Combination station oil storage tank head gas and wharf oil gas recovery system

An oil and gas recovery system and oil storage tank technology, which is applied in the direction of gas fuel, petroleum industry, separation methods, etc., can solve the problems of emissions not meeting the requirements of environmental protection regulations, polluting the atmospheric environment, and emissions exceeding the standard, so as to protect the surrounding area Environment, high degree of automation, high energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

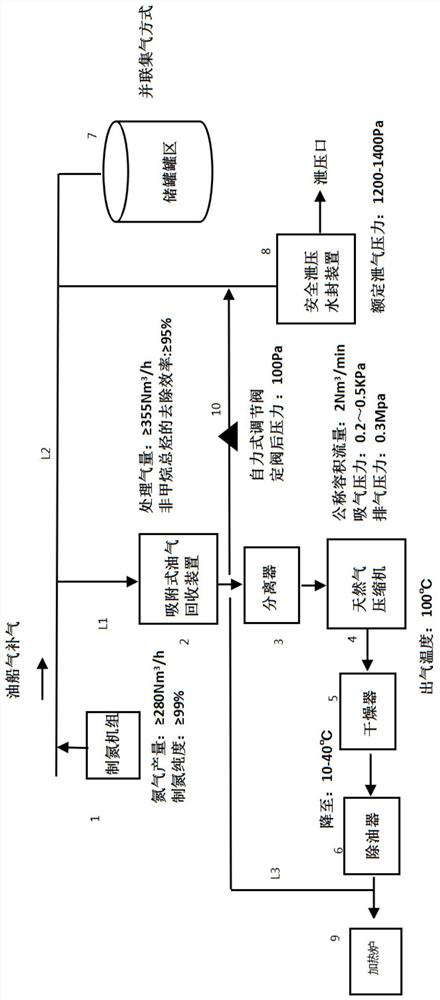

[0022] like figure 1 Illustrated, the combination station tank roof and piers hydrocarbon gas recovery system, a nitrogen comprising unit 1, downstream of the nitrogen unit 1 is provided with a first line L1 and a second line L2,

[0023] Downstream of the first conduit L1 sequentially provided with a vapor recovery adsorption 2, a separator 3, a blower 4, a dryer 5, a 6 and a degreasing furnace 9.

[0024] The second parallel line L2 is provided downstream of a reservoir tank 7 and a safety relief seal means 8,

[0025] The outlet of the demister 6 a third line L3 with a self-regulating valve 10 is connected to the outlet of the Self-regulating valve 10 is connected to the inlet of the safety relief device 8 through the seal.

[0026] Predetermined pressure after the valve 10 is self-regulating valve 100Pa. The set relief pressure safety relief seal means 8 1200 ~ 1400Pa, blower nominal volume flow is 2Nm 3 / Min, inspiratory pressure is 0.2 ~ 0.5KPa, vent pressure 15-30kpa.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com