Short-distance welding machine welding current wireless control system and use method thereof

A welding current and wireless control technology, which is applied in welding equipment, signal transmission system, auxiliary welding equipment, etc., can solve the problems of increasing welding machine load, unsteady current, and inconvenient operation, so as to protect machine equipment and improve work efficiency , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

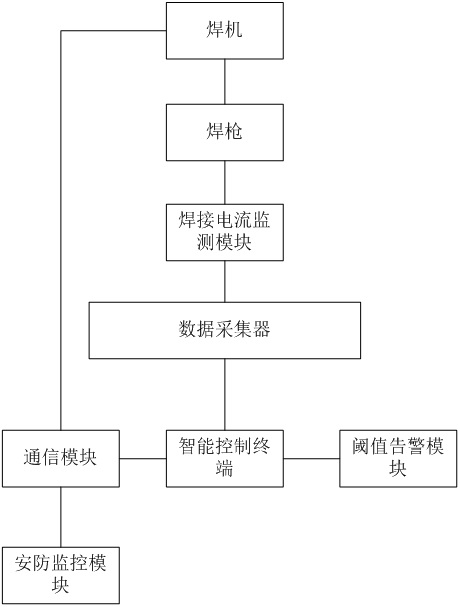

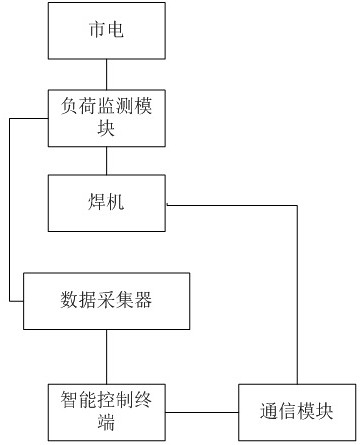

[0031] Such as Figure 1-2 , a short-distance welding machine welding current wireless control system, including a welding machine and a welding torch, the power input end of the welding machine is connected to the mains through a load detection module, and the signal output end of the load monitoring module is connected to the first data collector A signal input terminal, the current output terminal of the welding machine is connected to the current input terminal of the welding torch, the welding torch is connected to the welding current detection module, and the signal output terminal of the welding current detection module is connected to the second signal input terminal of the data collector, The signal output end of the data collector is connected to the first signal input end of the intelligent control terminal, the intelligent control terminal is bidirectionally connected to the threshold alarm module, and the second signal output end of the intelligent control terminal...

Embodiment 2

[0040] On the basis of Embodiment 1, this embodiment proposes a method for using a wireless control system for welding current of a short-distance welding machine, which includes the following steps:

[0041] S1. Log in to the intelligent control terminal and start the monitoring and control of the welding machine through the visual operation interface of the intelligent terminal;

[0042] S2. Select the modules that need to be viewed or controlled through the visual operation interface, where the selectable modules include energy consumption analysis, load monitoring, threshold alarm, security monitoring and intelligent control;

[0043] S3. When the control of the intelligent control terminal is turned on, the monitoring module in the welding current control system of the short-distance welding machine starts to monitor the welding machine data in the working state in real time. When the intelligent control terminal receives a signal inconsistent with the threshold data, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com