Gas-liquid phase separation spray pipe device used for plasma spraying physical vapor deposition

A technology of physical vapor deposition and plasma spray gun, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of expensive replacement cost, expensive operation cost, and complicated spraying process, and achieve energy and powder utilization rate High, good economic benefits, the effect of high gas phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

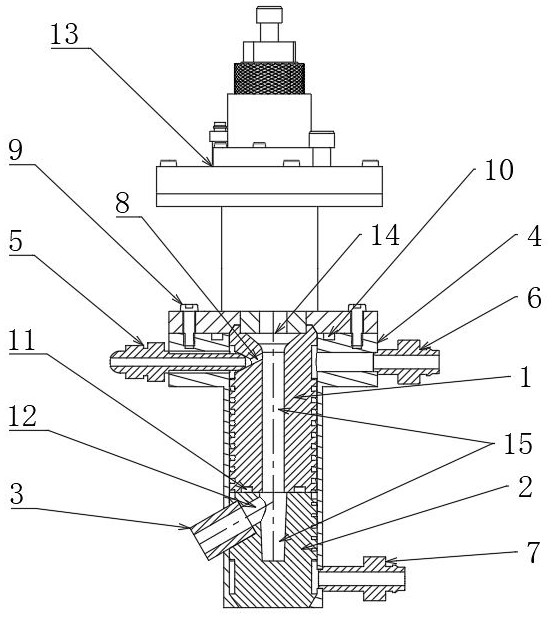

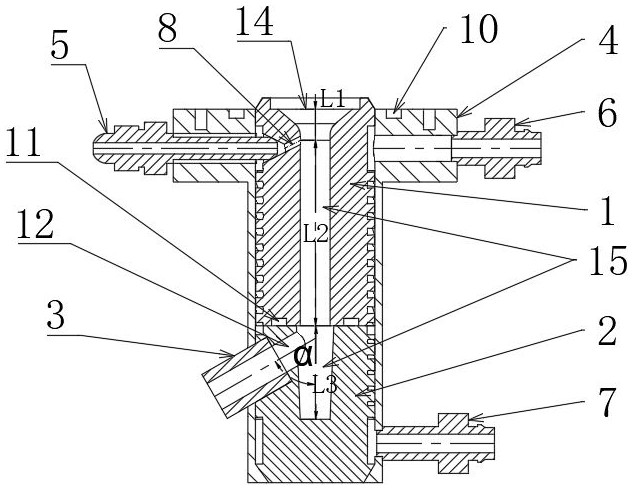

[0020] The above and other objects, features and advantages of the present invention will be more apparent through the following description of the embodiments of the present invention with reference to the accompanying drawings. The present invention is described below based on the embodiments, and those skilled in the art should understand that the drawings provided here are for illustration purposes, and the drawings are not necessarily drawn to scale.

[0021] Unless the context clearly requires, throughout the specification and claims, "comprises", "comprises" and similar words should be interpreted in an inclusive sense rather than an exclusive or exhaustive meaning; that is, "including but not limited to" meaning.

[0022] Such as figure 1As shown, the present invention discloses a gas-liquid phase separation nozzle device for plasma spraying physical vapor deposition, comprising an upper graphite nozzle 1, a lower graphite crucible 2, an outlet graphite short nozzle 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com