Double-end DDQ type three-phase wireless dynamic charging system for electric vehicle

A dynamic charging, electric vehicle technology, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of low power conversion efficiency, decreased power conversion efficiency, low coupling coefficient, etc., to improve power conversion efficiency, reduce Reduced charging efficiency and reduced effect of power supply cross-coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

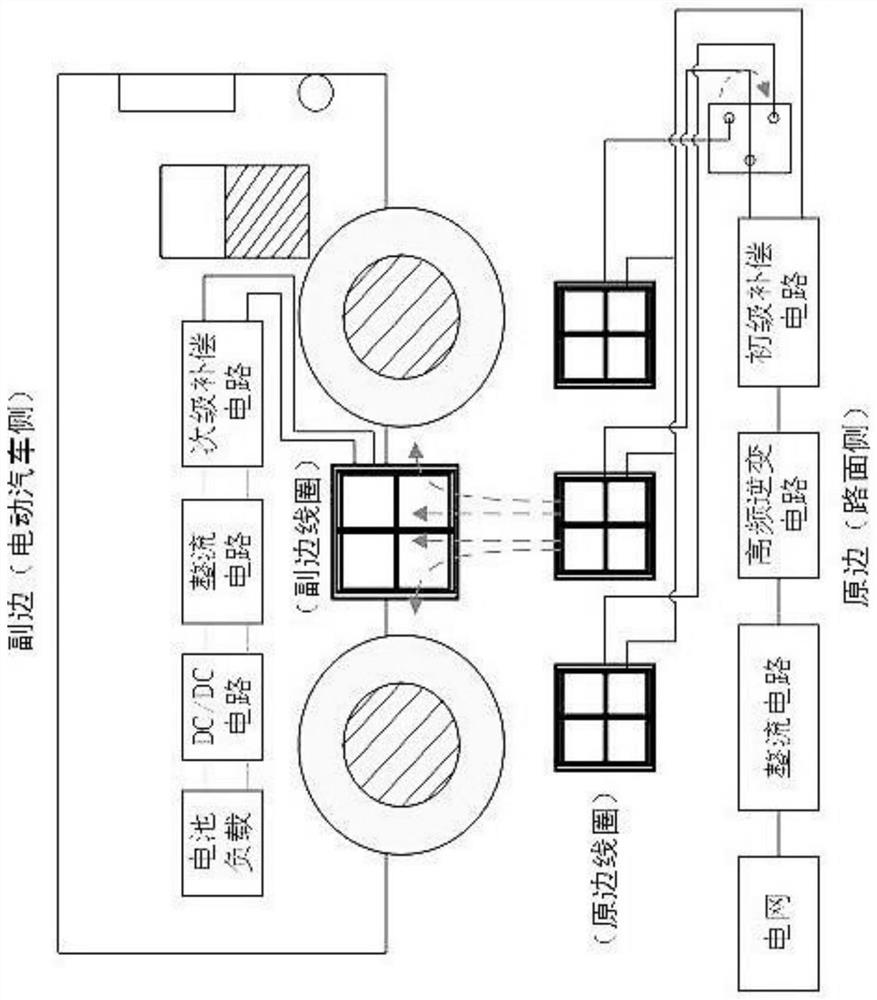

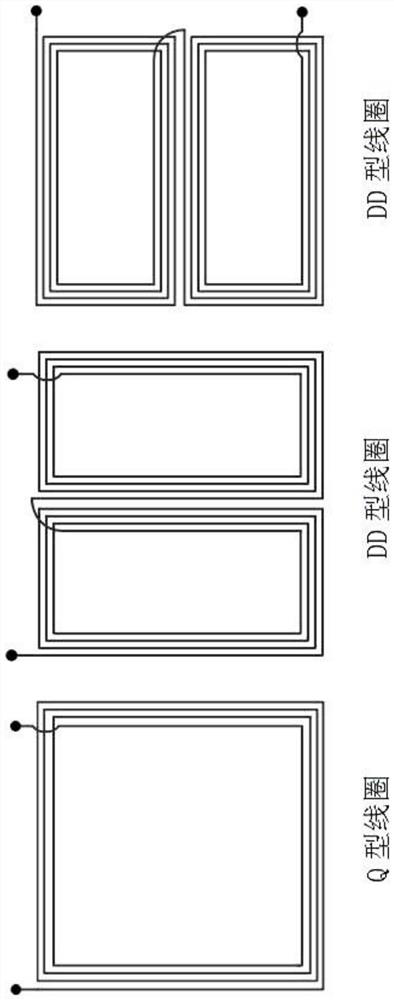

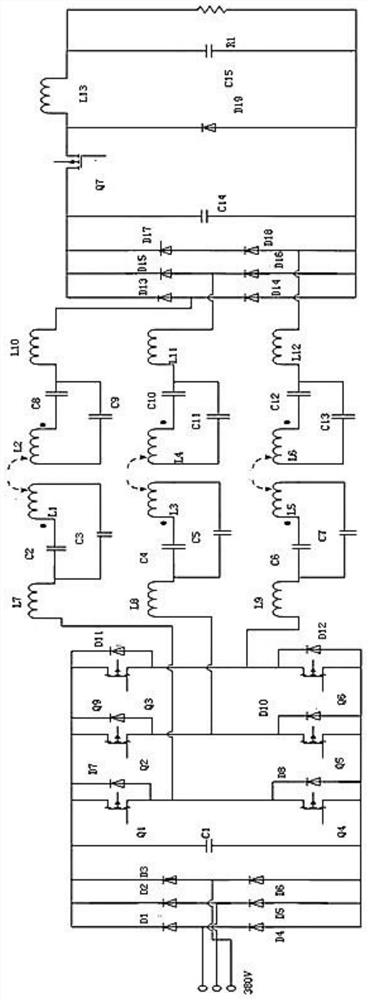

[0017] figure 1 , 2 , 3 shown in 3, an electric vehicle dual-end DDQ three-phase wireless dynamic charging system, including the rectifier circuit, inverter and primary compensation circuit, the original edge coil, and the sub-coil, secondary compensation of the receiving end on the vehicle. And the rectifier circuit, the DC / DC circuit, the original side is mounted on the ground, the secondary side is attached to the lower end of the vehicle; the original edge coil and the secondary coil have a set of Q-type coils, two sets of DD coils, original edge coils, and Q-shaped coil of the secondary coil, the first set of DD coils, the second set of DD coils, respectively, to the second set of DD coils and the first group of the original edge coil and the secondary coil, respectively, the original edge coil and the secondary coil, respectively. The DD coil is 90 ° distribution; the Q-shaped coil of the original edge coil, the DD coil, and the secondary coil of the secondary coil, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com