Method for preparing high-fluidity micron silver particles and device

A technology with strong fluidity and micron silver, applied in transportation and packaging, metal processing equipment, etc., can solve the problems of silver powder grain agglomeration, a large number of pores, silver powder residue, etc., to achieve high tap density, strong fluidity, and improved particle size. The effect of surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

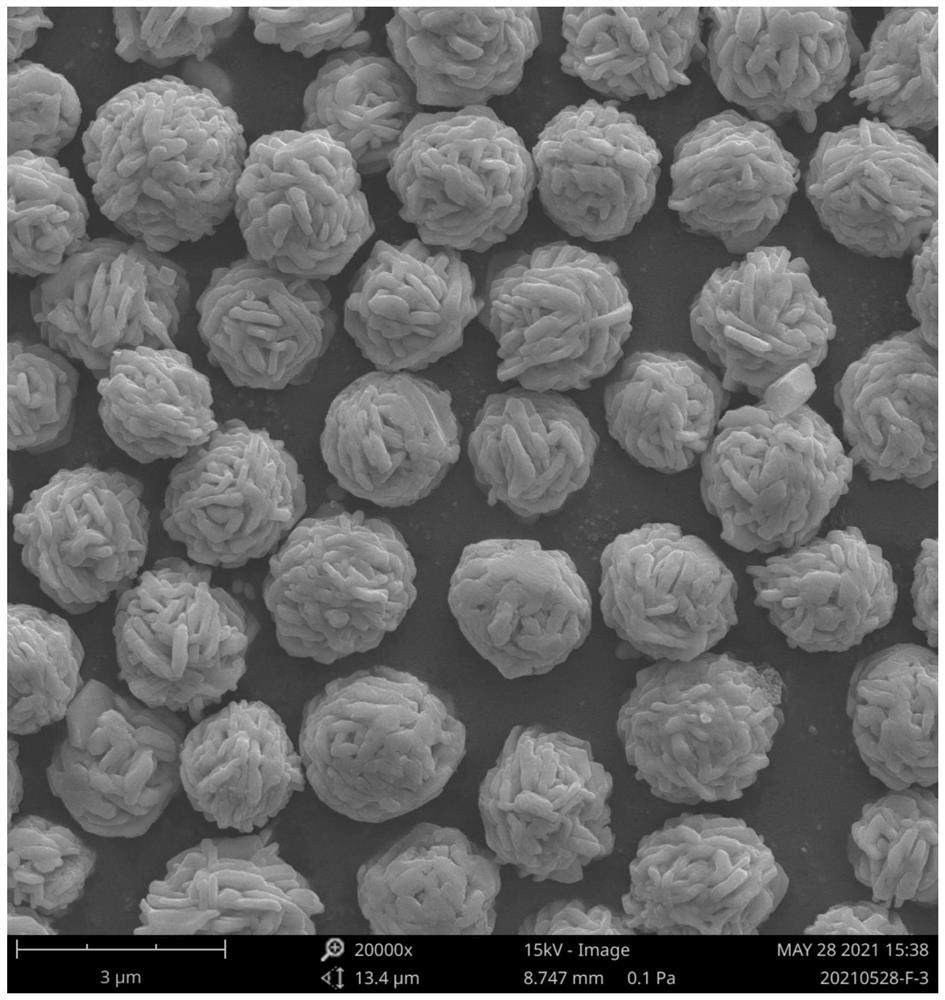

Embodiment 1

[0036] A kind of preparation method of strong fluidity micron silver particle of the present invention, comprises the following steps:

[0037] (1) Dissolve 255g of silver nitrate powder and 1.53g of sorbitol in 1000mL of deionized water, and stir thoroughly to obtain shaped silver source solution A;

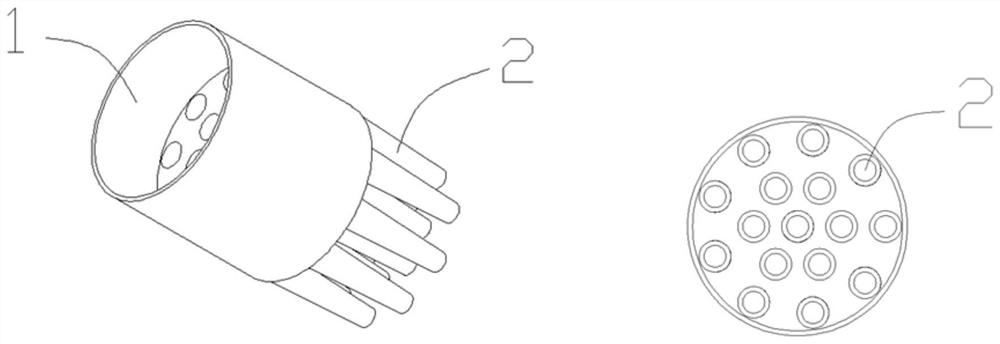

[0038] (2) At 20°C, 60g of hydroquinone white crystals and 26g of polyethylene glycol laurate were dissolved in 500mL and 1000mL of deionized water respectively to obtain reducing agent solution B and flow aid solution C respectively, and Place the glidant solution C in a container with an inclined cavity (40° inclination);

[0039] (3) Adjust the pH of the shaped silver source solution A to 3 with dilute nitric acid (the adjustment process is maintained at about 20°C), and then mix with the reducing agent solution B at 20°C in an ultrasonic dispersion environment, and pass through a point sieve dispersion device while rotating Dispersed and added to flow aid solution C for liq...

