Fe-Mn-Al-Ni-Cu superelastic alloy and preparation method thereof

A technology for superelastic alloys and sample alloys, which is applied in the field of iron-based superelastic alloy materials, can solve the problems that the preparation efficiency and material properties cannot be improved synchronously, and the difficulty in alloy production and application, so as to avoid natural aging phenomenon and have a wide range of applications , The process is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

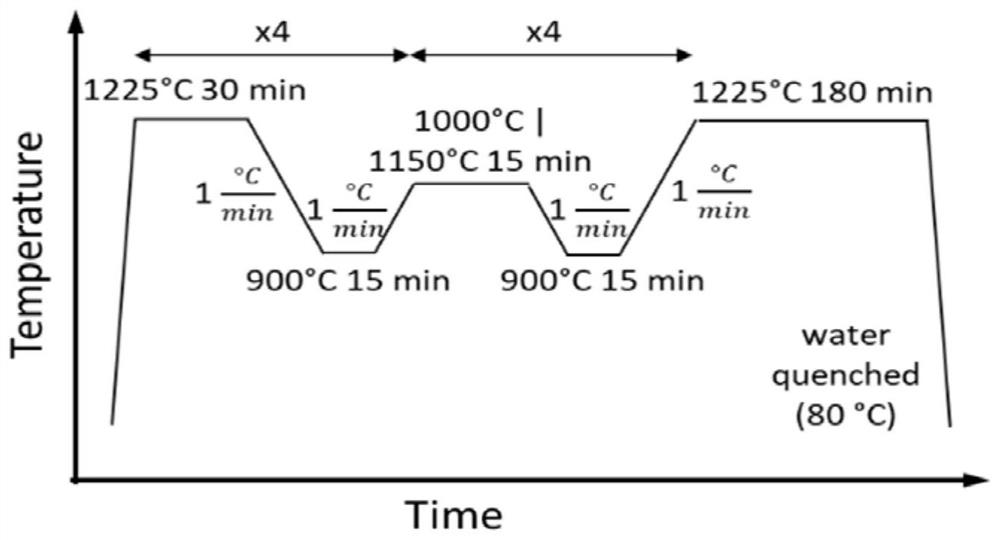

[0018] Select the pure metal raw materials metal iron, metal manganese, metal aluminum, metal nickel, and metal copper used in industry, and carry out ingredients according to the atomic percentage content of Fe 40.5%, Mn 34%, Al 15%, Ni 7.5%, and Cu 3%. The vacuum non-consumable electric arc furnace is smelted under the protection of argon. During the smelting process, the magnetic stirring technology is used to mix the metal solution evenly. The casting is heated to 1200°C for 2 hours and then hot-rolled, and then hot-rolled from 20mm to 6mm at room temperature. Then proceed as image 3 As shown in the schematic diagram of cyclic heat treatment, the sample after cyclic heat treatment was aged at 200°C for 3 hours and then water-cooled.

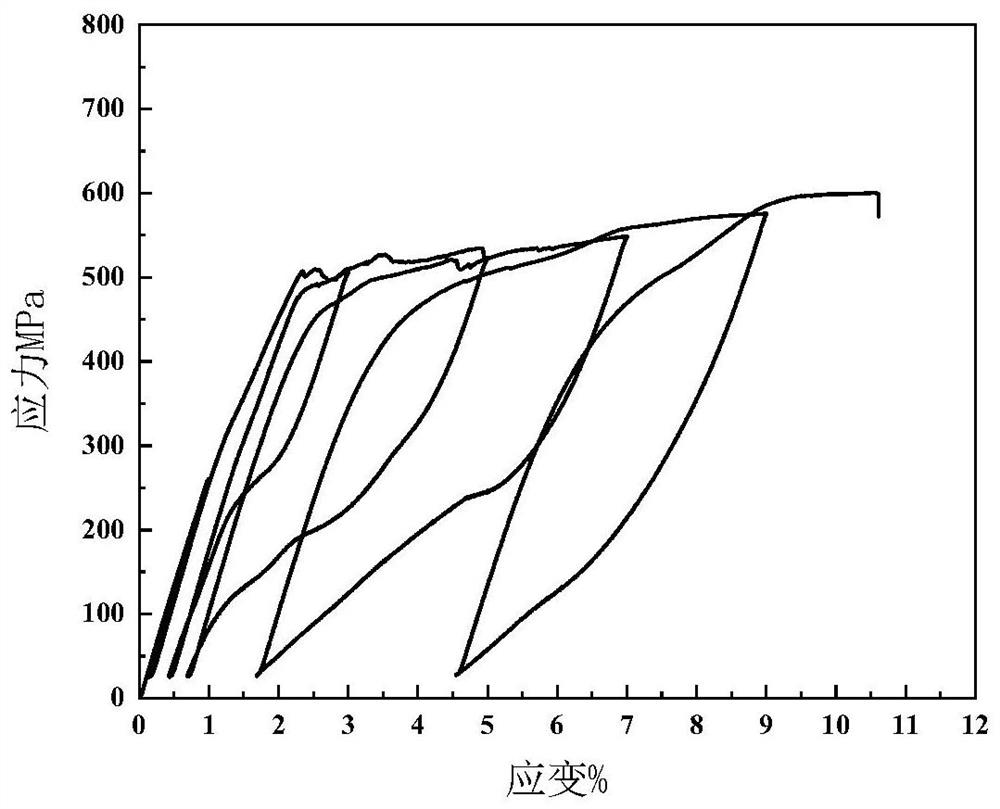

[0019] The polycrystalline Fe-Mn-Al-Ni-Cu superelastic alloy obtained in this embodiment is loaded-unloaded at room temperature The stress-strain curve obtained is shown in the appendix figure 1 . From attached figure 1 It can be seen fr...

Embodiment 2

[0021] Select pure metal raw materials used in industry, such as iron, manganese, aluminum, nickel, and copper, according to the atomic percentage content of Fe 30-50%, Mn 25-40%, Al 10-20%, Ni 1-15%, Cu 1~10% is used for batching, and the vacuum non-consumable electric arc furnace is used for melting under the protection of argon. During the melting process, the magnetic stirring technology is used to mix the metal solution evenly. During the melting process, the alloy is repeatedly smelted 5 times, and finally the suction Cast into columns. The casting is heated to 1200°C for 2 hours and then hot-rolled, then hot-rolled from 20mm to 6mm at room temperature. The superelastic alloy is directional annealed at a temperature above the γ-phase precipitation temperature. a. The temperature of the hot zone for directional annealing is between 600-1300°C, and the width of the hot zone is between 1-100mm. b. The moving speed of the directional annealing hot zone is between 0.1-500 μm...

Embodiment 3

[0023]Select pure metal raw materials used in industry, such as iron, manganese, aluminum, nickel, and copper, according to the atomic percentage content of Fe 30-50%, Mn 25-40%, Al 10-20%, Ni 1-15%, Cu 1~10% is used for batching, and the vacuum non-consumable electric arc furnace is used for melting under the protection of argon. During the melting process, the magnetic stirring technology is used to mix the metal solution evenly. During the melting process, the alloy is repeatedly smelted 5 times, and finally the suction Cast into columns. The casting is heated to 1200°C and homogenized for 2 hours, then hot-rolled, and then hot-rolled from 20mm to 6mm at room temperature. The superelastic alloy can be obtained by heat treatment at a temperature above the γ-phase precipitation temperature, directional annealing and cyclic heat treatment. Single crystal Or columnar Fe-Mn-Al-Ni-Cu superelastic alloy.

[0024] Directional annealing: a. The temperature of the hot zone for direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com