent X-ray. An erasing of the latent x-ray image may be accomplished in the same machine apparatus that generates the representative image. Preferably, multiple erasure operations are performed with a relaxation period, e.g., three to ten seconds between successive erasing operations. The laser is accurately positioned by an adjustment mechanism in an axial direction to focus the laser light on receiving optical fiber ends and in a radial direction to align the rotational axis substantially coaxially to the axis of the arc for the optical fibers. Electrical power is delivered through a brush and contact to leads in a rotating drive shaft for the rotating laser. The preferred light guide comprises an inlet positioned to receive phosphorescent light from the imaging plate and rearward and forward reflective surfaces for reflecting incoming light back and forth within the light guide that was not directly aligned for travel along a straight line path directly to the light collector, e.g., a photomultiplier tube. A substantial portion of this reflected light will eventually travel forwardly along a path of travel to hit the photomultiplier tube.

Owner:ESSEX ELECTRO ENGINEERS

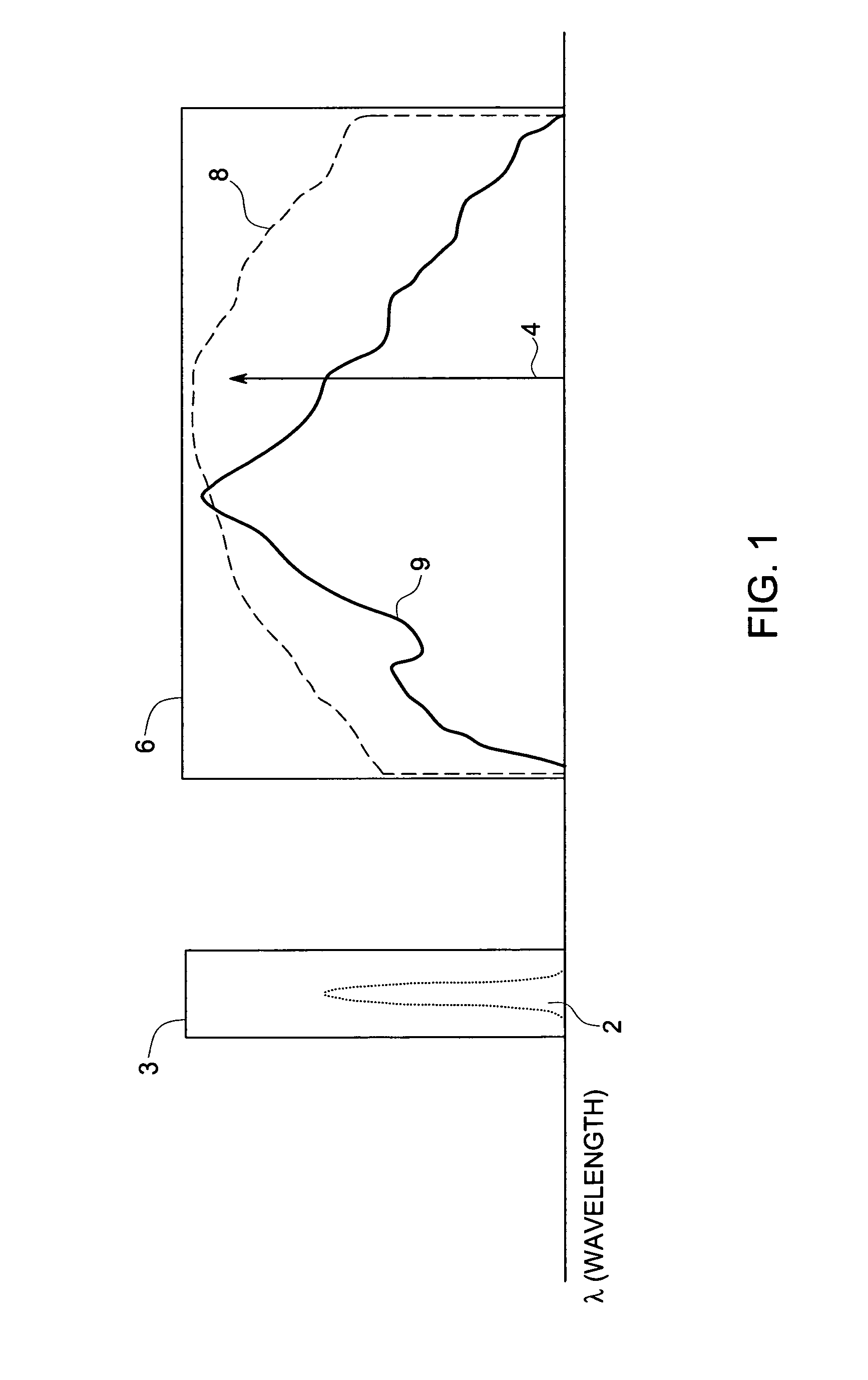

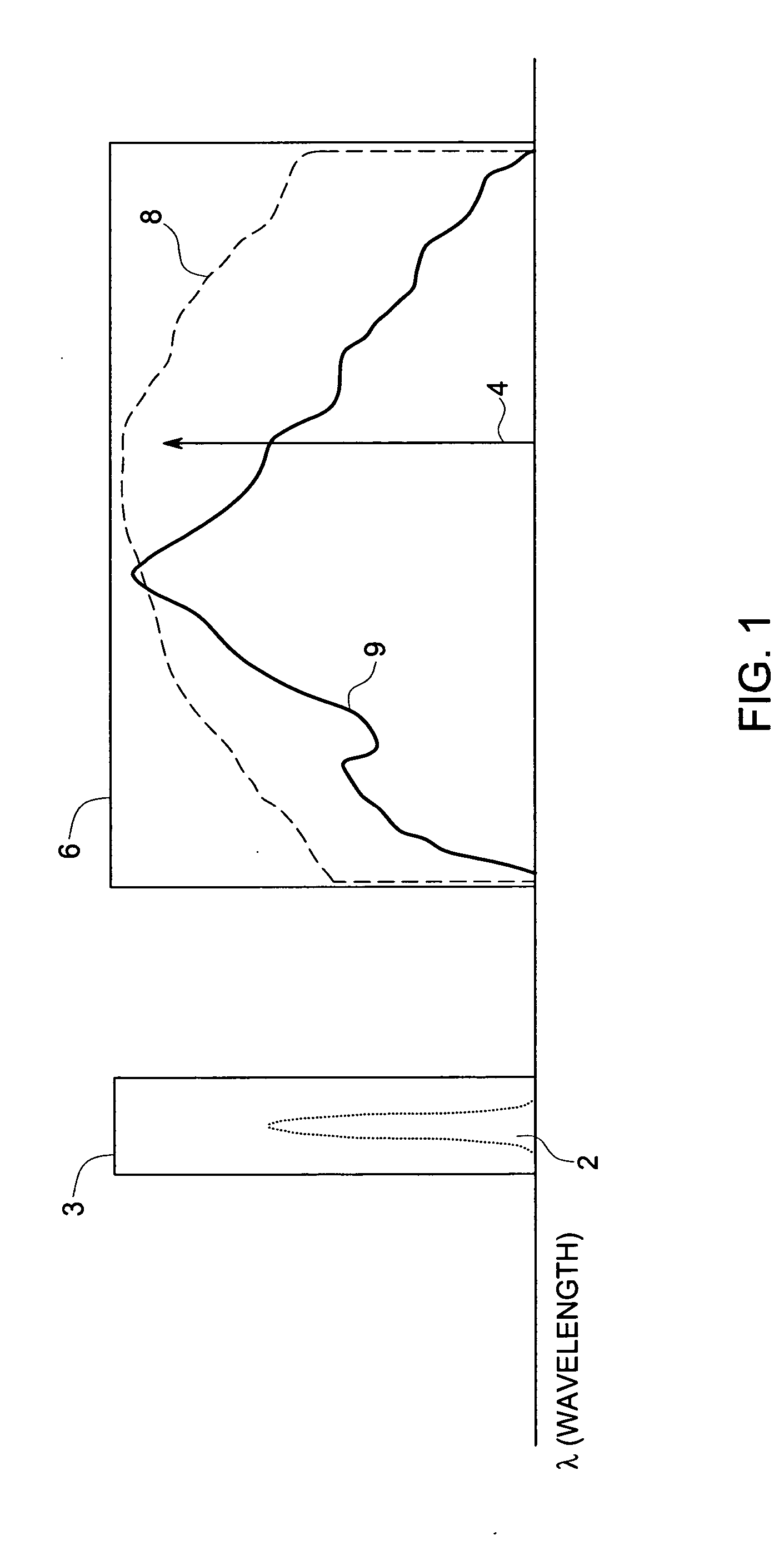

Adaptive image processing and display for digital and computed radiography images

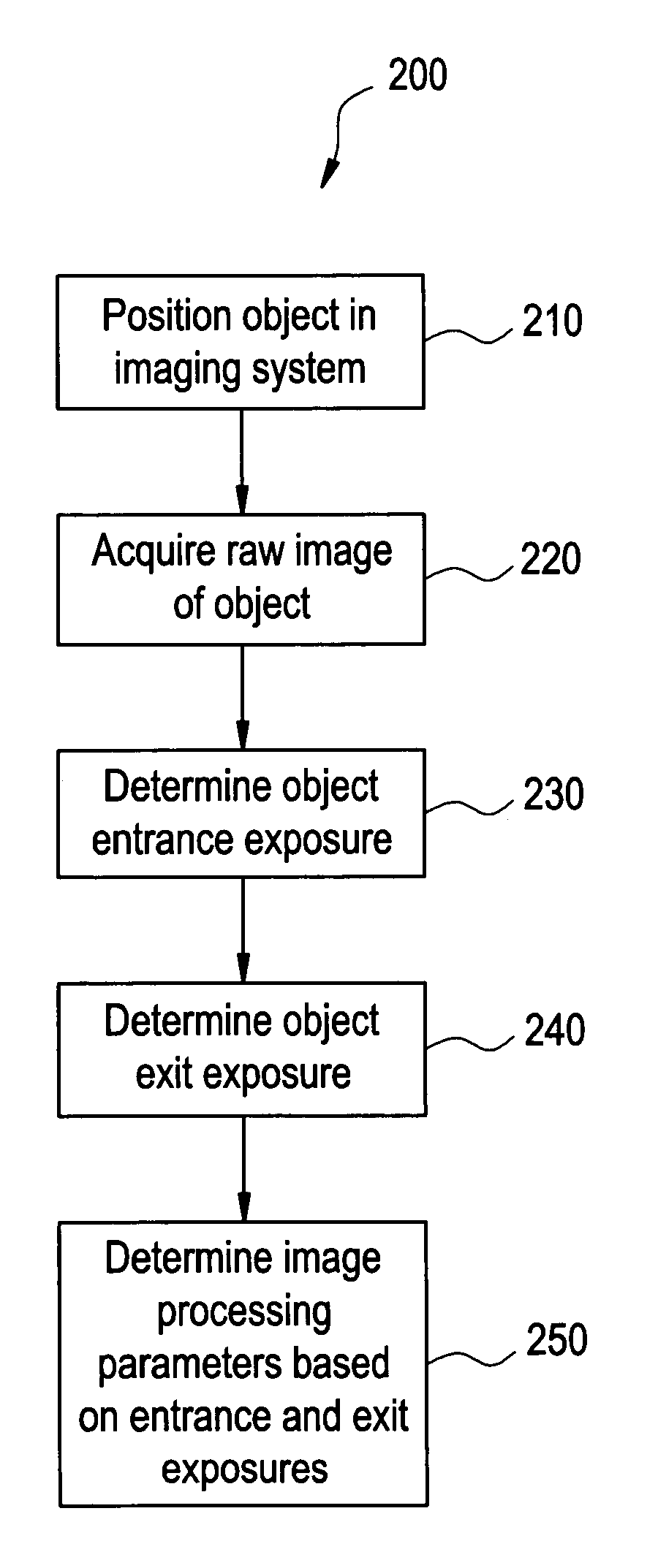

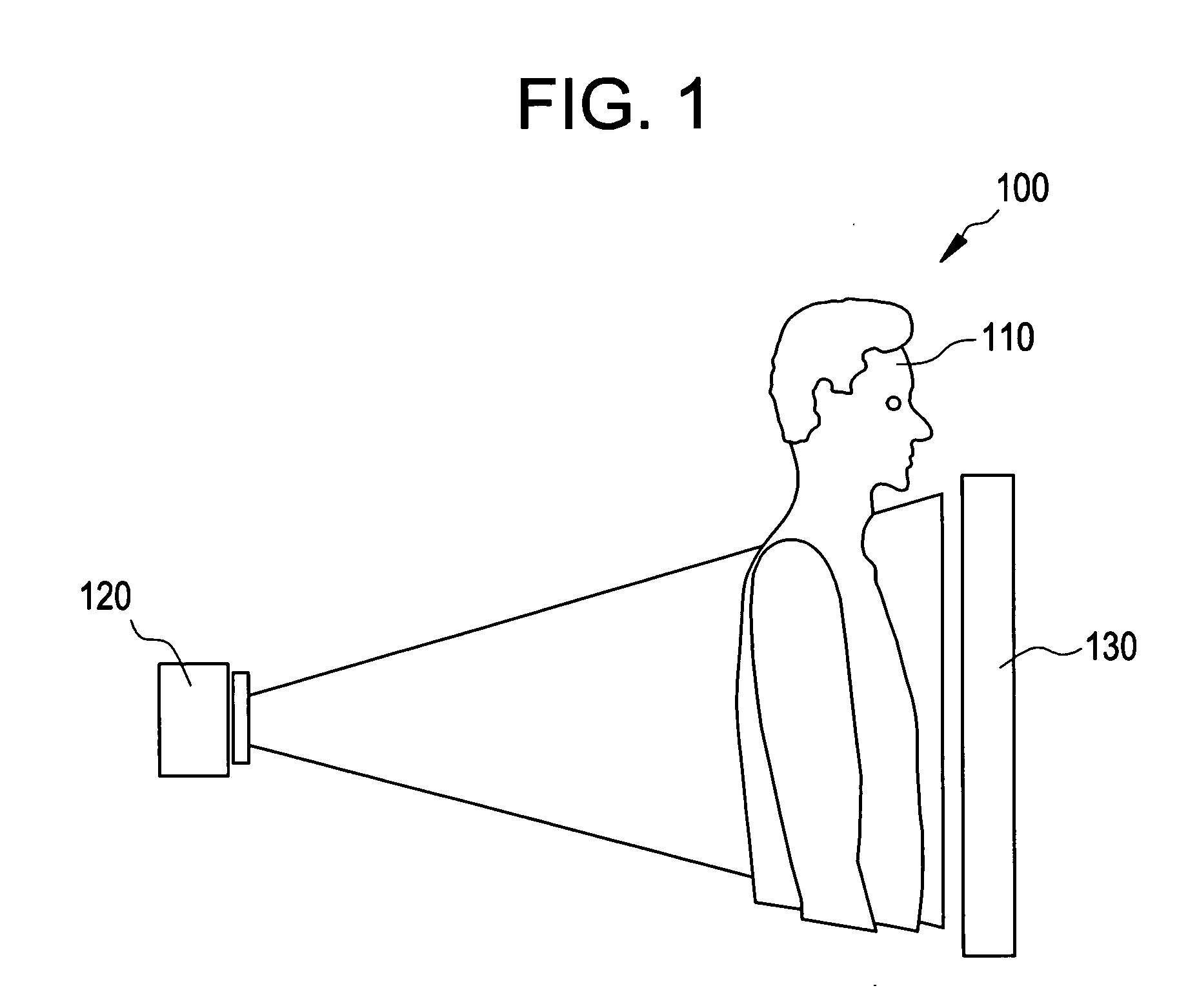

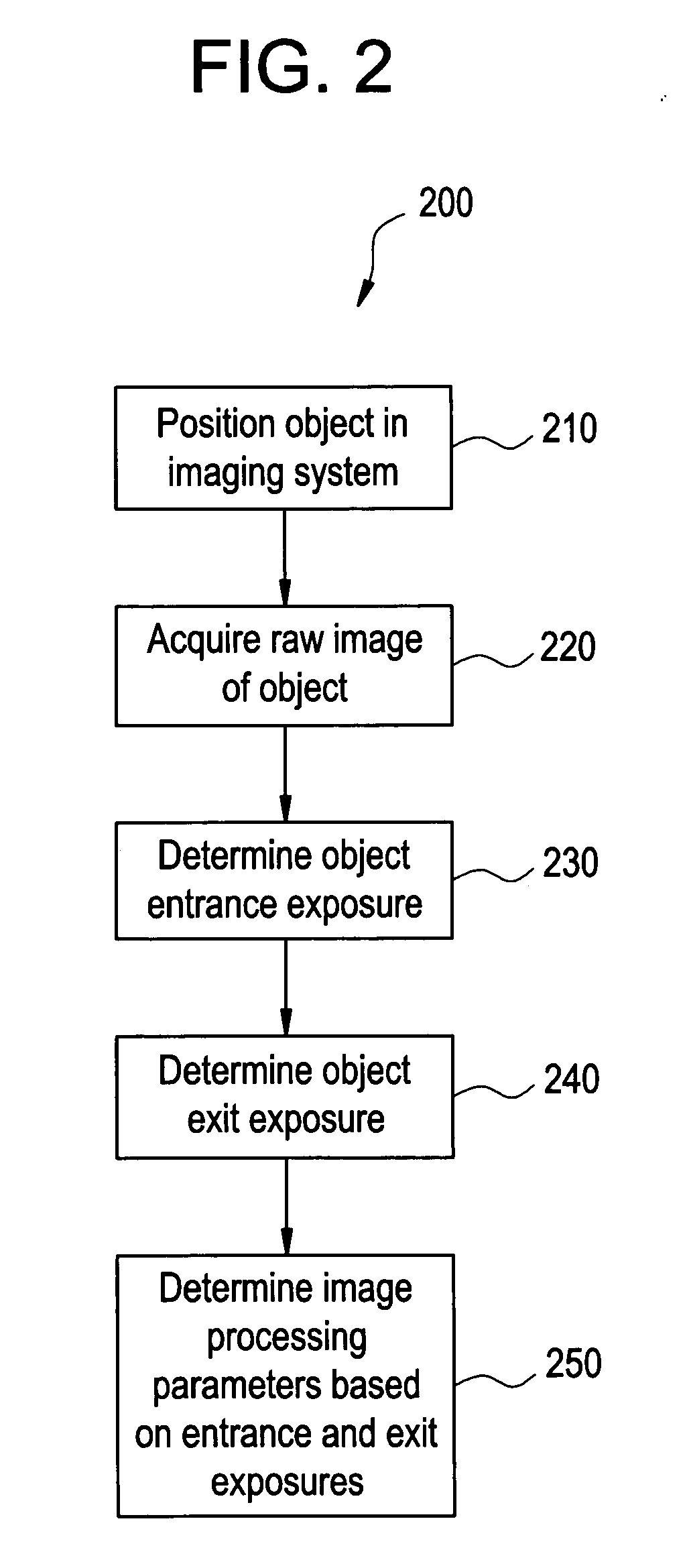

ActiveUS20070116348A1Wavelength-division multiplex systemsCharacter and pattern recognitionUltrasound attenuationImaging processing

The presently described technology provides a method for adaptive image processing. The image processing method includes determining an entrance exposure of an object, determining an exit exposure of the object, and determining one or more image processing parameters based at least in part on the entrance and exit exposures. The presently described technology also provides a method for adaptive image display. The image display method includes determining an entrance exposure of an object, determining an exit exposure of the object, and displaying an attenuation map based at least in part on the entrance and exit exposures.

