Laser crystal, laser and preparation method of hundred-picosecond laser

A laser crystal and laser technology, applied in the field of optics, can solve problems such as unfavorable operation, large size, and poor treatment effect, achieve compact structure design, improve threshold, and achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

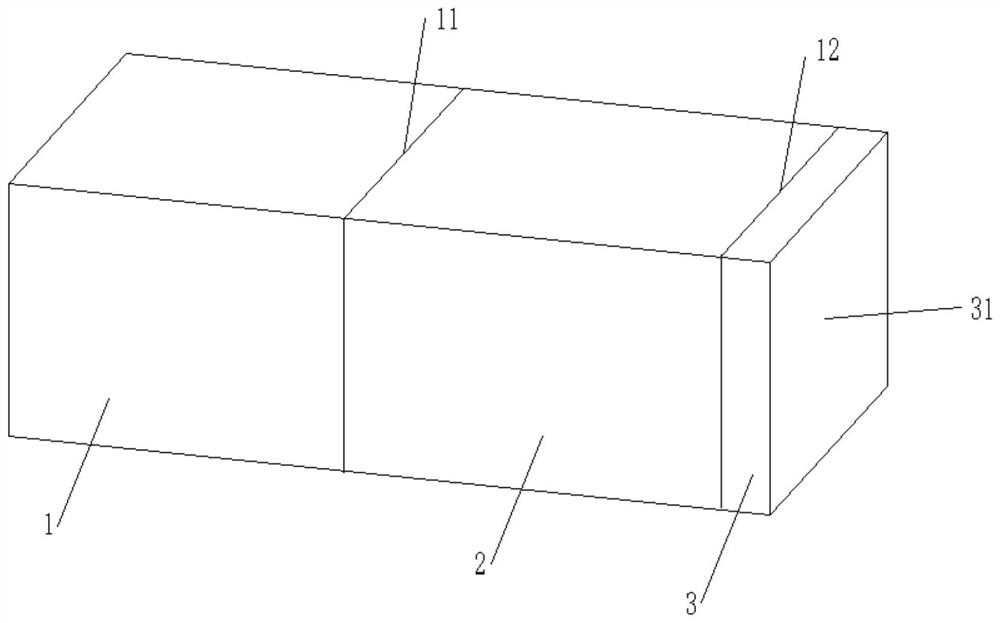

[0038] Please refer to figure 1 , the laser provided by Embodiment 1 of the present invention has a small size, a compact and regular structure, and facilitates miniaturization of the laser.

[0039] In this embodiment, the laser crystal includes a YAG crystal 3, a Cr:YAG crystal 2 and a Nd:YAG crystal 1, and these three crystals are sequentially bonded to form a small-sized passive Q-switched laser crystal.

[0040] Wherein, the second bonding surface 12 is formed between the YAG crystal 3 and the Cr:YAG crystal 2, the first bonding surface 11 is formed between the Cr:YAG crystal 2 and the Nd:YAG crystal 1, and the first bonding surface 11 and the second bonding surface The two bonding surfaces 12 are parallel to each other.

[0041] Wherein, the Nd:YAG crystal 1 is provided with a pump light incident end face 13 parallel to the first bonding face 11, and the YAG crystal 3 is provided with a laser emitting end face 31 parallel to the second bonding face 12, specifically , t...

