Sulfur paste sulfur melting machine

A technology of melting sulfur and sulfur paste, which is applied in the field of desulfurization, can solve problems such as uneven heating of sulfur-containing materials, poor sulfur separation and purification effect and accuracy, and serious pollution of the operating environment, so as to improve the separation and purification effect and achieve high-precision sulfur paste Separation and improvement of the effect of the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

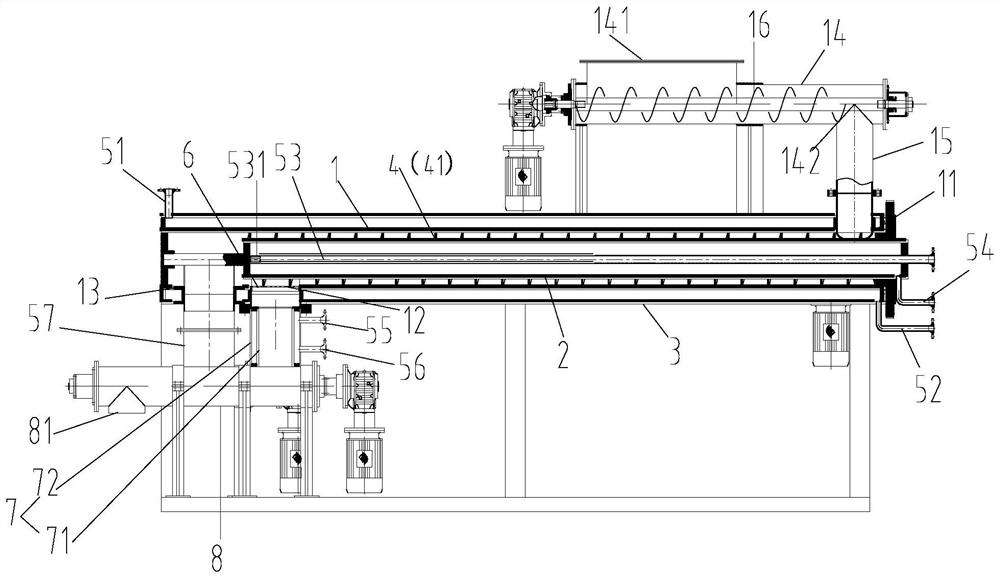

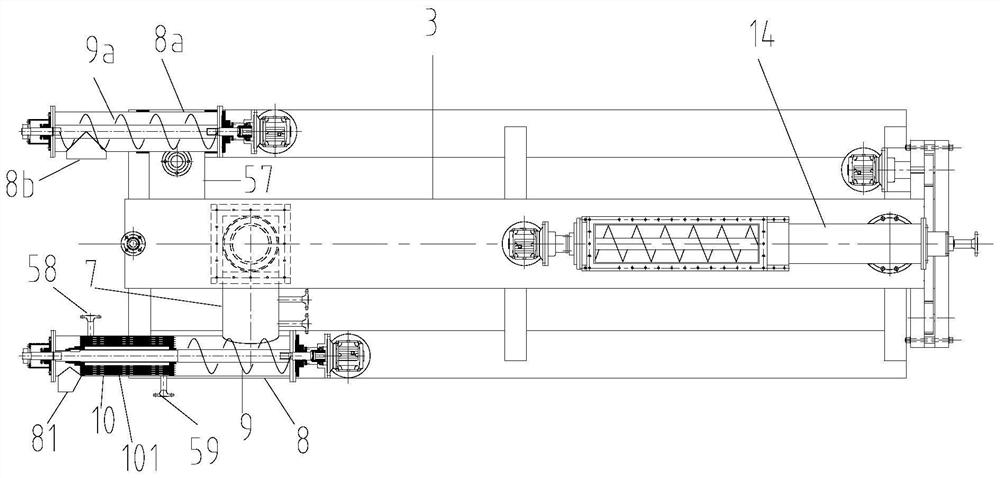

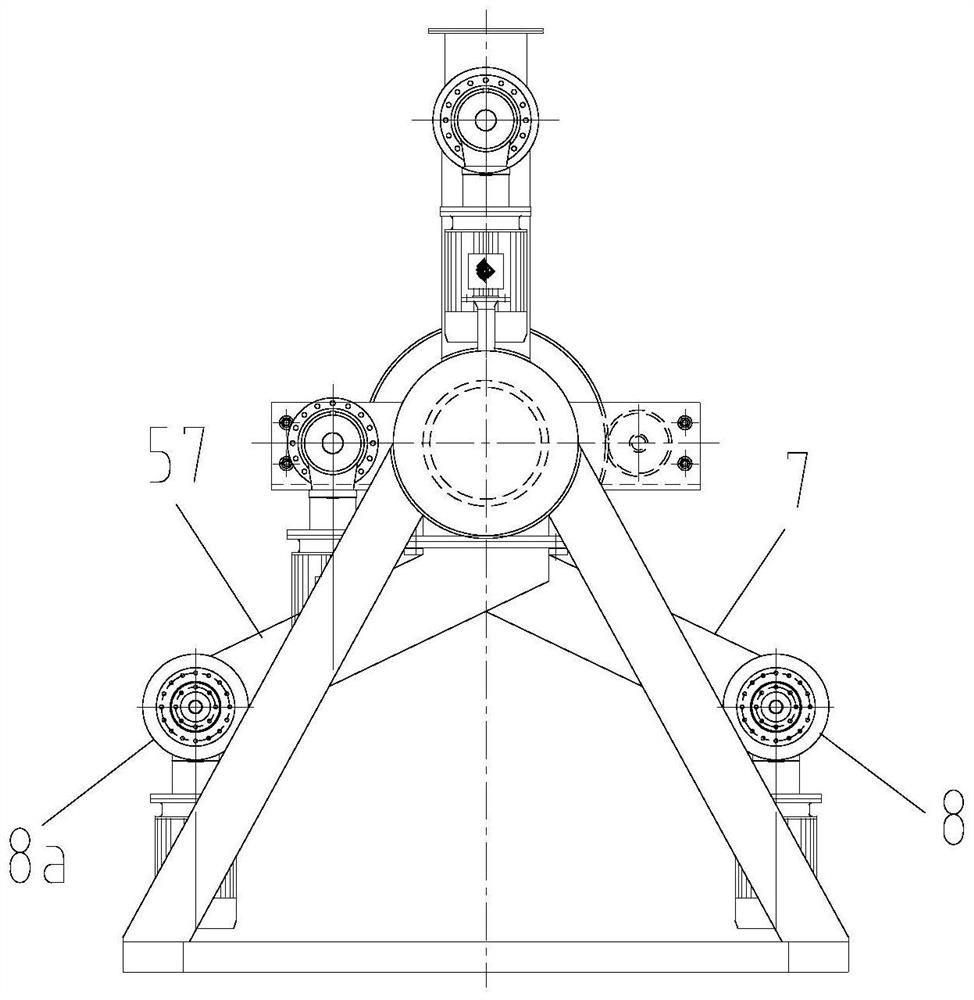

[0027] Such as Figure 1-3 Shown, the present invention provides a kind of sulfur paste melting machine, it comprises:

[0028]The sulfur melting cylinder 1, the first inner cylinder 2 and the first outer cylinder 3, the first inner cylinder 2 is installed inside the sulfur melting cylinder 1, the first outer cylinder 3 is sleeved on the The outer circumference of the melting sulfur cylinder 1 is arranged, and the sulfur melting cylinder 1 includes a first inlet 11 and a first outlet 12, and the first inlet 11 can suck sulfur-containing materials (preferably sulfur-containing pasty materials, i.e. sulfur paste , Sulfur paste is a by-product of chemical production. Sulfur paste becomes sulfur after heating and dehydration. It is a paste with high water content. In the sulfur melting cylinder 1, the first outlet 12 can lead out the sulfur heated to liquid in the sulfur melting cylinder 1, and the first heating fluid is passed into the first inner cylinder 2 to The material bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com