Intermediate infrared rapid batch detection method for alpha s1-casein in milk

A batch detection and casein technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long time-consuming determination, high cost, complicated operation, etc., and achieve the effect of fast identification, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Establishment of a method for detecting αs1-casein content in milk by infrared spectroscopy:

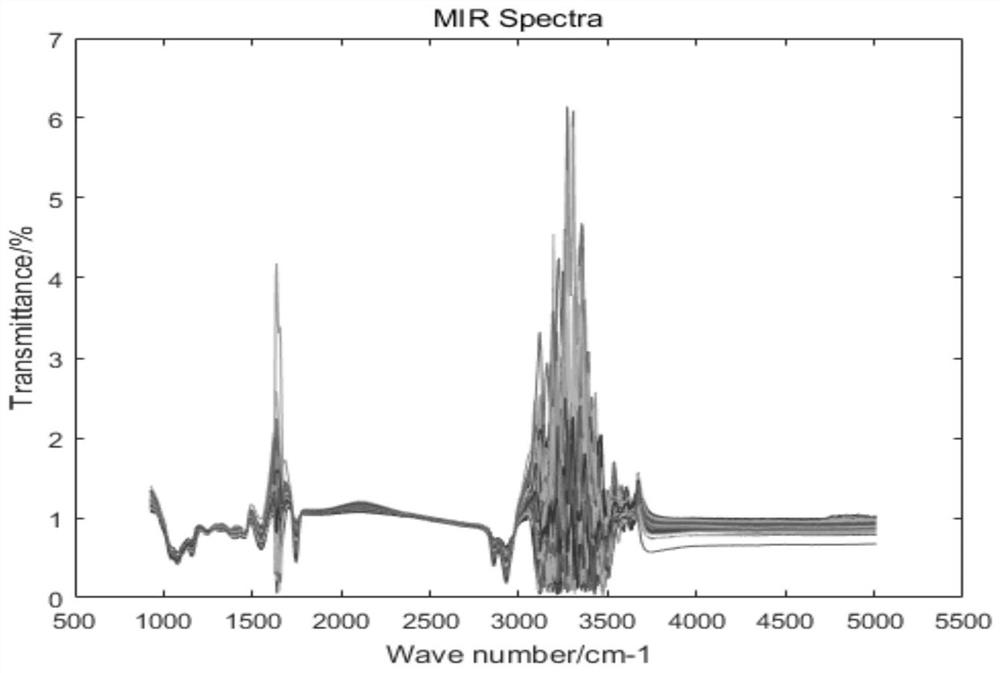

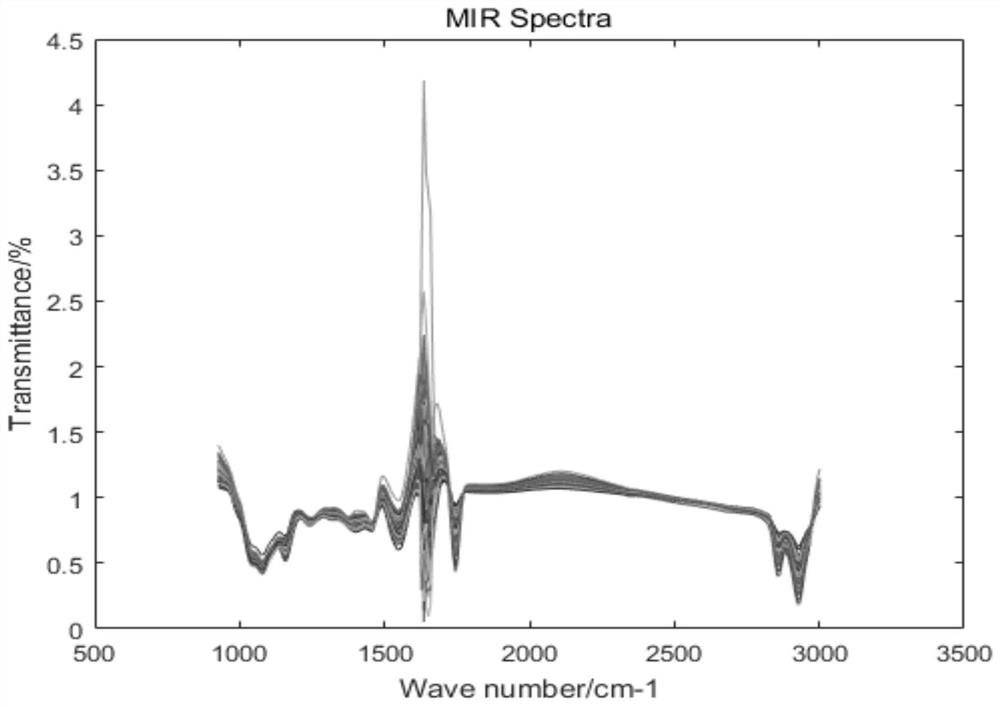

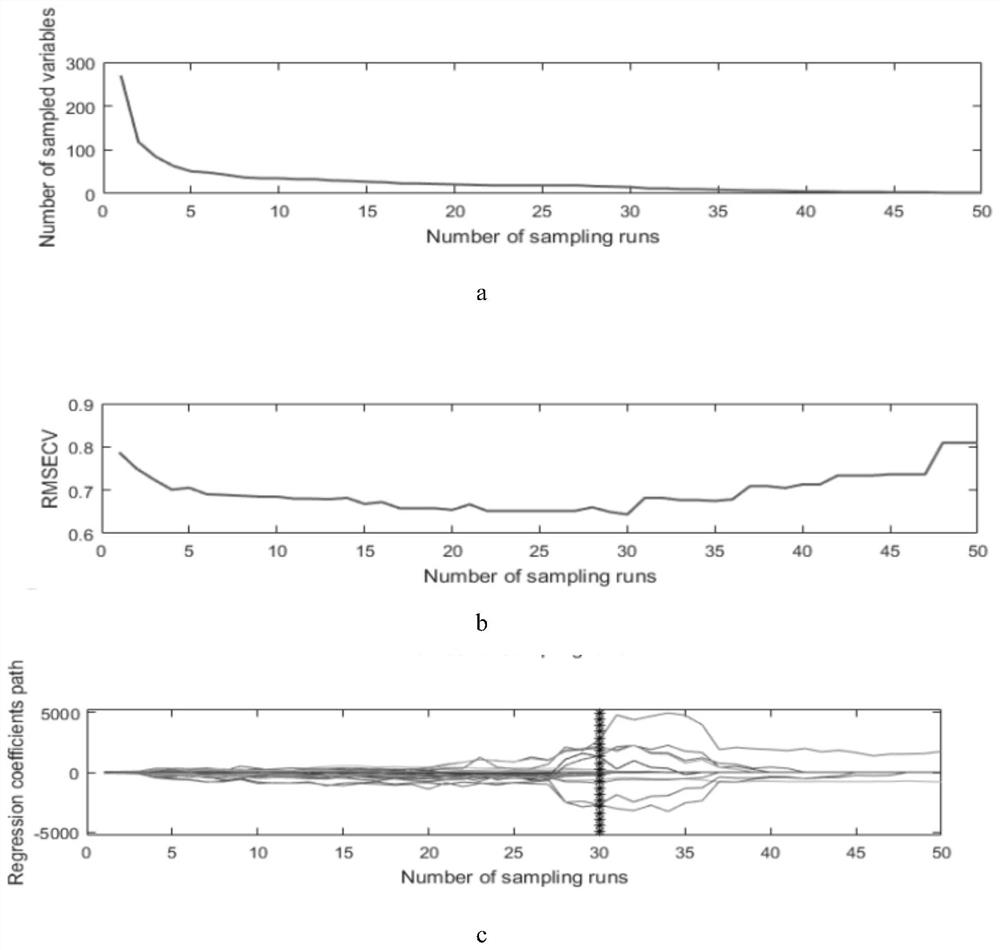

[0029] Milk samples from 6 different dairy farms in 4 different regions were selected and numbered. Pour the sample into a cylindrical sample tube with a diameter of 3.5cm and a height of 9cm, bathe in a water bath at 42°C for 15-20min, and use MilkoScan from FOSS Company TM 7RM milk component detector, the solid fiber optic probe is extended into the liquid, the sample is scanned, and the light transmittance of the milk sample is obtained through the computer ( figure 1 ). Due to 4089.48cm -1 -2758.47cm -1 , 3005-3680cm -1 The spectral information fluctuates greatly in the wavenumber range, and contains a large amount of noise data. If it is used for subsequent analysis and modeling, the generalization ability of the model will be deteriorated; 2758.47cm -1 -1716.81cm -1 , 3680cm -1 -4000cm -1 There is less effective information in the wavenumber range, and the contri...

Embodiment 2

[0046] alpha in milk s1 -Application of the mid-infrared rapid batch detection method for casein:

[0047] Take 20 α s1 - Casein samples to make predictions for the model. Comparison of predicted results with real values (reverse-phase high-performance liquid chromatography, RP-HPLC) (Wang Hao, Zhang Zhiguo, Chang Yanzhong, Duan Xianglin, Zhao Shuqiang, Zhang Nan, Shi Zhenhua. Separation of main milk proteins in dairy products by RP-HPLC And quantitative determination [J]. Food Science, 2009, 30 (24): 376-380.) comparison.

[0048] Method: Collect the spectrum of the sample according to the method in Example 1, and substitute the spectral data into the SG1-CARS-SVR model constructed in Example 1 to output the prediction results, as shown in the table. Rp=0.8998, RMSEP=1.3726.

[0049]

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com