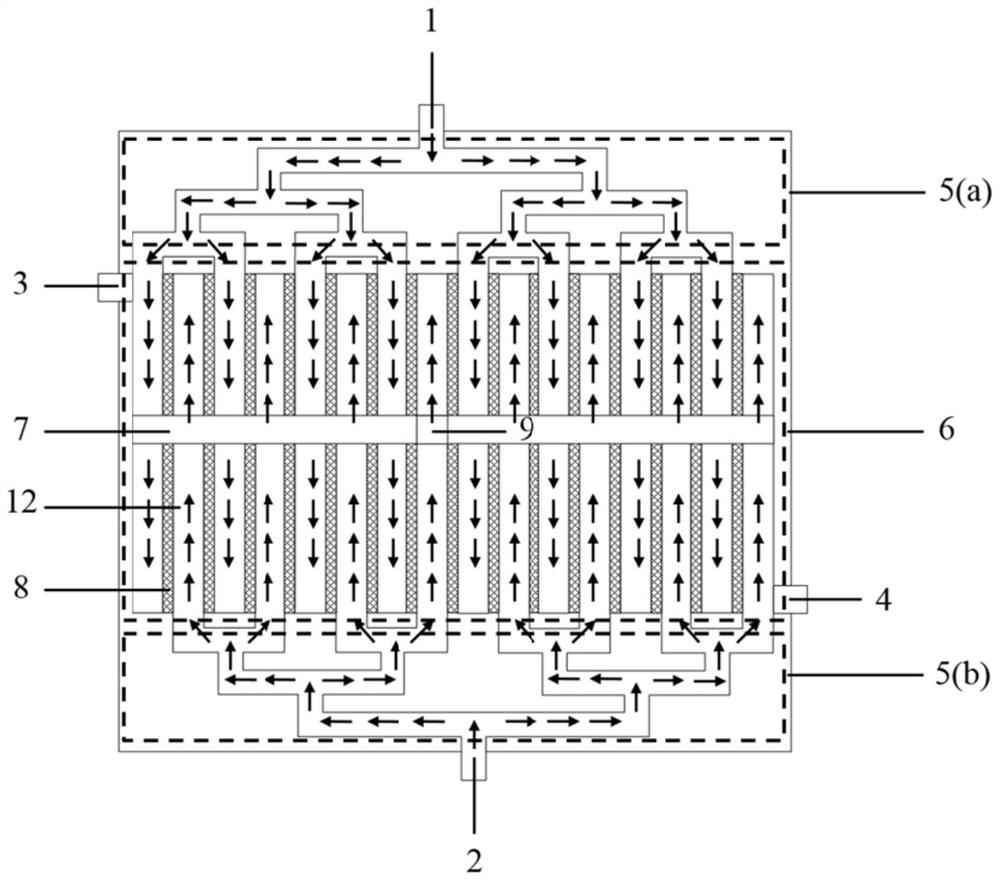

Micro-channel reactor and application thereof

A microchannel reactor and microchannel technology, applied in chemical/physical/physicochemical reactors, chemical instruments and methods, organic chemistry, etc., can solve problems such as inability to effectively control temperature and affect the normal and orderly progress of reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

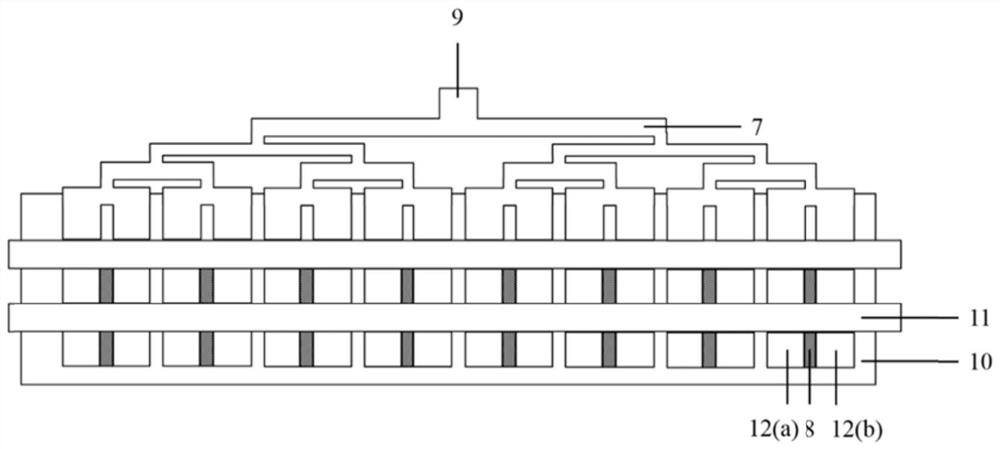

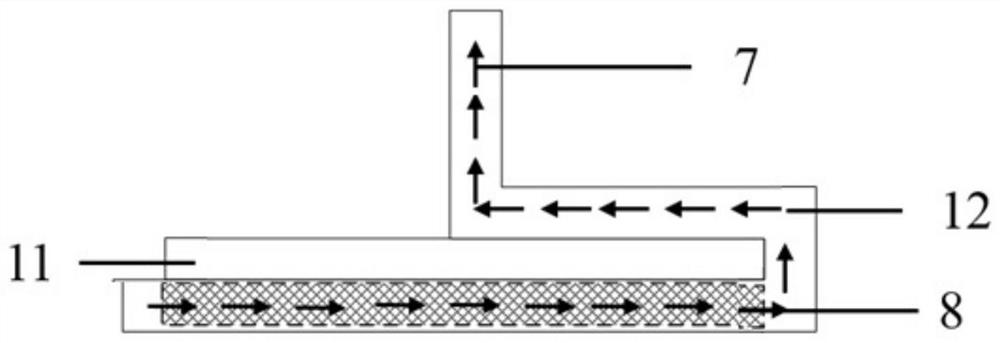

Method used

Image

Examples

Embodiment 1

[0091] (1) Device construction: The main body of the microchannel reactor is made of stainless steel 316L. Micron-scale grooves are manufactured on the reaction substrate through precision machining. The plane of the heat exchange substrate is pressed and sealed with the reaction substrate to form a micron-scale channel. The inner member of the porous sieve plate is built in the position of the channel. The specific arrangement and size are: the hydraulic diameter of the fluid channel in the distribution area is 1200 microns, and the total length is 5 cm. The hydraulic diameter of the fluid channel in the reaction area is 500 microns, and the total length is 5 cm. The width of the built-in porous sieve plate internal member between the fluid channels in adjacent reaction areas is equal to the width of the fluid channels in the reaction area. The hydraulic diameter of the micropores is 50 microns, the porosity is 80%, and the thickness of the heat exchange substrate is 2.5 cm, t...

Embodiment 2

[0094] All the steps in this example are basically the same as in Example 1, except that the hydraulic diameter of the fluid channel in the distribution area is 2000 microns, and the total length is 1 cm; the product analysis results show that the conversion rate of 2-pyrrolidone is 93.2%. The selectivity to N-vinylpyrrolidone was 86.5%.

Embodiment 3

[0096] All the steps in this example are basically the same as in Example 1, except that the hydraulic diameter of the fluid channel in the distribution area is 500 microns, and the total length is 8 cm; the product analysis results show that the conversion rate of 2-pyrrolidone is 97.2%, The selectivity to N-vinylpyrrolidone was 81.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com