High-elasticity rubber ring convenient for secondary forming

A high-elasticity rubber, secondary molding technology, applied in the field of rubber rings, can solve the problems of poor overall strength and elasticity, and achieve the effect of high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

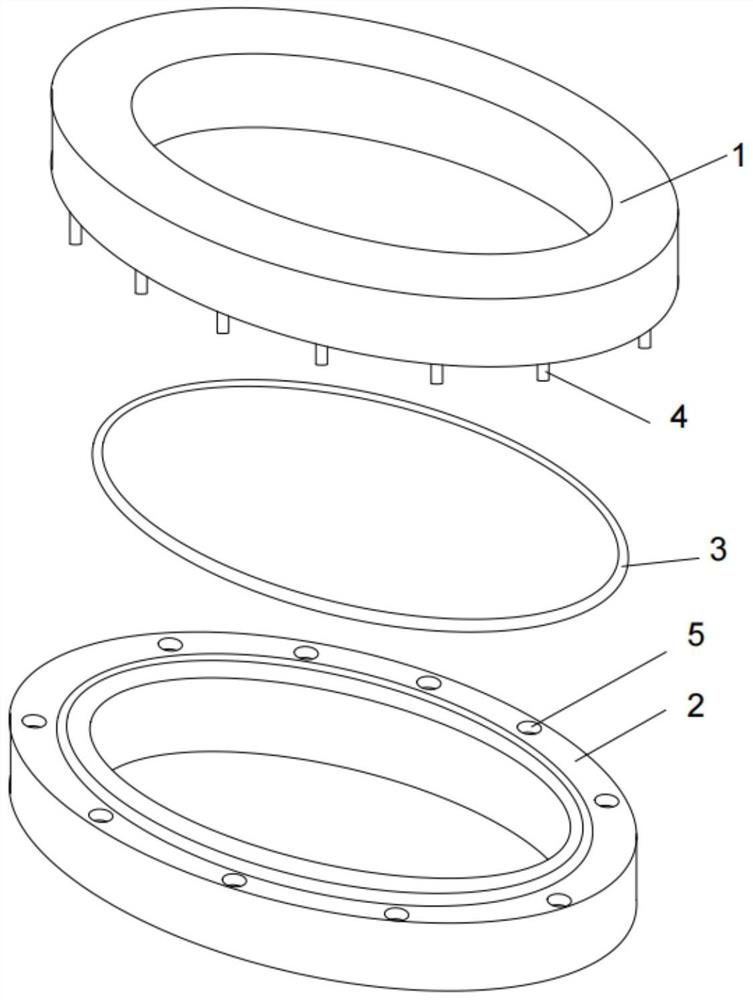

[0027] see figure 1 , an embodiment provided by the present invention: a high-elastic rubber ring that is convenient for secondary molding, including an upper half 1 and a lower half 2 formed by die-casting each other, between the upper half 1 and the lower half 2 Reinforcing ribs 3 are provided, and more than one stretching ribs 4 are circularly distributed on the lower surface of the upper half 1, and a limiting groove 5 cooperating with the stretching ribs 4 is arranged on the upper surface of the lower half 2, the upper half Part 1 includes raw materials in the following proportions: 120-125 parts of EPDM rubber, 50-60 parts of acrylonitrile, 10-15 parts of carbon black, 15-20 parts of recycled rubber ring powder; 3-5 parts of fatty acid parts; 3-5 parts of plasticizing softener, 8-10 parts of anti-aging agent; the raw materials of the lower part 2 according to the following proportions: 20-30 parts of neoprene rubber; 30-40 parts of recycled rubber ring powder 12-13 part...

