Method for treating organic wastewater by activating peroxymonosulfate with assistance of visible light

An organic wastewater, monosulfate technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problem of narrow pH range, secondary pollution of transition metal ions, stable metal ion leakage and circulation To achieve the effect of promoting high-efficiency degradation and promoting high-speed degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: Preparation of carbon nitride material

[0050] Weigh 20 g of urea into a covered crucible, then place it in a muffle furnace, and raise the temperature to 550°C at a heating rate of 2.5°C / min, keep it warm for 4 hours, then cool to room temperature, and grind to obtain a light yellow solid Powdered carbon nitride material.

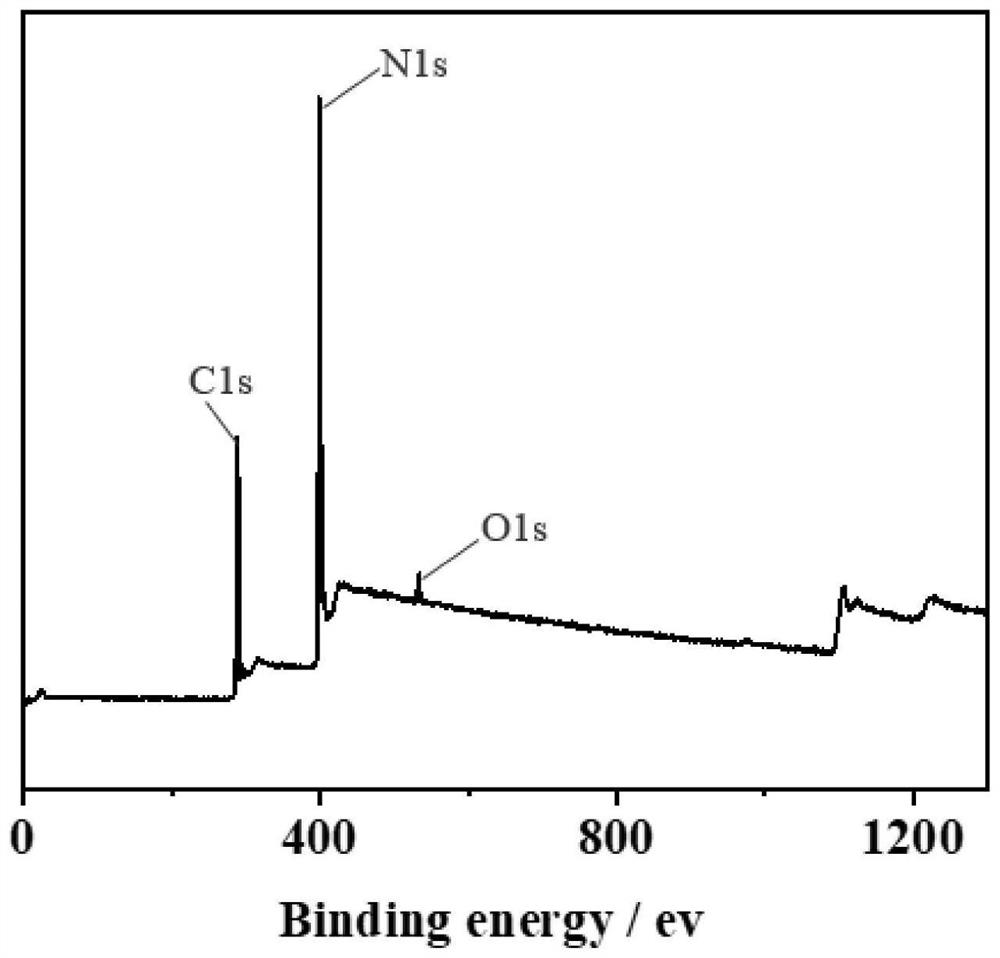

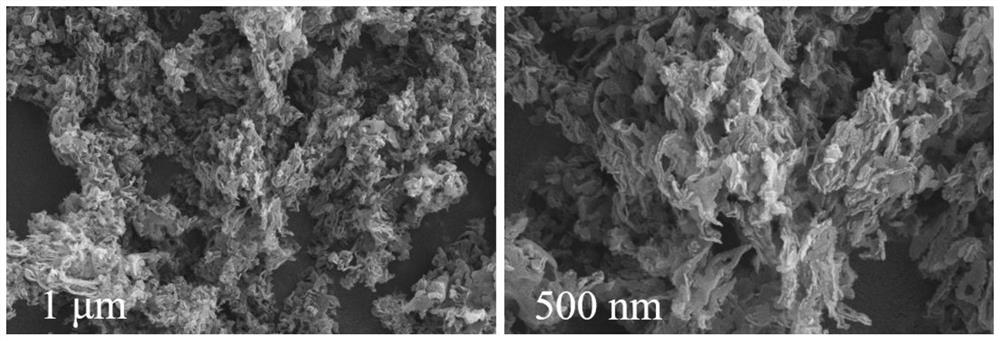

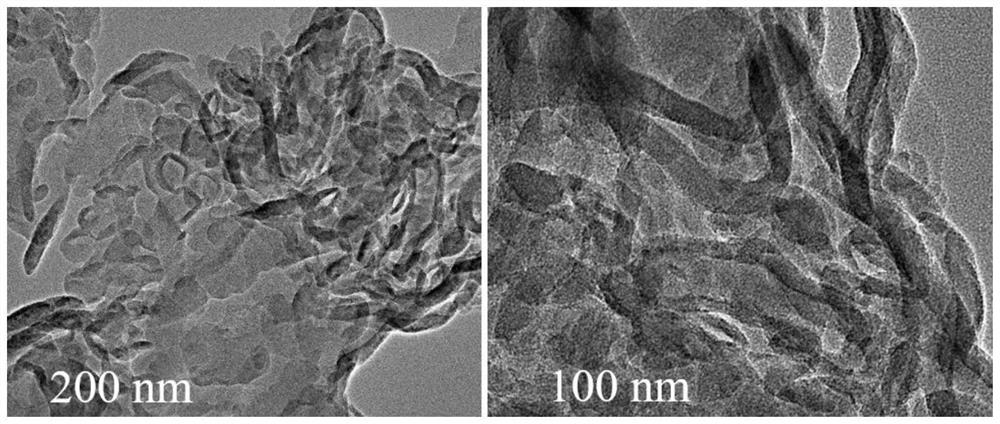

[0051] The phase characterization results, scanning electron micrographs and high-resolution transmission electron micrographs of carbon nitride are as follows: figure 1 , figure 2 and image 3 shown by figure 1 It can be seen that C, N and O elements can be found in the X-ray photoelectron spectrum at the same time, which is consistent with the main elements in their own structure; figure 2 It can be seen that the synthesized carbon nitride material is composed of multiple sheets, and these sheets are stacked together to form an irregular nanosheet structure. Compared with the traditional bulk carbon nitride, its specific surfa...

Embodiment 2

[0052] Example 2: Application of carbon nitride-peroxymonosulfate system to remove rhodamine B in water