Embodiment 2

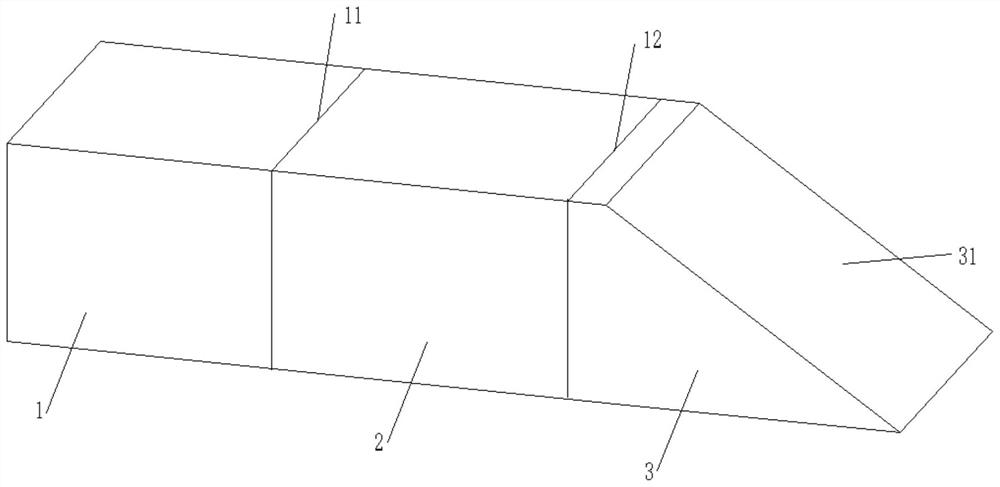

[0053] Please refer to figure 2 with image 3 , the laser crystal provided in Embodiment 2 is basically the same as the crystal structure of Embodiment 1, and the similarities will not be described in detail. The difference lies in:

[0054] In the second embodiment, the laser emitting end surface 31 and the second bonding surface 12 are set at a preset angle, optionally, the preset angle is 28°-32°, specifically, the preset angle is 30°.

[0055] In this embodiment, the pumping light is perpendicular to the pumping light incident end face 13 and enters the laser crystal. At this time, the laser emitting end face 31 is 60° to the pumping light incident direction. Therefore, when the laser is output from the laser emitting end face 31, a deflection.

[0056] In this embodiment, the laser emitting end surface 31 of the YAG crystal 3 is not coated with a film system, and one end of the YAG crystal 3 provided with the laser emitting end surface 31 is provided with an output mir...

Embodiment 3

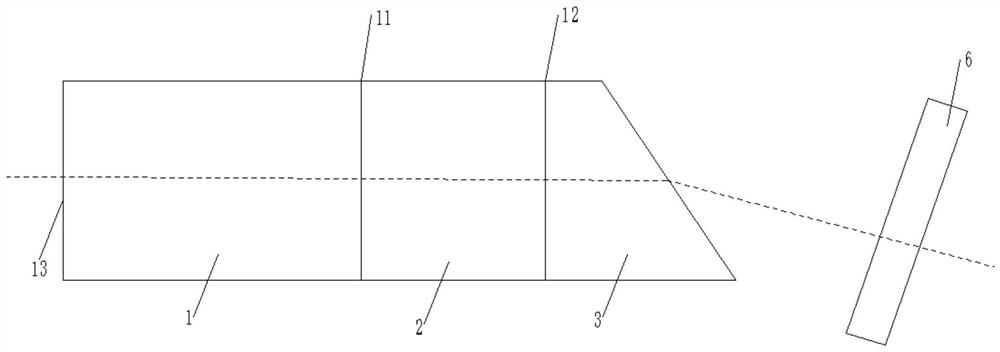

[0061] Please refer to Figure 4 with Figure 5 , the structure of a laser crystal provided in the third embodiment is basically the same as that in the second embodiment, and the similarities will not be repeated, but the difference is:

[0062] In the third embodiment, the laser emitting end surface 31 and the second bonding surface 12 are set at 30°, and the material of the output mirror 6 is YAG crystal 3. The output mirror 6 is used to output the laser after changing the laser output path. Specifically, the The output mirror 6 deflects the deflected laser path again, so that the final output path is consistent with the incident direction of the pump light.

[0063] In a specific embodiment, the output mirror 6 of YAG crystal material is wedge-shaped, and the output mirror 6 includes a deflection surface and an output surface, wherein the deflection surface is close to the laser exit end face 31 and is parallel to the laser exit end face 31, and the output surface is para...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com