Method for preparing infrared coating paint from metallurgical solid waste

An infrared coating and coating technology, which is applied in the direction of alkali metal silicate coatings, coatings, fireproof coatings, etc., can solve the problems of high preparation cost and poor radiation performance, achieve good high incidence rate, improve infrared radiation performance, and strong The effect of the corresponding properties of the infrared radiation

Active Publication Date: 2022-07-05

PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The technical problem to be solved by the present invention is that the radiation performance of the infrared coating under the high temperature condition is poor and the preparation cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0043] The present invention provides a group of examples of preparing infrared coating paint by the method of the present invention. The chemical components of the solid waste high-temperature carbonized slag used in this example are: Ti 14.6%, TiC 17.2%, Al 2 O 3 18.7%, SiO 2 22.1%, CaO 26.4%, and inevitable impurities.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Login to View More

Abstract

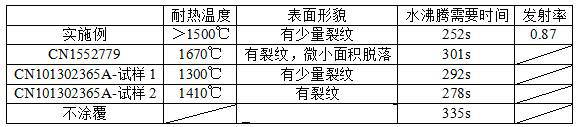

The invention discloses a method for preparing infrared coating paint by utilizing metallurgical solid waste, and belongs to the field of infrared energy-saving materials. The method for preparing infrared coating paint by using metallurgical solid waste includes the following steps: a. Mixing the metallurgical solid waste and iron oxide red evenly; b. sintering the mixture in stages, and cooling to obtain a calcined material; c. Mix evenly with the transition metal oxide; d. The mixture is sintered again, cooled, and mechanically crushed to obtain infrared coating powder; e. After fully mixing the infrared coating powder, high-temperature binder and water, an infrared coating is obtained. layer of paint. The material prepared by the method of the invention has a softening temperature of not lower than 1500° C., good high-temperature adhesion, a comprehensive emissivity of not less than 0.87, a low-band emissivity (1-5 μm) of not less than 0.93, and excellent comprehensive performance. , the production cost is low, and the problems of poor radiation performance and high preparation cost of the infrared coating paint under the existing high temperature conditions can be effectively solved.

Description

technical field [0001] The invention belongs to the field of infrared energy-saving materials, and relates to a method for preparing infrared coating paint by utilizing metallurgical solid waste. Background technique [0002] In recent years, infrared coating coatings have made great progress in aviation, construction, photocatalysis, energy saving and environmental protection and other fields, especially the application of infrared coating coatings in the field of energy saving and environmental protection is the main development trend of infrared coating coatings. However, compared with foreign coatings, there is a huge gap in product performance between my country's infrared coatings and foreign coatings. The utilization rate of infrared coatings in many developed countries has reached 40%, and the emissivity is above 0.9, while the utilization rate of infrared coatings in industrial furnaces in my country is only 15%, and the infrared emissivity is also around 0.8, which...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D1/02C09D7/61

CPCC09D1/02C09D7/61C09D5/18Y02P20/10

Inventor 樊河雲倪伟彭碧君王海波

Owner PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com