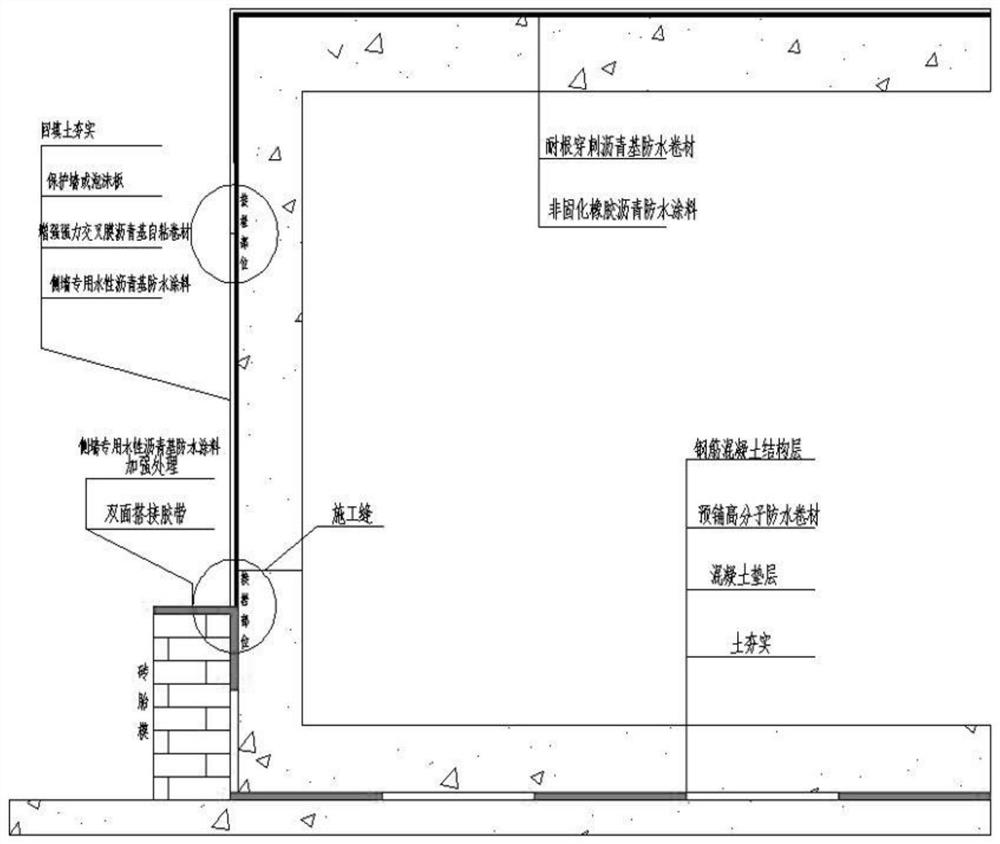

Coating-rolling composite waterproof system structure suitable for underground side wall

A system structure and side wall technology, applied in the field of coating-roll composite waterproof system and coating-roll composite waterproof system construction, to achieve the effect of fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

