Foam drainage agent composition for high-condensate-gas well as well as preparation method and application of foam drainage agent composition

A foam drainage and composition technology, which is applied in the directions of drilling compositions, chemical instruments and methods, and earth-moving drilling, etc., can solve the problems of insufficient oil resistance of foam, poor foam drainage performance, and bottom-hole fluid accumulation, etc. Achieve the effect of reducing emulsification performance, improving foam oil resistance and reducing gas flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

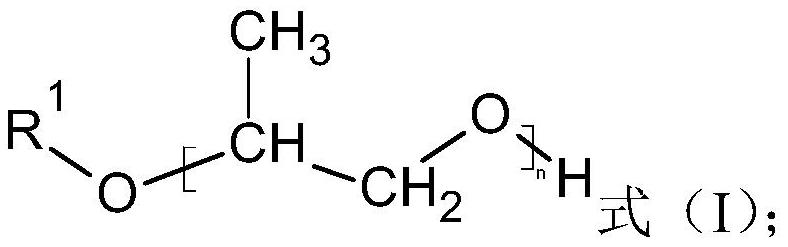

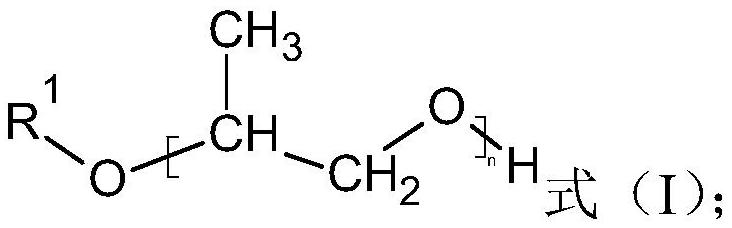

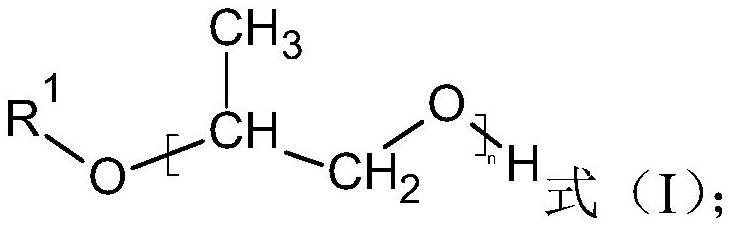

[0031] The source of the isomeric alcohol polyoxypropylene ether is not particularly limited in the present invention, and it can be prepared by any existing method, and can also be obtained commercially. The following takes a specific preparation method of an isomeric alcohol polyoxypropylene ether as an example to illustrate, and the present invention is not limited thereto. The specific preparation method of the isomeric alcohol polyoxypropylene ether may include: reacting isomeric alcohol and propylene oxide under the condition of a reaction temperature of 85-160 ° C and a pressure of 0-0.8 MPa gauge pressure under the action of a catalyst to obtain isomeric alcohol poly Oxypropylene ether; wherein the molar ratio of propylene oxide to iso-alcohol is 1-25:1; the catalyst is a basic compound of potassium, and the dosage is 0.3%-3% by weight of iso-alcohol.

[0032] The present invention has a wide optional range for the structure of the isomeric alcohol polyoxypropylene eth...

Embodiment 1

[0060] This example is used to illustrate the foam discharge agent composition of the present invention and its preparation method.

[0061] In this embodiment, the isomeric alcohol polyoxypropylene ether is isomeric tridecanol polyoxypropylene ether, and n=1, R 1 for C 13 H 27 . The preparation method of the isotridecanol polyoxypropylene ether comprises: adding 1 mole of isotridecanol (commercially available from Nantong Runfeng Petrochemical Co., Ltd.) and 1% hydrogen peroxide of isotridecanol weight into the reactor Potassium catalyst, heated to 135 ℃, opened the vacuum system, dehydrated for 1 hour, then purged with nitrogen 3-4 times to remove the air in the system, and then adjusted the reaction temperature of the system to 150 ℃ and fed 1 mole of propylene oxide to control The alkoxylation reaction was carried out at a pressure of less than 0.6 MPa for 2 hours. After the reaction was completed, the system was purged with nitrogen, and after cooling, the isotridecano...

Embodiment 2

[0064] This example is used to illustrate the foam discharge agent composition of the present invention and its preparation method.

[0065] In this embodiment, the isomeric alcohol polyoxypropylene ether is isomeric tridecanol polyoxypropylene ether, and n=3, R 1 for C 13 H 27 . The preparation method of isotridecanol polyoxypropylene ether comprises: adding 1 mole of isotridecanol (commercially available from Nantong Runfeng Petrochemical Co., Ltd.) and 2% by weight of isotridecanol into a reactor Potassium catalyst, heated to 135°C, opened the vacuum system, dehydrated for 1 hour, then purged with nitrogen 3-4 times to remove the air in the system, then adjusted the reaction temperature of the system to 150°C and fed 3 moles of propylene oxide to control The alkoxylation reaction was carried out at a pressure of less than 0.6 MPa for 3 hours. After the reaction was completed, the system was purged with nitrogen, and after cooling, the isotridecanol polyoxypropylene ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com