Owner:GENERAL ELECTRIC CO

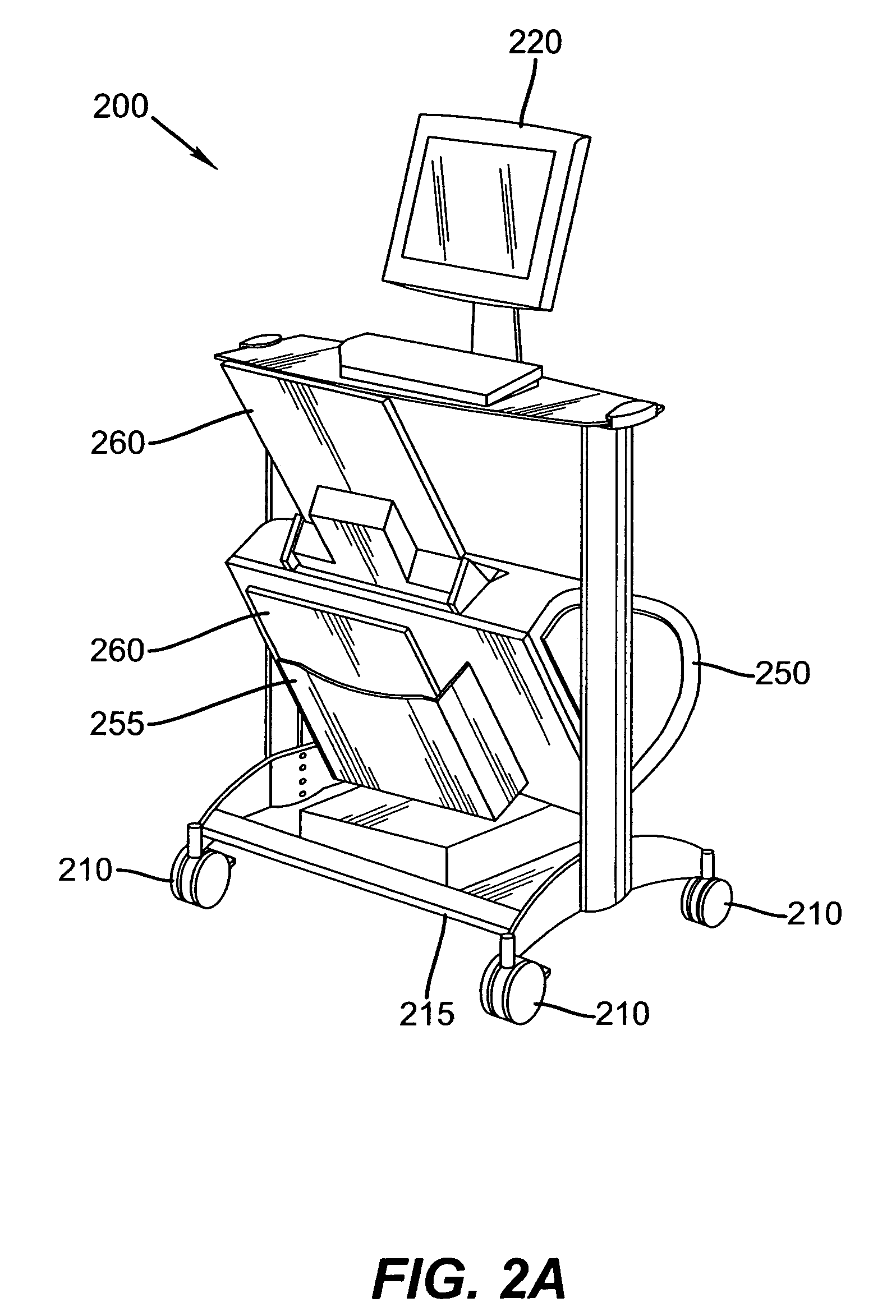

Mobile computed radiography and digital radiography

InactiveUS20090034688A1Easy to transportCathode ray tubes/electron beam tubesX-ray apparatusImage recordingDisplay device

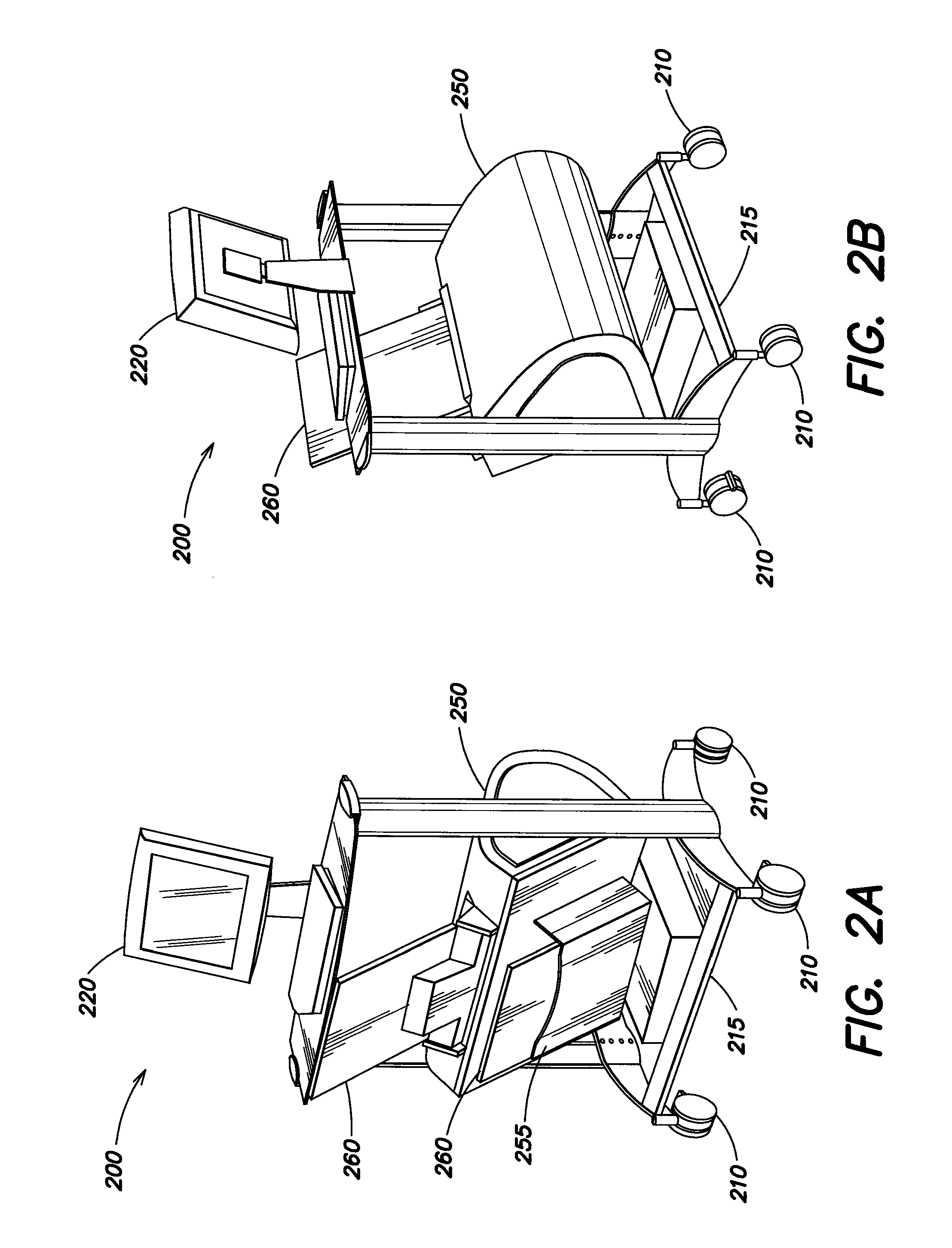

A mobile apparatus. The mobile radiography apparatus includes: a frame; a transport mechanism coupled to the frame, the transport mechanism adapted to facilitate transport of the mobile apparatus between locations; an x-ray source mounted to the frame; a computed radiography (CR) scanner coupled to the frame and adapted to acquire one or more images from an image recording medium; a storage area disposed on the frame configured to removably retain at least one digital radiography (DR) detector; and a display coupled to the frame and connected to the CR scanner and the DR detector to display the one or more images acquired by the CR scanner or DR detector.

Owner:CARESTREAM HEALTH INC

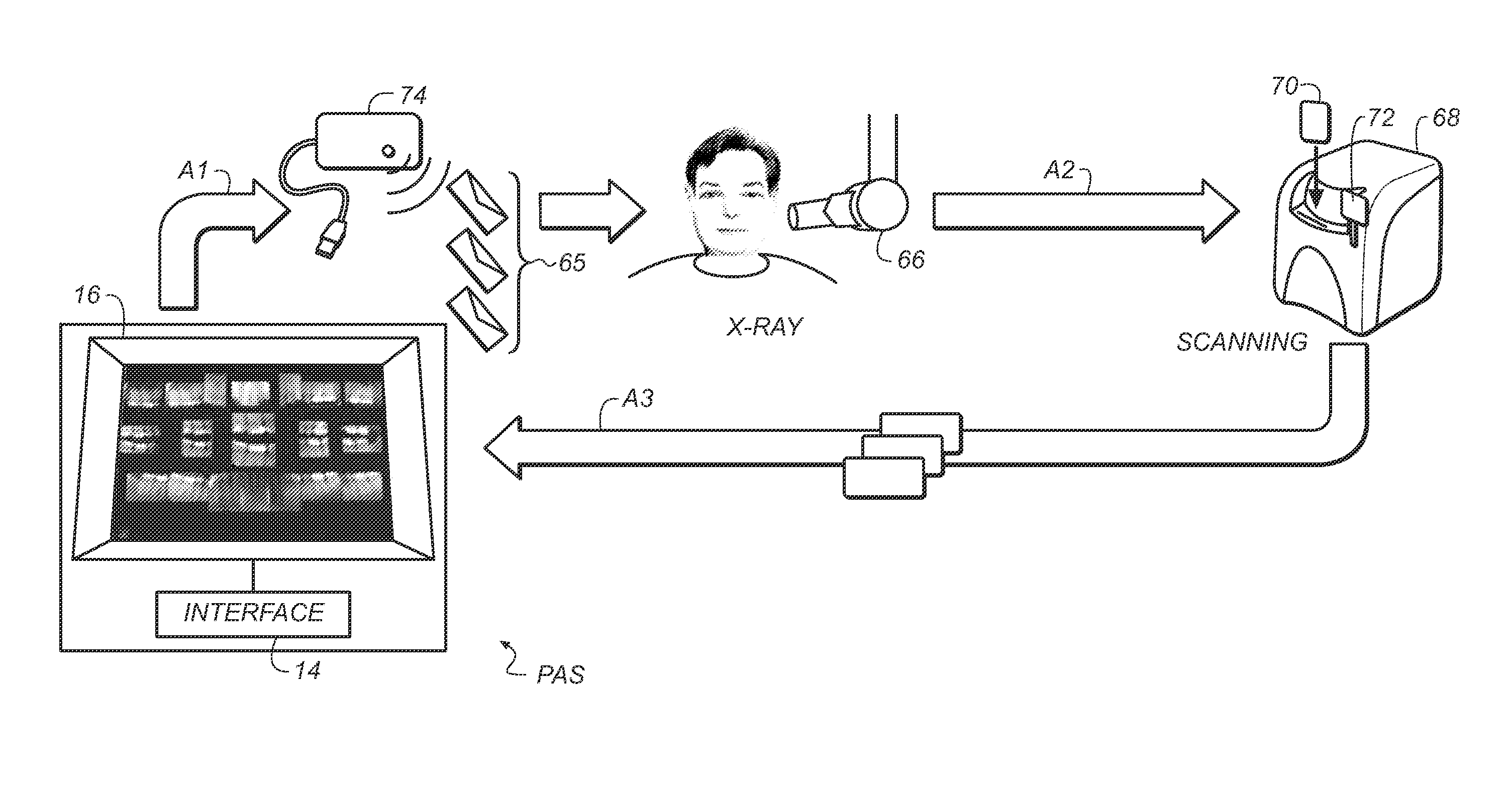

Method and system for computed radiography

InactiveUS20120001737A1Simple and convenient and reliablePrevent their inadvertent or intentional mismatchSensing record carriersMedical imagesX-rayX ray image

A method for obtaining an X-ray image of a subject on a flexible information carrier plate for computed radiography. A memory is affixed to a surface of the plate, wherein the affixed memory stores information about the plate and is in wireless communication with a computer. A first scan date is stored in the affixed memory. Obtaining the X-ray image uses steps of storing at least a job identifier and a scan status for the plate in the affixed memory; acquiring image data from a scan of the plate following exposure to X-rays, acquiring at least the job identifier from the affixed memory, and associating the acquired image data with the acquired job identifier; incrementing a scan count value and updating the scan status in the affixed memory; erasing image content from the plate; and storing the acquired image data in a second, computer-accessible memory according to the acquired job identifier.

Owner:CARESTREAM HEALTH INC

X-ray CR (computed radiography) detection method of aeronautical composite honeycomb structural component

InactiveCN103512906ARealize the digitization of radiographic inspectionAvoid harmMaterial analysis by transmitting radiationAviationX-ray

The invention discloses an X-ray CR (computed radiography) detection method of an aeronautical composite honeycomb structural component. The X-ray CR detection method of the aeronautical composite honeycomb structural component comprises the following steps: designing and manufacturing an artificial defect test block of a honeycomb structural component; manufacturing an artificial defect standard film; performing X-ray CR detection and traditional film X-ray detection on the artificial defect test block for equivalence analysis; optimizing X-ray CR detection imaging parameters. The X-ray CR detection method of the aeronautical composite honeycomb structural component has the advantages as follows: detection on the composite honeycomb structural component in the field of aviation by a CR X-ray detection technology is achieved, and digitalization of ray detection on the composite honeycomb structural component is achieved so as to improve the detection efficiency, the detection effect, the sensitivity, the resolution and the video effect better by a digital technology; an integral detection process is relatively conducive to application of the technology to the composite honeycomb structural component; an IP (image plate) in the CR technology replaces the conventional film, so that the detection cost can be saved to a great extent and damage of a great deal of waste liquid to the environment brought by film processing is avoided.

Owner:航天海鹰(镇江)特种材料有限公司

Computed radiography system

InactiveUS20110001052A1Material analysis by optical meansRadiation intensity measurementLatent imageFluorescence

A computed radiography system comprises a radiation detecting system wherein an image is formed by the steps of (1) exposing an object to radiation; (2) forming a first digitized image directly captured from said radiation by a detector; (3) storing said digitized image from said radiation on an intermediate medium; (4) forming a latent image originating from the same radiation, as an image stored in a photostimulable phosphor layer, and (5) retrieving said directly captured digitized image and superposing it onto a digitized image originating from said latent image in said photostimulable phosphor layer after photostimulation of said phosphor layer with radiation having a lower energy than the said exposure radiation.

