Device and method for power generation through coal gangue incineration coupled CFB boiler unit

A boiler unit and coal gangue technology, which is applied to combustion methods, incinerators, fuels burned in a molten state, etc., can solve the problems of low utilization rate of coal gangue solid waste, high solid waste treatment cost, and low mixing ratio. The effect of saving primary energy, reducing the burden of slag discharge and anti-wear, and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

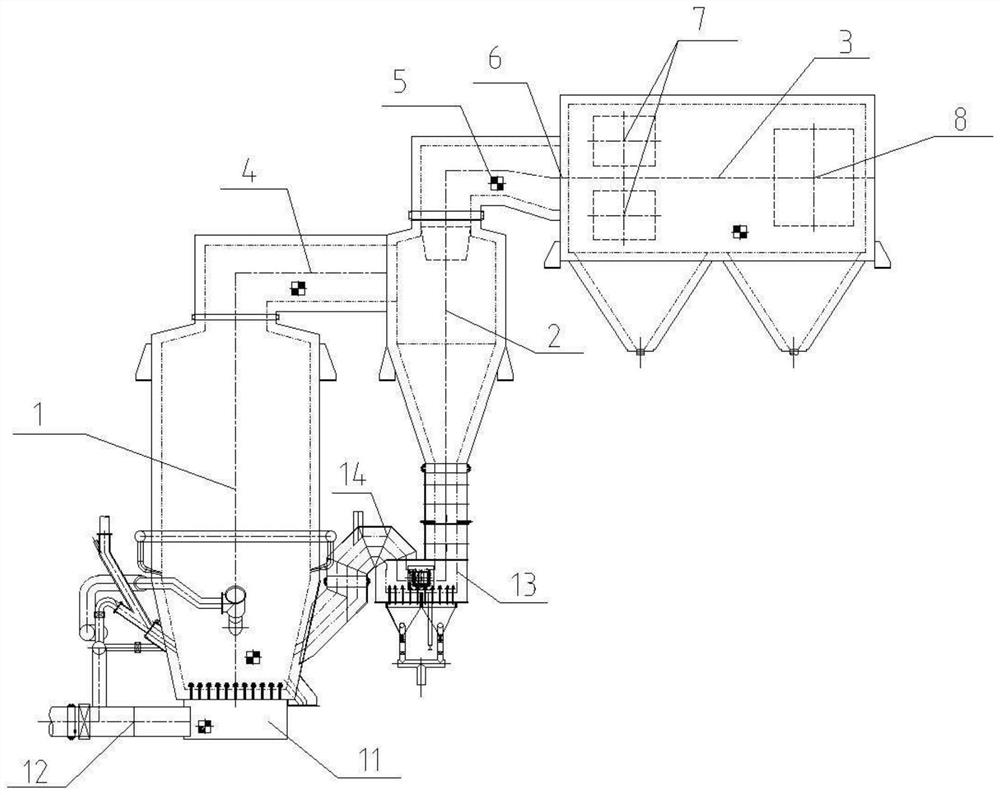

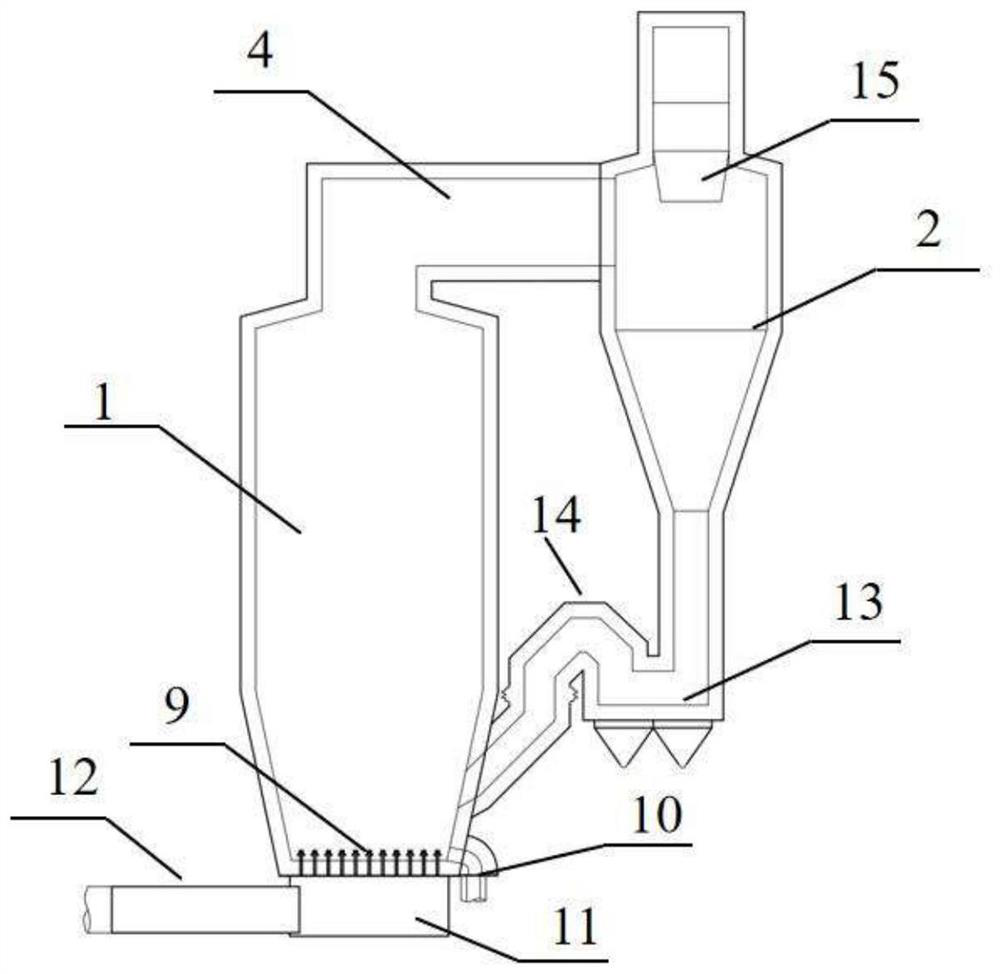

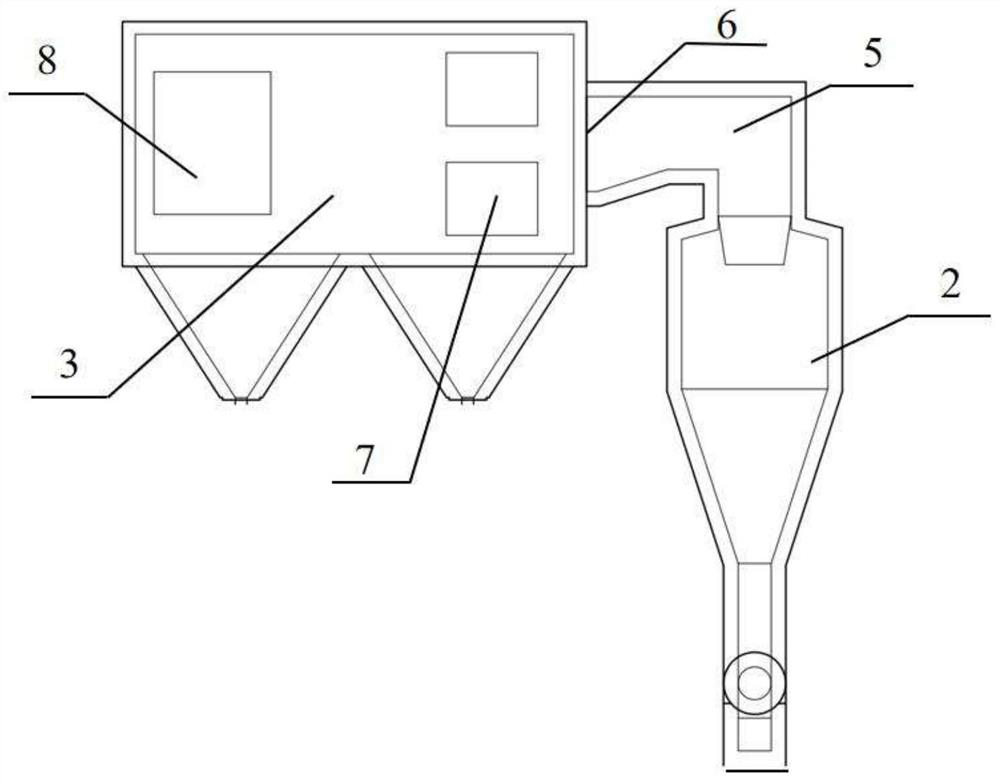

[0031] Such as Figure 1~3 As shown, in a preferred embodiment, the present invention provides a device for incinerating coal gangue coupled with a CFB boiler unit to generate electricity, including an incineration chamber 1, a separator 2 and a mixing air box 3, and the upper part of the incineration chamber 1 is connected by The flue 4 is connected to the separator 2, and the separator 2 is connected to the mixing air box 3 through the outlet flue 5, and the mixing air box 3 is provided with a flue gas inlet 6, a secondary air inlet 7 and a mixing air outlet 8. The secondary air inlet 7 is connected to the secondary air duct of the CFB boiler, the mixed air outlet 8 is connected to the mixed air duct, and the mixed air duct is connected to the CFB boiler unit.

[0032] Incineration chamber 1, the combustion-supporting primary air is passed into the incineration chamber 1, and the coal gangue solid waste is burned in the fluidized bed in the incineration chamber 1 to release ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com