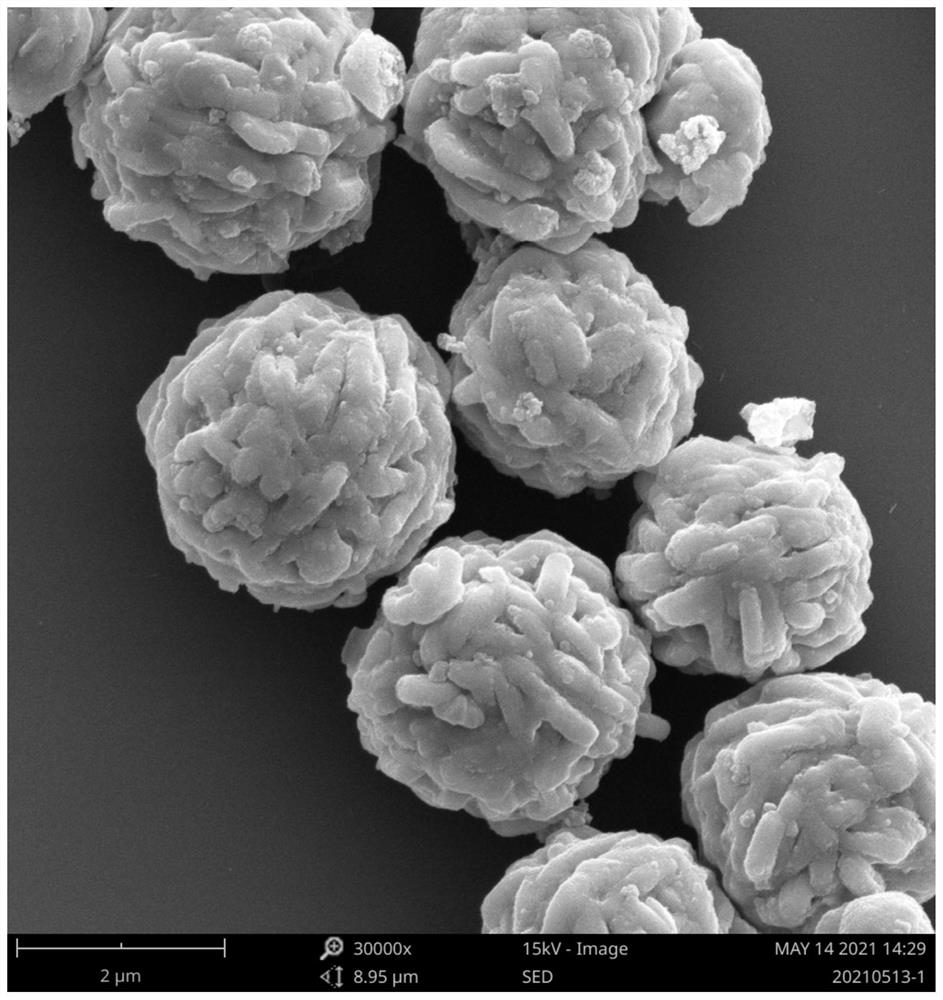

Embodiment 2

[0044] A kind of preparation method of strong fluidity micron silver particle of the present invention, comprises the following steps:

[0045] (1) Dissolve 306g of silver nitrate powder and 1.8g of polyethylene glycol in 1000mL of deionized water, and stir thoroughly to obtain shaped silver source solution A;

[0046] (2) At 20°C, 60g of hydroquinone white crystals and 30g of polyethylene glycol lauricate were dissolved in 500mL and 1000mL of deionized water respectively to obtain reducing agent solution B and flow aid solution C respectively, and Place the glidant solution C in a container with an inclined cavity (inclination of 35°);

[0047] (3) Adjust the pH of the shaped silver source solution A to 4 with dilute nitric acid (the adjustment process is maintained at about 20°C), and then mix with the reducing agent solution B at 20°C in an ultrasonic dispersion environment, and pass through the point sieve dispersion device while rotating Dispersed and added to flow aid s...

Embodiment 3

[0052] A kind of preparation method of strong fluidity micron silver particle of the present invention, comprises the following steps:

[0053] (1) Dissolve 68g of silver nitrate powder and 1.8g of polyethylene glycol in 1000mL of deionized water, and stir thoroughly to obtain shaped silver source solution A;

[0054] (2) At 25°C, 60g of hydroquinone white crystals and 30g of polyethylene glycol laurate were dissolved in 500mL and 1000mL of deionized water respectively to obtain reducing agent solution B and flow aid solution C respectively, and Place the glidant solution C in a container with an inclined cavity (inclination of 35°);

[0055] (3) Adjust the pH of the shaped silver source solution A to 4.2 with dilute nitric acid (the adjustment process is maintained at about 25°C), and then mix with the reducing agent solution B at 25°C in an ultrasonic dispersion environment, and pass through a point sieve dispersion device while rotating Dispersed and added to flow aid solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com