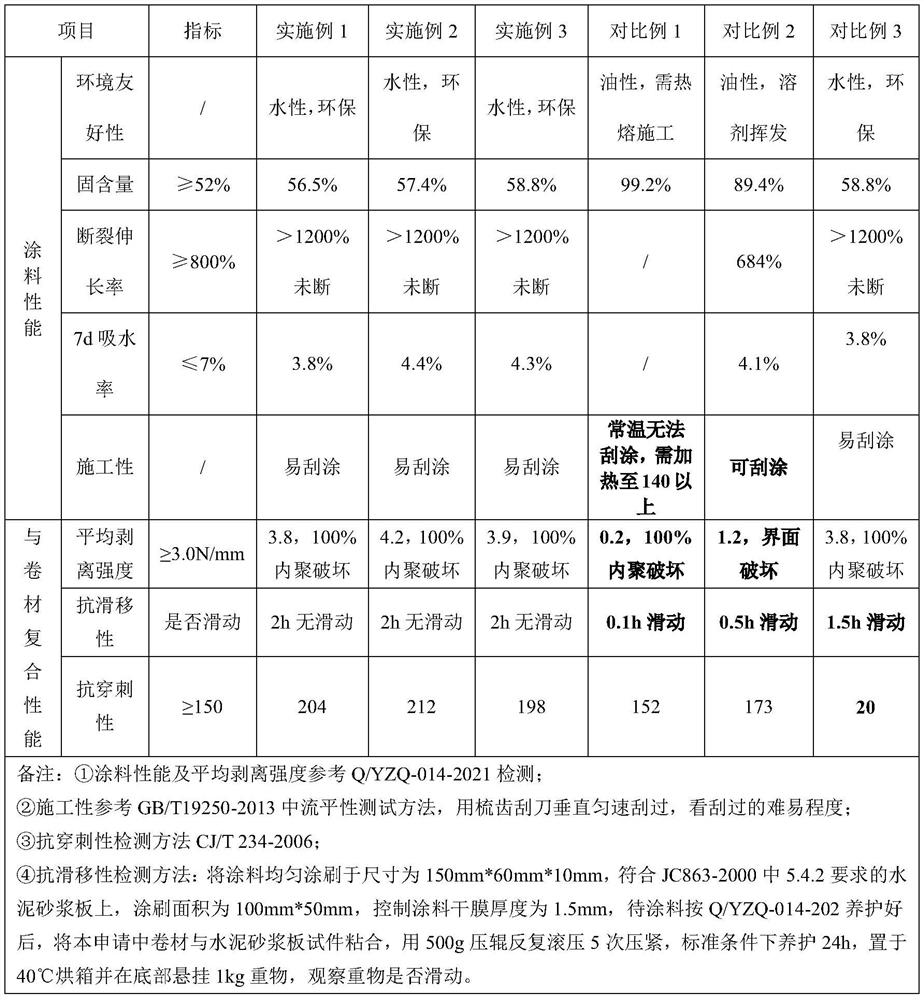

Examples

Embodiment 1

[0021] A method for preparing two main materials in the construction of a coating-roll composite waterproof system suitable for underground side wall waterproofing:

[0022] Asphalt-based waterproof coating for side walls (parts by mass):

[0023] First add 22.5 parts of low Tg acrylic emulsion, 22.5 parts of high Tg acrylic emulsion, 0.1 part of dispersant, 0.15 part of defoamer into the mixing tank, stir at 600-800r / min for 30 minutes, then add 45 parts of slow-cracking emulsification Asphalt and petroleum resin emulsion 10 parts viscosifying emulsion, after continuing to stir for 30 minutes, add a mixed dispersion consisting of 0.15 parts of hydroxyethyl cellulose ether and 1 part of water, and continue stirring at 600-800r / min until there is no graininess Finally, add 0.4 parts of polyurethane thickener, disperse and stir for 30 minutes, and then filter to obtain the above-mentioned asphalt-based waterproof coating for side walls.

[0024] Bitumen-based self-adhesive memb...

Embodiment 2

[0030] A method for preparing two main materials in the construction of a coating-roll composite waterproof system suitable for underground side wall waterproofing:

[0031] Asphalt-based waterproof coating for side walls (parts by mass):

[0032] First add 25 parts of low Tg acrylic emulsion, 25 parts of high Tg acrylic emulsion, 0.2 part of dispersant, 0.35 part of defoamer into the stirring tank, stir at 600-800r / min for 30 minutes, then add 55 parts of slow-cracking emulsification Asphalt and petroleum resin emulsion 8 parts viscosifying emulsion, after continuing to stir for 30 minutes, add a mixed dispersion consisting of 0.3 parts of hydroxyethyl cellulose ether and 1.5 parts of water, and continue stirring at 600-800r / min until there is no graininess Finally, add 0.3 parts of polyurethane thickener, disperse and stir for 30 minutes, and then filter to obtain the above-mentioned asphalt-based waterproof coating for side walls.

[0033] Bitumen-based self-adhesive membr...

Embodiment 3

[0039] A method for preparing two main materials in the construction of a coating-roll composite waterproof system suitable for underground side wall waterproofing:

[0040] Asphalt-based waterproof coating for side walls (parts by mass):

[0041] First add 35 parts of low Tg acrylic emulsion, 20 parts of high Tg acrylic emulsion, 0.5 part of dispersant, 0.5 part of defoamer into the stirring tank, stir at 600-800r / min for 30 minutes, then add 60 parts of slow-cracking emulsification Asphalt and petroleum resin emulsion 6 parts viscosifying emulsion, after continuing to stir for 30 minutes, add a mixed dispersion consisting of 0.5 parts of hydroxyethyl cellulose ether and 2 parts of water, and continue stirring at 600-800r / min until there is no graininess Finally, add 0.2 parts of polyurethane thickener, disperse and stir for 30 minutes, and then filter to obtain the above-mentioned asphalt-based waterproof coating for side walls.

[0042] Bitumen-based self-adhesive membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com