Owner:T2PHARMA GMBH

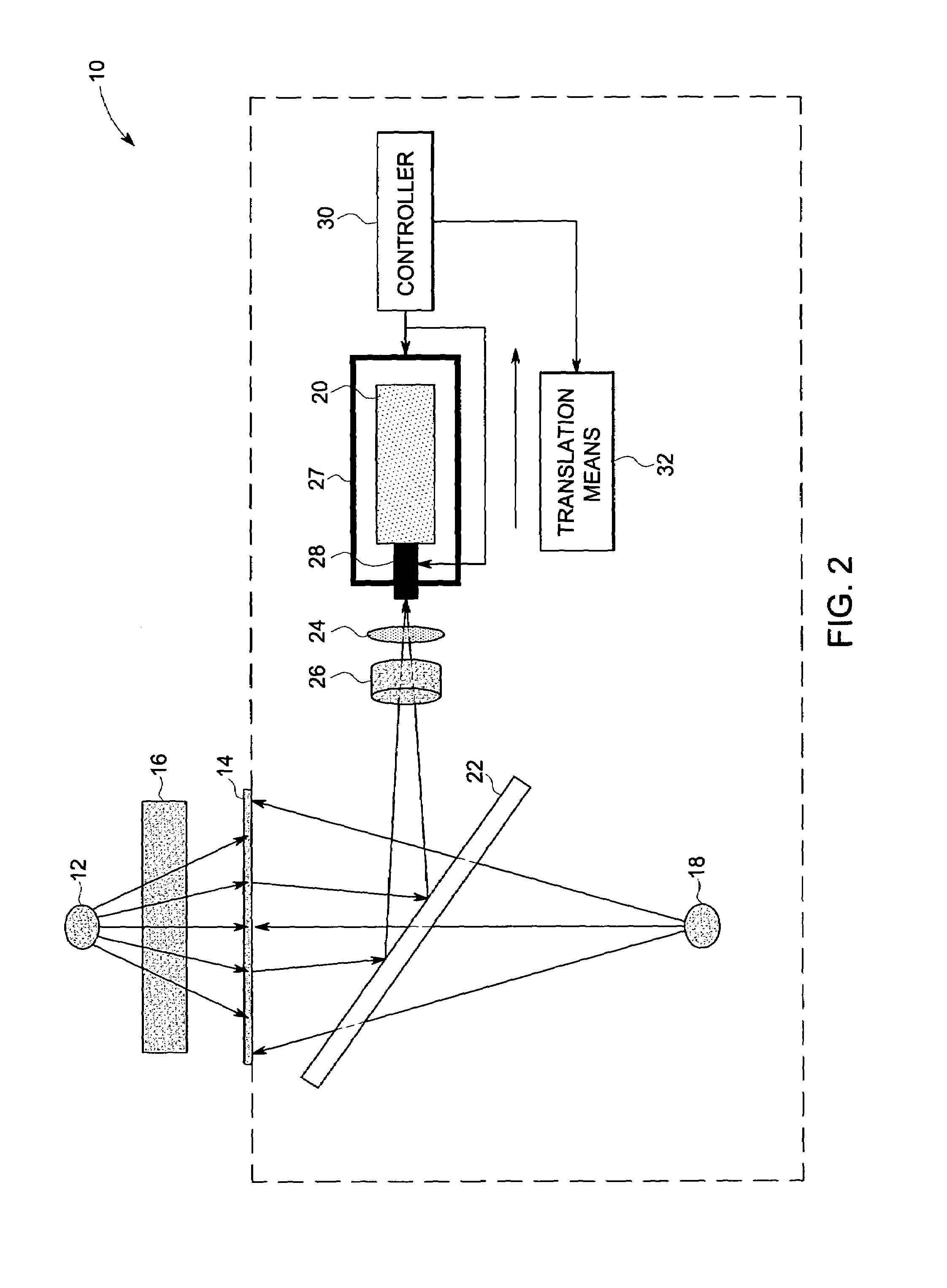

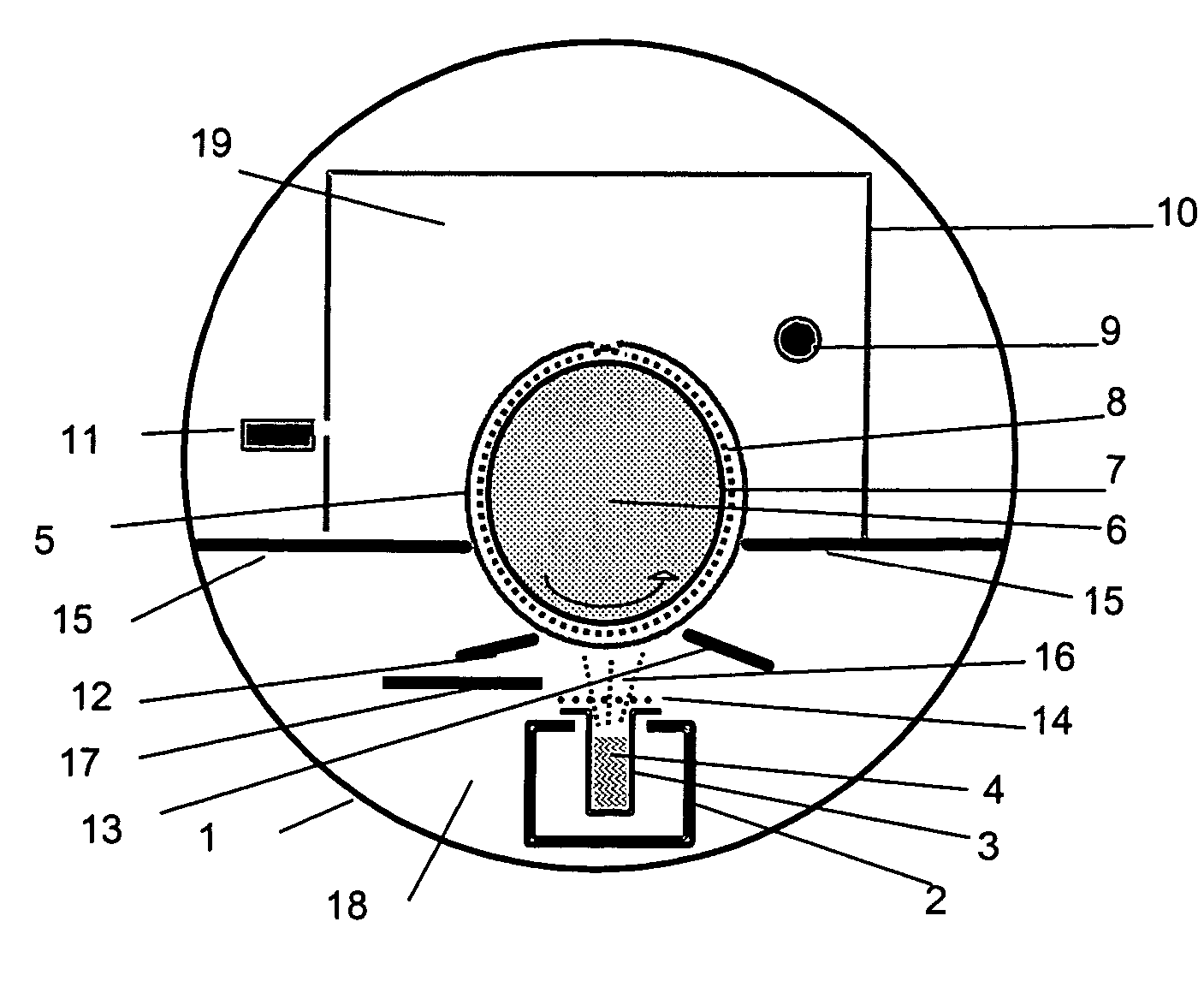

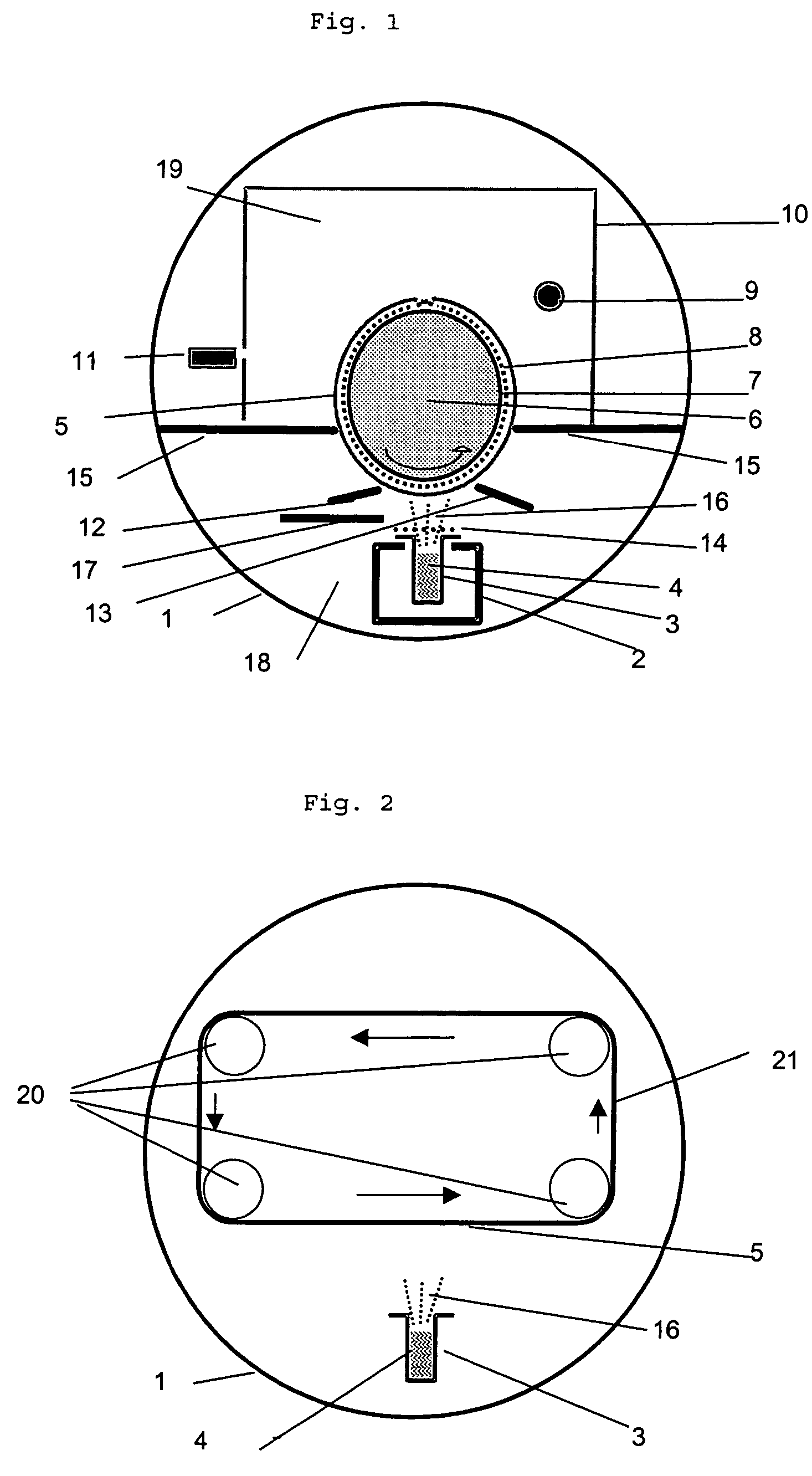

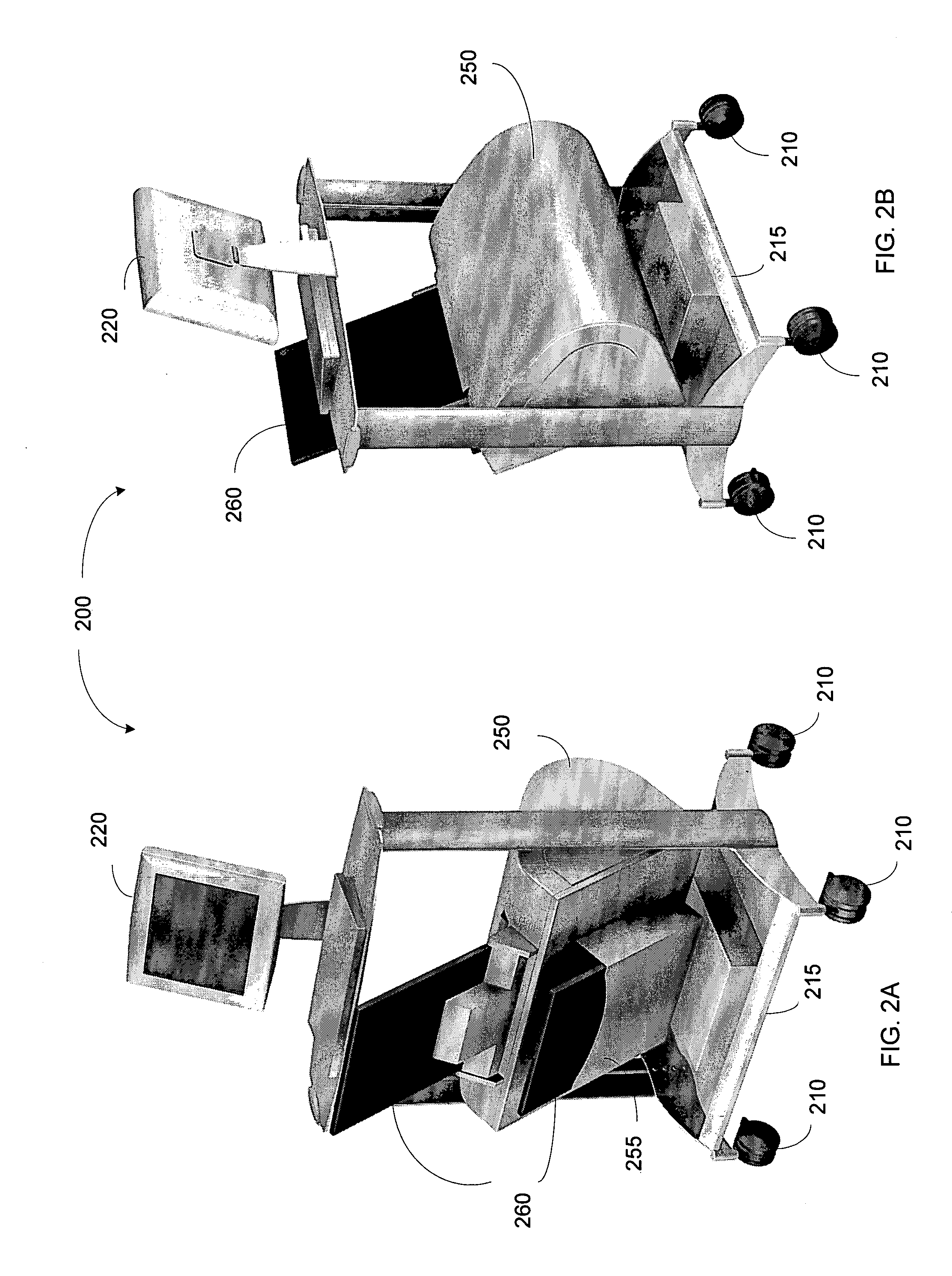

Enhanced light detector for computed radiography

InactiveUS20100243925A1Stable internal performanceMaterial analysis by optical meansRecord information storageFluorescencePhosphor

