Shielding assembly of semiconductor equipment and reaction chamber

A reaction chamber and semiconductor technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of uneven wafer temperature, poor film uniformity, and inability to achieve heat dissipation, so as to improve uniformity , increase production capacity, and increase the effect of a single working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order for those skilled in the art to better understand the technical solution of the present invention, the shielding assembly and the reaction chamber of the semiconductor device provided by the present invention will be described in detail below with reference to the accompanying drawings.

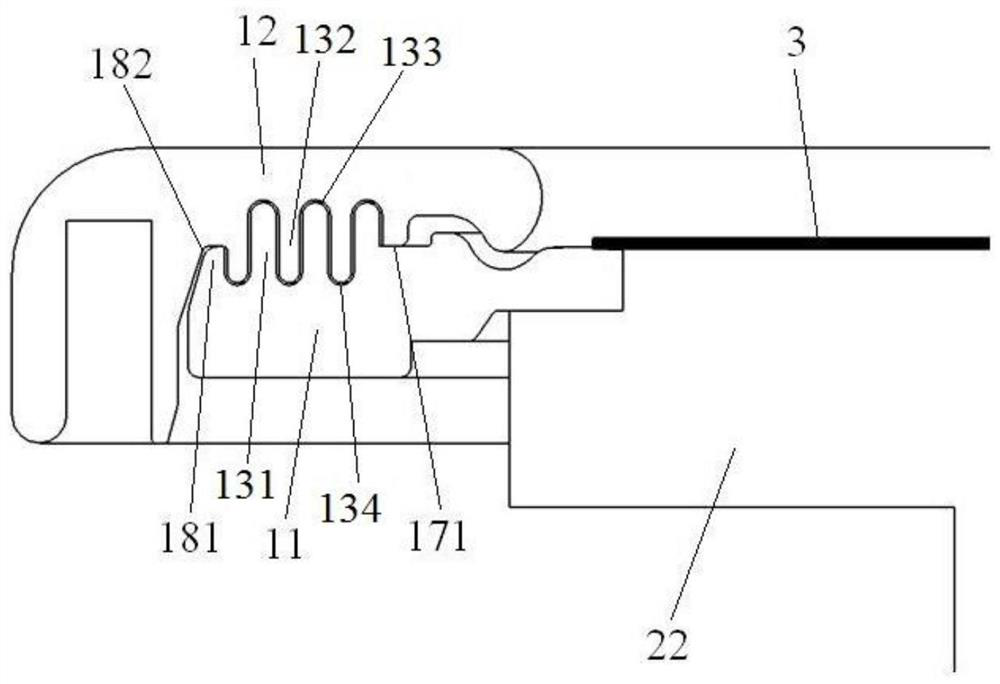

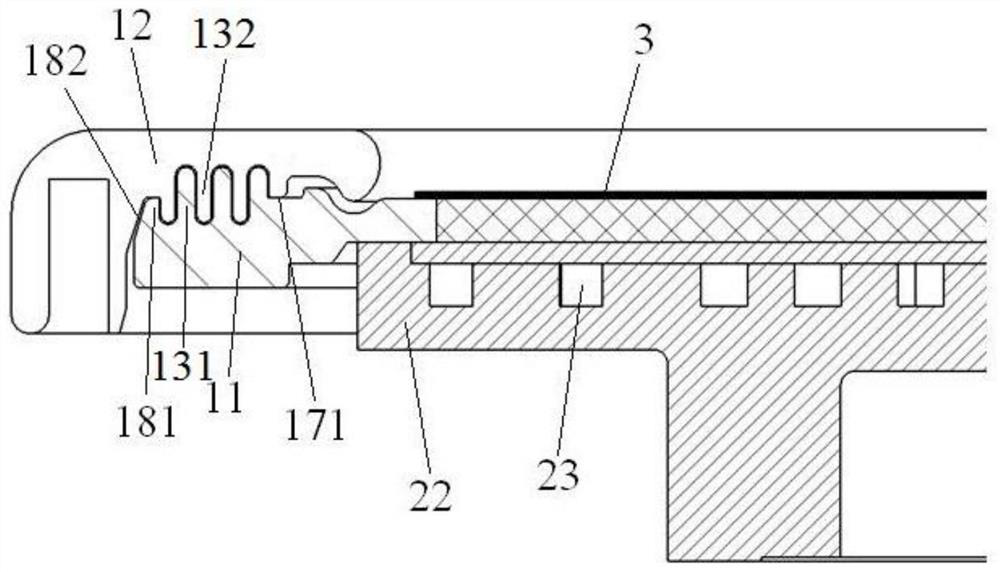

