Preparation process of high-heat-dissipation multi-layer PCB

A technology of PCB circuit board and preparation process, which is applied in the direction of multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc. Problems such as heat accumulation, to achieve the effect of ensuring heat transfer efficiency, improving production safety, and ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

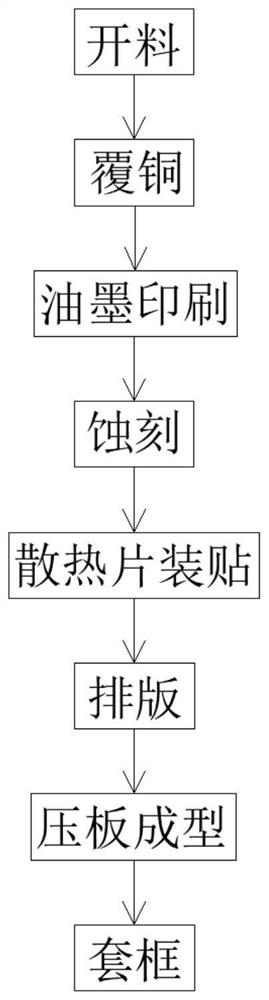

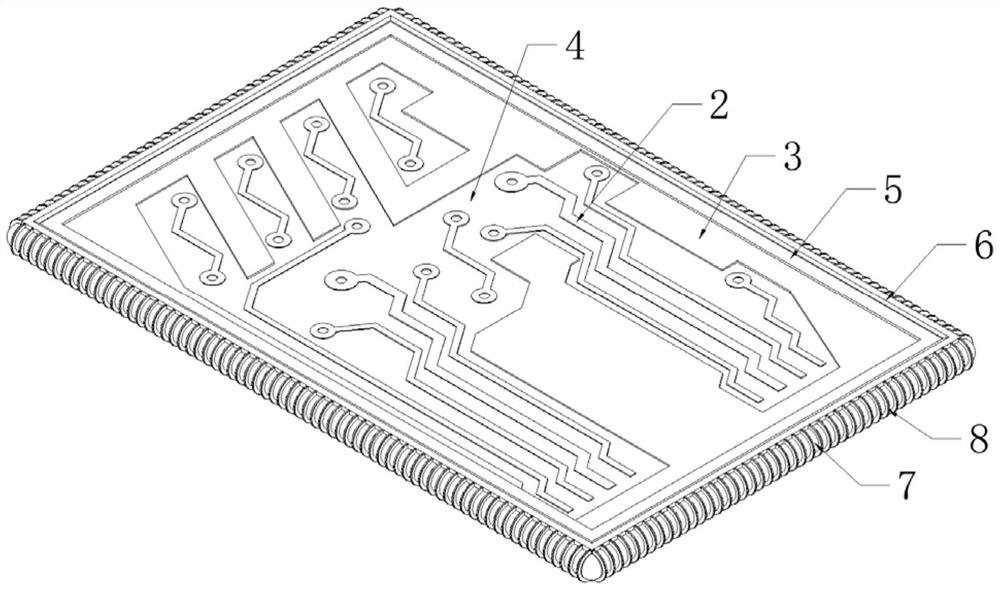

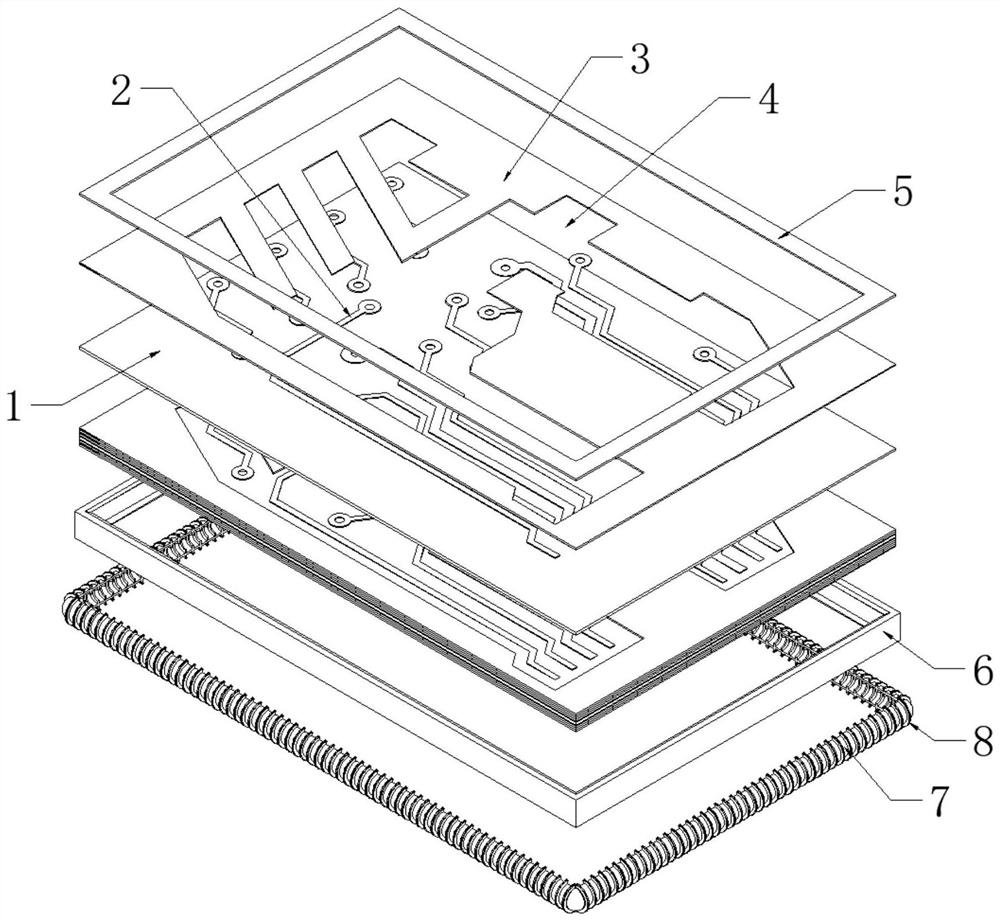

[0053] see Figure 1-10 , a preparation process of a high heat dissipation multilayer PCB circuit board, comprising the following steps:

[0054] S1, material cutting, according to the design requirements of the produced PCB circuit board, the entire PCB board is cut into substrates 1 of equal size by a cutting device;

[0055] S2, copper covering, according to the design requirements of the PCB circuit board, evenly and fixedly cover the metal copper layer on the outer surface of the substrate 1;

[0056] S3, ink printing, printing the pre-designed circuit ink layer on the metal copper layer on the outer surface of the substrate 1 through a hot press;

[0057] S4, etching, the substrate 1 after ink printing is put into the inside of the etching device, and the metal copper layer not covered by the circuit ink layer on the outer surface of the substrate 1 is corroded by the overlooking liquid in the etching device, and the metal under the circuit ink layer is corroded. The c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap