High-reliability double-bus mutual hot backup automatic compensation device and control method

An automatic compensation, double bus technology, applied in two-wire DC circuits, output power conversion devices, circuit devices, etc., can solve the problems of input stage short circuit, large inrush current, complex logic judgment and sequence control, etc. Simple control, long service life, and fast output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] A high-reliability automatic compensation device with double busbars as hot backup for each other of the present invention will be further described in detail in conjunction with the accompanying drawings and specific implementation methods.

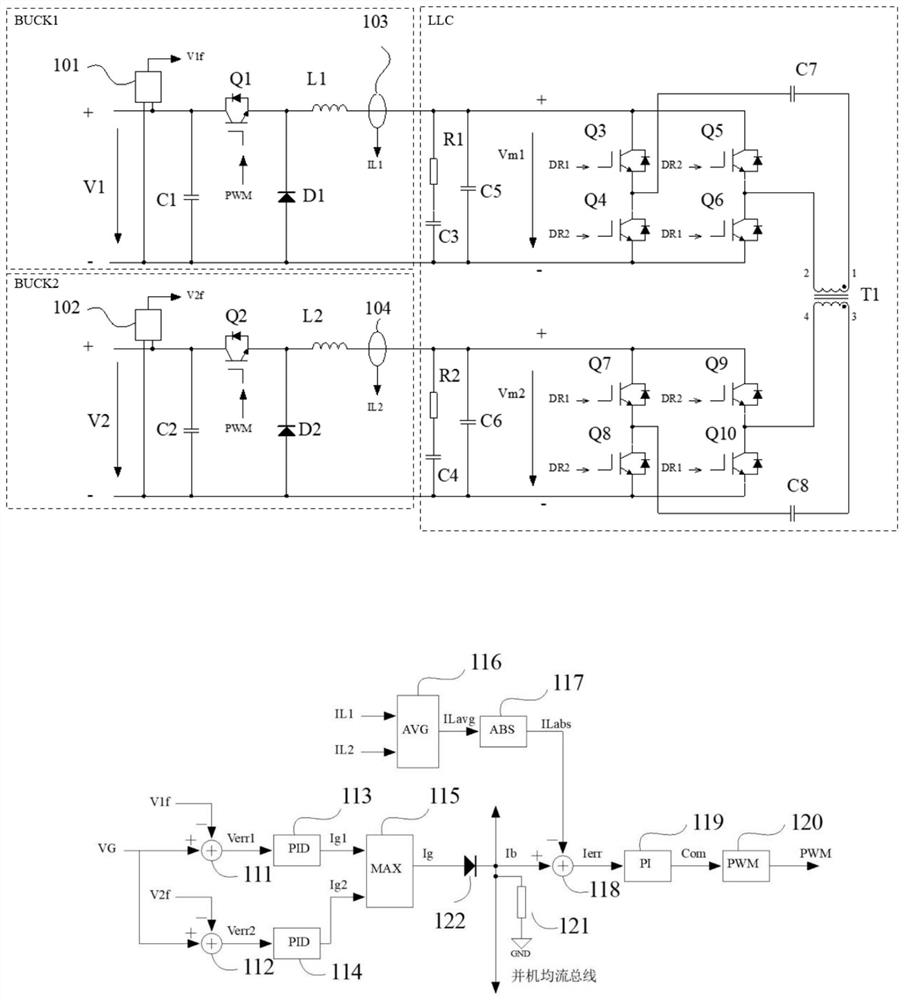

[0085] Such as figure 1 , Figure 8 and Figure 9 As shown, it is a circuit diagram of an automatic compensation device with high reliability dual busbars as hot backup for each other in the present invention.

[0086] The working process of the system is described in detail below:

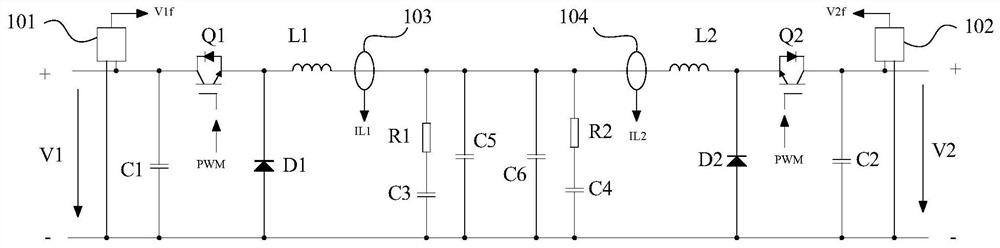

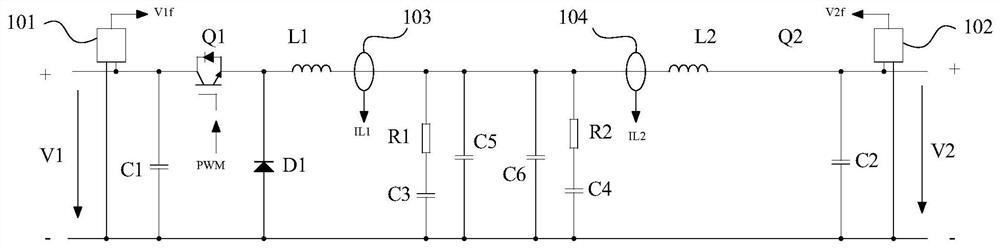

[0087] The intermediate stage DCDC is in the open-loop working mode, and the working frequency is the resonant frequency of LLC. The switching tubes Q3~Q10 are always in the state of zero-voltage on and zero-current off, and the energy flows in both directions with a gain of 1. Therefore, the voltage of the bus V1m and the bus V2m are equal, which can be equivalent to figure 2 shown.

[0088] When the current flows from V1 to V2, the BUCK conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com