Processing method of nickel electroplated pressure gauge

A processing method and technology of electroplating nickel, applied in the field of pressure gauges, can solve the problems of virtual welding, unclean plating of the electroplating layer, easy blackening of joints, etc., and achieve the effects of reducing costs, avoiding natural aging treatment, and fast welding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

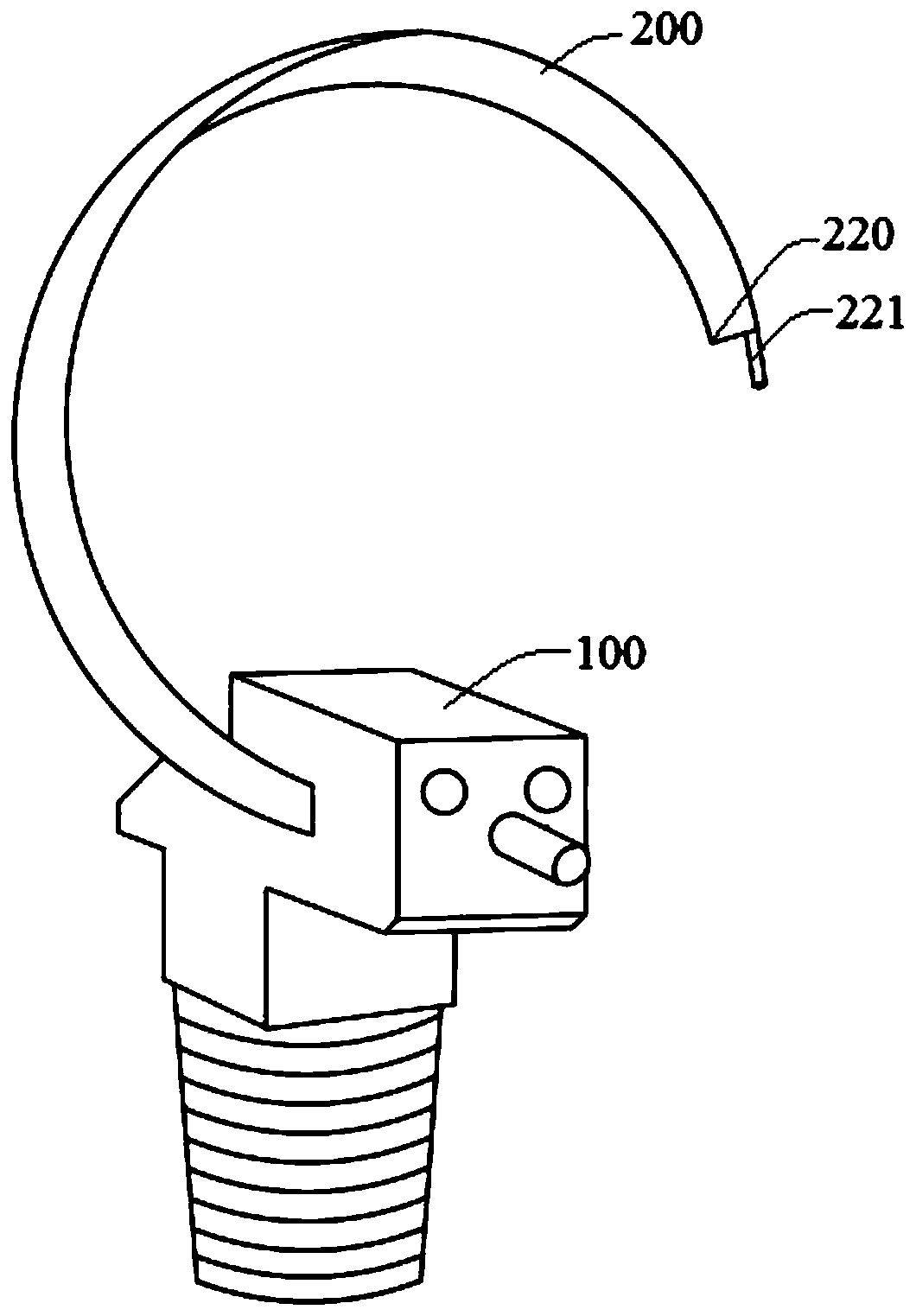

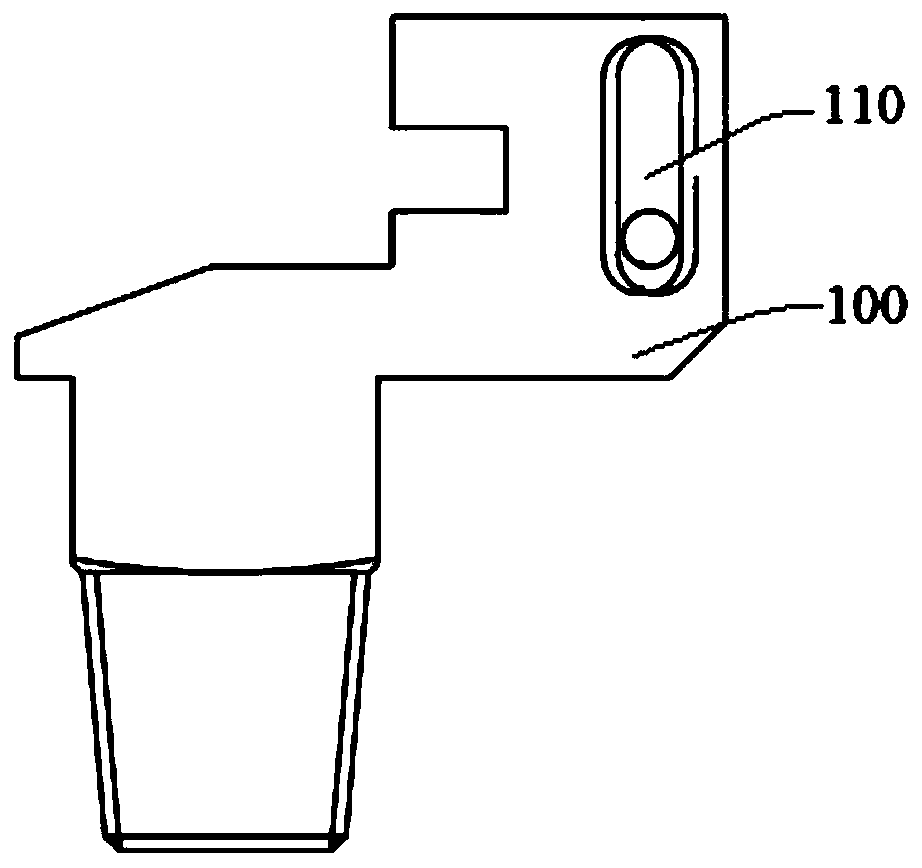

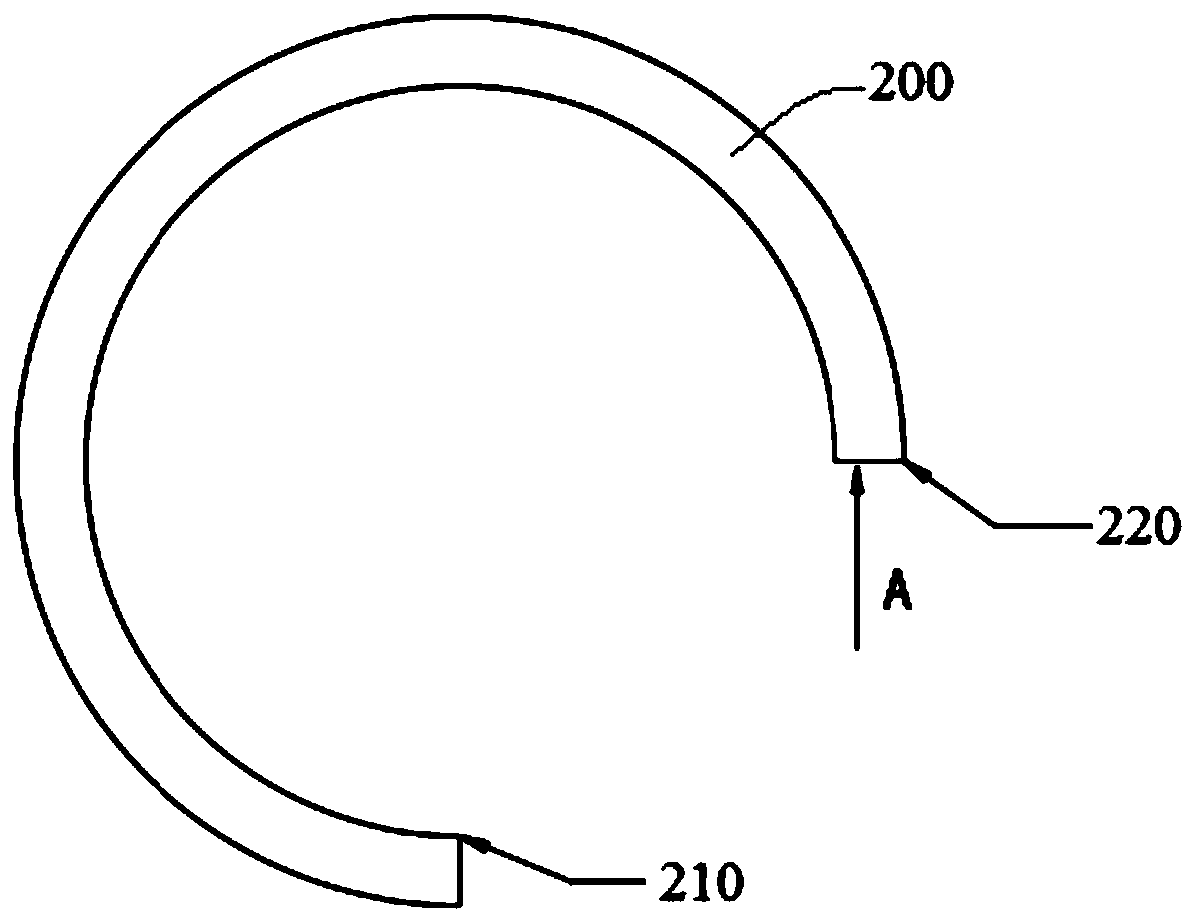

[0049] The processing method of a kind of electroplating nickel pressure gauge of this embodiment, comprises two process steps of electroplating nickel process and welding process in turn; Wherein, electroplating nickel process is to electroplate nickel layer on the surface of gauge joint 100 of copper pressure gauge, gauge joint 100 is structured like figure 2 As shown, its upper end is provided with a spring tube groove 110 for inserting and welding the spring tube 200; the welding process is to weld the copper surface joint 100, the spring tube 200 and the sealing piece 221 sequentially, and the structure of the spring tube 200 is as follows