Interconnection material and series welding process of battery strings

A battery and process technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems such as not so beautiful, increased shading area, increased risk of overlapping points, etc., to achieve the effect of ensuring equipment production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

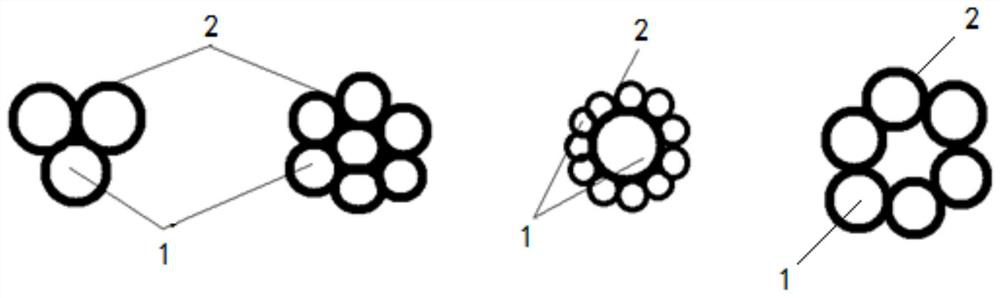

[0032] combined with figure 1 , a kind of interconnection material of the present embodiment, comprises welding wire, and the radial dimension of described welding wire is 0.05-0.35mm, is preferably 0.1-0.25mm, for example, 0.1mm, 0.15mm and 0.2mm etc., and described welding wire is made of 2 - 15 microwires 1 twisted, at least some of which are copper wires for conducting electricity, each of said microwires 1 having a radial dimension between 30-200 μm, for example, 30 μm, 100 μm and 200 μm etc., the surface of each microwire 1 is provided with a metal coating 2 with a low melting point, and the material of the metal coating 2 can be low melting point metals such as tin, lead, and bismuth. The material is preferably tin, which can resist oxidation, increase reflection, and enhance welding. Of course, the metal coating 2 can also contain a small amount of silver and copper components to adjust welding performance and reliability. The surface of the microwire 1 has a metal co...

Embodiment 2

[0041] A string welding process for battery strings, comprising the steps of welding a stranded welding wire on the bus electrode on the front of the battery sheet, and flattening one end of the welding wire cut into a fixed length to a thickness of 0.5-0.1mm before welding, and simultaneously welding the welding wire Apply flux on the surface; after welding, the flattened part is exposed to the edge of the cell by 5-35mm, and the flattened part can extend to the front edge of the cell; the single cell with welding wire is connected in series, in order to facilitate positioning, you can Position and place the front part of the good welding wire of the battery sheet welding machine facing down, and then place the battery sheets one by one so that the welding wire exposed on the front edge is aligned with the bus electrode on the back, and then perform heating welding, repeat the same process, and make the battery string Reach the set length; the welding wire on the battery sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com