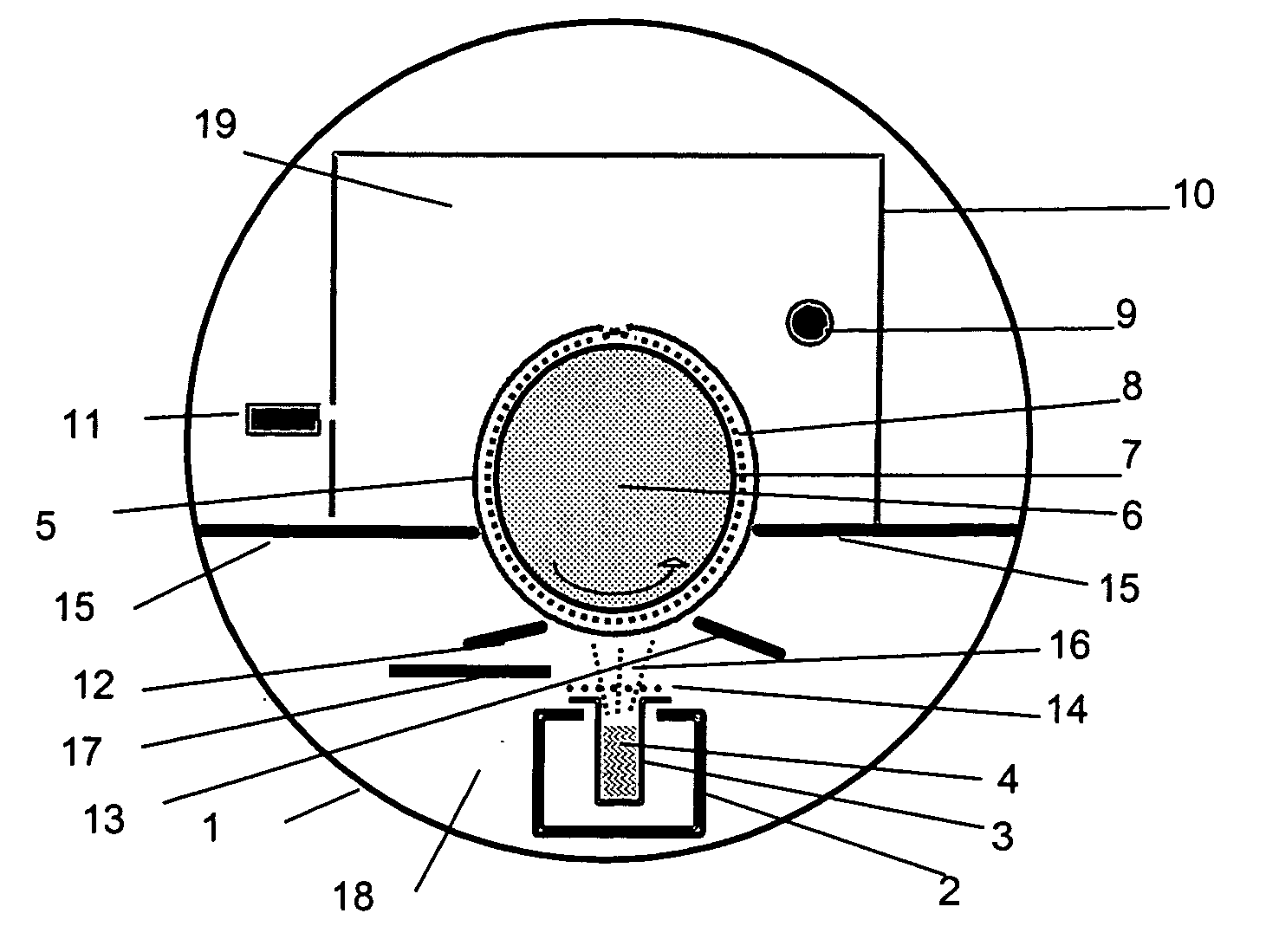

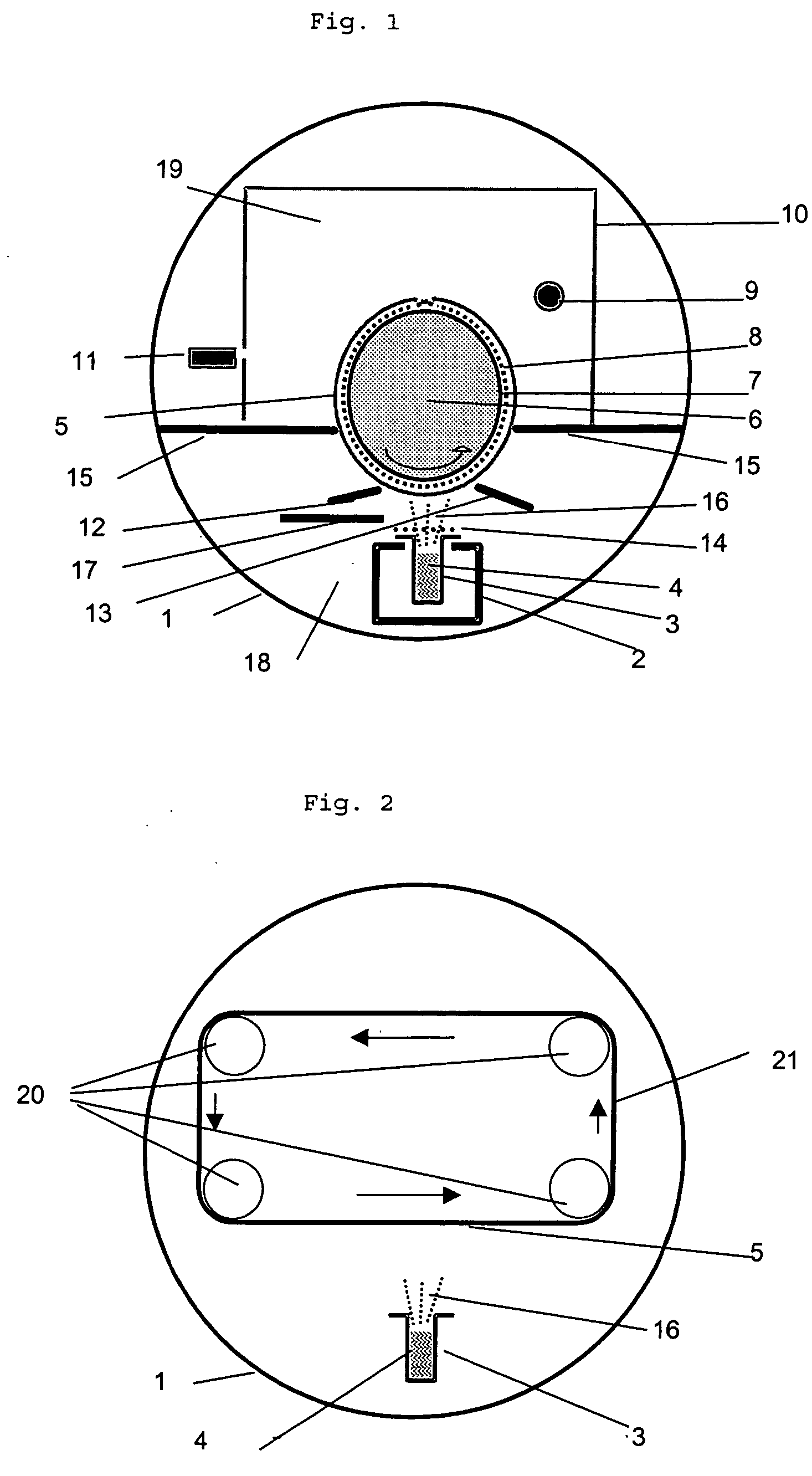

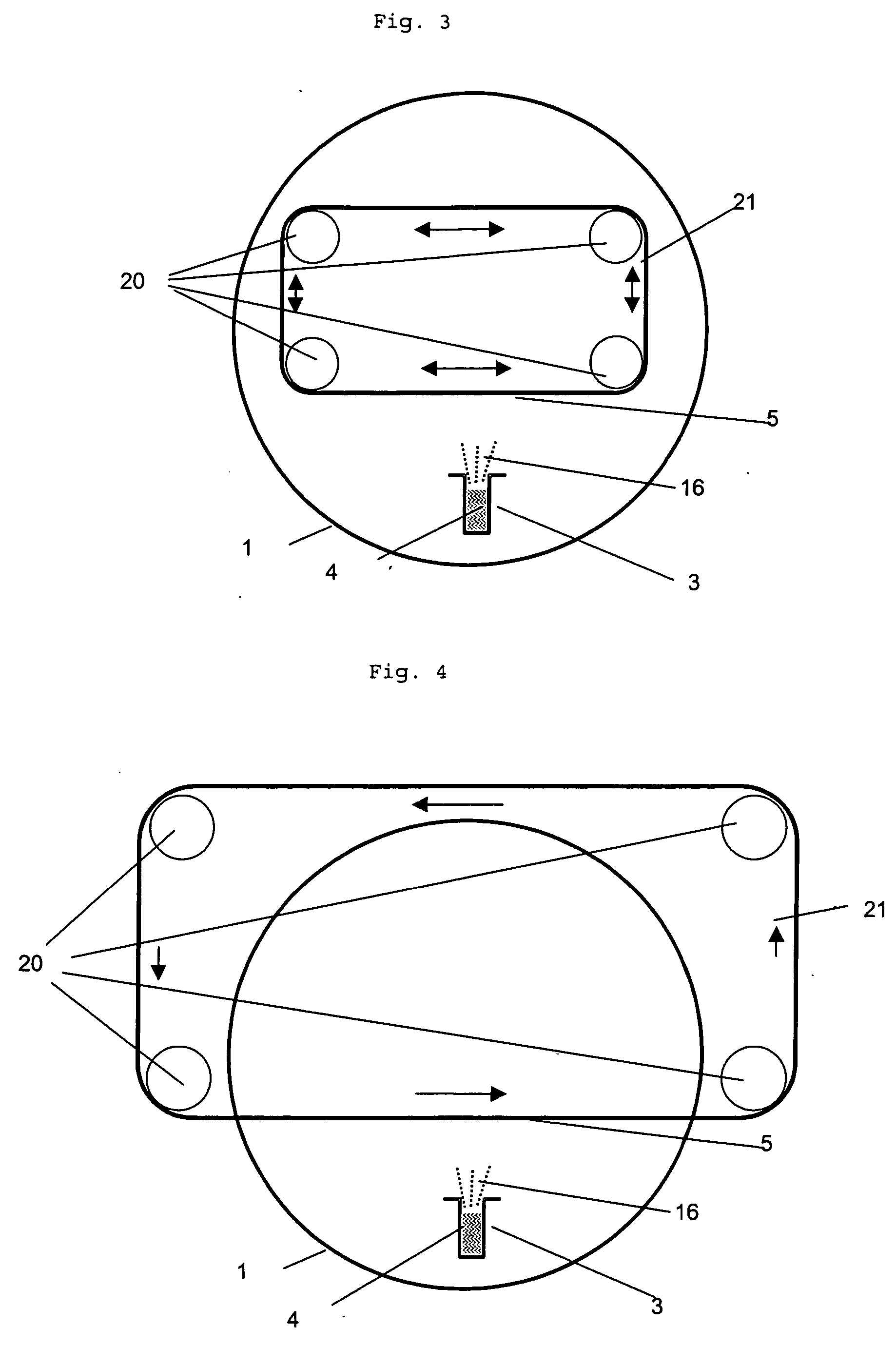

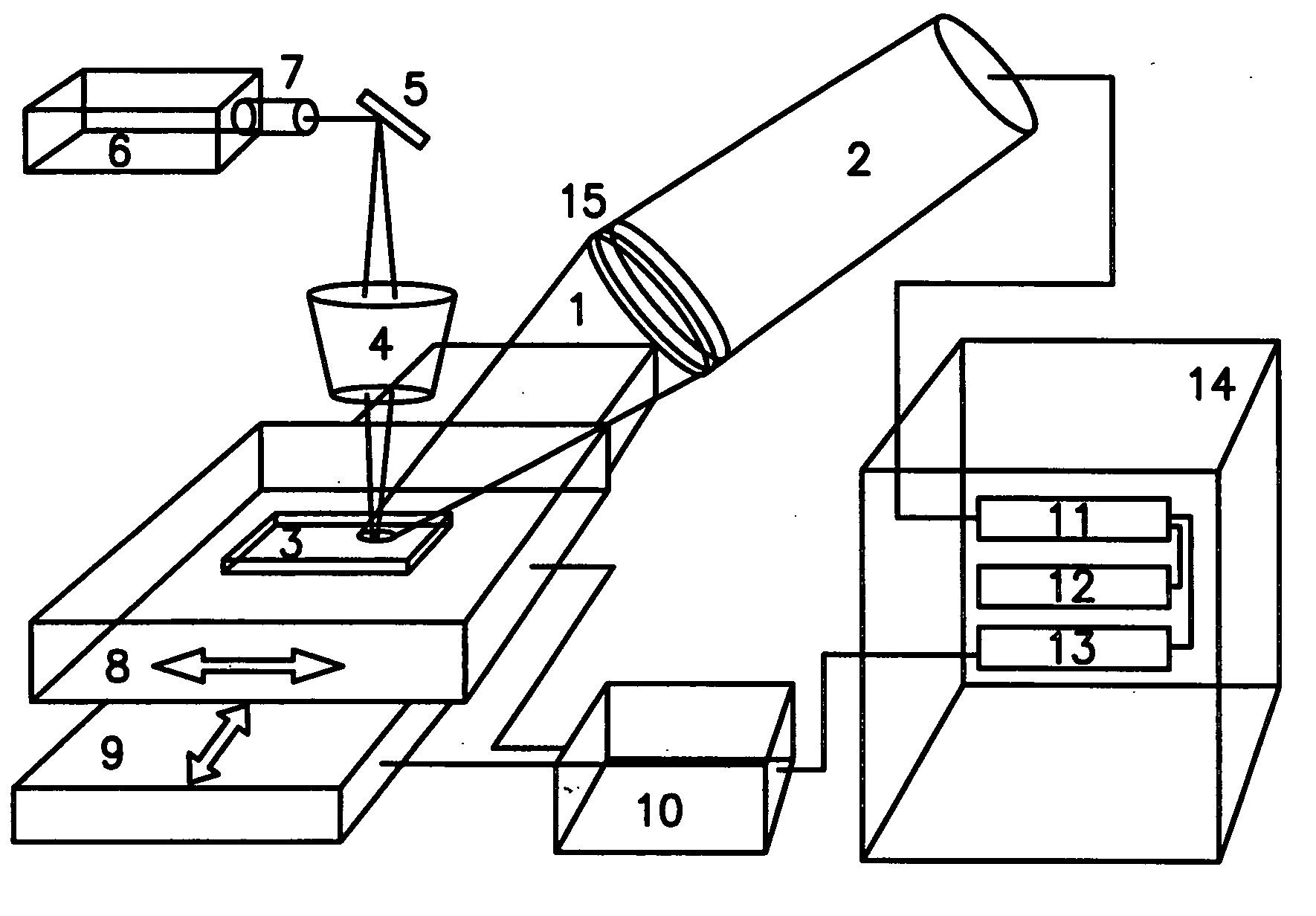

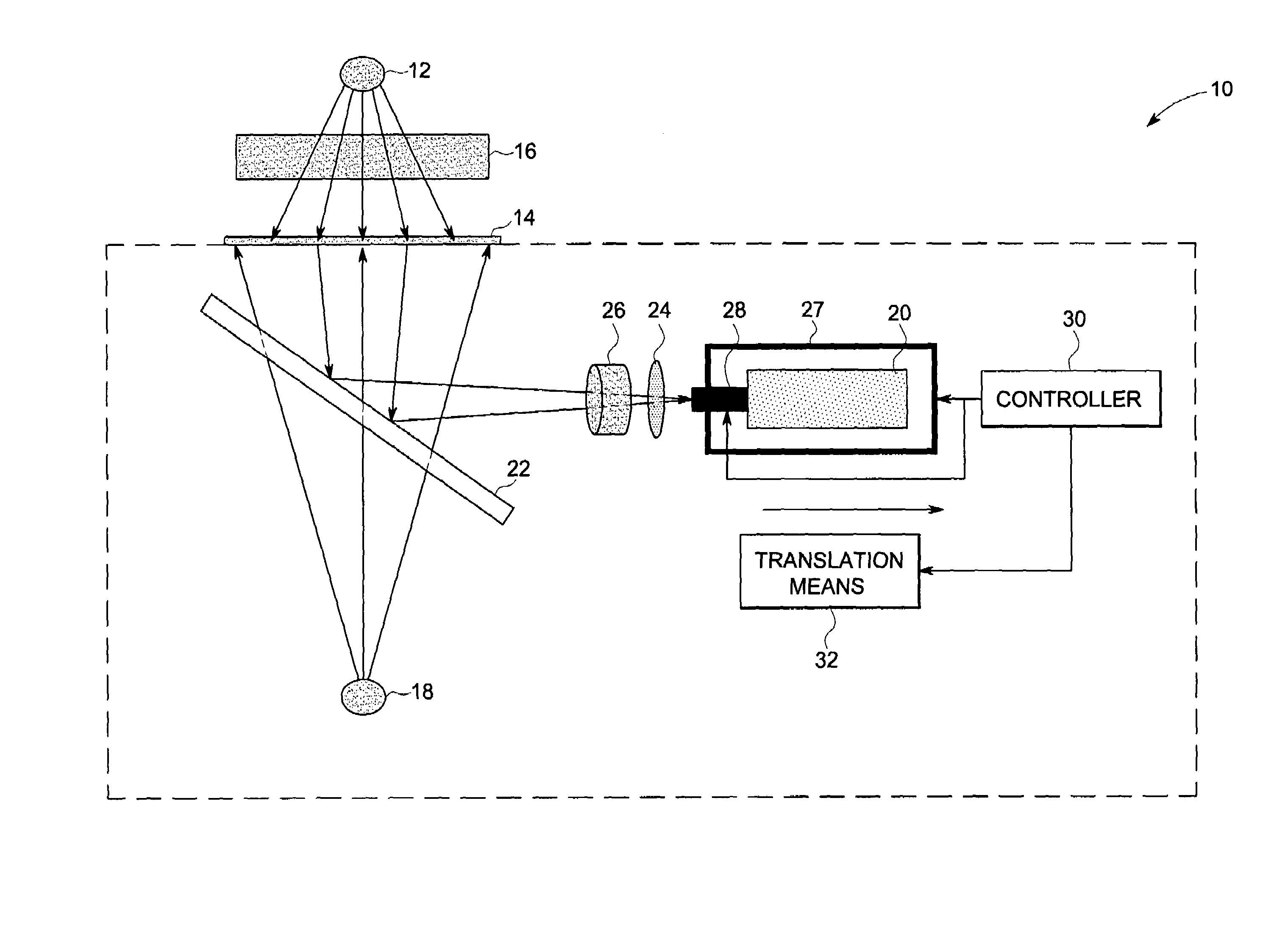

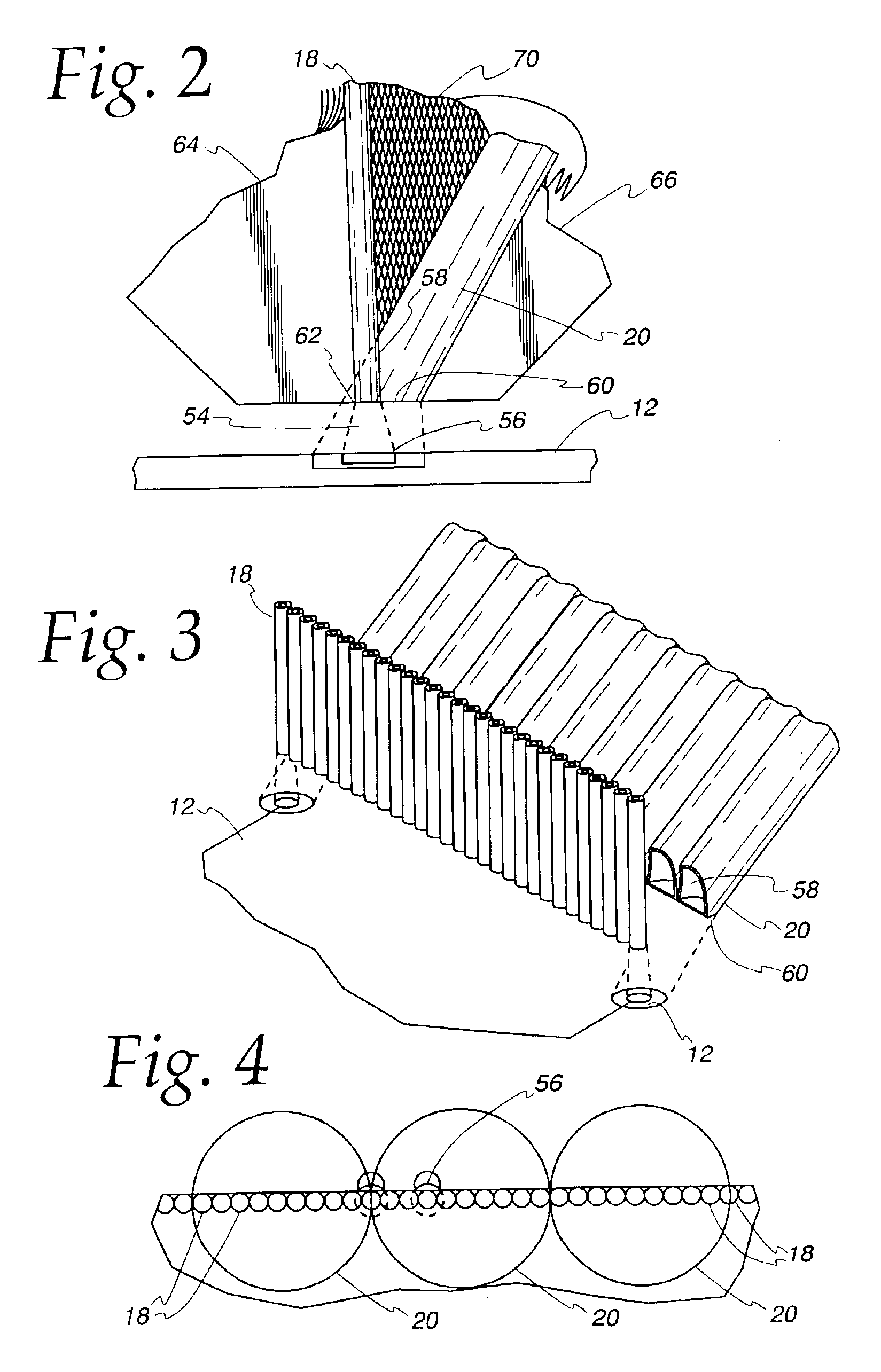

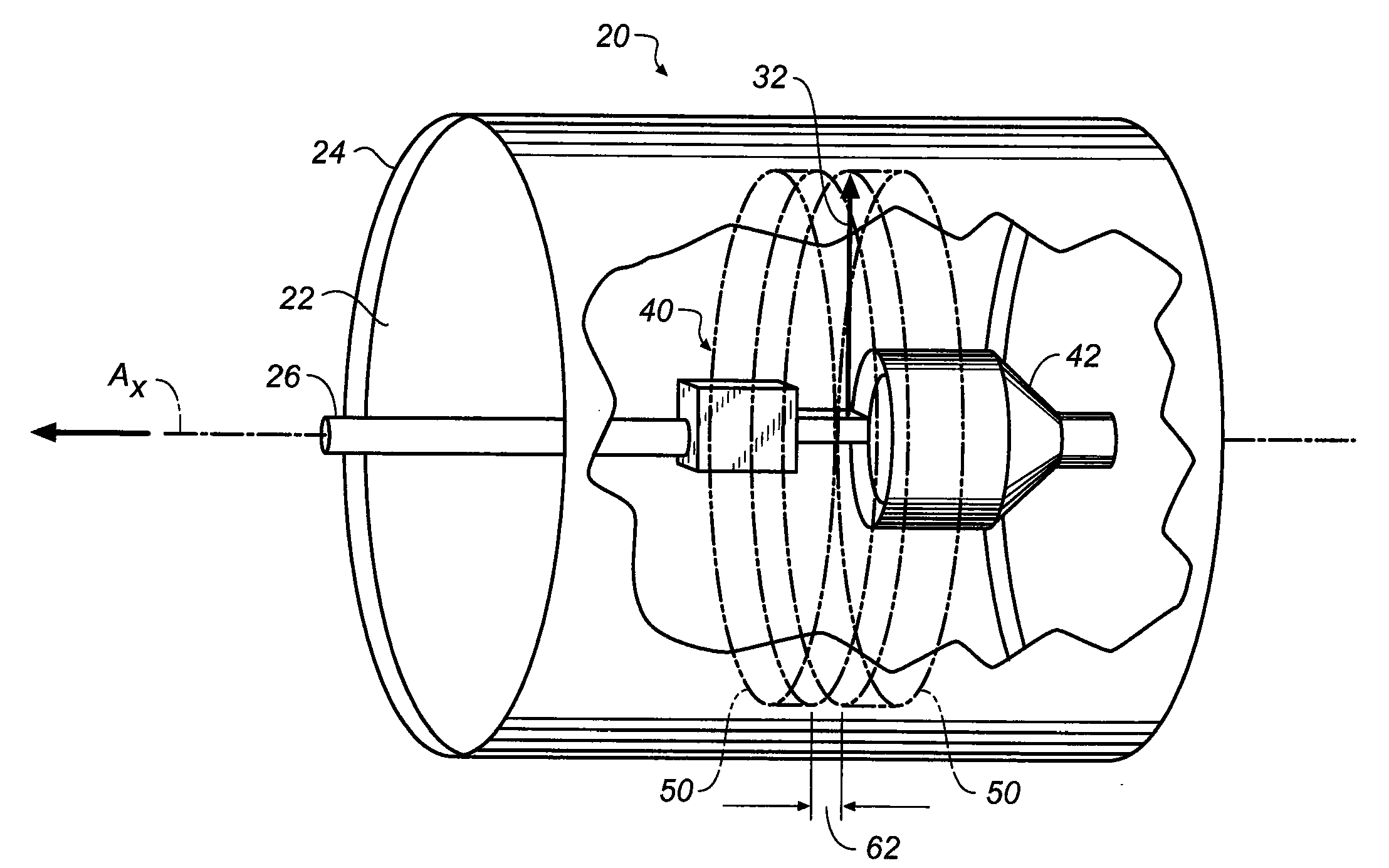

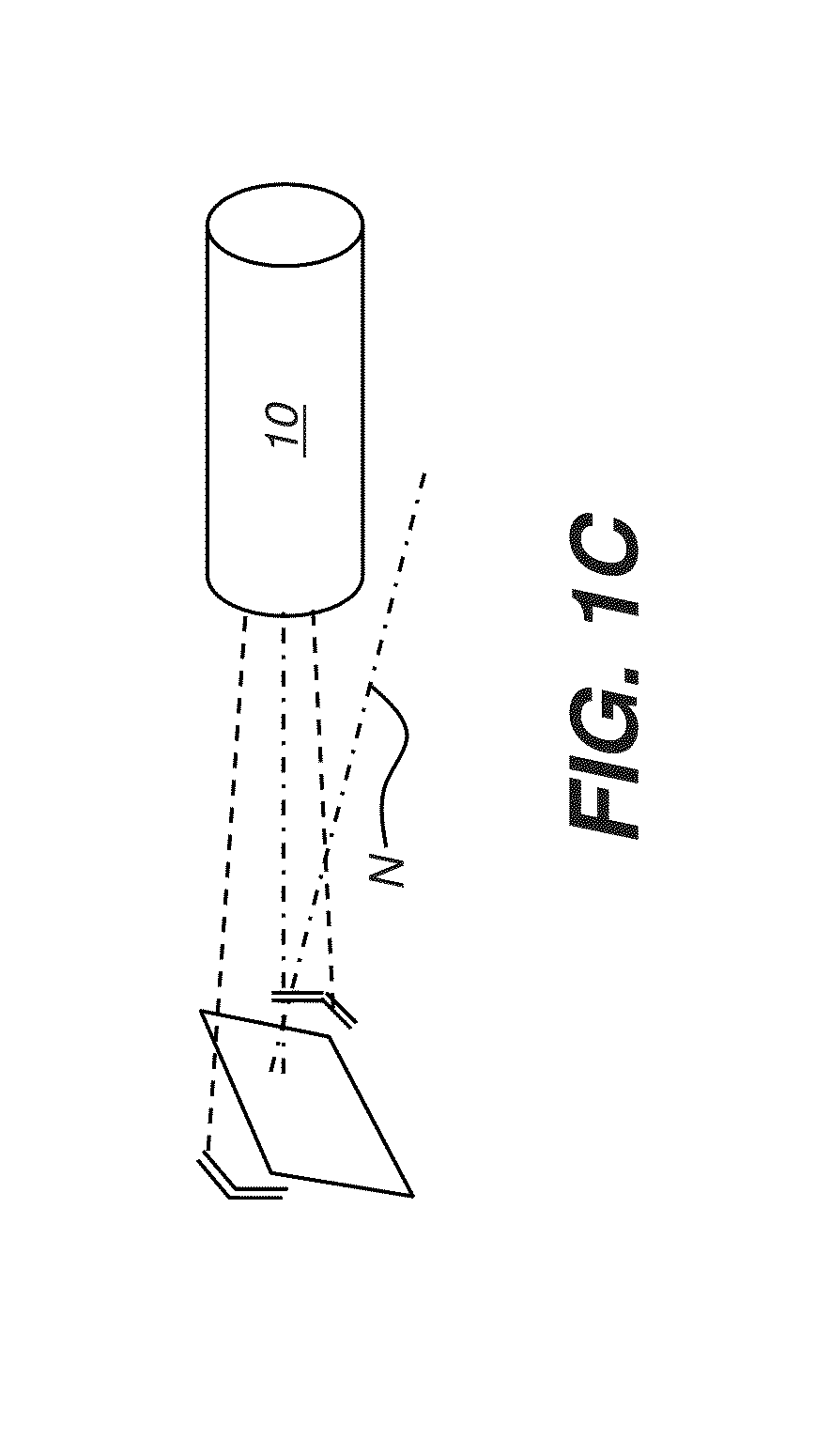

A scanning apparatus for obtaining an image from a phosphor sheet has a cylindrical drum having an inner axis and having an inner surface that is concave with respect to the axis. A light collector is coupled to a transport mechanism that is actuable to translate the light collector along a direction parallel to the axis. The light collector has a beam generator with a light source and a rotatable beam deflector that is actuable to provide a rotating scanning beam. There are first and second cylindrical hoops circumferentially disposed about the axis and spaced apart from each other along the direction of the axis to define a slot aligned with the rotating scanning beam as it scans the phosphor sheet. At least one light detector is disposed to detect light stimulated from the phosphor sheet by the scanning beam.

Owner:CARESTREAM HEALTH INC

Computed radiography systems and methods of use

ActiveUS20070138419A1X-ray/infra-red processesMaterial analysis by optical meansStimulated emissionComputed radiography

A computed radiography (CR) system for imaging an object is provided. The system includes a radiation source, a storage phosphor screen, an illumination source and a two dimensional imager. The radiation source is configured to irradiate the storage phosphor screen, and the storage phosphor screen is configured to store the radiation energy. The illumination source is configured to illuminate at least a sub-area of the storage phosphor screen to stimulate emission of photons from the storage phosphor screen. The two dimensional (2D) imager is configured to capture a two dimensional image from the storage phosphor screen using the stimulated emission photons. A method of reading a storage phosphor screen is also provided. The method includes illuminating at least a sub-area of the storage phosphor screen using an illumination source to stimulate emission of photons from the storage phosphor screen. The method further includes capturing at least one 2D image using a 2D imager, from at least a sub-array of the storage phosphor screen using the stimulated photons.

Owner:BAKER HUGHES INC

Binderless storage phosphor screen

An image storage screen or panel, suitable for use in applications related with computed radiography comprises, on a support, a binderless needle-shaped stimulable CsBr:Eu phosphor layer, wherein, besides low amounts of a europium activator or dopant in favor of homogeneous distribution of said activator in the CsBr matrix, presence of well-defined amounts of rubidium halide and cesium chloride in said matrix, and, optionally, further presence of alkali metal, alkaline earth metal and / or metal earth salts, and / or, optionally, other metal salts or oxides, provides a remarkable speed increase, without loss in sharpness.

