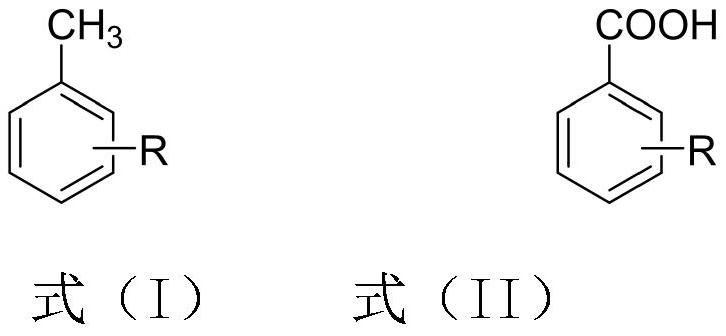

Continuous production method of benzoic acid derivative

A production method and derivative technology, applied in the direction of organic chemical methods, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as pipeline blockage, stirring paddle break safety accidents, etc., to promote the reaction, increase the degree of turbulence, Increase the effect of gas-liquid mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

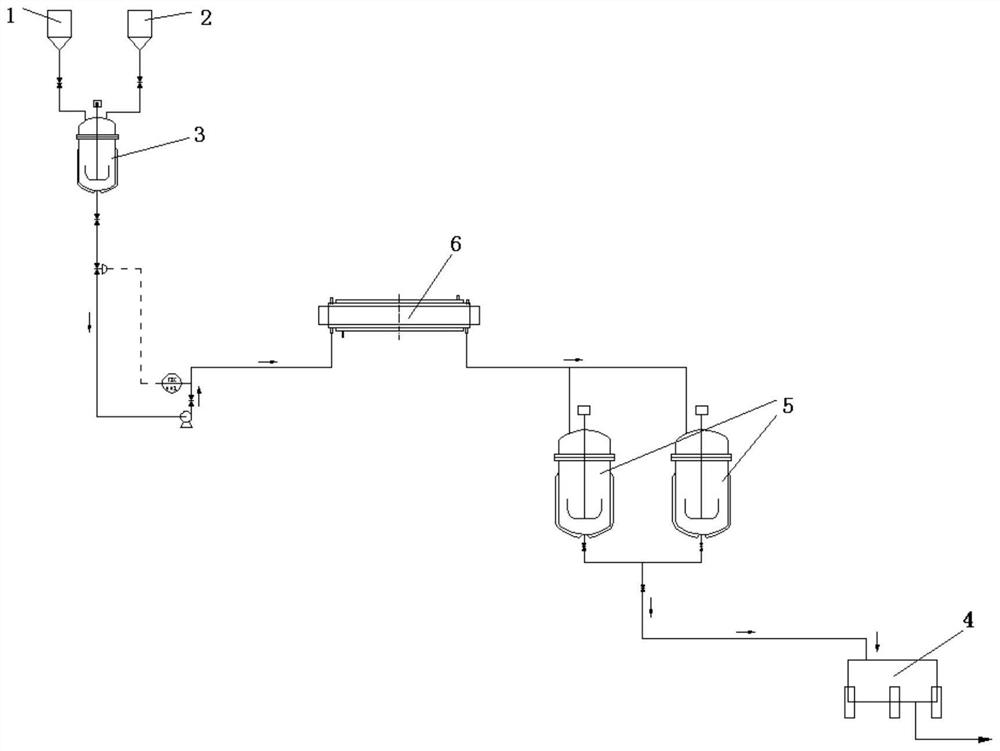

[0028] About the device

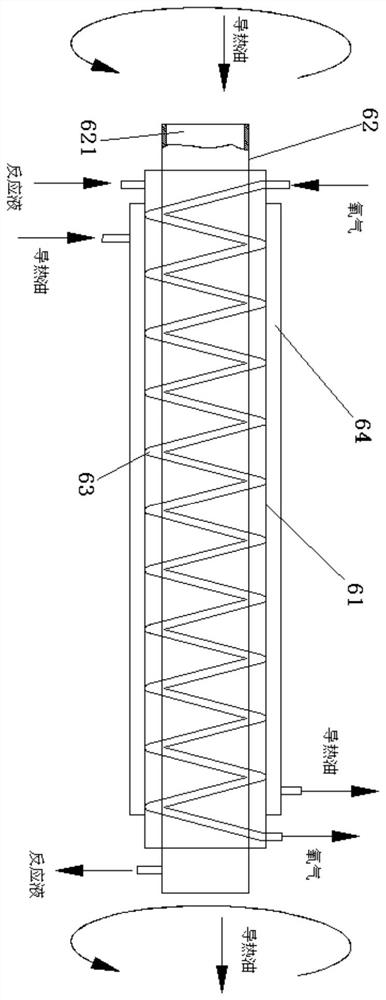

[0029]The continuous reaction device comprises successively connected head tanks 3 (the head tanks 3 connect toluene derivative storage tanks 1 and nitric acid storage tanks 2), a circular reactor 6, a crystallization kettle 5 and a centrifuge 4; the crystallization kettle 5 is two , when the liquid holding capacity of one of the crystallization tanks 5 exceeds 70%, the material flowing out from the return-shaped reactor 6 is diverted to another crystallization tank 5 . The circular reactor 6 comprises a small-diameter casing 62, the small-diameter casing 62 is covered with a large-diameter casing 61 (coaxially sleeved together), and a circular cavity is formed between the small-diameter casing 62 and the large-diameter casing 61 , be provided with small pipeline 63 in the back-shaped cavity, be provided with some apertures on the small pipeline 63, be oxygen in the small pipeline, small-diameter sleeve pipe 61 rotates, large-diameter sleeve pipe 62 i...

Embodiment 2-12

[0033] Embodiment 2-12 The reaction parameters are shown in the table below, the device is the same, and other operations are the same as in the examples.

[0034]

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com