image 3 As shown, it is a three-quarter arc tube with an oblate cross-section, such as Figure 4 As shown, one end of the arc tube is a welding end 210, which is used to insert into the spring tube groove 110 of the gauge joint 100, and the spring tube 200 and the gauge joint 100 are welded as a whole; the other end of the arc tube is...

Embodiment 2

[0063] The processing method of a kind of electroplated nickel pressure gauge of this embodiment is basically the same as that of Embodiment 1, and the difference is that in the electroplated nickel process, a forged blank of brass (copper alloy) is selected to be forged into forged copper; in the welding process, use The rosin core solder wire is used for soldering, and the rosin flux is located inside the solder wire, which can ensure that the rosin flux in the rosin flux actually participates in the soldering process, and the amount of rosin is constant; and the flux is located inside the solder wire to prevent soldering process. , the high temperature makes the rosin splash, reduces the rosin splash value, improves the welding quality, and the welding effect is good; it can also improve the fluidity of the liquid solder, and can also prevent the oxide film from appearing on the welded surface joints, spring tubes and sealing pieces, which is stronger than the solid solder wi...

Embodiment 3

[0077] The processing method of an electroplated nickel pressure gauge in this embodiment is basically the same as that in Embodiment 2, the difference being that in the nickel electroplating process, a forged blank of tin phosphor bronze (copper alloy) is selected to be forged into forged copper.

[0078] Specifically, the steps of the electroplating nickel process are:

[0079] (1) Selection of materials: select bronze forging blanks to forge into forged copper;

[0080] (2) Preliminary processing: process the forged copper into the primary shape of the pressure gauge joint to ensure that the size of the gauge joint 100 is 0.1-0.15 mm smaller than the standard size, so as to ensure that the tolerance after electroplating can meet the standard size of the finished product; process the spring tube groove When 110, the size of the slot hole is reserved with a margin of 1-2 mm to ensure that after the fine grinding of the spring tube slot 110, the electroplating layer in the spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com