Owner:T2PHARMA GMBH

Manufacturing method of phosphor or scintillator sheets and panels suitable for use in a scanning apparatus

In a method for coating a phosphor or a scintillator layer onto a flexible substrate, within a sealed zone maintained under vacuum conditions, by the step of vapor deposition, said phosphor or scintillator layer is, continuously or discontinuously, deposited onto said substrate, and said substrate is deformed at least before, during or after said step of vapor deposition, in order to provide the manufacturer, by a process of exceptionally high yield, with large deposited phosphor or a scintillator sheets having constant speed and image quality properties, further offering availability of all formats as desired for screens, plates or panels ready-for-use in a scanning apparatus in computed radiography, screen / film radiography and direct radiography.

Owner:AGFA NV

Mobile computed radiography

ActiveUS20050199835A1Easy to transportMaterial analysis by optical meansStereoscopic photographyDisplay deviceImage recording

In one aspect, a mobile computed radiography (CR) unit is provided. The mobile CR unit includes a CR scanner adapted to acquire one or more images from an image recording medium, and a transport mechanism coupled to the CR scanner, the transport mechanism adapted to facilitate transport of the mobile CR apparatus between locations. In another aspect, the mobile CR unit in constructed as a single free-standing integrated device having a frame that couples together the CR scanner, a display adapted to view the one more images acquired by the CR scanner, and a plurality of wheels that allow the mobile CR unit to be transported from one location to another.

Owner:CARESTREAM HEALTH INC

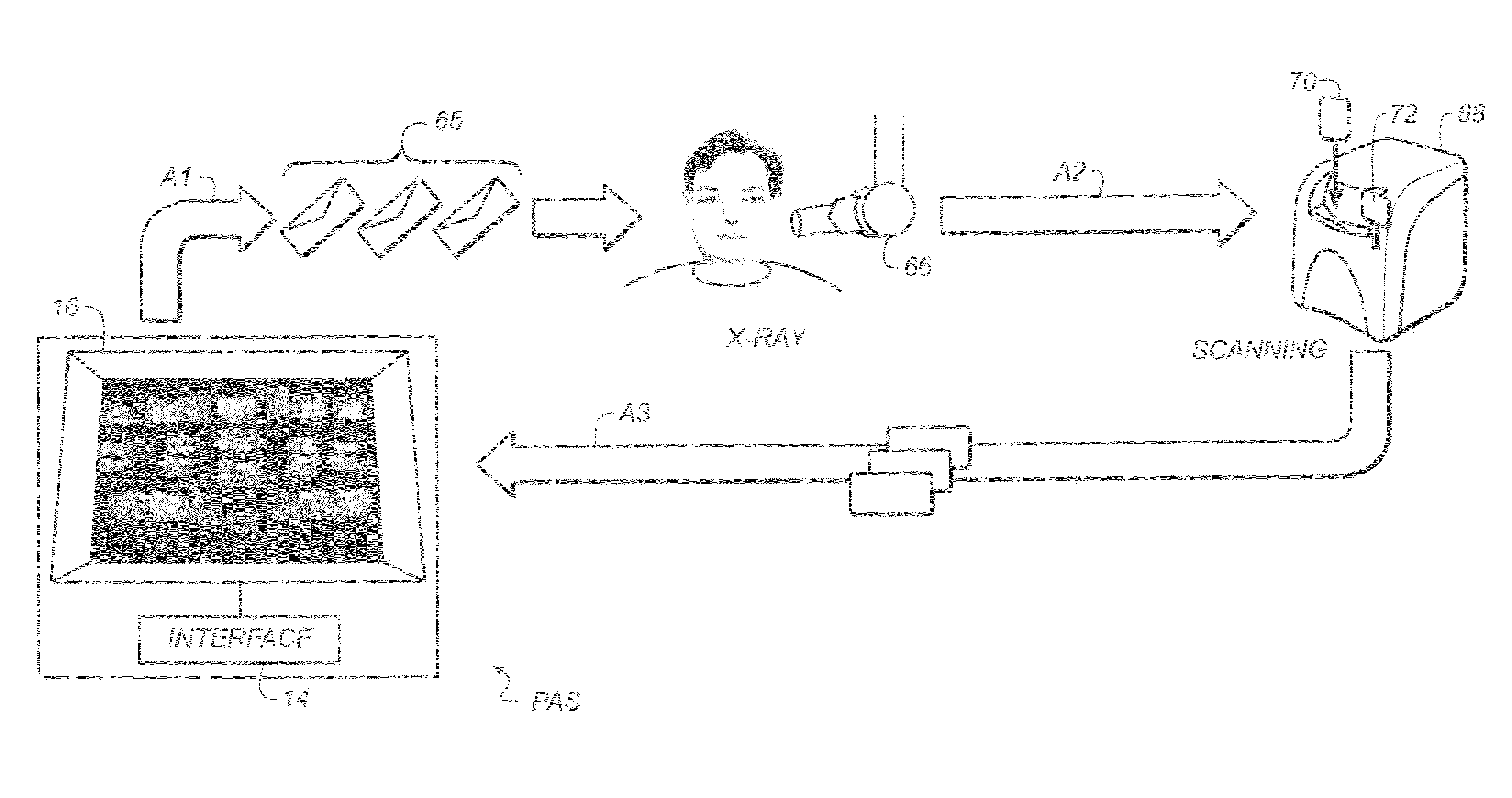

Method and system for phosphor plate identification in computed radiography

InactiveUS20140191852A1Simple and convenient and reliablePrevent their inadvertent or intentional mismatchSubscribers indirect connectionSensing by electromagnetic radiationPhosphorX-ray

A method for obtaining an intra-oral X-ray image of a subject on a flexible information carrier plate for computed radiography affixes a memory to a surface of the information carrier plate, wherein the affixed memory stores information about the plate and wherein the affixed memory is in wireless communication with a computer, stores at least a first scan date in the affixed memory, exposes the subject and obtains the intra-oral X-ray image of the subject using steps of: (i) storing identification data about the subject and about the image exposed in the affixed memory; (ii) acquiring image data from a scan of the flexible information carrier plate following exposure to X-rays, acquiring at least the stored identification data from the affixed memory, and associating the acquired image data with the acquired identification data; (iii) erasing image content from the flexible information carrier plate; and (iv) storing the acquired image data in a second, computer-accessible memory according to the acquired identification data.

