Preparation method and application of a two-dimensional mxene/polydopamine composite desalination electrode material

A technology of polydopamine and electrode materials, applied in separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as capacity cannot be further increased, electrolyte ion diffusion limitation, material specific surface area limitation, etc., to improve electrolyte transmission Efficiency, improved utilization, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

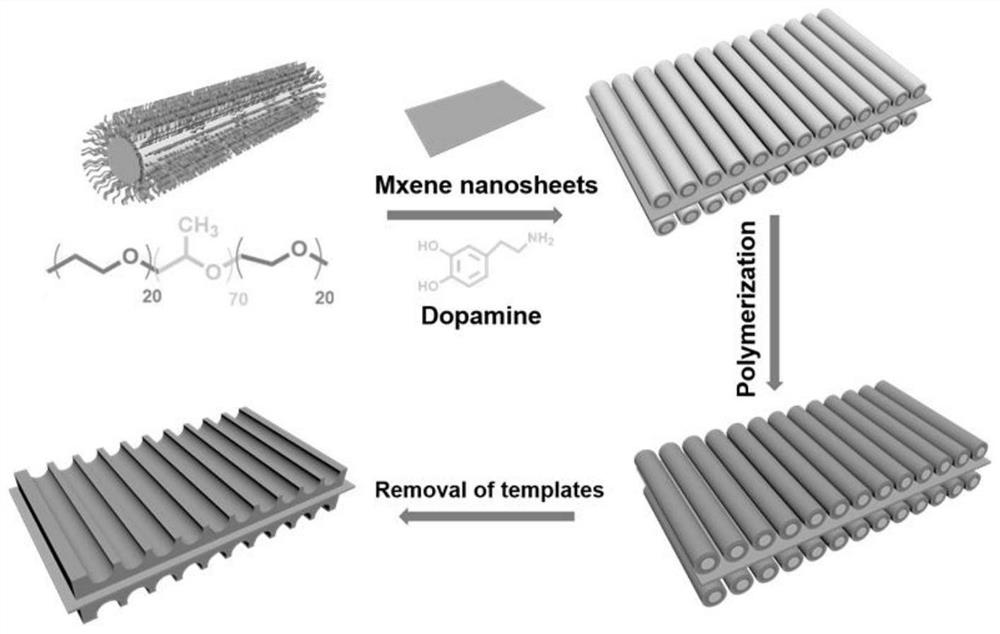

[0029] The preparation method of mPDA / MXene is as follows:

[0030] (1) PEO 20 -b-PPO 70 -b-PEO 20 Self-assembly into cylindrical micelles: Dissolve 100 mg of P123 in 40 mL of deionized water and stir at 40 °C for 2 hours to form a polymer micelle solution.