Embodiment 2

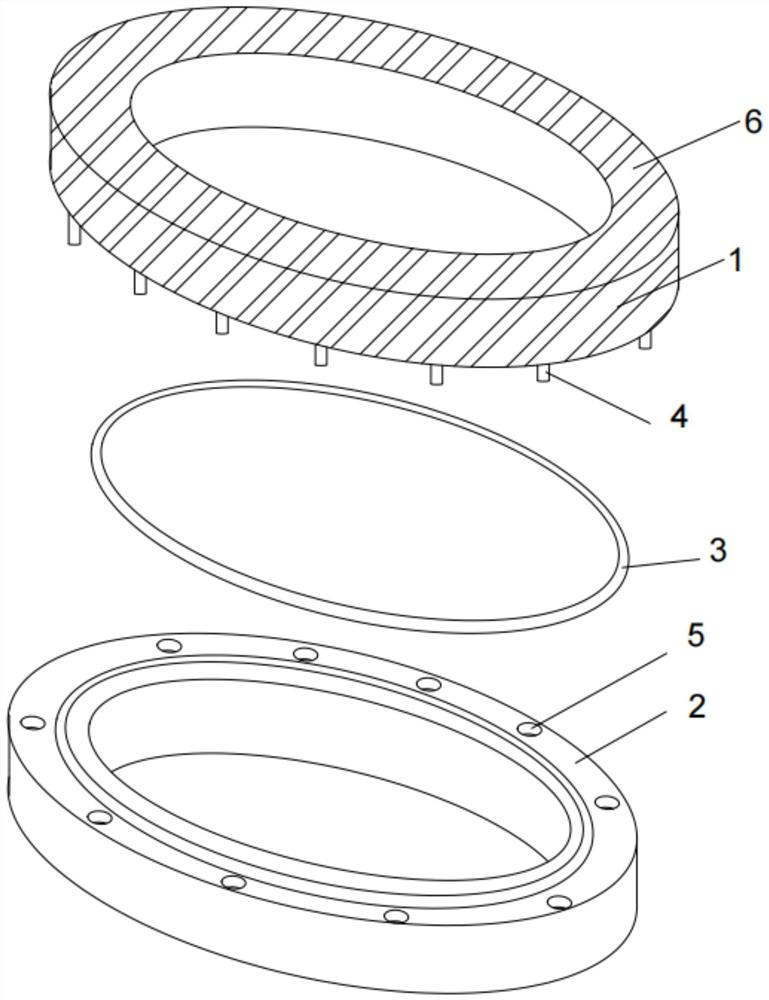

[0032] see figure 2 , an embodiment provided by the present invention: a high-elastic rubber ring that is convenient for secondary molding, including an upper half 1 and a lower half 2 formed by die-casting each other, between the upper half 1 and the lower half 2 Reinforcing ribs 3 are provided, and more than one stretching ribs 4 are circularly distributed on the lower surface of the upper half 1, and a limiting groove 5 cooperating with the stretching ribs 4 is arranged on the upper surface of the lower half 2, the upper half Part 1 includes raw materials in the following proportions: 120 parts of EPDM rubber, 50 parts of acrylonitrile, 10 parts of carbon black, 15 parts of recycled rubber ring powder; 3 parts of fatty acid; 3 parts of plasticizer softener, anti-aging 8 parts of agent; the raw materials of the lower part 2 according to the following proportions: 20 parts of neoprene rubber; 30 parts of recycled rubber ring powder; 12 parts of sodium cetyl sulfonate; cetyl ...

Embodiment 3

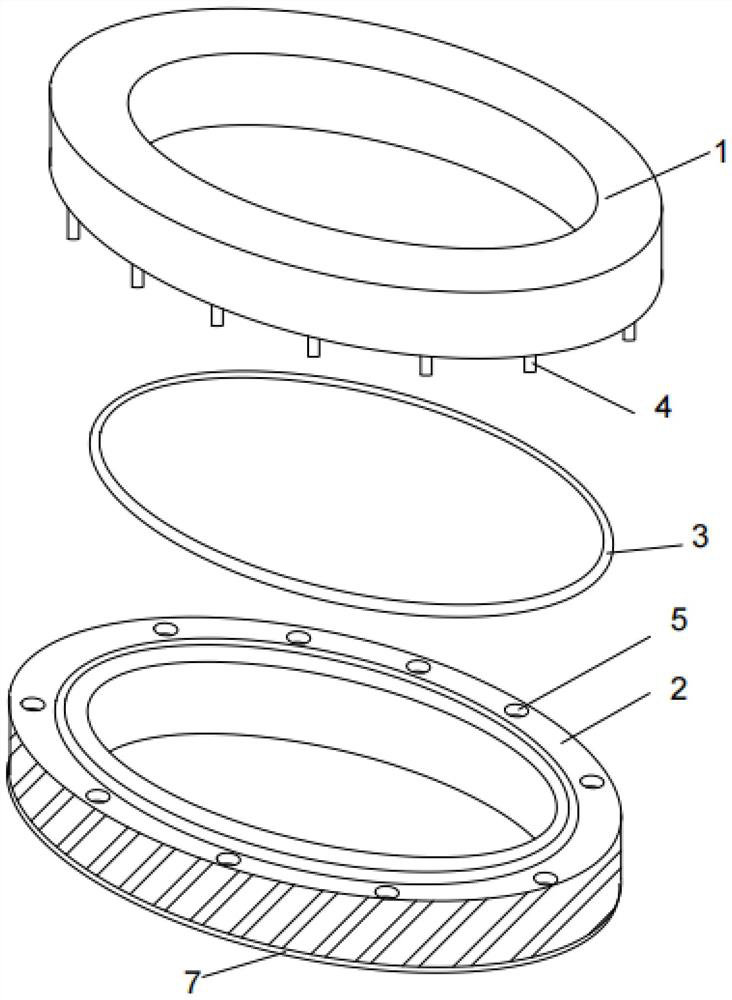

[0036] see image 3 , an embodiment provided by the present invention: a high-elastic rubber ring that is convenient for secondary molding, including an upper half 1 and a lower half 2 formed by die-casting each other, between the upper half 1 and the lower half 2 Reinforcing ribs 3 are provided, and more than one stretching ribs 4 are circularly distributed on the lower surface of the upper half 1, and a limiting groove 5 cooperating with the stretching ribs 4 is arranged on the upper surface of the lower half 2, the upper half Part 1 includes raw materials in the following proportions: 125 parts of EPDM rubber, 60 parts of acrylonitrile, 15 parts of carbon black, 20 parts of recycled rubber ring powder; 5 parts of fatty acid; 5 parts of plasticizer softener, anti-aging 10 parts of agent; the raw material of the lower part 2 according to the following proportions: 30 parts of neoprene rubber; 40 parts of recycled rubber ring powder; 13 parts of sodium cetyl sulfonate; calcium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com