Owner:CARESTREAM HEALTH INC

Computed radiography positioning method and system

InactiveUS20140112439A1Improve artImprove abilitiesRadiation beam directing meansRadiation diagnostics for dentistryTransceiverX-ray

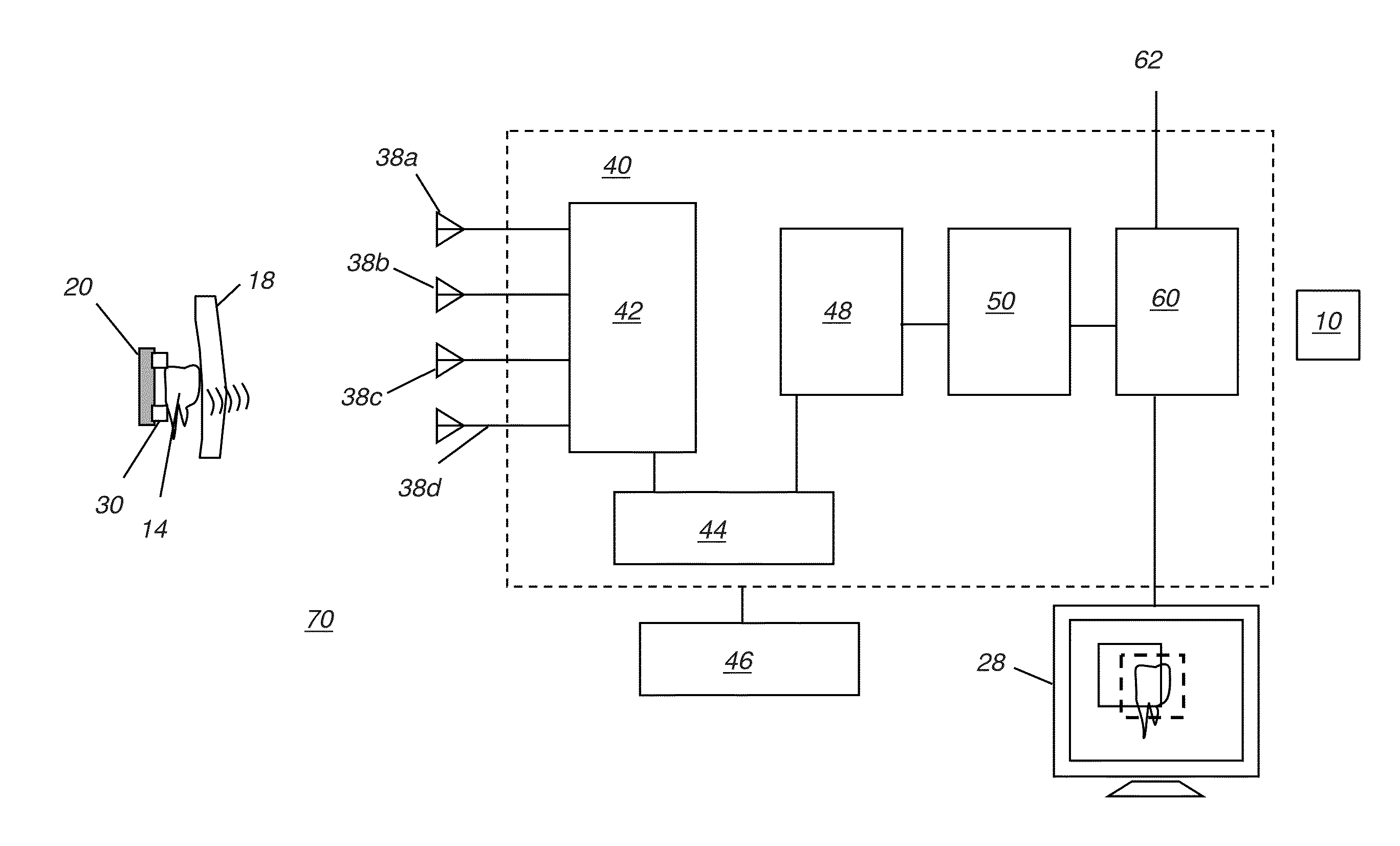

An apparatus for obtaining an intraoral x-ray image from a patient, the apparatus has an x-ray source and a radio-frequency transceiver coupled to the x-ray source and energizable to transmit an interrogation signal, wherein the transceiver is in signal communication with four or more antennae. An intraoral image detector forms an image upon exposure to radiation received from the x-ray source. A radio-frequency transponder is coupled to the image detector and is configured to respond to the interrogation signal by transmitting a wireless response signal. A control logic processor is in communication with the transceiver and provides an output signal indicative of the spatial position of the image detector according to response signals received from the transponder at the four or more antennae. An indicator responds to the output signal by indicating the relative position of the image detector.

Owner:CARESTREAM DENTAL TECH TOPCO LTD

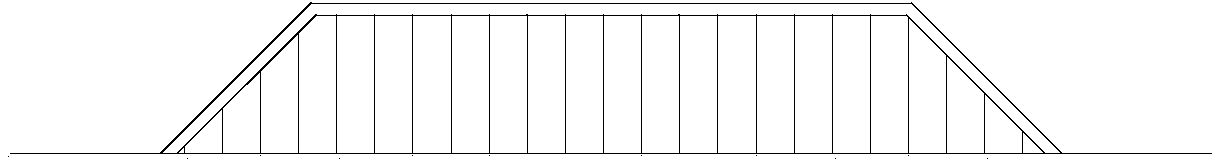

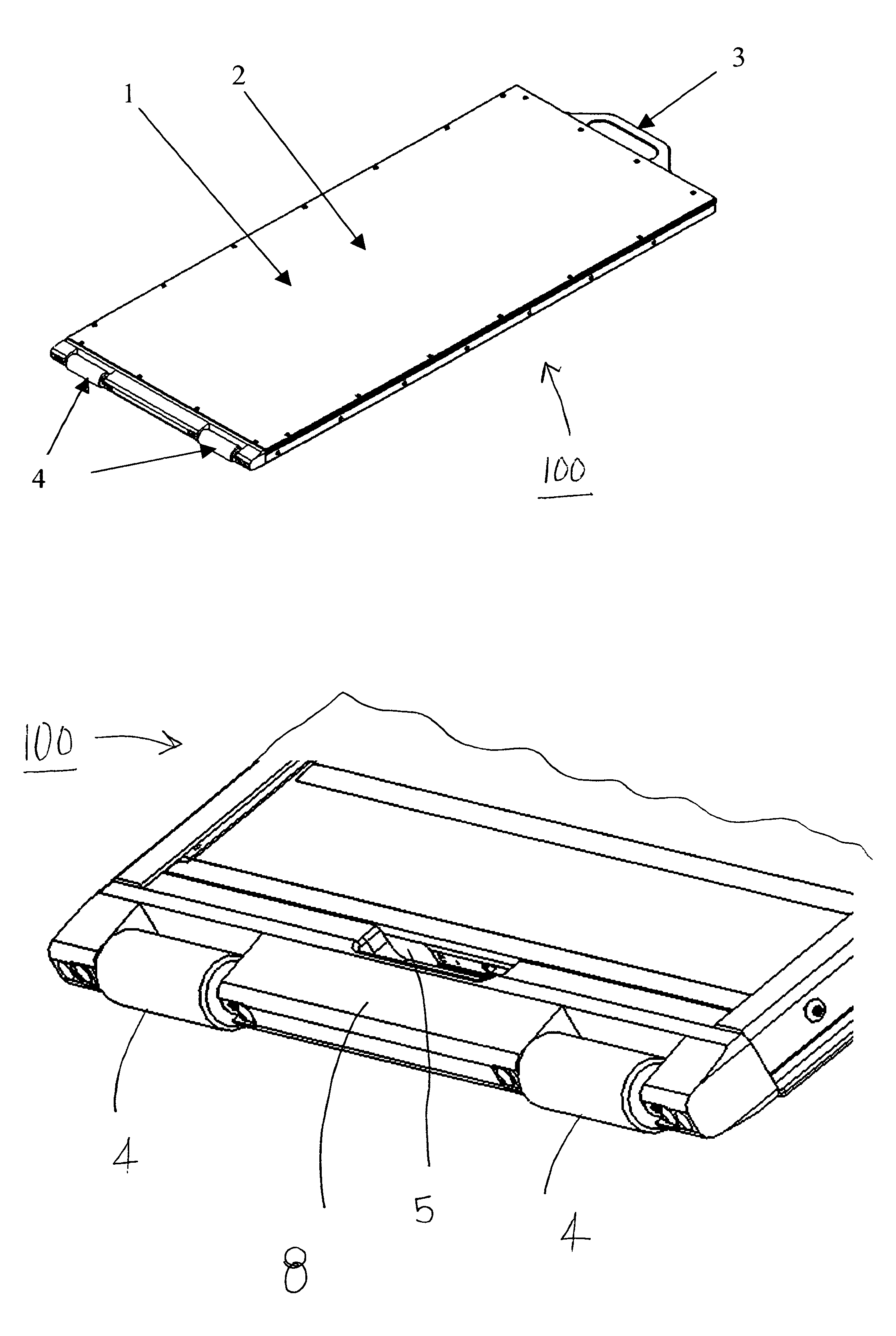

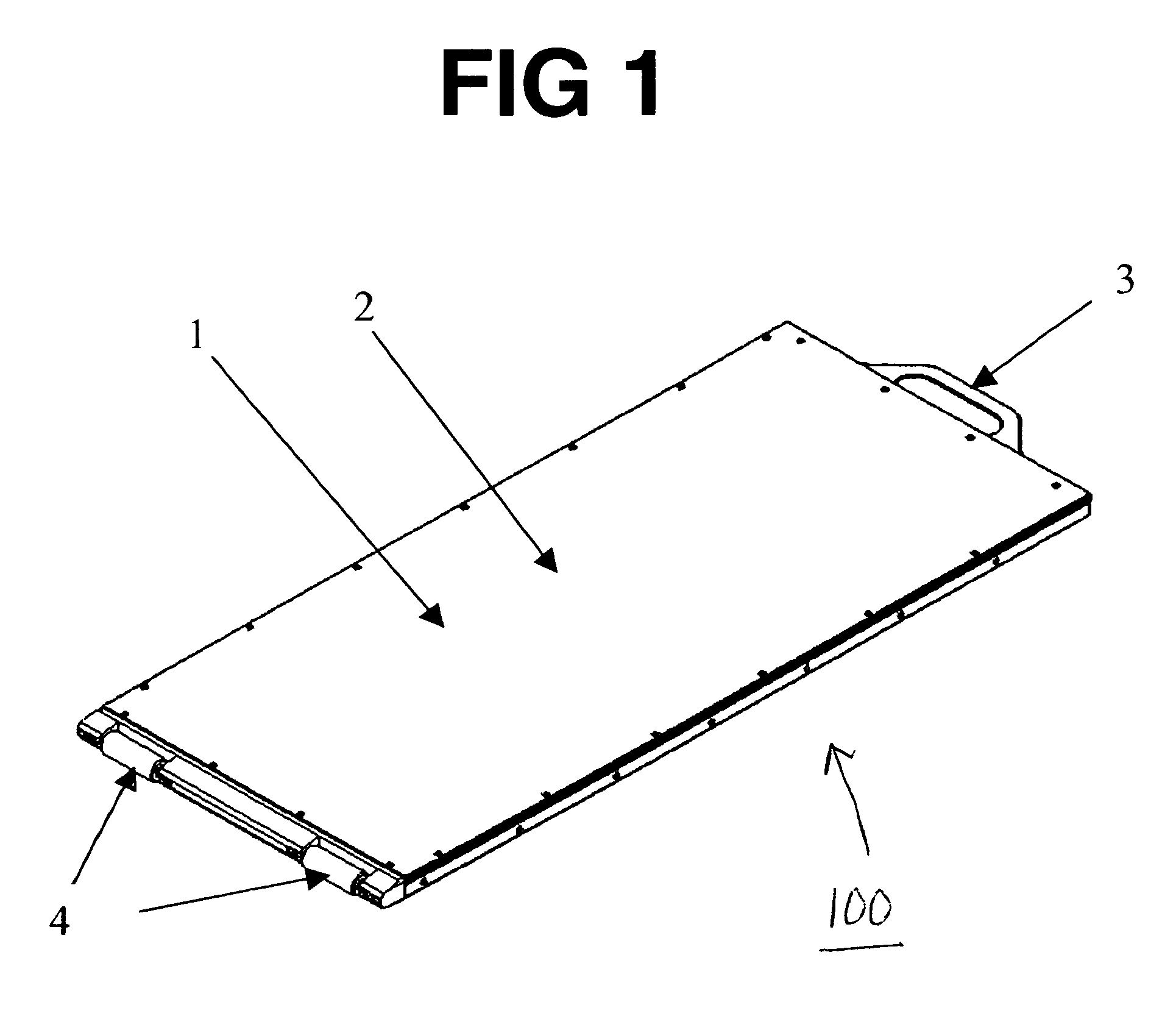

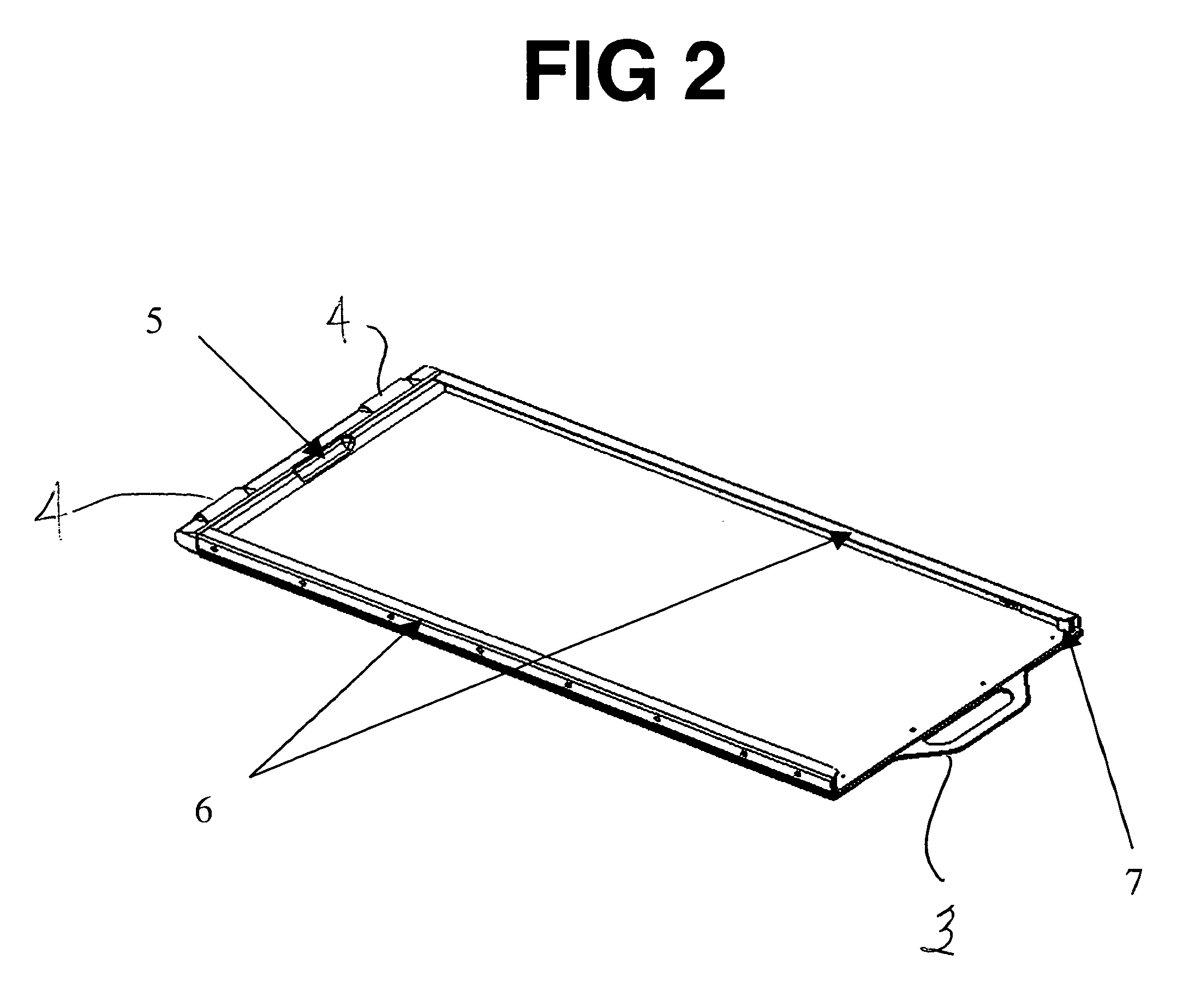

Grid assembly for use with a cassette

A grid assembly for use with an imaging cassette, for example, a computed radiography cassette, particularly an elongated radiography cassette. The grid assembly includes: an anti-scatter grid; a radiographically translucent enclosure housing the anti-scatter grid and having two ends; a transport member disposed proximate a first end of the enclosure; at least one roller disposed proximate a second end of the enclosure; and a receiving member attached to the enclosure and adapted to removably receive and secure the imaging cassette.

Owner:CARESTREAM HEALTH INC

Mobile computed radiography

ActiveUS7434997B2Easy to transportMaterial analysis by optical meansStereoscopic photographyImage recordingDisplay device

Owner:CARESTREAM HEALTH INC

Mobile computed radiography

ActiveUS20070116182A1Easy to transportStereoscopic photographyX/gamma/cosmic radiation measurmentX-rayDisplay device

A mobile computed radiography (CR) unit. The mobile CR unit includes a CR scanner adapted to acquire one or more images from an image recording medium, a frame that supports the CR scanner, an x-ray source mounted to the frame, a transport mechanism coupled to the frame and adapted to facilitate transport of the mobile CR apparatus between locations, and a display coupled to the frame and connected to the CR scanner to display the one or more images acquired by the CR scanner. The mobile CR unit in constructed as a single free-standing integrated device which provides for the exposure of a storage phosphor media, the scanning of the exposed media to generate a digital medical image, and the display of the generated digital medical image.

