Negative pole piece of lithium ion battery as well as preparation method and application of negative pole piece

A technology of lithium ion battery and negative pole piece, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of difficult processing, difficult to exert advantages, low compaction, etc., to achieve low cost and improve fast charging. Performance, effect of high fast charging target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

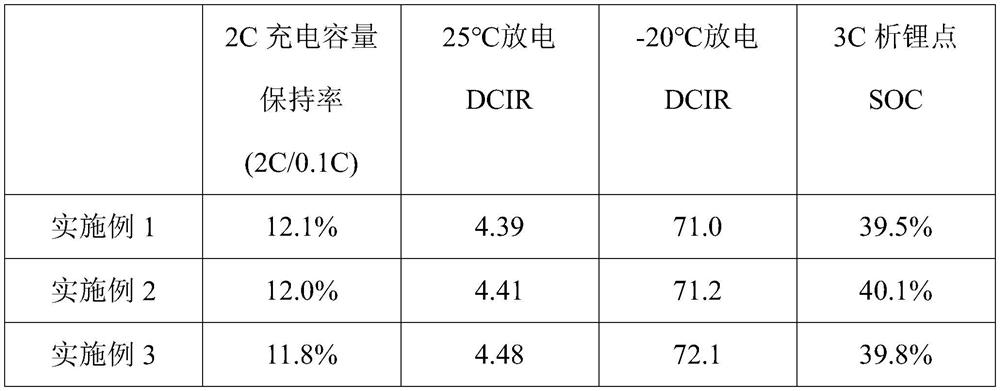

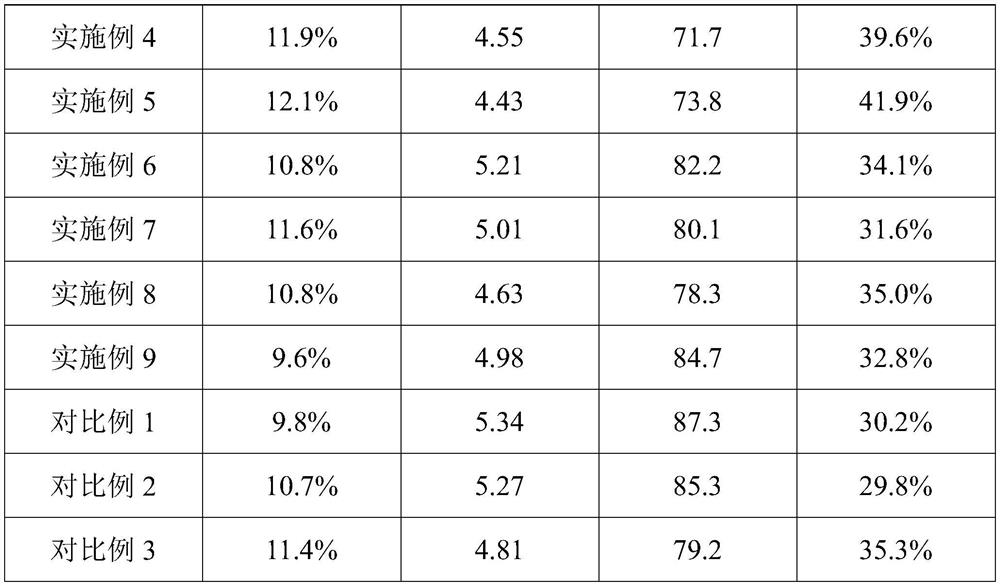

Examples

Embodiment 1

[0081] This embodiment provides a preparation method of lithium ion battery negative electrode material, and the preparation method comprises the following steps:

[0082] (1) 1 part of conductive carbon black and 55 parts of deionized water dissolving 1 part of sodium carboxymethyl cellulose are mixed and stirred at a stirring rate of 800rmp for 10min, and then the powder of 95 parts of artificial graphite is added and stirred at a stirring rate of 800rmp Mix and stir for 30 minutes, add 15 parts of deionized water again for dispersing and stirring at a stirring rate of 2200rmp for 30 minutes, and finally add 1 part of styrene-butadiene rubber for viscosity adjustment and stirring at a stirring rate of 800rmp for 10min, and reverse stirring at a stirring rate of 2200rmp 1min for defoaming treatment to prepare the precursor of the first active material layer;

[0083] (2) 1 part of conductive carbon black and 55 parts of deionized water dissolving 1 part of sodium carboxymethy...

Embodiment 2

[0087] This embodiment provides a preparation method of lithium ion battery negative electrode material, and the preparation method comprises the following steps:

[0088] (1) 0.5 parts of carbon nanotubes and 50 parts of deionized water dissolving 0.5 parts of sodium polyacrylate are mixed and stirred at a stirring rate of 600rmp for 12min, and then 96 parts of natural graphite powder is added for mixing and stirring at a stirring rate of 600rmp for 31min , adding 10 parts of deionized water again for dispersing and stirring at a stirring rate of 2100rmp for 31min, and finally adding 1.5 parts of styrene-butadiene rubber for viscosity adjustment stirring at a stirring rate of 600rmp for 11min, and removing bubble treatment to prepare the precursor of the first active material layer;

[0089] (2) 1.5 parts of graphene and 60 parts of deionized water dissolving 1.5 parts of sodium polyacrylate were mixed and stirred at a stirring rate of 600rmp for 11min, and then 98 parts of n...

Embodiment 3

[0093] This embodiment provides a preparation method of lithium ion battery negative electrode material, and the preparation method comprises the following steps:

[0094] (1) 0.7 parts of carbon nanotubes and 57 parts of N-methylpyrrolidone dissolving 1.2 parts of sodium carboxymethyl cellulose are mixed and stirred at a stirring rate of 700rmp for 13min, and then the powder of 97 parts of artificial graphite is added and the stirring rate is Mix and stir at 500rmp for 32min, add 17 parts of N-methylpyrrolidone again for dispersing and stirring at a stirring rate of 2000rmp for 35min, and finally add 1.2 parts of polyvinylidene fluoride for viscosity adjustment at a stirring rate of 1000rmp for 13min, and pass the stirring rate Reverse stirring at 2200rmp for 1min to perform defoaming treatment to prepare the precursor of the first active material layer;

[0095] (2) 0.5 parts of carbon nanotubes and 52 parts of N-methylpyrrolidone dissolved in 1.2 parts of sodium polyacrylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com