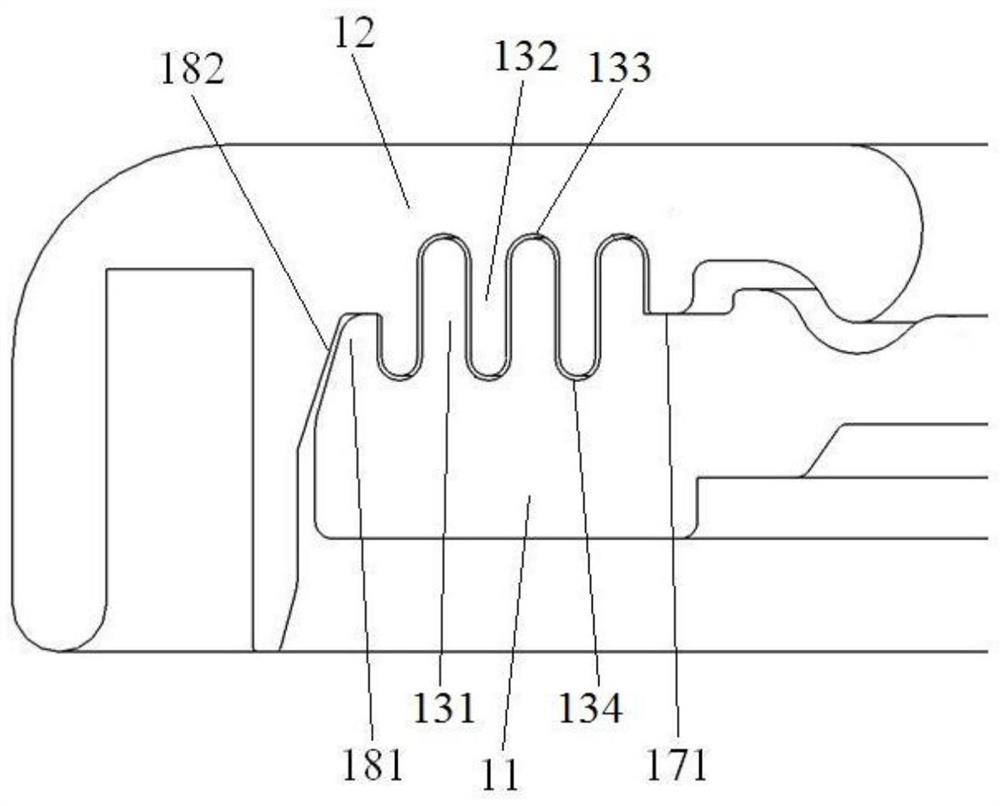

[0032] Such as figure 1 and Figure 7 As shown, the embodiment of the present invention provides a shielding assembly for a semiconductor device, which is arranged in a reaction chamber. The shielding assembly includes a first ring body 11 and a second ring body 12. The first ring body 11 is used to surround the reaction chamber On the outer peripheral wall of the carrier part 22, the second ring body 12 is movably arranged on the lining 27 in the reaction chamber, and the second ring body 12 is located above the first ring body 11, the first ring body 11 and The second ring body 12 can be selectively separated or abutted, and the two surfaces of the first ring body 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com