Owner:CARESTREAM HEALTH INC

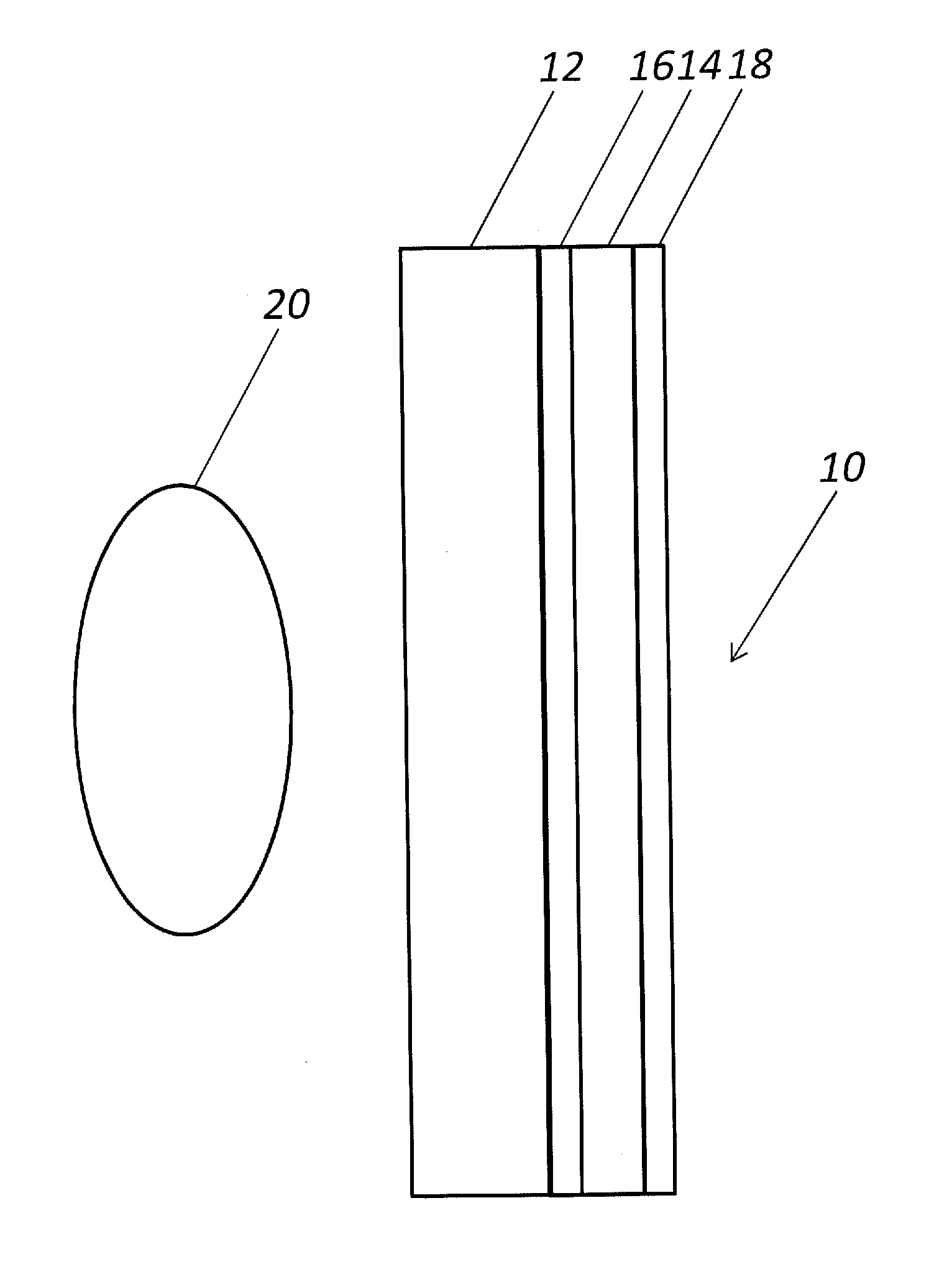

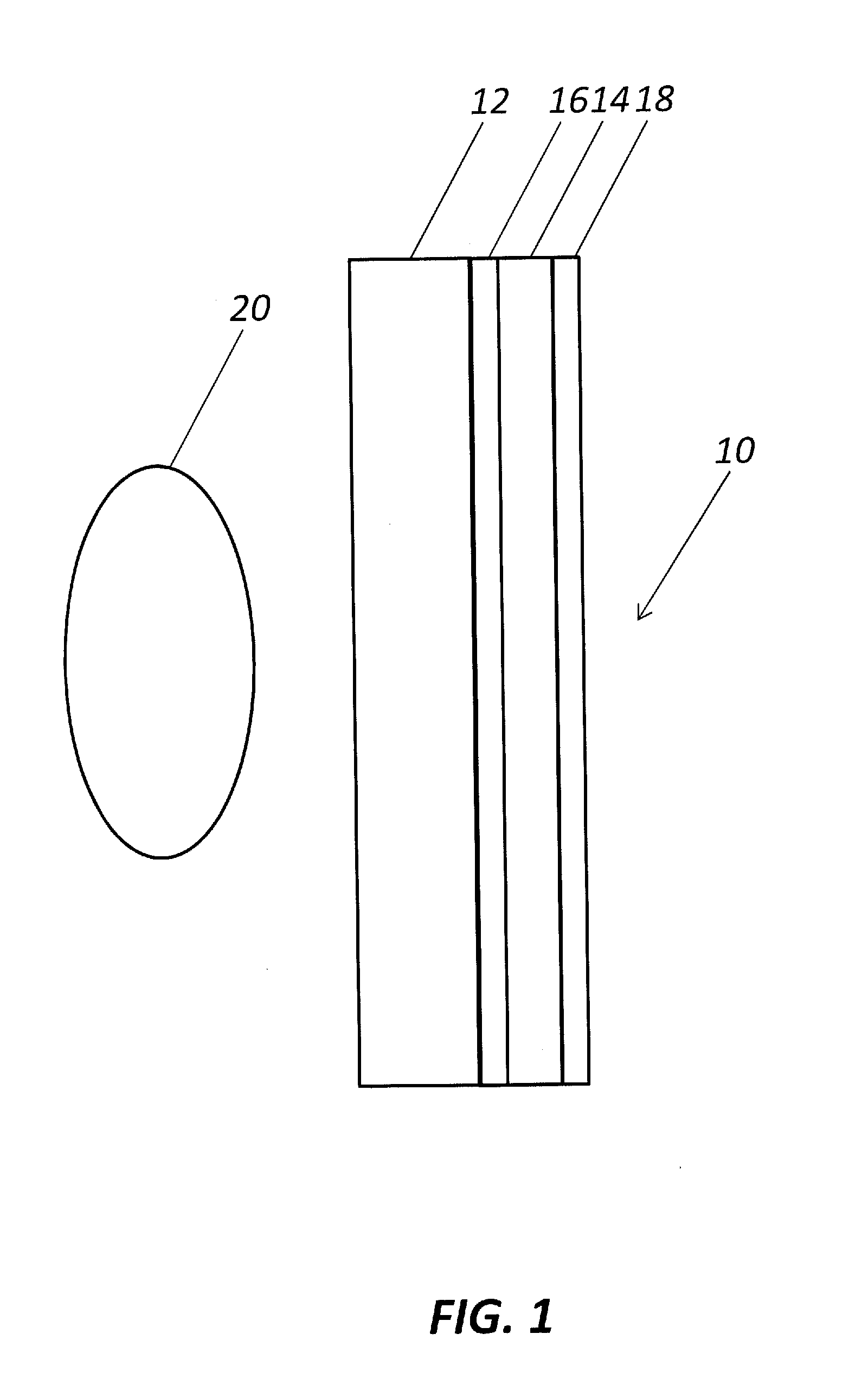

Computed radiography imaging plates and associated methods of manufacture

ActiveUS20140264083A1Decreasing internal scatteringHigh resolutionPhotometryFluorescence/phosphorescencePhosphorImage resolution

Computed radiography imaging plates incorporating an intensifying material that is coupled to or intermixed with the phosphor layer, allowing electrons and / or low energy x-rays to impart their energy on the phosphor layer, while decreasing internal scattering and increasing resolution. The radiation needed to perform radiography can also be reduced as a result.

Owner:CONSOLIDATED NUCLEAR SECURITY

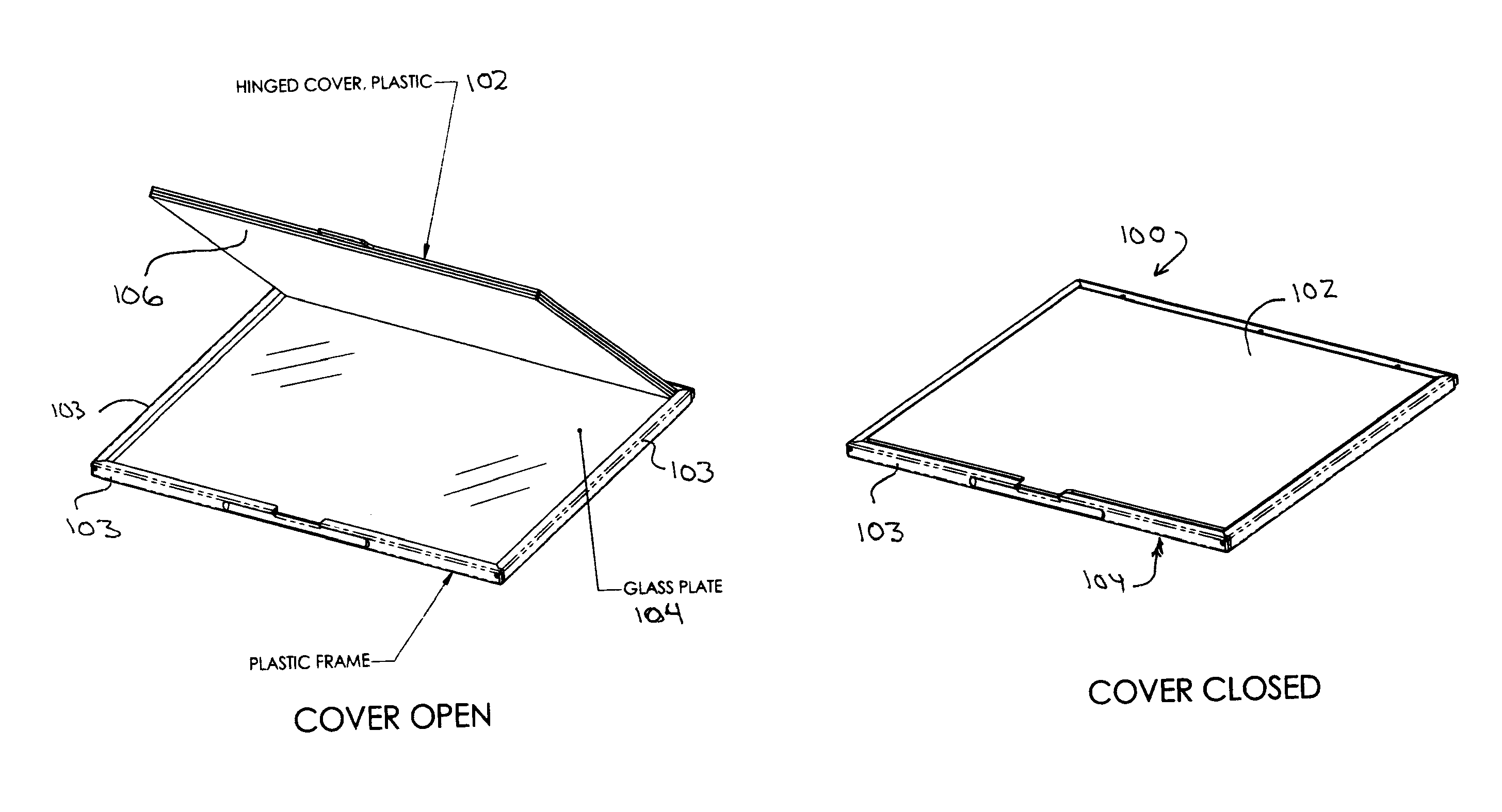

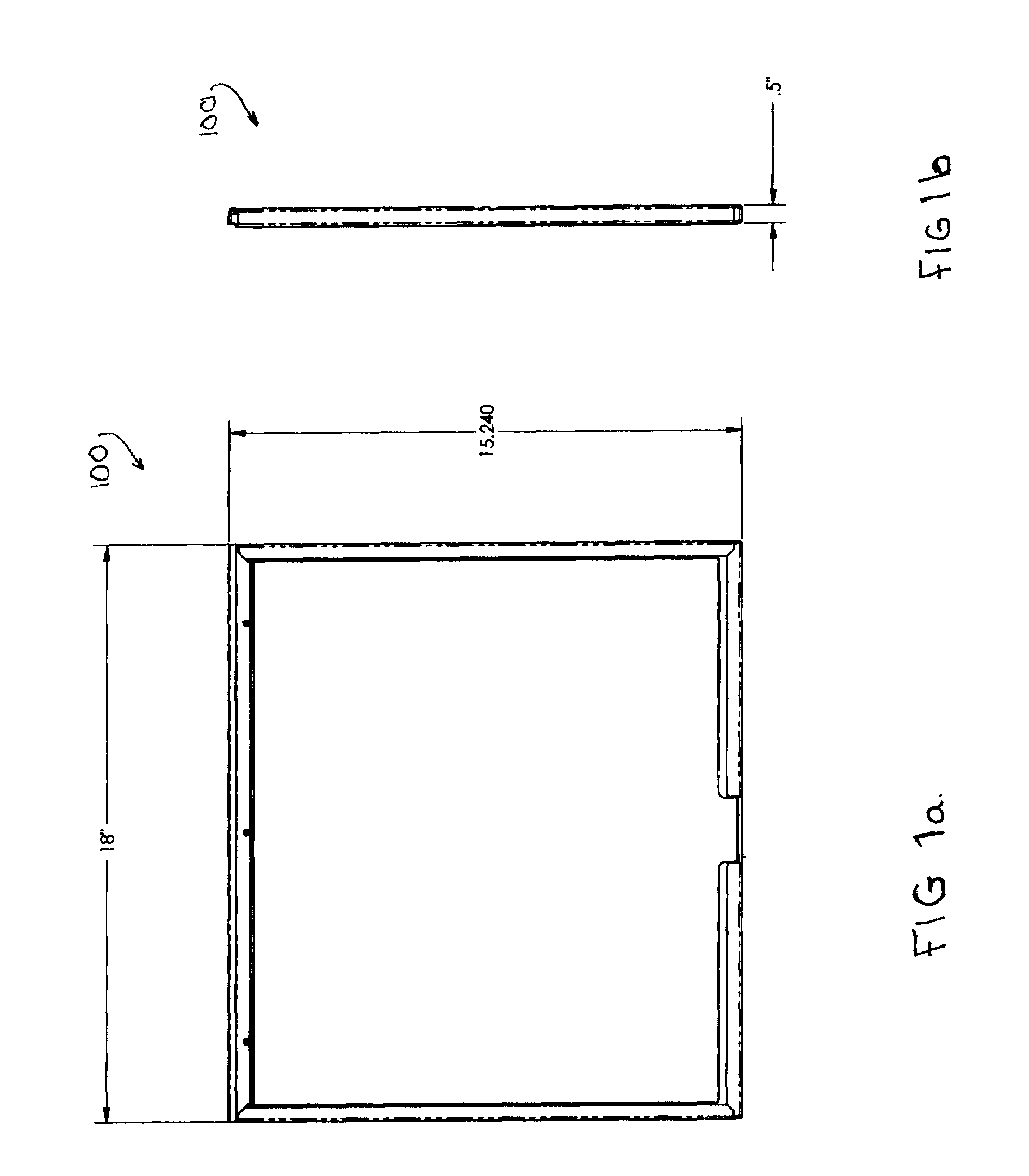

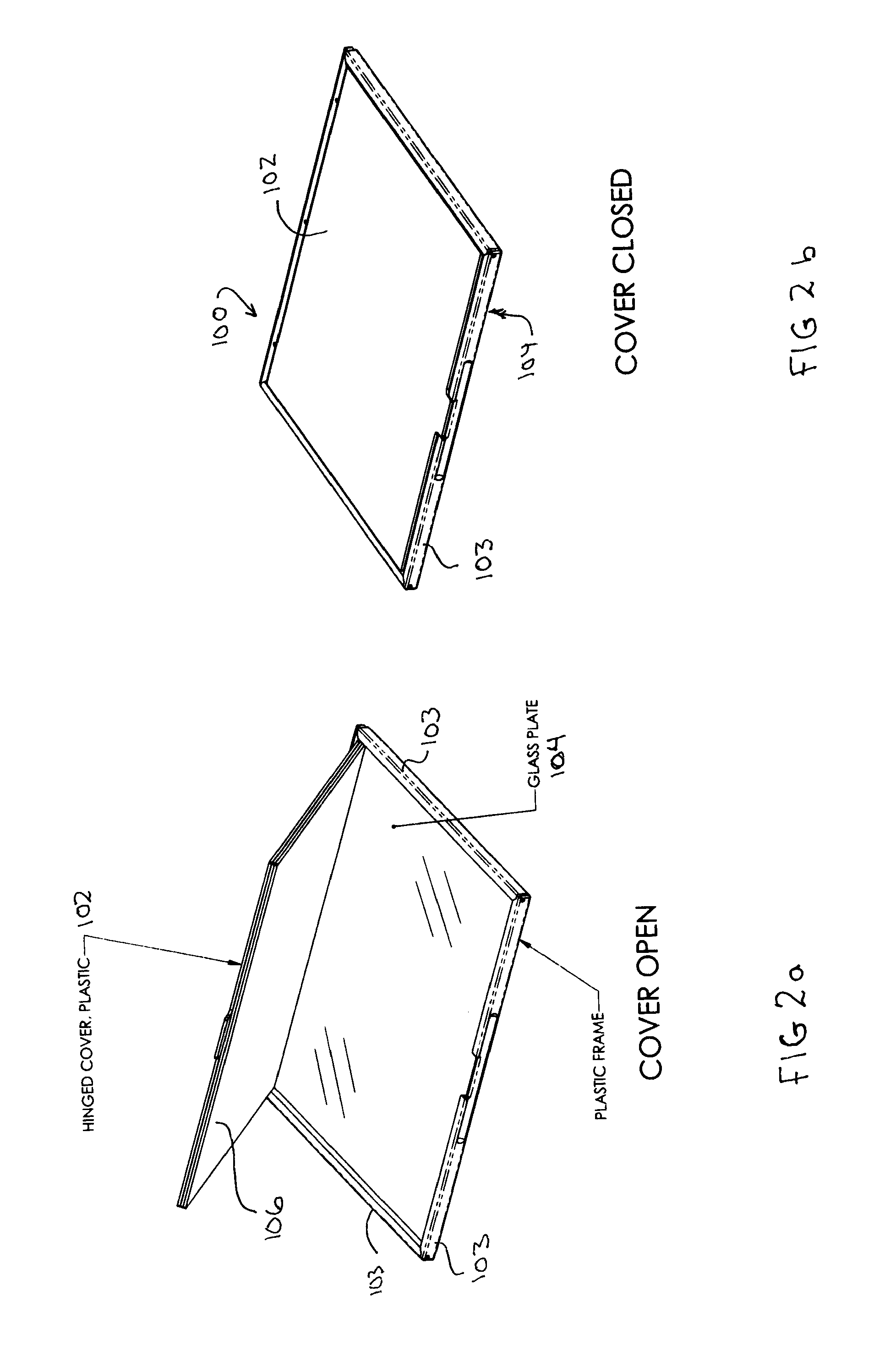

Glass cassette for scanning imaging plates

InactiveUS7507974B1Electroluminescent light sourcesPictoral communicationEngineeringComputed radiography

The invention provides a cassette enclosure having an energy translucent portion for supporting an imaging plate. The cassette is adapted for use with a computed radiography device wherein an image set forth on the imaging plate can be scanned without removing the plate from the cassette.

