Method for judging optimal harvesting time of grape raw materials for brewing brandy

A harvesting period and brandy technology, which is applied in the field of judging the best harvesting period of grape raw materials for brewing brandy, can solve the problems of brandy aroma loss, sugar content index impact, total sugar and total acid content are higher, to improve quality stability, Enhance the effect of aroma richness and taste delicateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

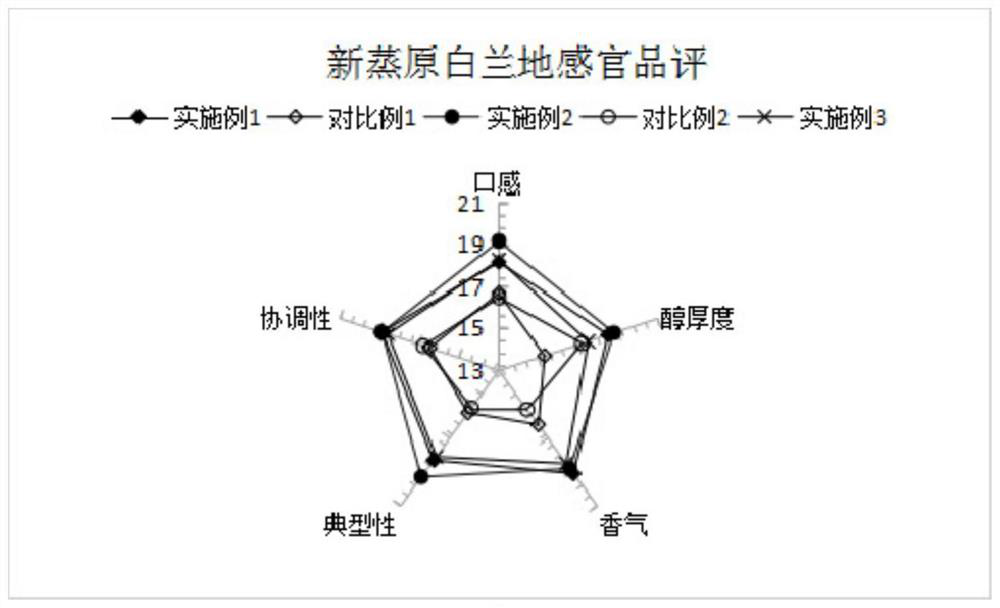

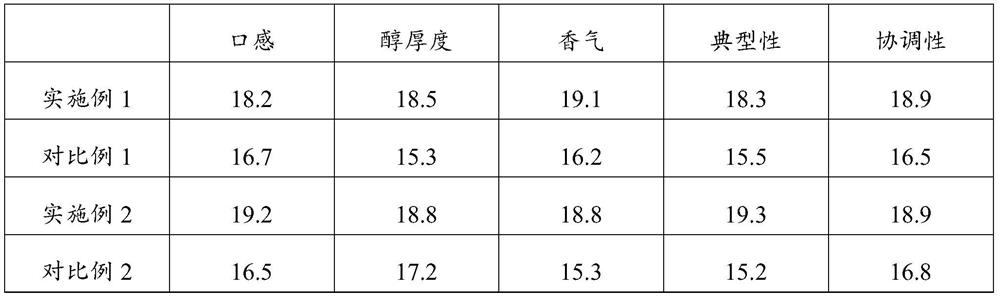

Examples

Embodiment 1

[0023] 1. Determine the best harvesting period for plot A of Ugni Blanc grapes for winemaking. Plot A is located in Yantai City, Shandong Province. The specific implementation steps are as follows:

[0024] (1) Sample collection: Ugni Blanc grapes began to enter the veraison period on July 20, 2020, and began to sample around August 6, randomly sampling from different positions in the plot and different parts of the plant; the initial sampling frequency was once a week, each time 30 spikes.

[0025] (2) 100-grain weight measurement: After each sampling, randomly cut the grapes from the upper, middle, lower, inner and outer parts of each ear of grapes, take 100 grains and weigh them, record the data and draw the change of 100-grain weight curve.

[0026] (3) Determination of sugar-acid ratio: After measuring 100-grain weight, all grape samples were destemmed and crushed, fully mixed, then juice was taken, centrifuged at 3000 rpm for 5 minutes, supernatant was taken, and the ...

Embodiment 2

[0035] 1. Determine the best harvesting period for plot B of Ugni Blanc grapes for winemaking. Block B is located in Yantai City, Shandong Province. The specific implementation steps are as follows:

[0036] (1) Sample collection: Ugni Blanc grapes will enter the veraison period on July 20, 2021, and sampling will begin on August 4, randomly sampling from different positions in the plot and different parts of the plant; the initial sampling frequency is once a week, 30 days each time ear.

[0037] (2) 100-grain retest determination: with embodiment 1.

[0038] (3) sugar-acid ratio measurement: with embodiment 1.

[0039] (4) After testing, when the sugar-acid ratio reached 20 on August 25, the sampling frequency was changed to once a day; the sampling method was the same as step (1); after each sampling, the 100-grain weight and sugar were tested according to the aforementioned method At the same time, the content of glucose and fructose in grapes was detected, and the mas...

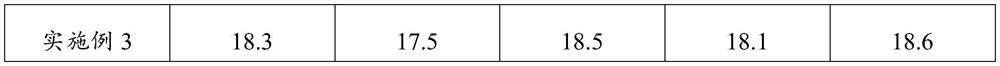

Embodiment 3

[0047] 1. Determine the best harvesting period for plot C of Ugni Blanc grapes for winemaking. Plot C is located in Shihezi City, Xinjiang Province. The specific implementation steps are as follows:

[0048](1) Sample collection: Ugni Blanc grapes will enter the veraison period on July 30, 2021, and sampling will begin on August 15, randomly sampling from different locations on the plot and different parts of the plant; the initial sampling frequency is once a week, 30 days each time ear.

[0049] (2) 100-grain retest and measure: with embodiment 1

[0050] (3) sugar-acid ratio measurement: with embodiment 1.

[0051] (4) After testing, when the sugar-acid ratio reached 18 on September 5, the sampling frequency was changed to once a day; the sampling method was the same as in step (1); after each sampling, the hundred-grain weight and sugar were tested according to the aforementioned method At the same time, the content of glucose and fructose in grapes was detected, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com