[0053] Add the carbon nitride material powder obtained in Example 1 into the solution with Rhodamine B as the treatment object, and the dosage is 0.2 g / L. Add 0.5 mM peroxymonosulfate under magnetic stirring, and turn on the xenon lamp to react. Figure 4 In order to test the degradation kinetics curves of different concentrations of Rhodamine B in the carbon nitride material-peroxymonosulfate system, it can be seen from the figure that within 12 minutes, Rhodamine B with a concentration within 50 mg / L can be effectively The removal rate of rhodamine B at a concentration of 100 mg / L was less than 40%.

Embodiment 3

[0054] Embodiment 3: recycling of carbon nitride materials

[0055] The carbon nitride material of processing 10 mg / L rhodamine B solution in embodiment 2 is reclaimed and reused, and the rhodamine B concentration is restored to 10 mg / L by continuing to add high-concentration rhodamine B solution, and cast under magnetic stirring Add 0.5mM persulfate, turn on the xenon lamp to react. After 12 minutes of reaction, the removal rate of Rhodamine B was detected. Repeatedly add rhodamine B and peroxymonosulfate to the reactor according to the above scheme, and monitor the removal rate of rhodamine B after 12 minutes until the catalytic ability decreases and the rhodamine B in the solution cannot be effectively degraded. Figure 5 It is the removal rate of rhodamine B by activation of peroxymonosulfate within 12 min of each cycle of the carbon nitride material. It can be seen from the figure that the carbon nitride material shows good stability in the first 9 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com