Homogenized coated particle dispersion fuel and preparation method thereof

A technology of coating particles and dispersing fuel, which is applied to fuel elements, manufacturing reactors, nuclear power generation, etc., can solve problems such as inaccurate calculations, reduce the temperature gradient of coated particles and disperse fuel, and achieve radial distribution and reduce damage. Risk, Optimal Uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A homogenized coated particulate fuel comprising a matrix material, coated TRISO coated fuel particles and a series of silicon carbide cylinders; wherein:

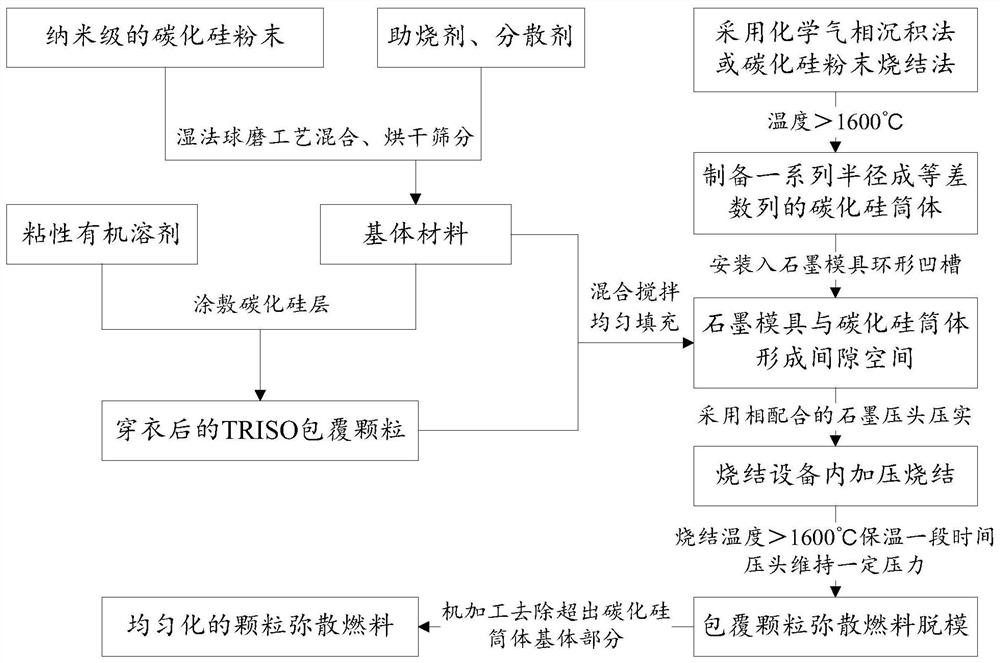

[0034] The matrix material is made by adding Al 2 o 3 As a sintering aid, it is added to nano-scale silicon carbide powder, using alcohol as a dispersant, mixed evenly by wet ball milling, then dried and sieved;

[0035] Clothed TRISO-coated fuel particles are obtained by coating a silicon carbide layer on the surface of TRISO-coated particles whose fuel core material is composed of uranium dioxide. The outer layer of TRISO-coated fuel particles is damaged due to the collision of TRISO-coated fuel particles;

