Production method of large-capacity cell shake flasks

A production method and large-capacity technology, applied in the production field of large-capacity cell shake flasks, can solve the problem of unpublished cell shake flask production methods and production molds, unable to meet the needs of large-capacity cell shake flasks, and loss of stability of plastic shake flasks And other problems, to achieve the effect of stable molding, reduce the probability of production, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples.

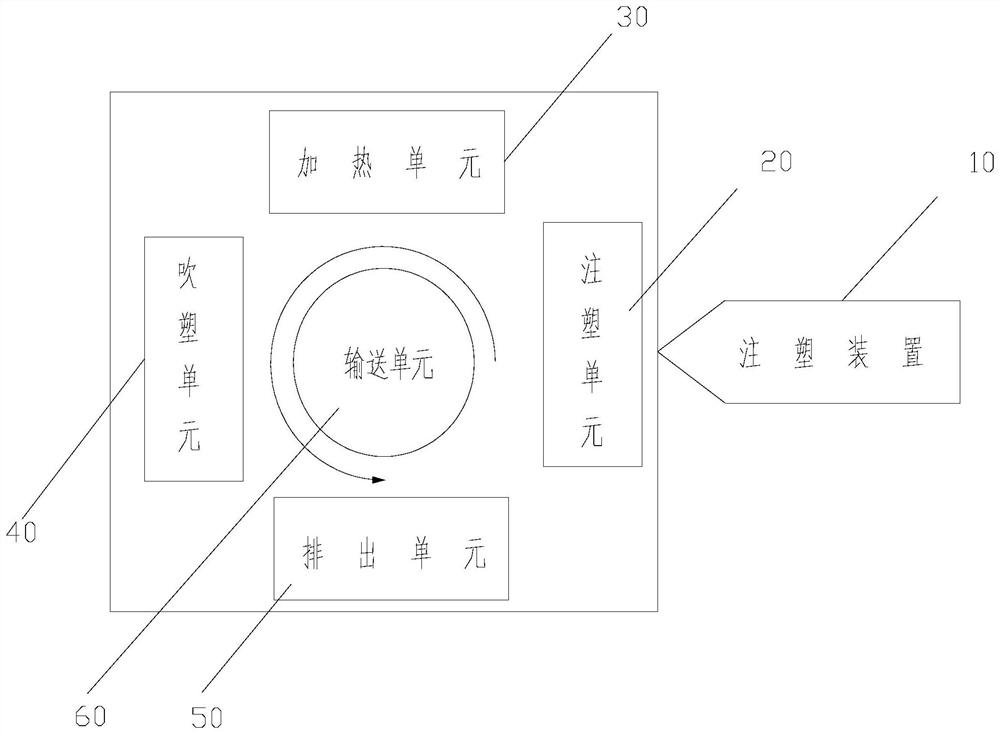

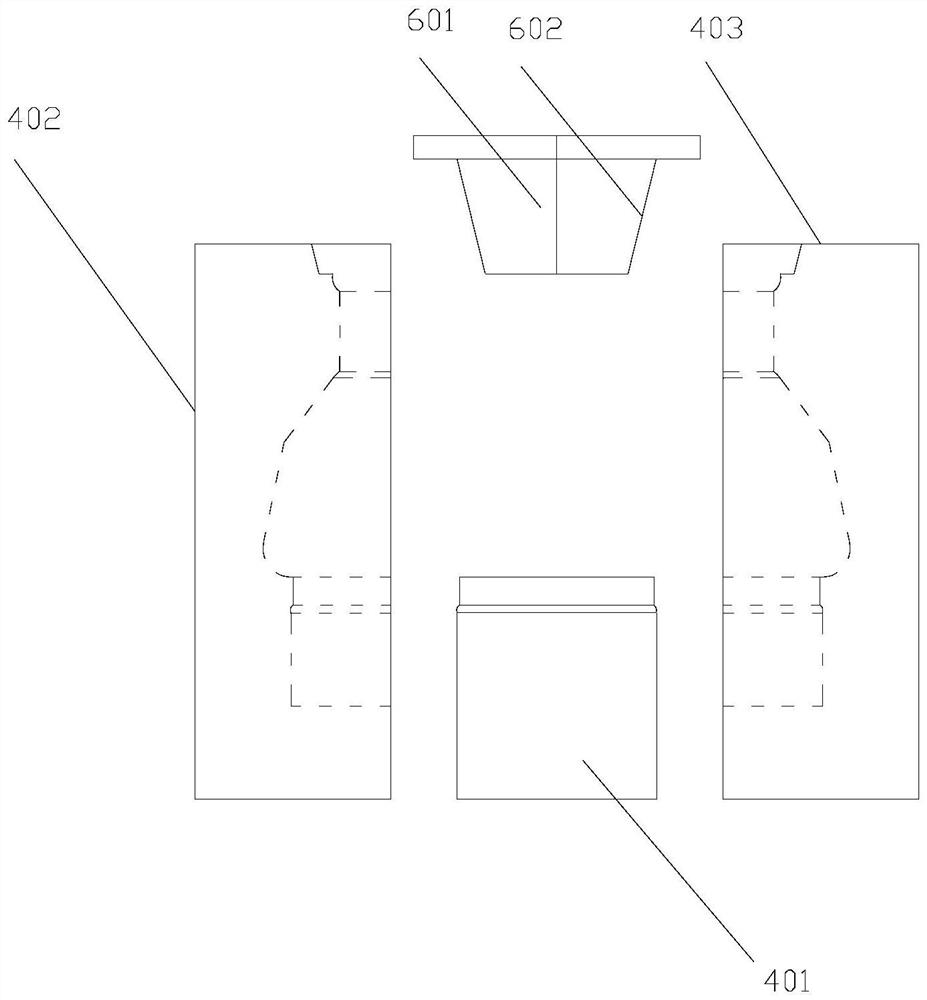

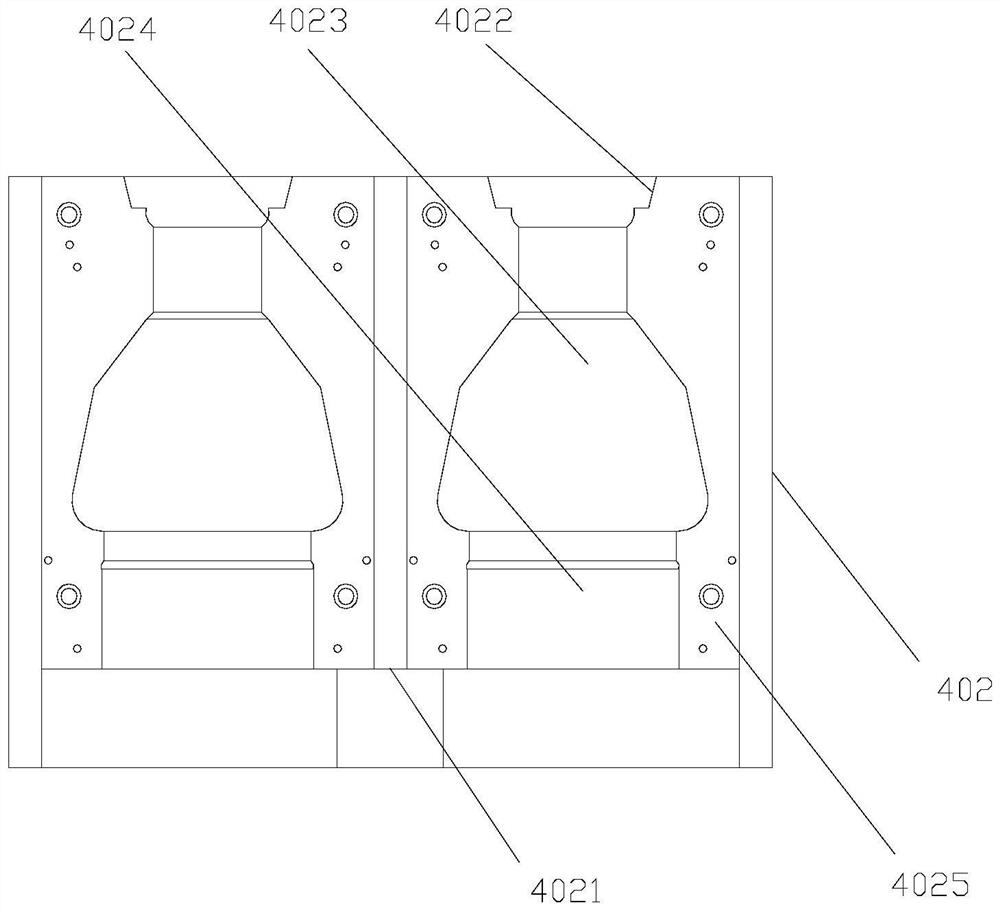

[0033] like figure 1 Shown, a kind of production method of large-capacity cell shake flask, the production equipment that utilizes is the fully automatic integrated blow molding equipment ASB-650EXHS, according to the following steps, produce such as Image 6 Large-capacity cell shaker flasks are shown.

[0034] The raw materials for the production of large-capacity cell shake flasks are selected from materials that are easy to injection stretch-blow molding, and the melt flow rate is 1.0-10.0g / 10min, and the melt flow rate is preferably 3.0-5.0g / 10min.

[0035] Specifically, the production raw materials can be specifically selected from PETG materials, PC materials, COP materials, COC materials, CBC materials and PET materials.

[0036] A kind of production method of lar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com