A kind of solar silicon chip diamond wire cutting fluid, its preparation method and application

A technology for cutting solar silicon wafers and diamond wires, which is used in lubricating compositions, petroleum industry, etc., can solve problems such as the inability to meet the needs of large-scale silicon wafer cutting, and achieves reduction of sewage treatment costs, good permeability and film-forming properties, The effect of reducing the amount of pure water used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10 and comparative example 1-3

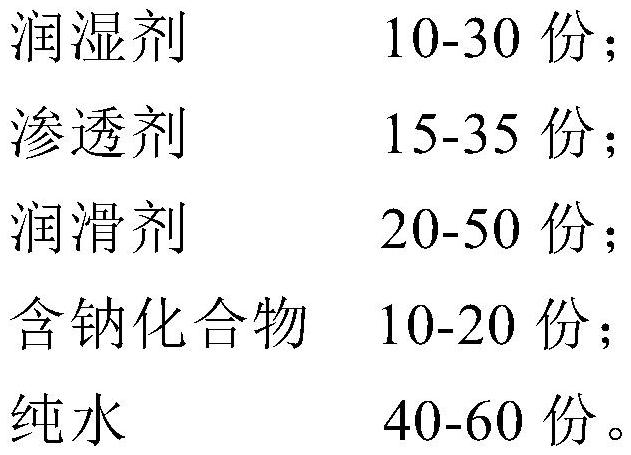

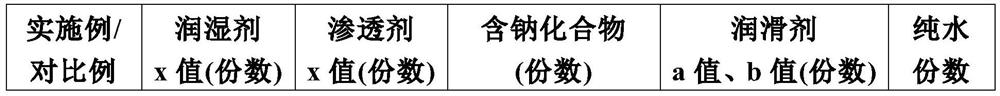

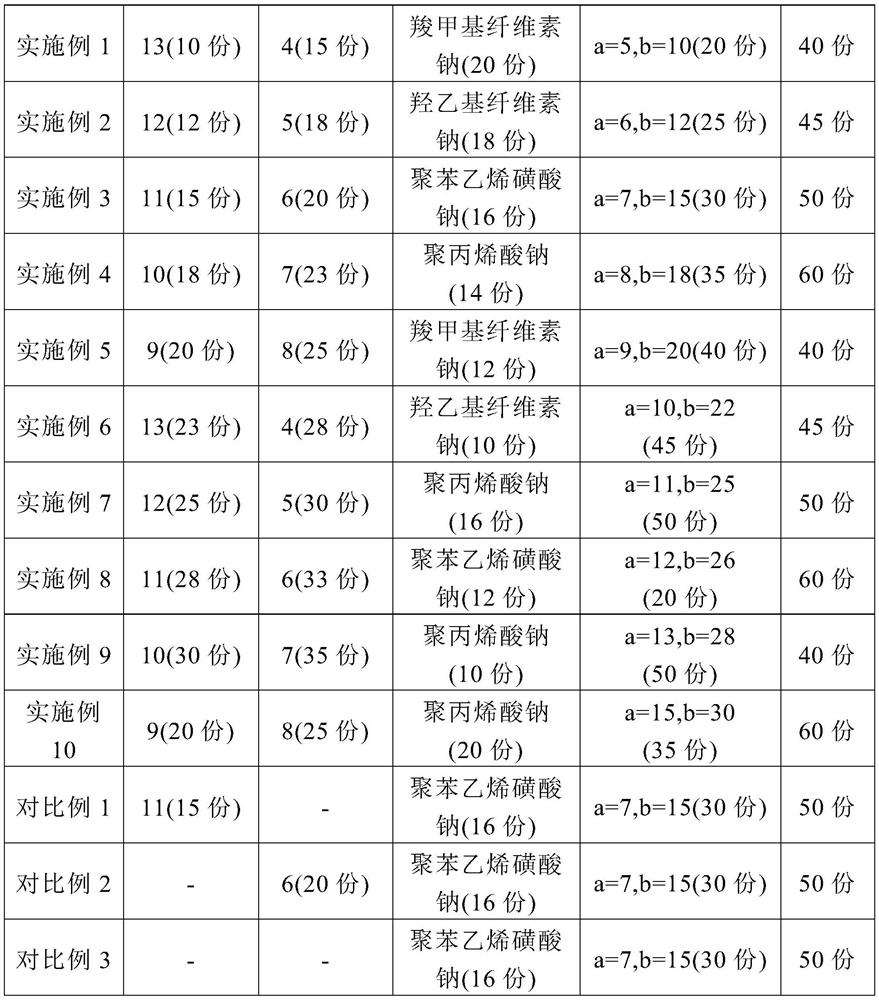

[0034] The components of the diamond wire cutting fluid prepared in Examples 1-10 and Comparative Examples 1-3 and their mass parts are shown in Table 1.

[0035] Table 1 Examples 1-10 and Comparative Examples 1-3

[0036]

[0037]

[0038] Note: The chemical formula of wetting agent and penetrant are RO(CH 2 CH 2 O) x H, R is C 10 H 21 , the chemical formula of the lubricant is HO(C 3 H 6 O) a (CH 2 CH 2 O) b H.

[0039] The preparation method of the diamond wire cutting liquid of embodiment 1-10 is as follows:

[0040] S1: In a room temperature environment, pure water is added to the reactor after cleaning with pure water and stirring is started;

[0041] S2: Add wetting agent, penetrating agent, lubricant, sodium-containing compound in sequence and keep stirring;

[0042] S3: The temperature of the reactor is controlled and stirred at 35°C for 3 hours until it is completely dissolved;

[0043] S4: stop stirring and let stand for 6-12 hours;

[0044] S5: A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com