Owner:ICRCO

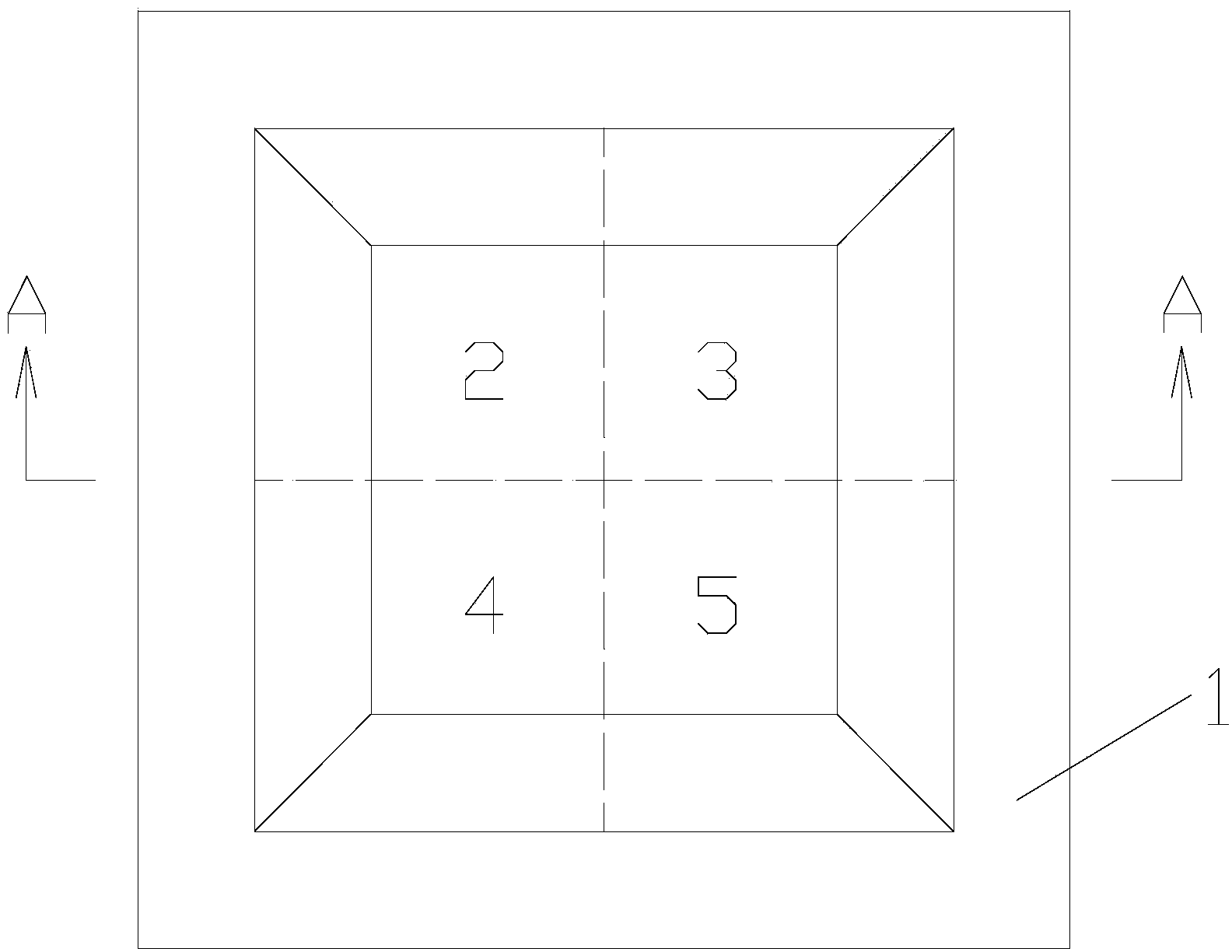

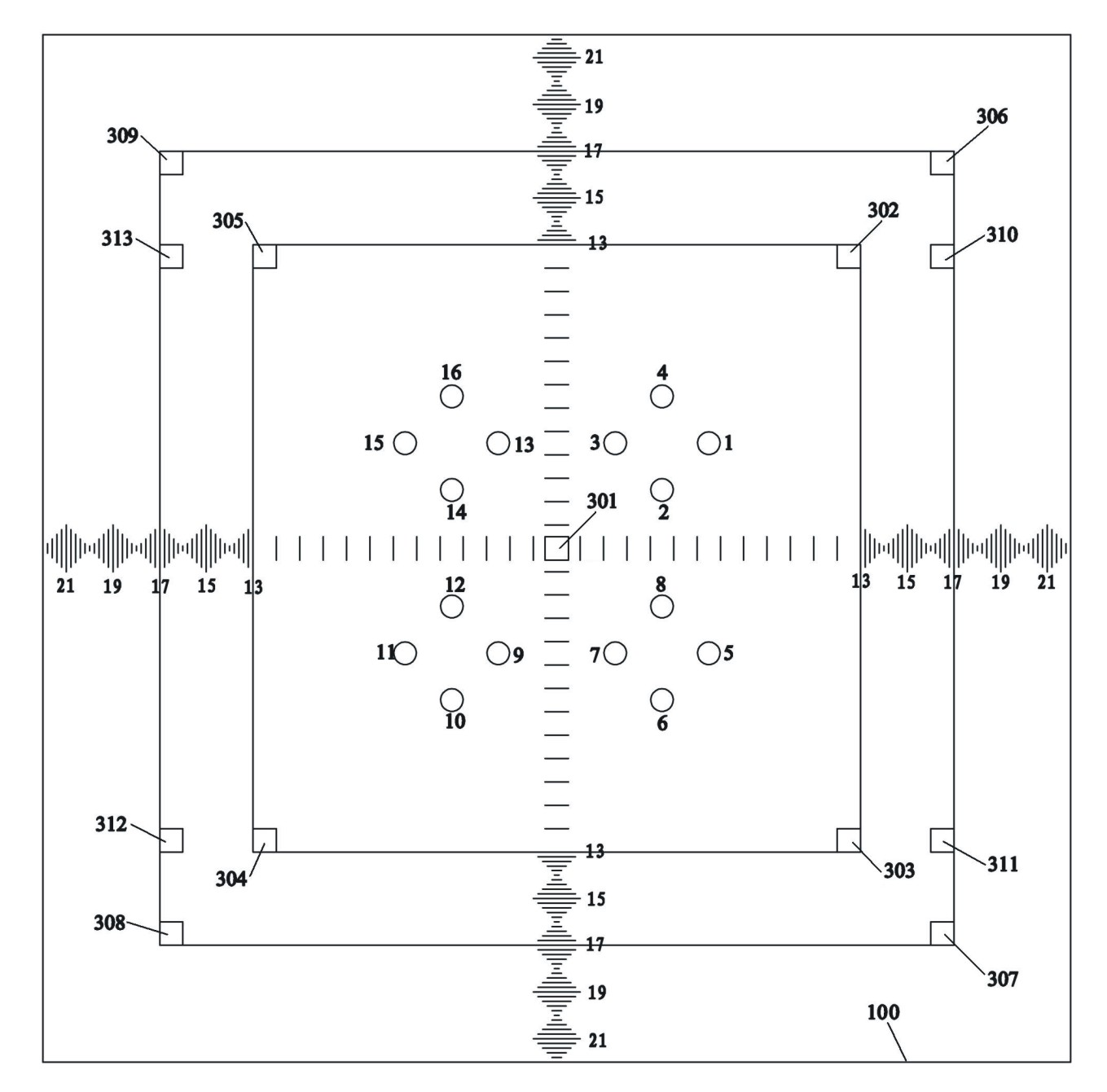

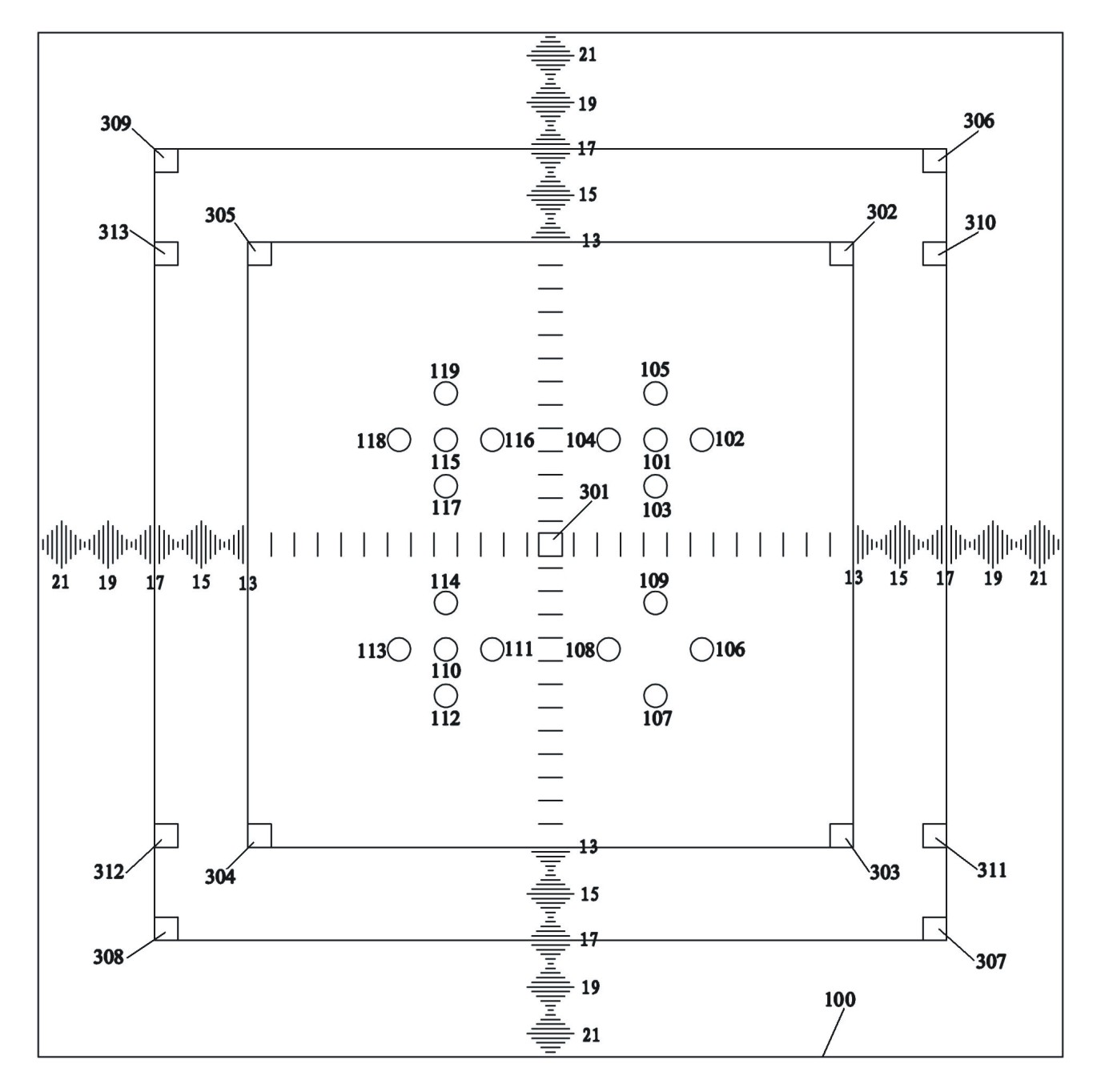

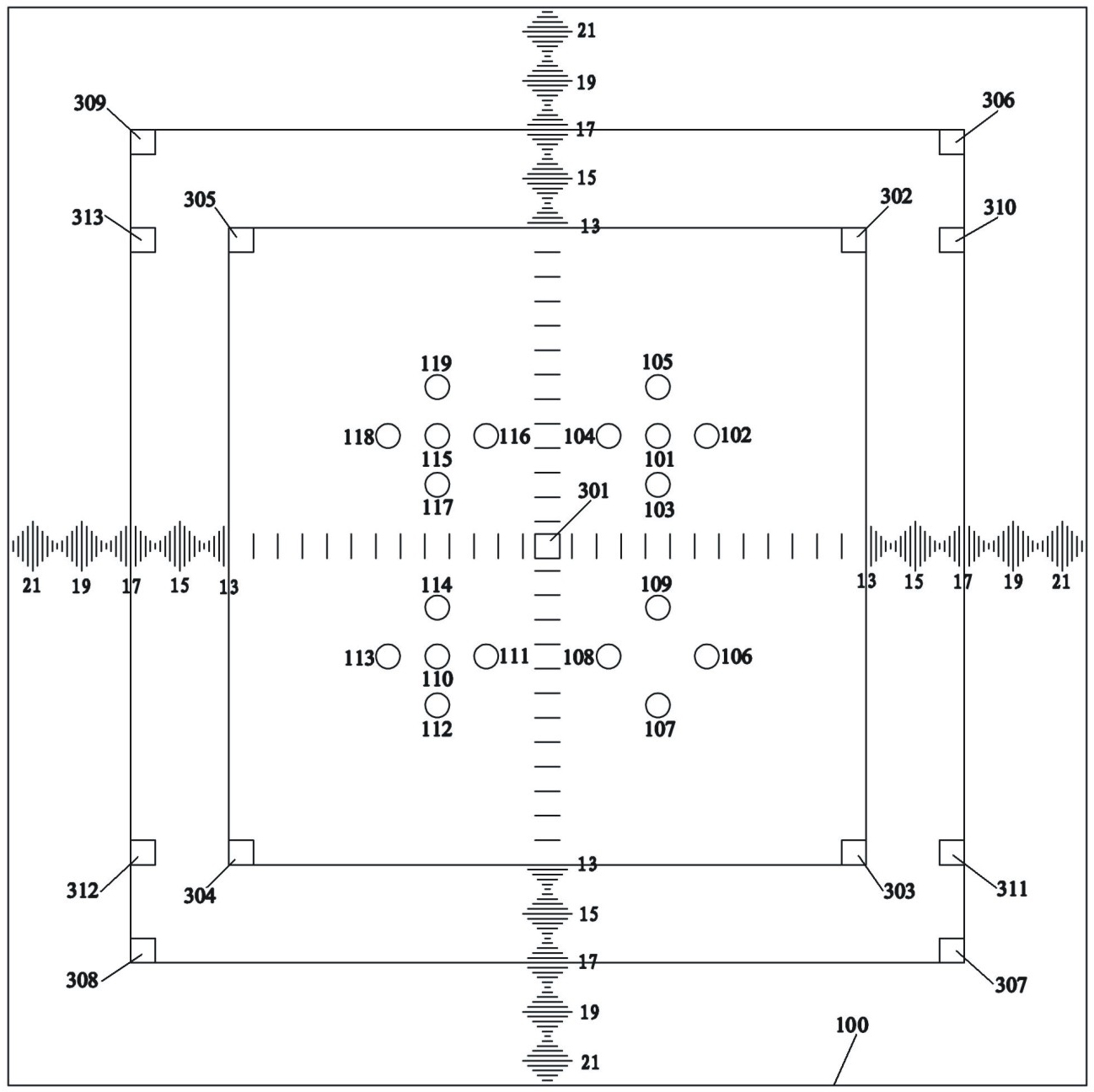

CR/DR (Computed Radiography/Direct Radiography) comprehensive detection die body

ActiveCN102631211AImprove detection efficiencyEasy to operateComputerised tomographsTomographyConsistency testX-ray

The invention discloses a CR / DR (Computed Radiography / Direct Radiography) comprehensive detection die body and belongs to a die body for the detection of a medical X-ray photography system. Transverse and longitudinal measuring rulers and three groups of image uniformity test points are arranged on the surface of a square pure-aluminum plate with the thickness of 20mm and the side length of greater than 430mm. 16 or 19 holes with the same diameter and sequentially decreasing depth are arranged on the surface of the pure-aluminum plate so as to be used as a low-contrast test card. The CR / DR detection die body disclosed by the invention is integrated with a ray field and light field consistency test card, a low-contrast test card and image uniformity test points, has high detection efficiency and is easy to operate and convenient to use.

Owner:范杰

Computed radiography imaging plates and associated methods of manufacture

ActiveUS9110175B2Decreasing internal scatteringHigh resolutionX-ray/infra-red processesPhotometryImage resolutionPhosphor

Computed radiography imaging plates incorporating an intensifying material that is coupled to or intermixed with the phosphor layer, allowing electrons and / or low energy x-rays to impart their energy on the phosphor layer, while decreasing internal scattering and increasing resolution. The radiation needed to perform radiography can also be reduced as a result.

Owner:CONSOLIDATED NUCLEAR SECURITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com