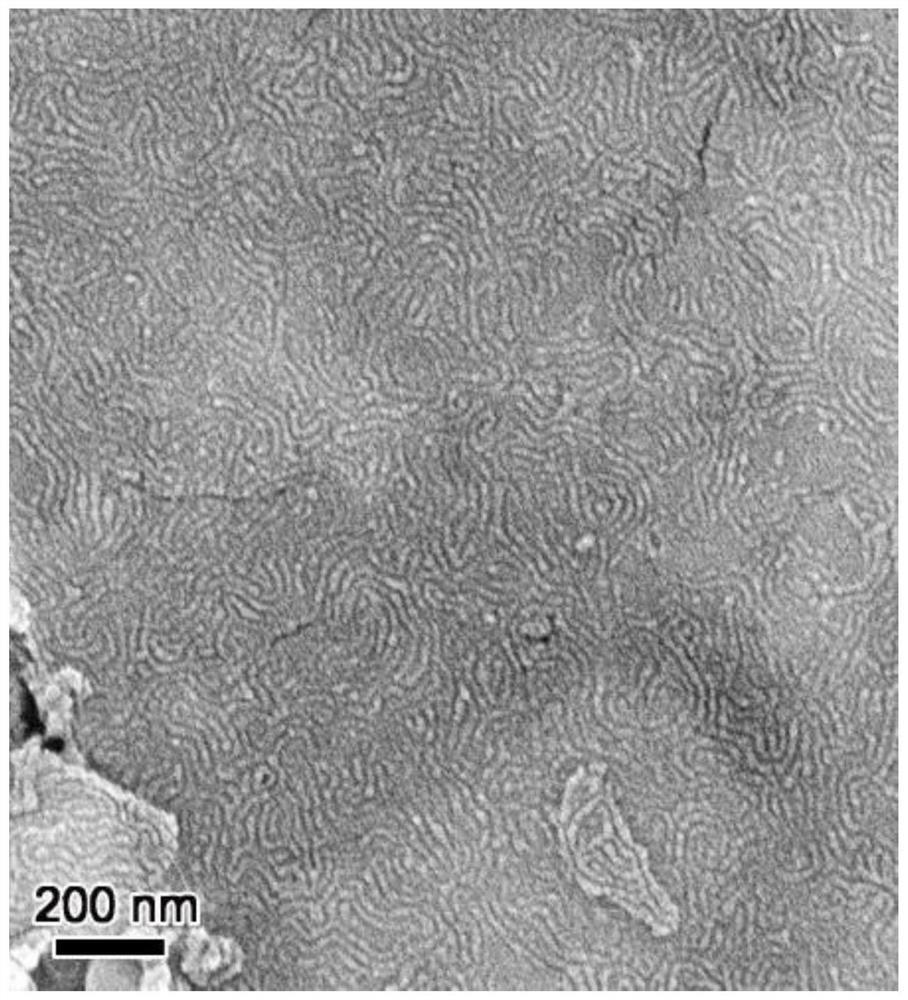

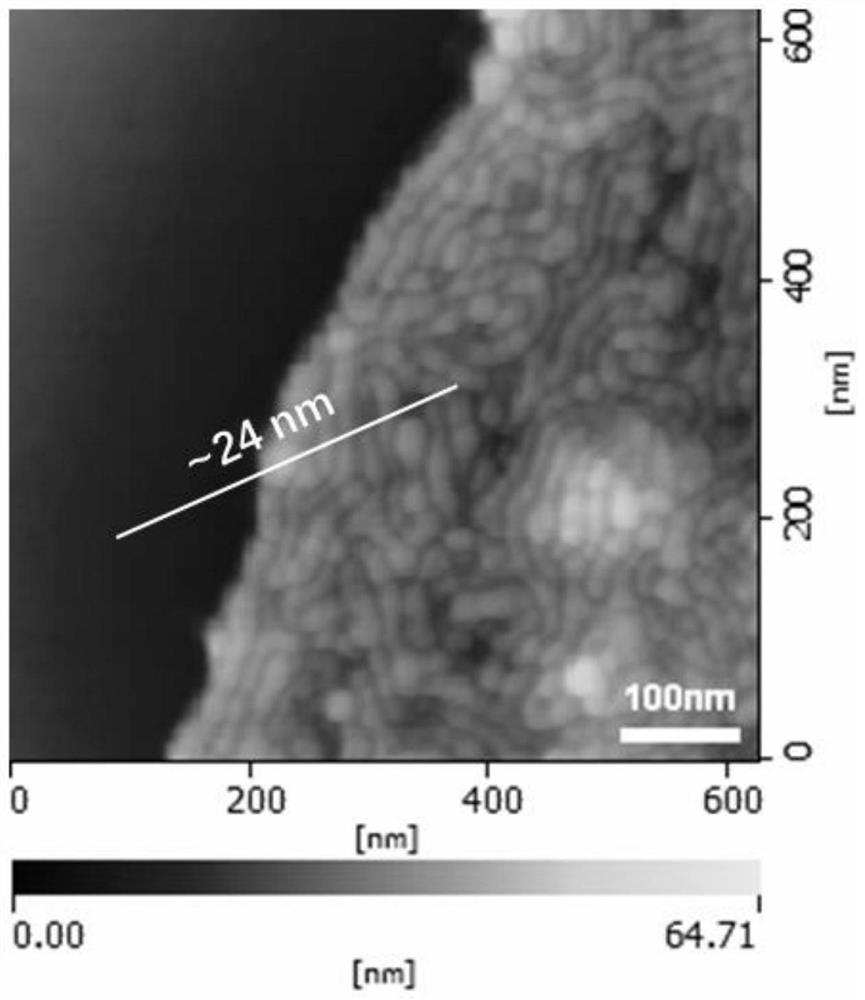

[0031] (2) Add 6 mL of MXene solution (2 mg / mL) to the above polymer solution, add 100 mg of dopamine hydrochloride (DA HCl) after stirring for 1 hour, and continue stirring for 1 hour. The micelles can be adsorbed on the The surface of MXene, while the dopamine monomer was adsorbed by PEO, resulting in the formation of the close packing of P123 / dopamine composite micelles on the MXene nanosheets. 100 mg of tris (Tris) was added and the solution was adjusted to pH 8.5. 200 μL of aqueous ammonia solution was added dropwise to the mixture to initiate polymerization of dopamine for 12 hours. Washed with ethanol and water several times, centrifuged, and finally freeze-dried to obtain columnar mesoporous MXene / polydopamin...

Embodiment 2

[0034] The preparation method of CDI battery is as follows:

[0035] mPDA / MXene as Na storage + electrode, activated carbon as Cl storage -electrodes, assembled into a CDI cell. Preparation of electrode material: active material, conductive carbon black and PVDF with a mass ratio of 70%:20%:10% were mixed in NMP solvent to form a slurry. Drop the slurry on graphite paper (2.5×2.5cm 2 ), and dried at 60 °C for 12 h to obtain a CDI electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com