Method and device for synthesizing chloromethane

A technology for the synthesis reaction of methyl chloride, which is applied in the field of preparing methane chloride, can solve the problems of high energy consumption, low-concentration hydrochloric acid, and long process, and achieve the effects of energy consumption, high conversion rate, and reduced pressure on waste acid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

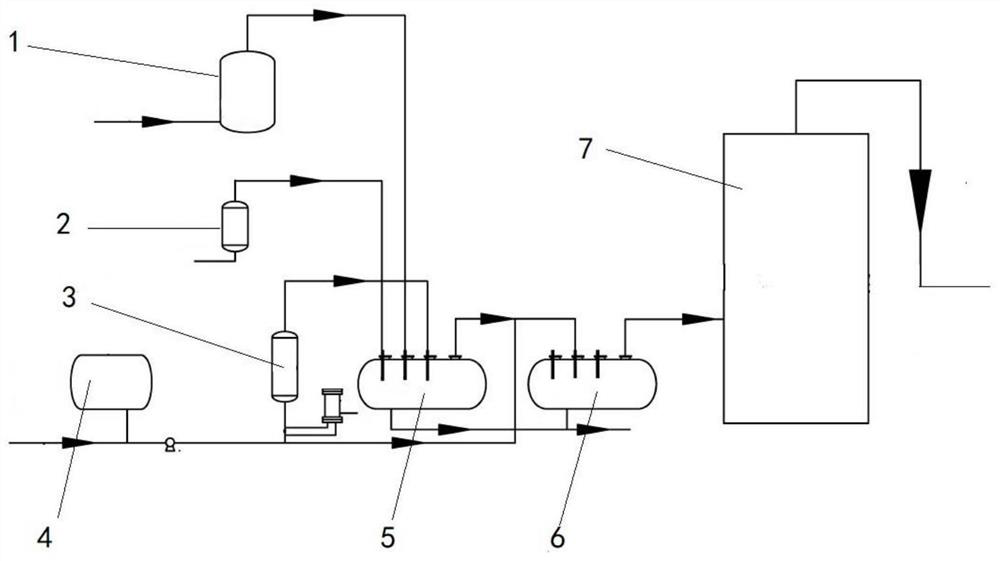

[0049] (1) 15% of gaseous hydrogen chloride is mixed with 35% hydrochloric acid solution and preheated gaseous methanol into the first reaction kettle 5 for synthesis reaction through preheated concentration, wherein the total moles of hydrogen chloride in gaseous hydrogen chloride and hydrochloric acid solution amount, the ratio with the molar amount of gaseous methanol is 1.05:1; the liquid level in the first reaction kettle 5 is controlled at 50%, the pressure in the kettle is 2barg, and the temperature is 120°C. During the reaction, the amount of hydrochloric acid solution is adjusted , preheating temperature, or the preheating temperature of methanol gas maintains the reaction temperature in the first reactor 5, and the conversion rate of hydrogen chloride in the first reactor 5 is 90%;

[0050] (2) Methane chloride at the outlet of the first reactor 5, and the mixed gas of unreacted excess hydrogen chloride and a very small amount of unreacted methanol gas are passed into...

Embodiment 2

[0052] (1) gaseous hydrogen chloride is mixed with 18% through the preheated concentration that is 35% hydrochloric acid solution, the gaseous methanol through preheating is passed in the first reactor 5 and carry out synthetic reaction, wherein the total mole of hydrogen chloride in gaseous hydrogen chloride and hydrochloric acid solution amount, the ratio with the molar amount of gaseous methanol is 1.1:1; the liquid level in the first reaction kettle 5 is controlled at 50%, the pressure in the kettle is 3barg, and the temperature is 120°C. During the reaction, the amount of hydrochloric acid solution is adjusted , preheating temperature, or the preheating temperature of methanol gas maintains the reaction temperature in the first reactor 5, and the conversion rate of hydrogen chloride in the first reactor 5 is 86%;

[0053] (2) Methane chloride at the outlet of the first reactor 5, and the mixed gas of unreacted excess hydrogen chloride and a very small amount of unreacted m...

Embodiment 3

[0055] (1) 20% of gaseous hydrogen chloride is mixed with 35% hydrochloric acid solution through preheated concentration, and gaseous methanol through preheating is passed in the first reactor 5 to carry out synthesis reaction, wherein the total moles of hydrogen chloride in gaseous hydrogen chloride and hydrochloric acid solution amount, the ratio with the molar amount of gaseous methanol is 1.05:1; the liquid level in the first reaction kettle 5 is controlled at 50%, the pressure in the kettle is 2barg, and the temperature is 140°C. , preheating temperature, or the preheating temperature of methanol gas maintains the reaction temperature in the first reactor 5, and the conversion rate of hydrogen chloride in the first reactor 5 is 88%;

[0056] (2) Methane chloride at the outlet of the first reactor 5, and the mixed gas of unreacted excess hydrogen chloride and a very small amount of unreacted methanol gas are passed into the second reactor 6 to continue the reaction. At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com