AGV scheduling path optimization method based on 5G Internet of Things

A technology of scheduling paths and optimization methods, which is applied in services based on location information, services based on specific environments, design optimization/simulation, etc., can solve problems such as unreasonable AGV scheduling strategies, lack of scientific guidance, and inability to AGV cars. Achieve the effect of reducing production waiting time, improving comprehensive competitiveness, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

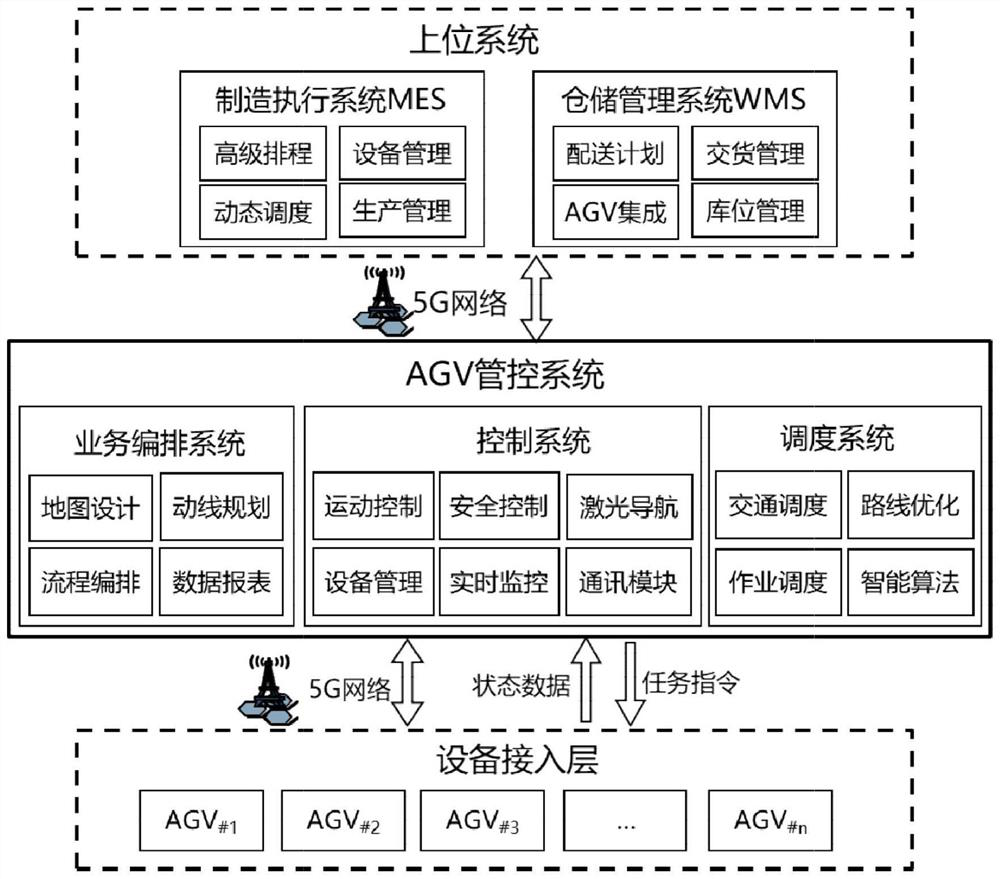

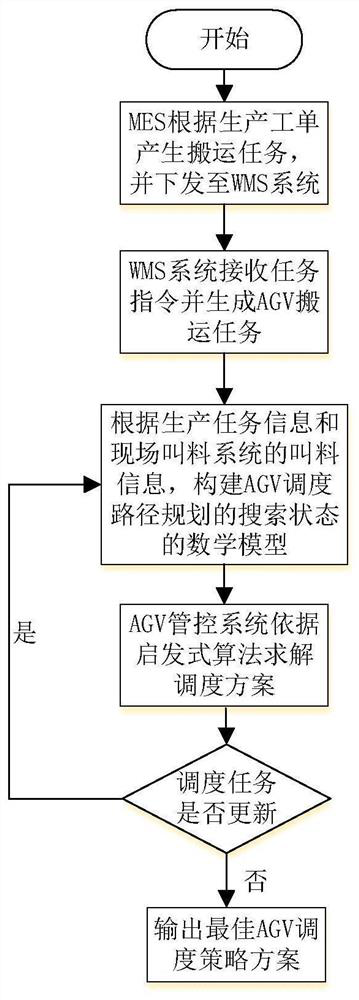

[0102] combine figure 1 and figure 2 , an AGV scheduling path optimization method based on 5G Internet of Things, comprising the following steps:

[0103] Step 1. The MES system (Manufacturing Execution System) generates a handling task according to the production work order and sends it to the WMS system (Warehouse Management System);

[0104] Step 2, WMS system (Warehouse Management System) receives task instructions and generates AGV handling tasks;

[0105] Step 3, according to the production task information and the call information of the on-site call system, construct a mathematical model of the search state of the AGV scheduling path planning;

[0106]Since the electronic map formed between the actual workshop production line equipment and the warehouse is of irregular shape, the layout of the site and resource equipment may also have various restrictions and restrictions. Therefore, the problem of AGV scheduling path optimization is more complicated. The logistics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com