Method for preparing poly (butylene succinate) by taking dimethyl succinate as raw material

A technology of polybutylene succinate and dimethyl succinate, which is applied in the field of preparing polybutylene succinate, can solve the problems of large amount of tetrahydrofuran generated, poor catalyst selectivity, and low molecular weight of polymers, etc. Achieve high molecular weight, improve catalytic activity, and reduce catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Dimethyl succinate and butanediol (wherein the mol ratio of dimethyl succinate and butanediol is 1:1.3, the quality sum of dimethyl succinate and butanediol is 35kg) is added to reaction device, then add 0.7g magnesium acetate (the quality of the transesterification catalyst is 0.005% of the total mass of dimethyl succinate and butanediol), and carry out the transesterification reaction for 3h at a negative pressure of 10kPa and at a temperature of 155°C. Then heat up to 225°C, add 1.75g of tetrabutyl titanate, 0.36g of trimethyl phosphate (the amount of trimethyl phosphate is 0.5 times the amount of tetrabutyl titanate), and reduce the pressure to 20Pa The polycondensation reaction was carried out for 6 h to obtain polybutylene succinate, which was denoted as PBS1.

Embodiment 2

[0064] Embodiment 2 has carried out test 2.1, test 2.2, test 2.3 and test 2.4 altogether 4 tests.

[0065] The difference between Test 2.1 and Example 1 is only that the molar ratio of succinic acid to butanediol is 1:1.0, and finally PBS2 is obtained.

[0066] The difference between test 2.2 and embodiment 1 is only that the mol ratio of succinic acid and butanediol is 1:1.65, finally obtaining PBS3.

[0067] The difference between test 2.3 and embodiment 1 is only that the mol ratio to succinic acid and butanediol is 1:1.8, finally obtaining PBS4.

[0068] The difference between test 2.4 and embodiment 1 is only that the mol ratio to succinic acid and butanediol is 1:2.2, and finally obtains PBS5.

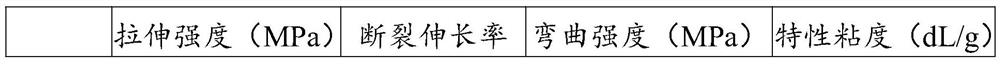

[0069] The present invention also tests the mechanical properties of PBS1, PBS2, PBS3, PBS4 and PBS5, and the tensile strength is tested according to GB / T 1040.2-2006 Part 2: The test conditions for molding and extruding plastics; the bending strength is tested according to GB ...

Embodiment 3

[0081] Embodiment 3 has carried out altogether 5 tests of test 3.1, test 3.2, test 3.3, test 3.4 and test 3.5.

[0082] The difference between test 3.1 and test 2.2 in embodiment 2 is only that the consumption of transesterification catalyst is 0.005% of the total mass of dimethyl succinate and butanediol, finally obtains PBS6, and the content of by-product tetrahydrofuran is 0.005% of the mass of butanediol. 4%.

[0083] The difference between test 3.2 and test 2.2 in embodiment 2 is only that the consumption of transesterification catalyst is 0.02% of the total mass of dimethyl succinate and butanediol, and finally obtains PBS7, and the content of by-product tetrahydrofuran is 0.02% of the mass of butanediol. 1%.

[0084] The difference between test 3.3 and test 2.2 in embodiment 2 is only that the consumption of transesterification catalyst is 0.03% of the total mass of dimethyl succinate and butanediol, and finally obtains PBS8, and the content of by-product tetrahydrofur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com