Reaction tank for high-strength gypsum production line

A high-strength gypsum, production line technology, applied in chemical/physical/physical chemical fixed reactor, detailed information of chemical/physical/physical chemical reactor, chemical/physical/physical chemical process, etc., can solve the production process of aqueous solution method Complicated, high production cost, difficult to wash and other problems, to achieve the effect of improving heating and reaction effect, easy replacement, and prolonging reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

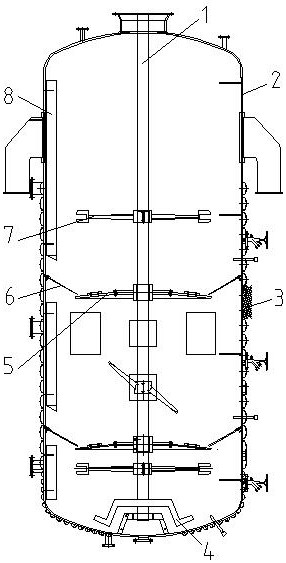

[0026] Such as figure 1 A reaction tank for a high-strength gypsum production line is shown, including a tank body 2 and a vertical stirring shaft 1 rotated in the tank body. The outside of the tank body is provided with an insulation layer 3, and the inner wall of the tank body is also fixed with The vertical turbulence strips 8 evenly distributed along the circumference, and the inner cavity of the tank is divided into at least two working areas by a number of partition devices distributed sequentially along the vertical direction. In this embodiment, there are three working areas, each of which is A heating device and a stirring fin 7 fixedly connected to the stirring shaft are provided, and a material channel connecting adjacent working areas is provided on the partition device.

[0027] The stirring fin includes a sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com