Multi-time crystallization equipment for fully-degradable plastic product by taking PLA (Polylactic Acid) as main base material

A plastic product and multiple crystallization technology, applied in the field of PLA production, can solve the problems that the blower does not have the effect of temperature control, the cooling efficiency of plastic products is limited, and thin-walled products are prone to deformation, etc., to achieve high temperature adjustable, Effect of improving high temperature resistance and increasing heat deflection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

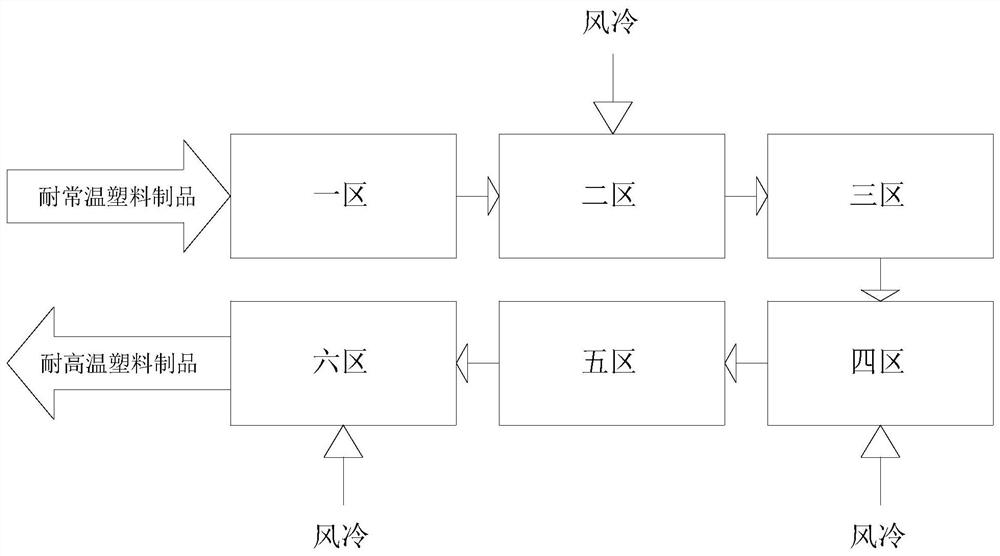

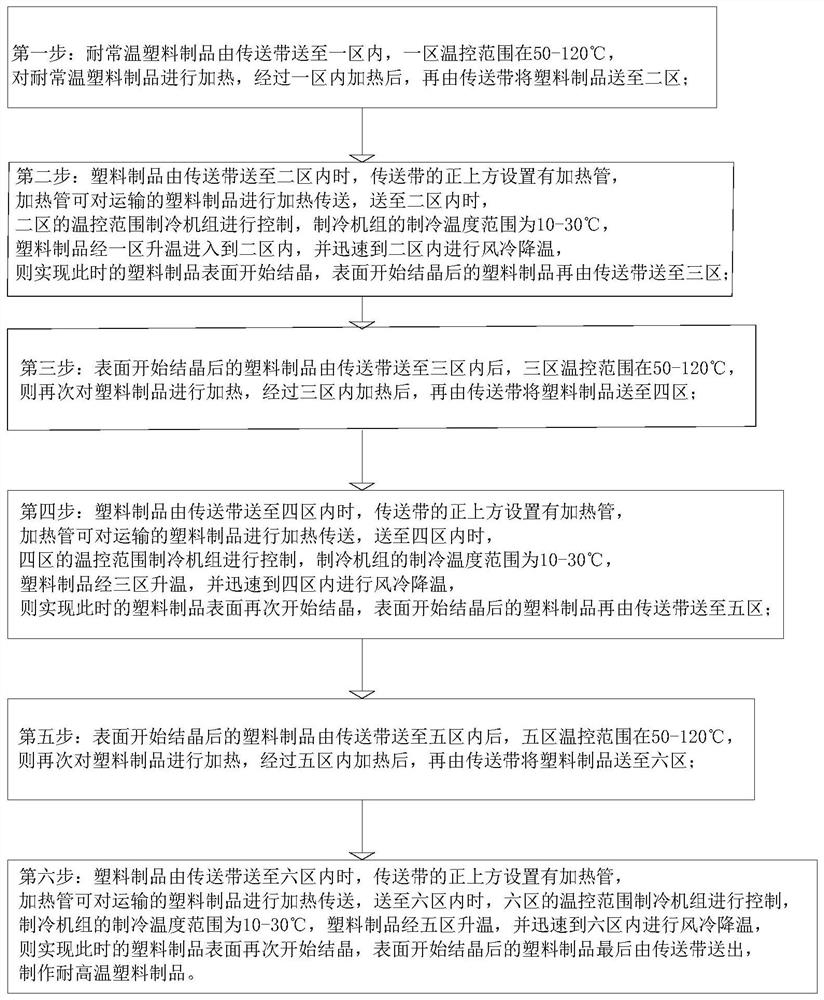

[0031] Embodiment: a kind of equipment with PLA as the main base material fully degradable plastic products multiple crystallization, such as figure 1 - figure 2 As shown, it includes multiple crystallization equipment. The multiple crystallization equipment includes zone 1, zone 2, zone 3, zone 4, zone 5, and zone 6. Each zone is connected by a conveyor belt in a straight line, and the conveyor belt is made of Teflon gauze. There are heating pipes directly above the conveyor belt, and refrigeration units are installed on the second, fourth and sixth districts, and the corresponding refrigeration units are integrated with the second, fourth and sixth districts respectively, and the refrigeration units The upper end of the integrated and corresponding area equipment, the refrigeration temperature range of the refrigeration unit is 10-30°C, the refrigeration unit can realize temperature and air volume adjustment, one zone, two zones, three zones, four zones, five zones, six zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com