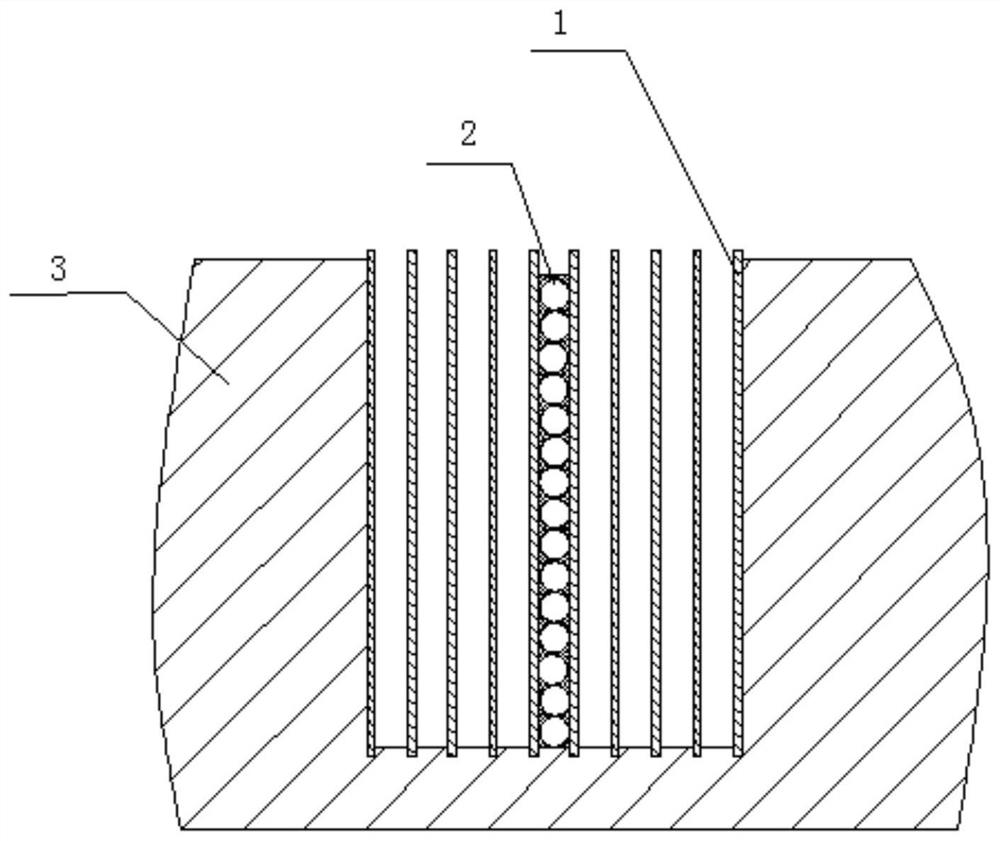

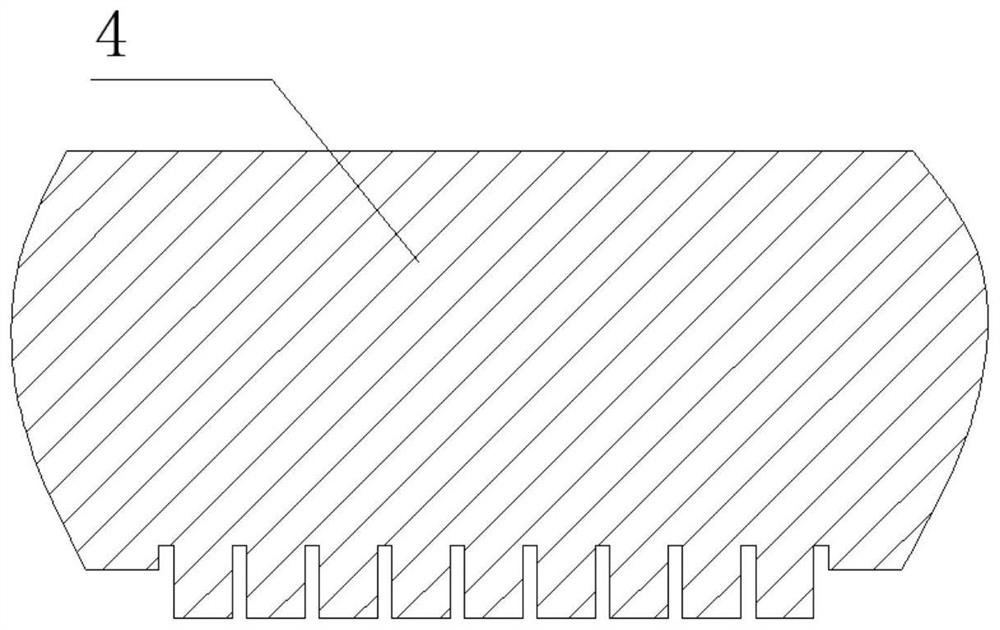

[0036] A series of silicon carbide cylinders are prepared by chemical vapor deposition at a temperature higher than 1600°C in an atmosphere of methyltrichlorosilane; the radii of the prepared series of silicon carbide cylinders form an arithmetic progression, and the etc. The tolerance of the difference ser...

Embodiment 2

[0046] A homogenized coated particulate fuel comprising a matrix material, coated TRISO coated fuel particles and a series of silicon carbide cylinders; wherein:

[0047] The matrix material is obtained by adding Y 2 o 3 As a sintering aid, it is added to nano-scale silicon carbide powder, using alcohol as a dispersant, mixed evenly by wet ball milling, then dried and sieved;

[0048] Clothed TRISO-coated fuel particles are obtained by coating a silicon carbide layer on the surface of TRISO-coated fuel particles whose fuel core material is composed of uranium dioxide. The coated silicon carbide layer acts as a buffer layer to avoid manipulation during the manufacturing process Cause TRISO-coated fuel particles to collide, resulting in damage to the outer layer of TRISO-coated fuel particles;

[0049] A series of silicon carbide cylinders are prepared by sintering silicon carbide powder at a temperature higher than 1600°C; the radii of the prepared series of silicon carbide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com